Patents

Literature

36results about How to "Same thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multiple Deposition, Multiple Treatment Dielectric Layer For A Semiconductor Device

InactiveUS20110256682A1Improve device performanceSmall sizeSemiconductor/solid-state device manufacturingSemiconductor devicesGate dielectricMultiple treatments

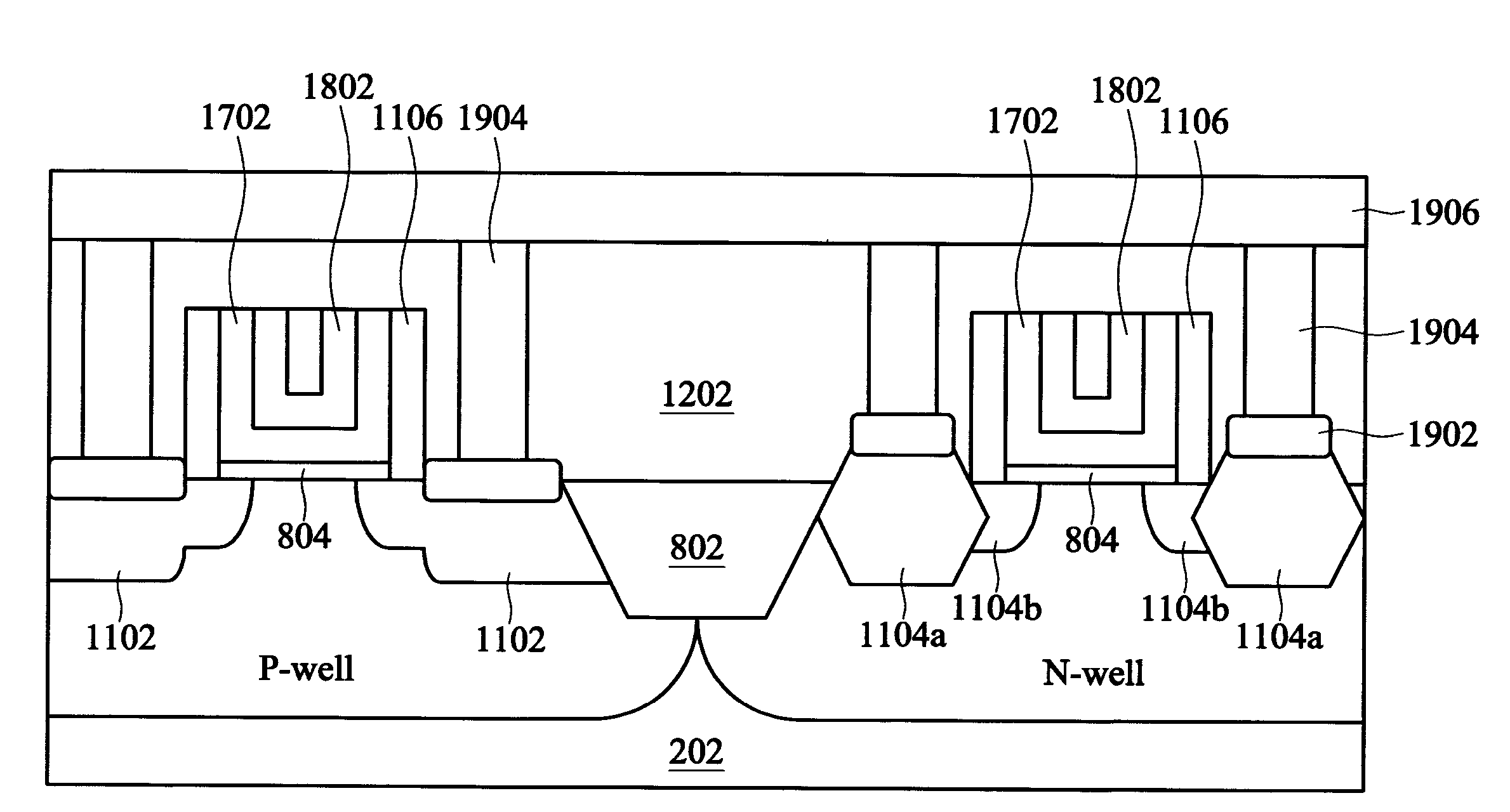

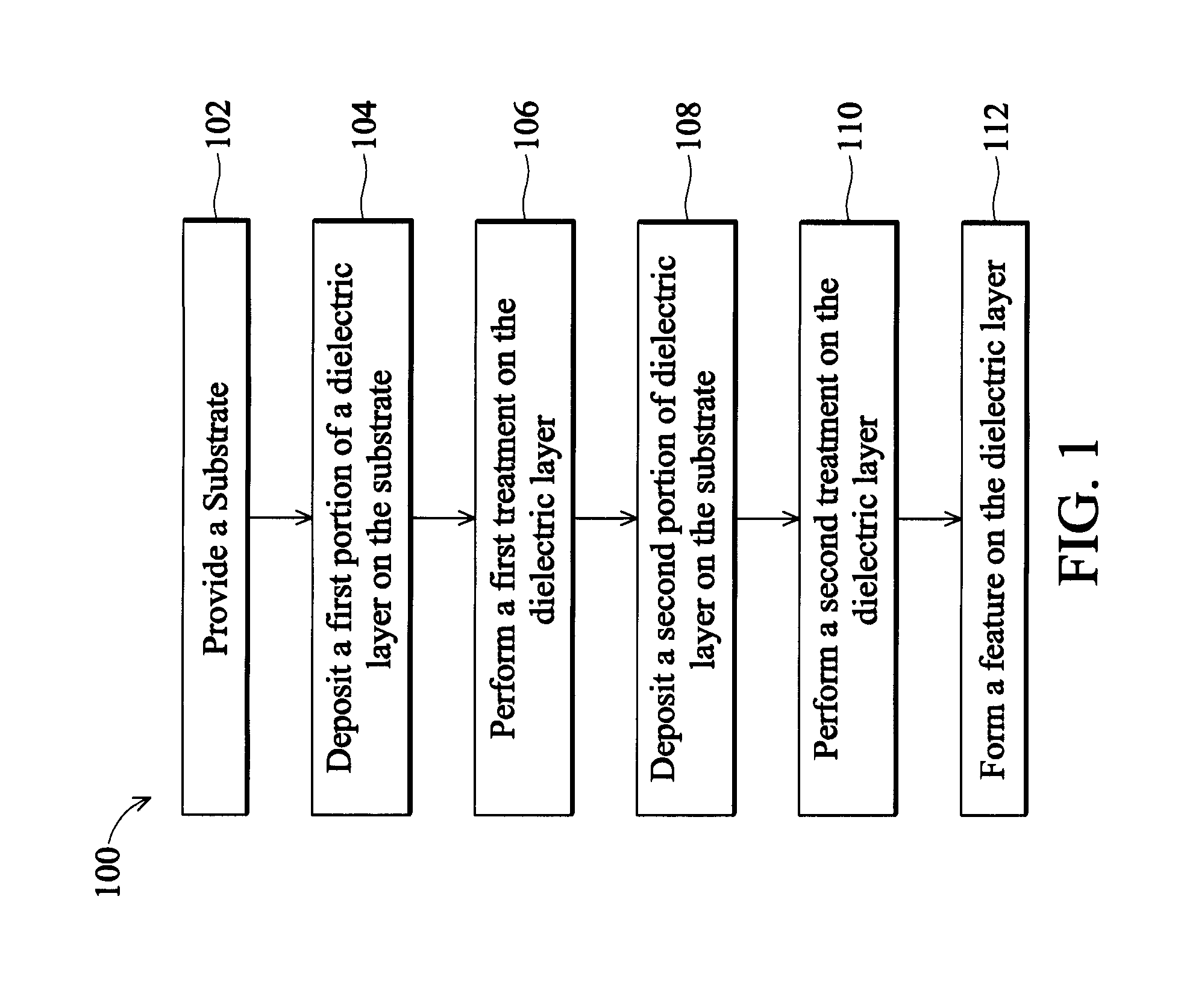

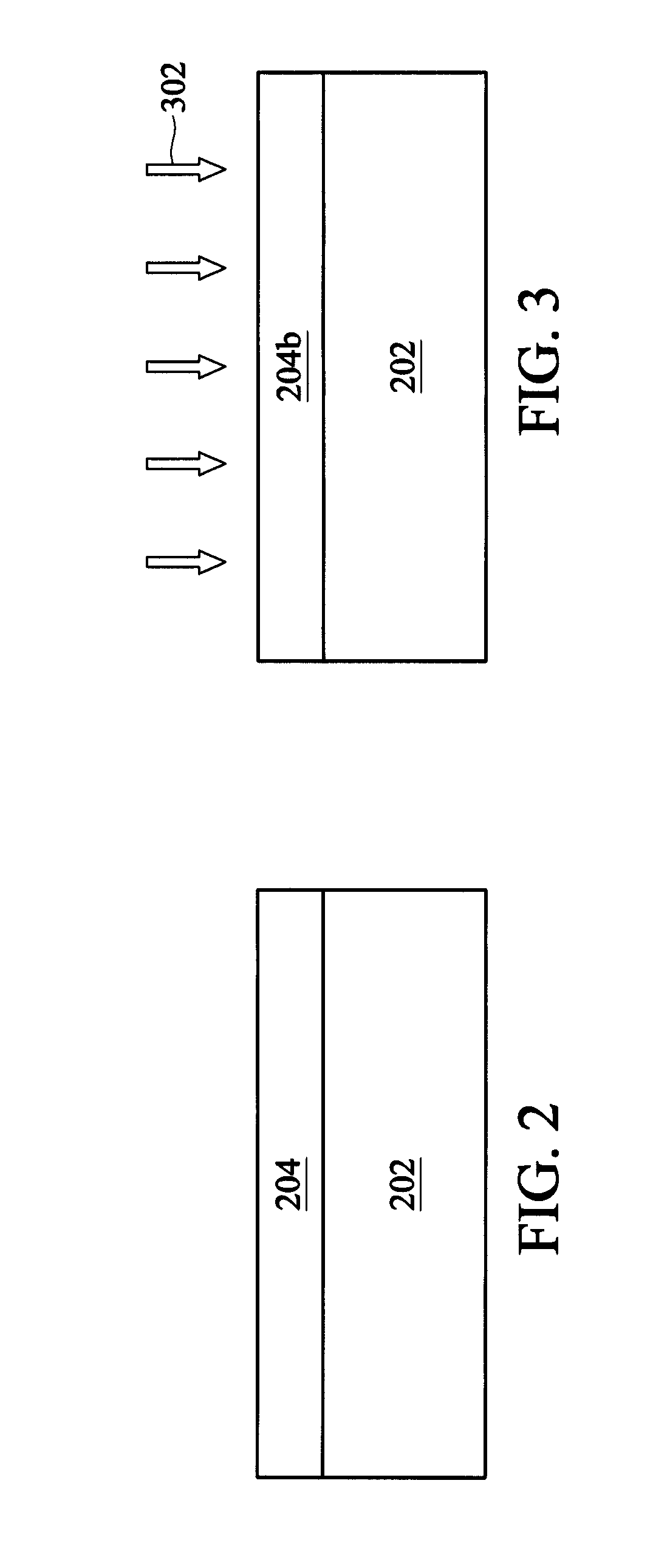

A method is provided for fabricating a semiconductor device. A semiconductor substrate is provided. A first high-k dielectric layer is formed on the semiconductor substrate. A first treatment is performed on the high-k dielectric layer. In an embodiment, the treatment includes a UV radiation in the presence of O2 and / or O3. A second high-k dielectric layer is formed on the treated first high-k dielectric layer. A second treatment is performed on the second high-k dielectric layer. In an embodiment, the high-k dielectric layer forms a gate dielectric layer of a field effect transistor.

