Dish-washing machine with heat pump

A dishwasher and heat pump technology, applied in the field of kitchen equipment, can solve the problems that the direction of fan air flow is easily blocked, affects the heat exchange efficiency of the evaporator, and increases the difficulty of system design, so as to improve heat exchange efficiency and reduce appearance size , Improve the effect of space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

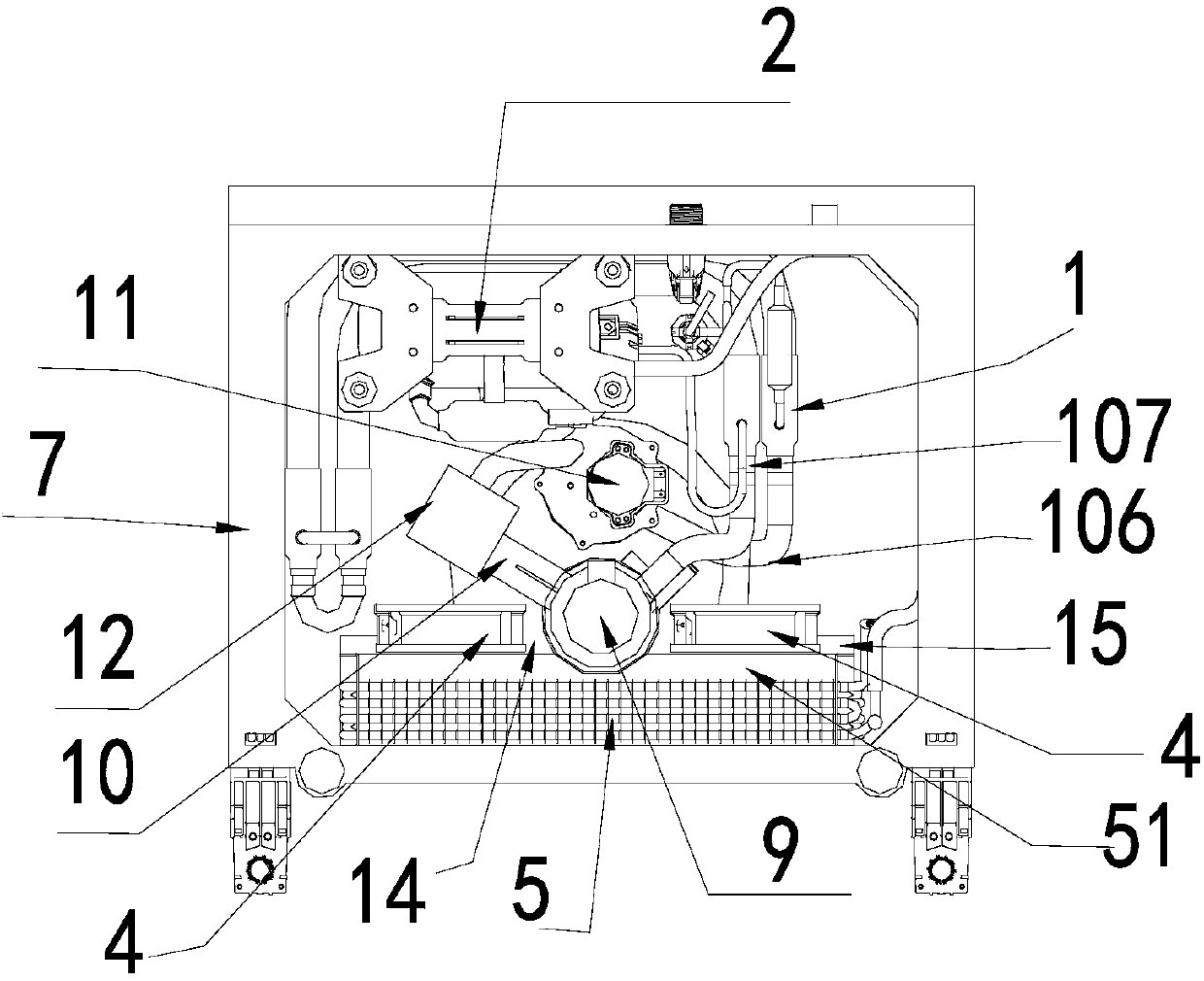

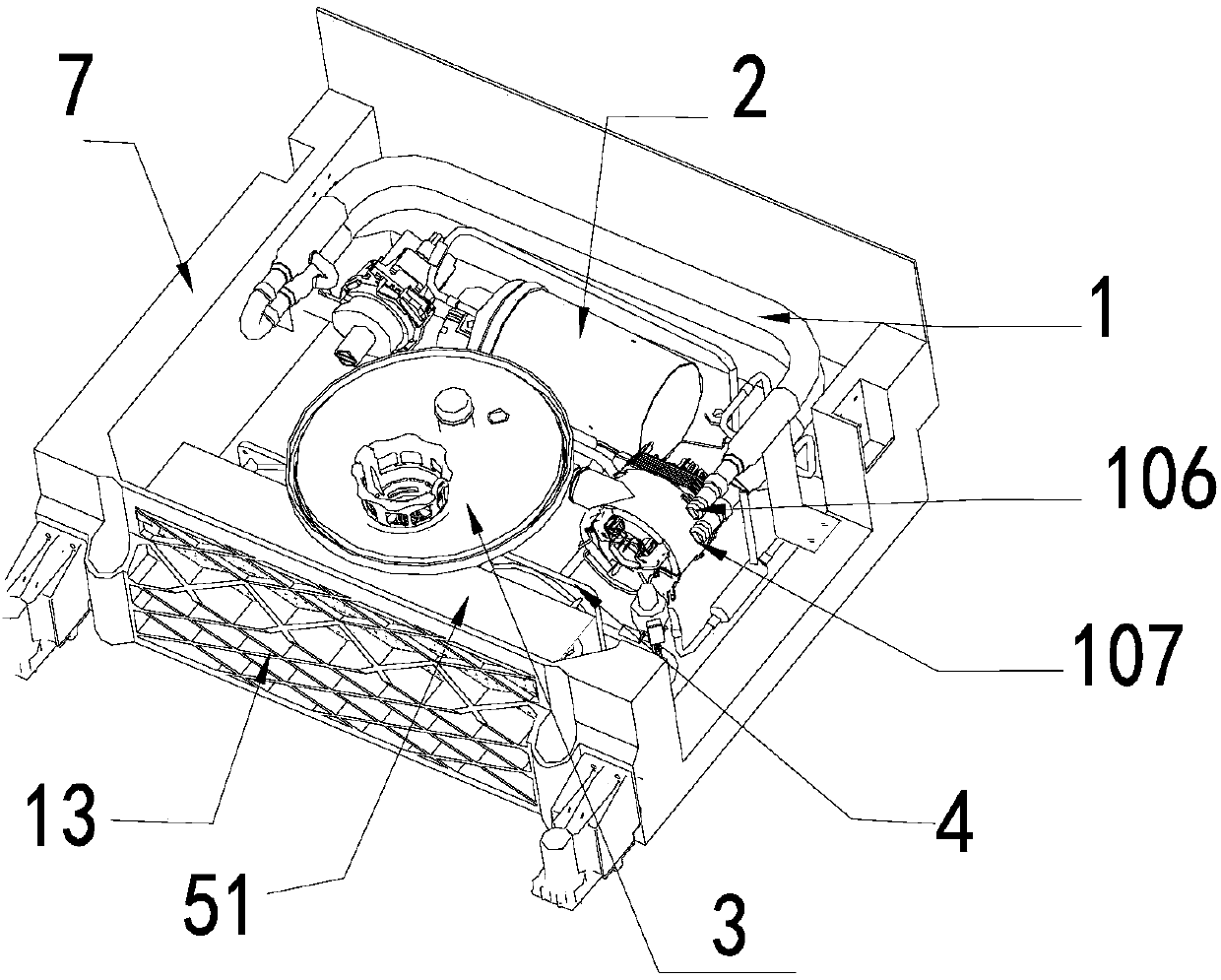

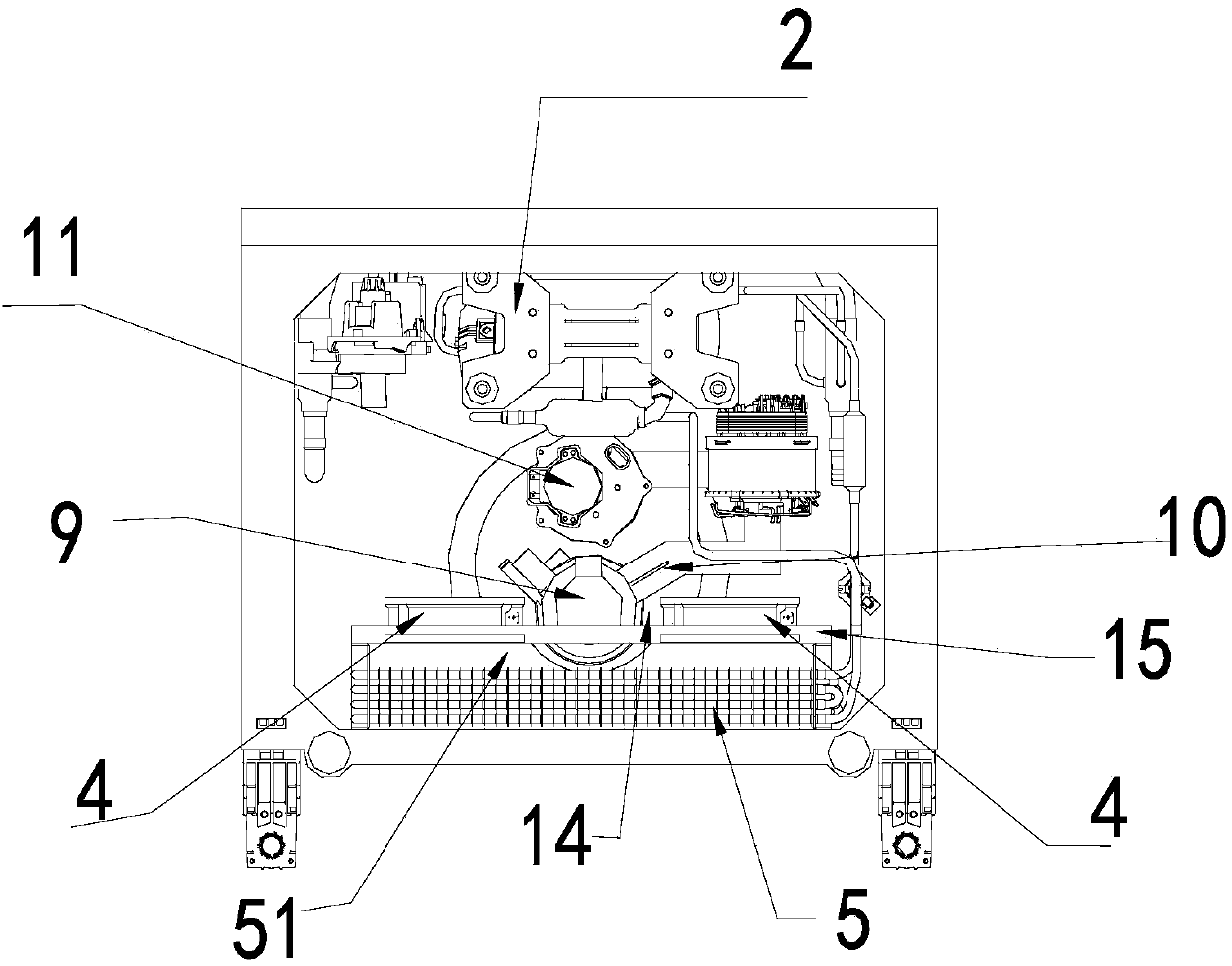

[0051] Such as figure 1 as shown in figure 1 As shown, a heat pump dishwasher is disclosed in this embodiment. The dishwasher includes a processing chamber not shown in the figure; the processing chamber is provided with a spray port, and the spray port is provided with washing water through a washing water channel to spray and clean the tableware located in the processing chamber. The washing water circuit is connected with a water inlet valve, a respirator, a drainage pump, a circulating pump and a spray port. The washing water enters the washing water channel through the water inlet valve, flows into the treatment chamber