Core crystallizer for casting hollow ingot and water-cooled crystallizer containing the core crystallizer

A crystallizer and hollow ingot technology, applied in the field of water-cooled crystallizers, can solve the problems of lower product use efficiency, easy pollution of ingot components, poor cooling effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

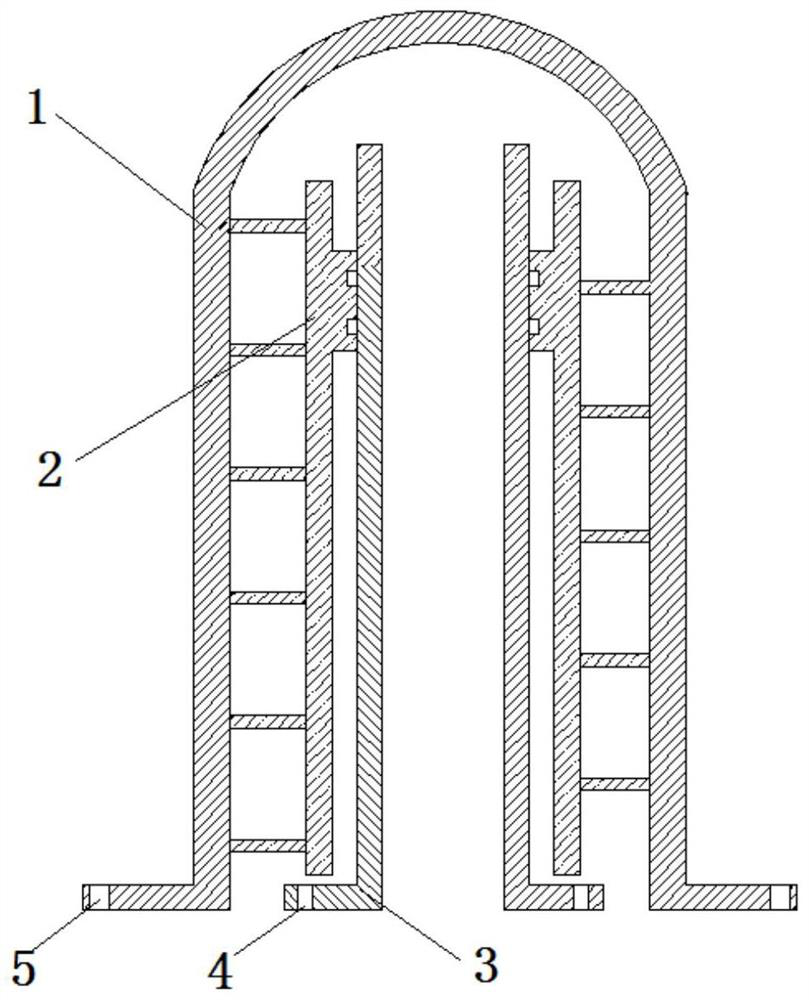

[0031] This embodiment is a water-cooled crystallizer used when casting a hollow titanium ingot in a cold bed electron beam furnace, which includes a core crystallizer and an external crystallizer. The same as the crucible, its production material is red copper, which has fast heat conduction, and can quickly take away the heat in the crucible through circulating cooling water, ensuring deep penetration of the inner wall surface of the ingot, improving the surface quality of the inner surface of the cast tube billet, and reducing casting defects.