Owner:TAIWAN SEMICON MFG CO LTD

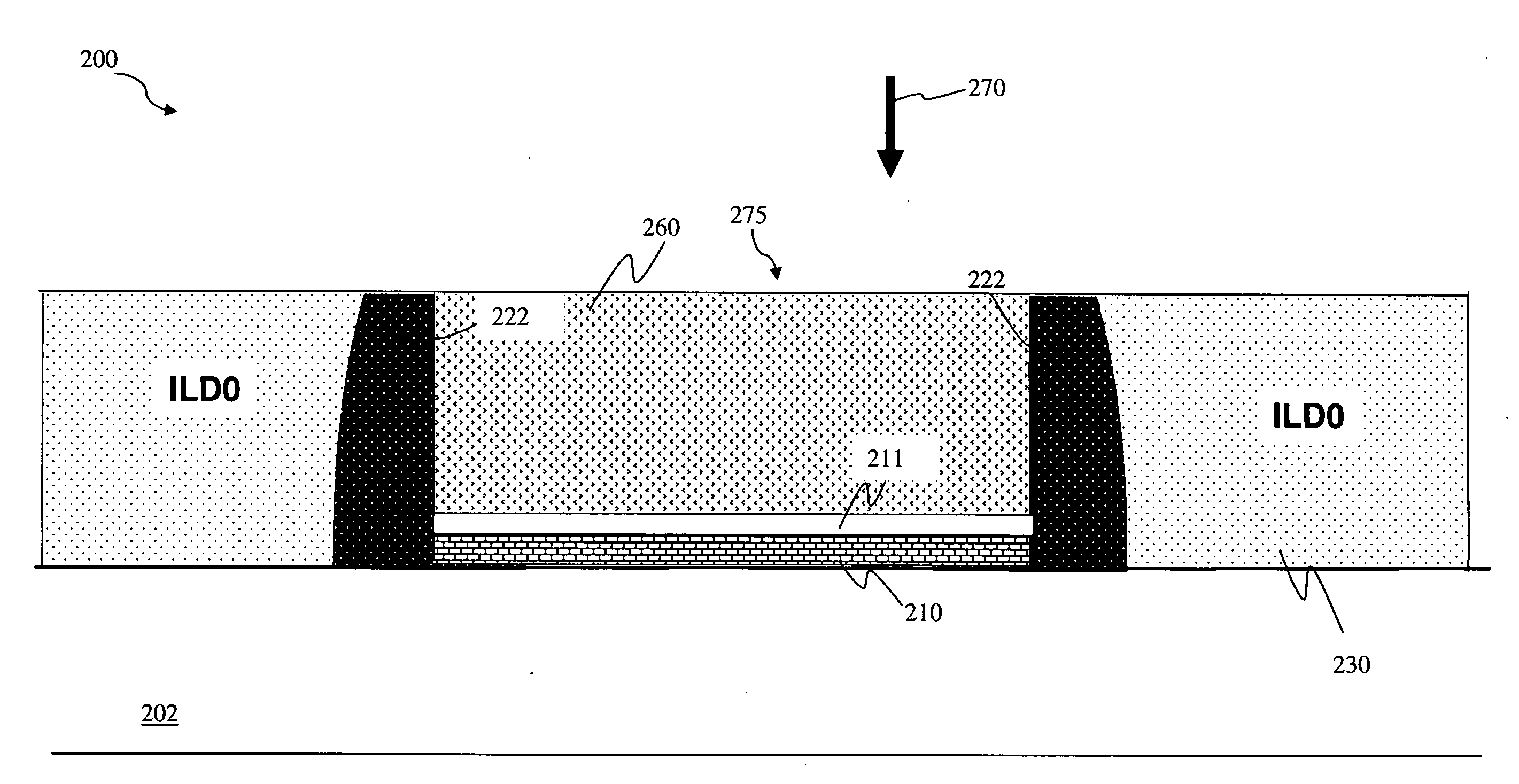

