Vertical cement clinker grate-type particle grading cooler and cooling method

A cement clinker and particle grading technology, which is applied to the vertical cement clinker grate type particle grading cooler and cooling field, can solve the problem of large resistance of vertical piled materials, vertical cooler stays in the theoretical calculation stage, and increased power consumption and other issues, to achieve a good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

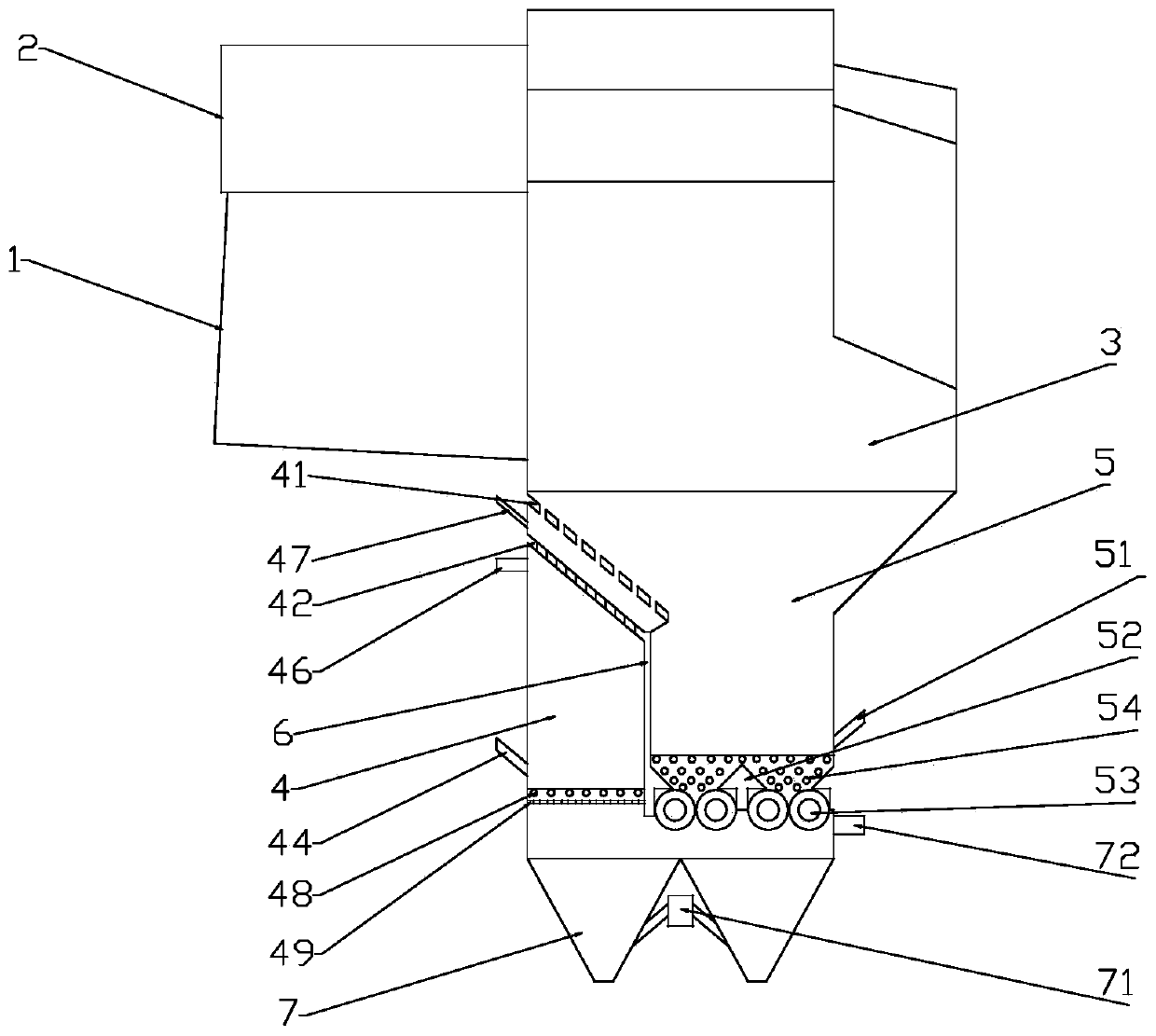

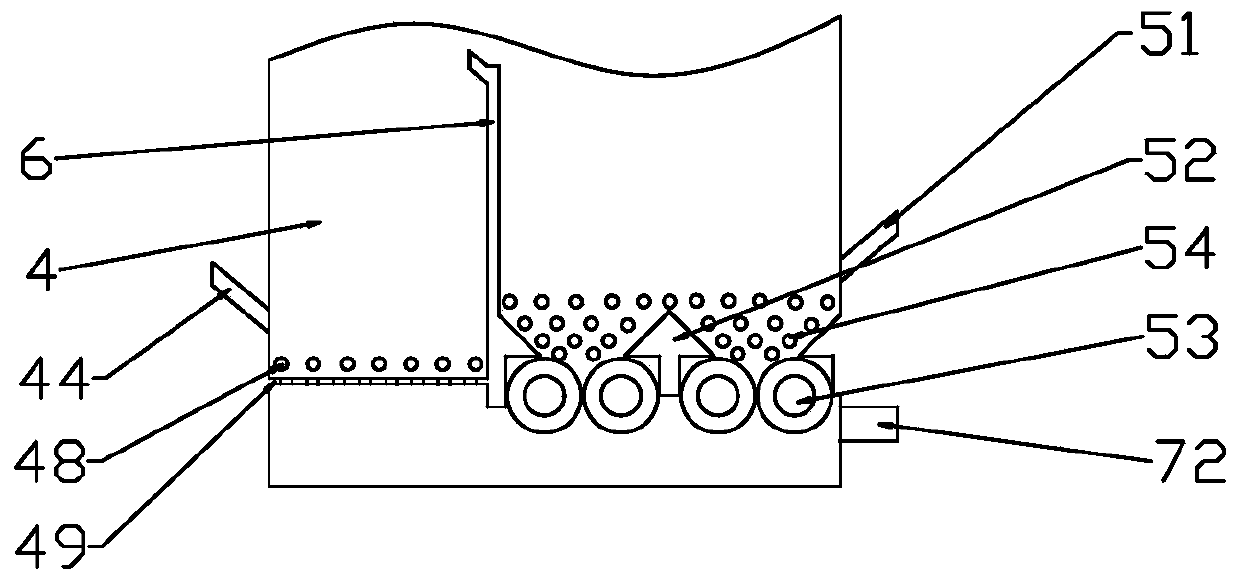

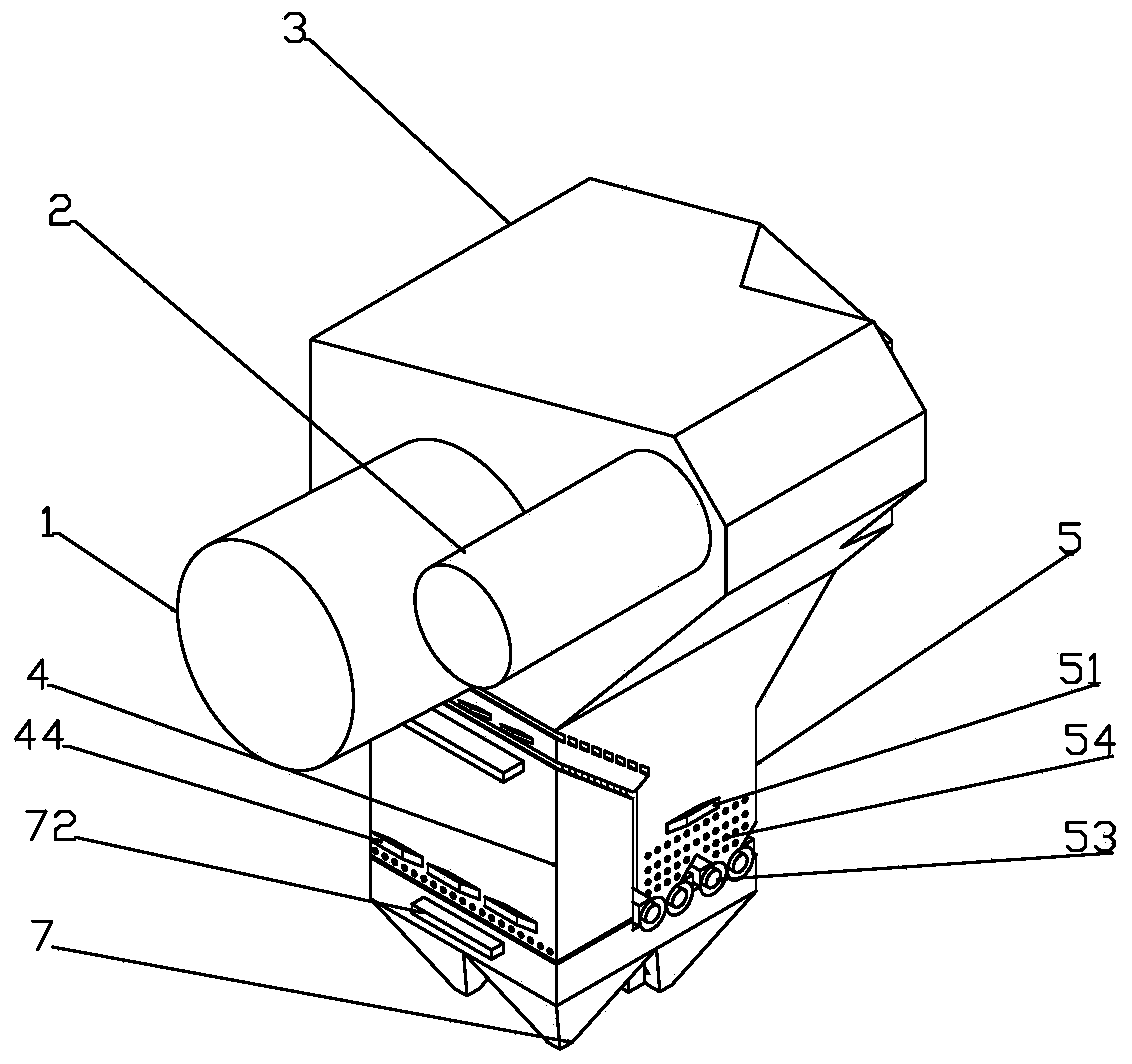

[0036] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0037] Such as Figure 1 to Figure 5 As shown, the present invention discloses a vertical cement clinker grate type particle grading cooler, the upper layer of the cooler is a kiln door cover 3; one side of the kiln door cover 3 is connected to the rotary kiln 1 and the tertiary air duct 2; The tertiary air pipe 2 is connected with the calciner; the temperature of the clinker after calcination in the rotary kiln is generally about 1400°C, and it falls after being unloaded through the kiln door cover 3, and the particles are classified and cooled; the high temperature of the heat exchange completed in the cooler is The hot air rises through the kiln door cover 3 and is divided into two parts, one of which enters the rotary kiln 1 as the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com