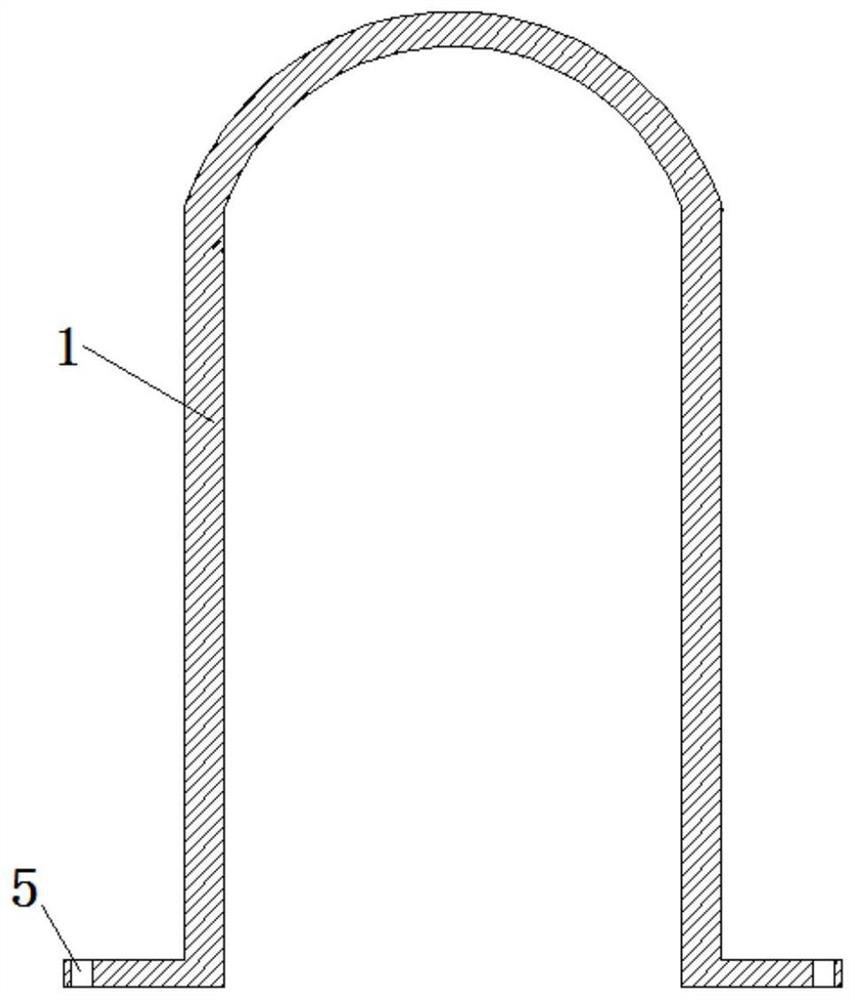

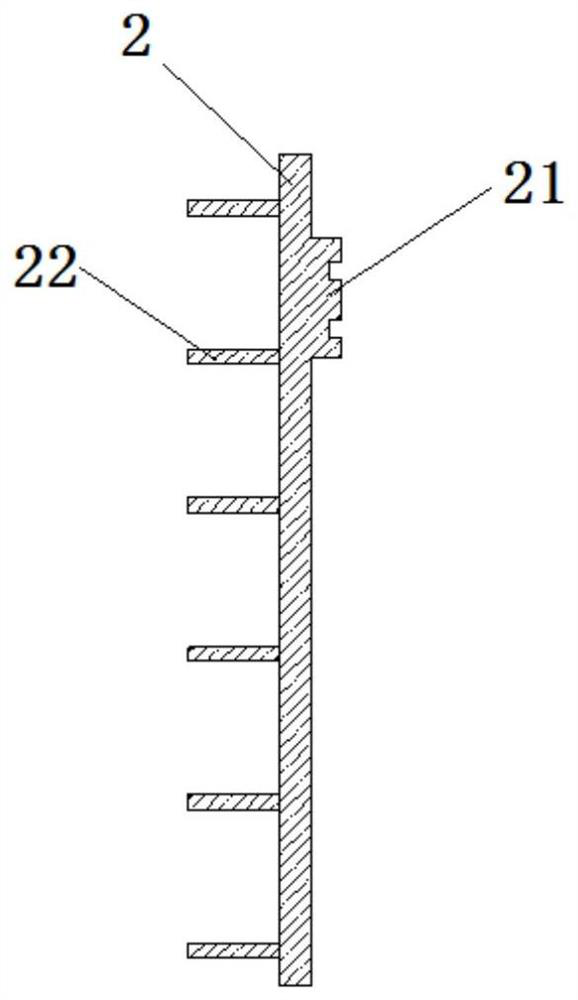

[0032] The structure of the core crystallizer in this embodiment includes an outer casing 1, a water guide pipe 2 and a water inlet pipe 3; the number of water inlet pipes 3 is 2, and the number of water guide pipes 2 is 2; The water pipes 2 are distributed symmetrically along the inner wall of the outer casing 1 . The shape of the outer casing 1 is an inverted U shape, and horizontal casings facing outward are respectively arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com