equipped with tableware, circulates the washing water in the washing water channel through the circulation pump, and sprays the tableware on the tableware through the spray port. After cleaning, the dirty water is discharged through the drain pump, and the respirator is used to prevent siphoning of the washing water channel.

[0052] In order to improve...

Embodiment 2

[0068] Such as Figure 1 to Figure 4 As shown, the evaporator 5 of the present embodiment is located at the bottom of the processing chamber, and the bottom of the processing chamber has a protrusion protruding from the lower surface, such as Figure 13 and Figure 14 As shown, the surface of the evaporator 5 has an inner concave portion 52 that cooperates with the convex portion and is depressed inward. The protruding portion is a protruding surface formed by protruding outward from the lower surface of the processing chamber, and / or a component installed outside the processing chamber and fixed to the lower surface of the processing chamber. The components are different according to design requirements, and may be a sump 9 for collecting washing water in the treatment chamber, and / or a water diversion valve 11 for controlling washing water in a dishwasher.

[0069] In this embodiment, the protrusion is the sump 9 . The sump 9 is located at the bottom of the dishwasher, an...

Embodiment 3

[0077] In this embodiment, the latent heat released by the condenser is used to heat the washing water. When washing, tap water enters the dishwasher after being softened by the softener through the water inlet valve. The circulation pump drives the washing water to wash the tableware through the shower. When the washing water needs to be heated, the circulating pump drives the water through the condenser (casing heat exchanger), and then the tableware is washed through the shower. Such as Figure 5 As shown, the condenser of the present invention is a jacketed heat exchanger, such as Figure 7 As shown, the sleeve-and-tube heat exchanger includes a plurality of heat exchange sleeves 1 bent in the same direction; The water pipelines communicate with each other, and the outer pipe 101 communicates with the heat pump working medium. When the washing water flows through the inner tube 102 of the sleeve-and-tube heat exchanger, the heat pump working fluid in the tube of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com