Air cooling dry type slag conveying system of coal-fired boiler

A coal-fired boiler, air-cooled technology, applied in the direction of lighting and heating equipment, can solve the problems of large damper diameter, affecting equipment operation, accumulation jams, etc., to reduce the wear and tear of conveying and crushing equipment, improve boiler thermal efficiency, and improve Accurate effect of air volume control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

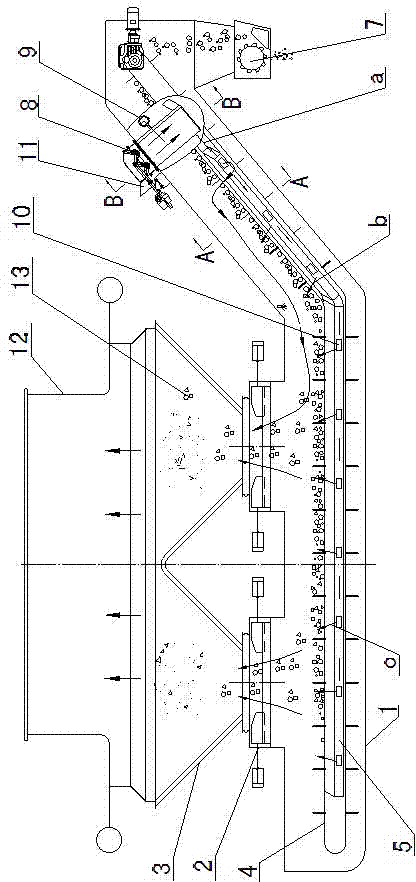

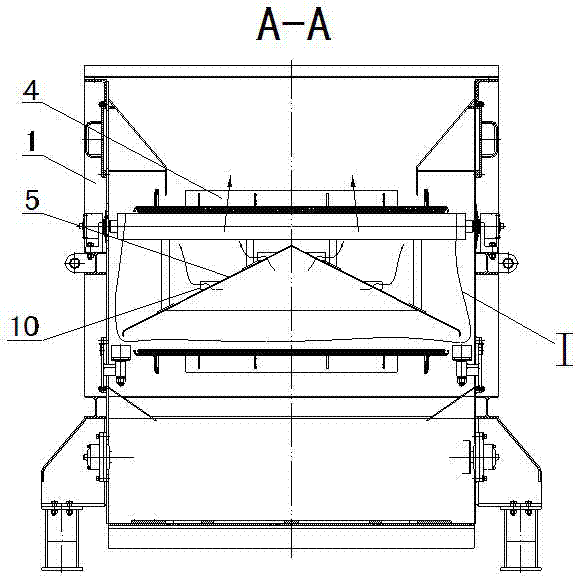

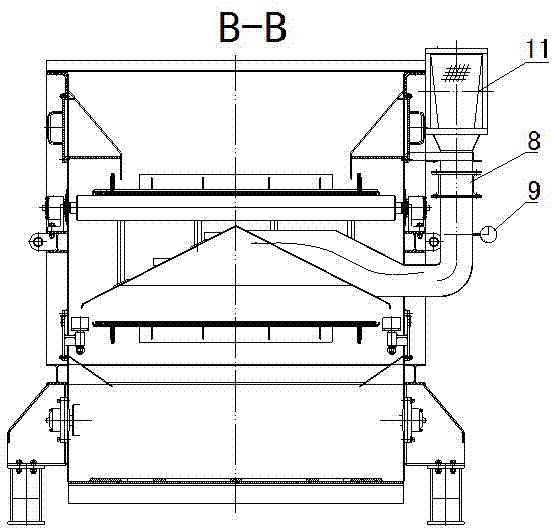

[0027] exist Figure 1 to Figure 6 Among them, the coal-fired boiler air-cooled dry slag conveying system of the present invention includes a casing 1, a large slag extrusion device 2 installed above the tail of the casing, and a slag hopper 3 installed on the casing above the large slag extrusion device , the ash and slag material conveyor belt 4 installed on the casing is located below the large slag extrusion device, and the female air duct 5 installed on the casing between the process and the return ash and slag material conveyor belt and provided with several small air outlets 10 is installed. Ash baffle 6 on the small tuyere of the main air duct, slag breaker 7 installed under the head of the casing, automatic flow regulating valve 8 installed in the air inlet 11 of the casing head, installed under the automatic flow regulating valve Flow meter 9 on the tuyere.

[0028] In the air-cooled dry slag conveying system of the coal-fired boiler of the present invention, the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com