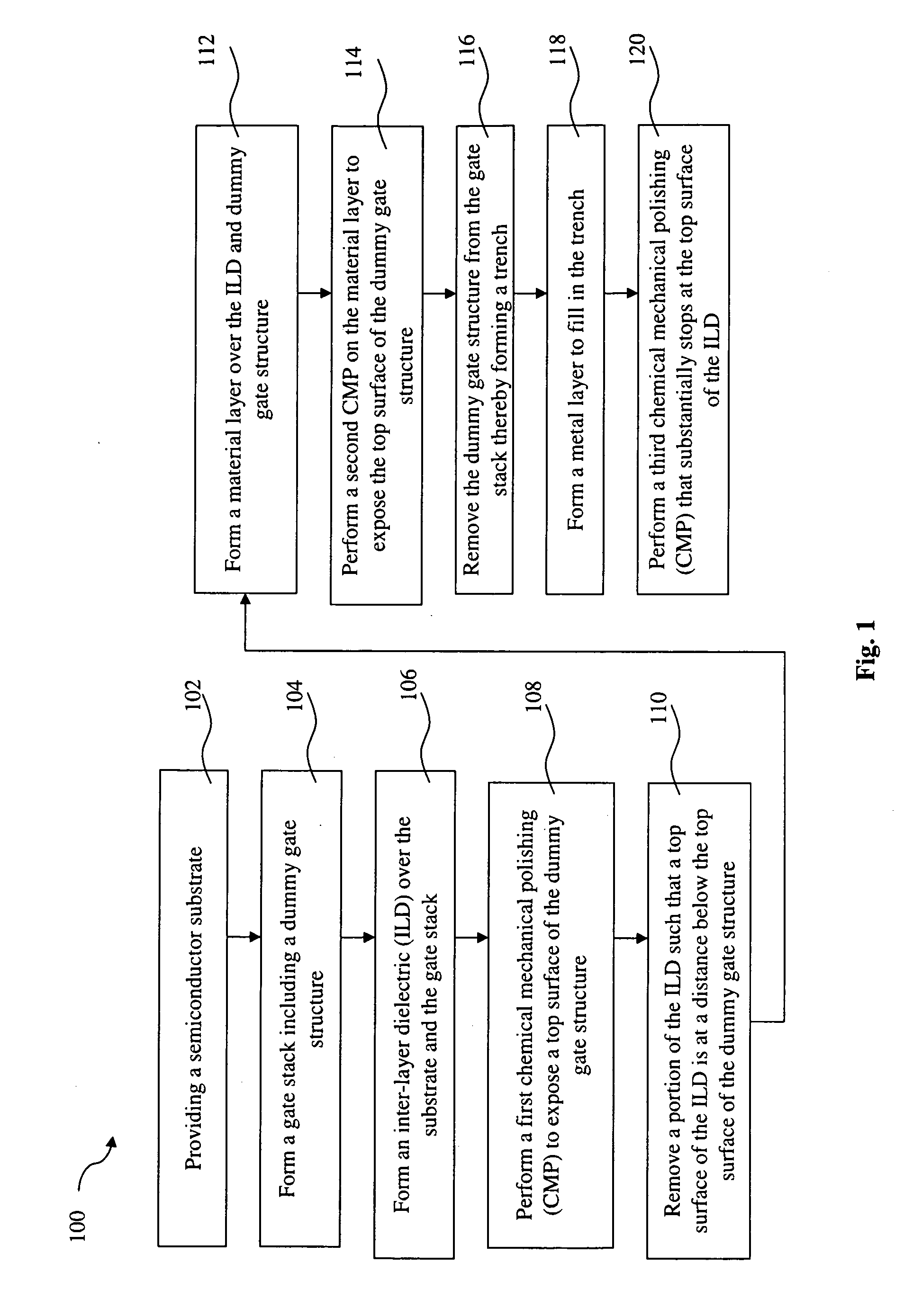

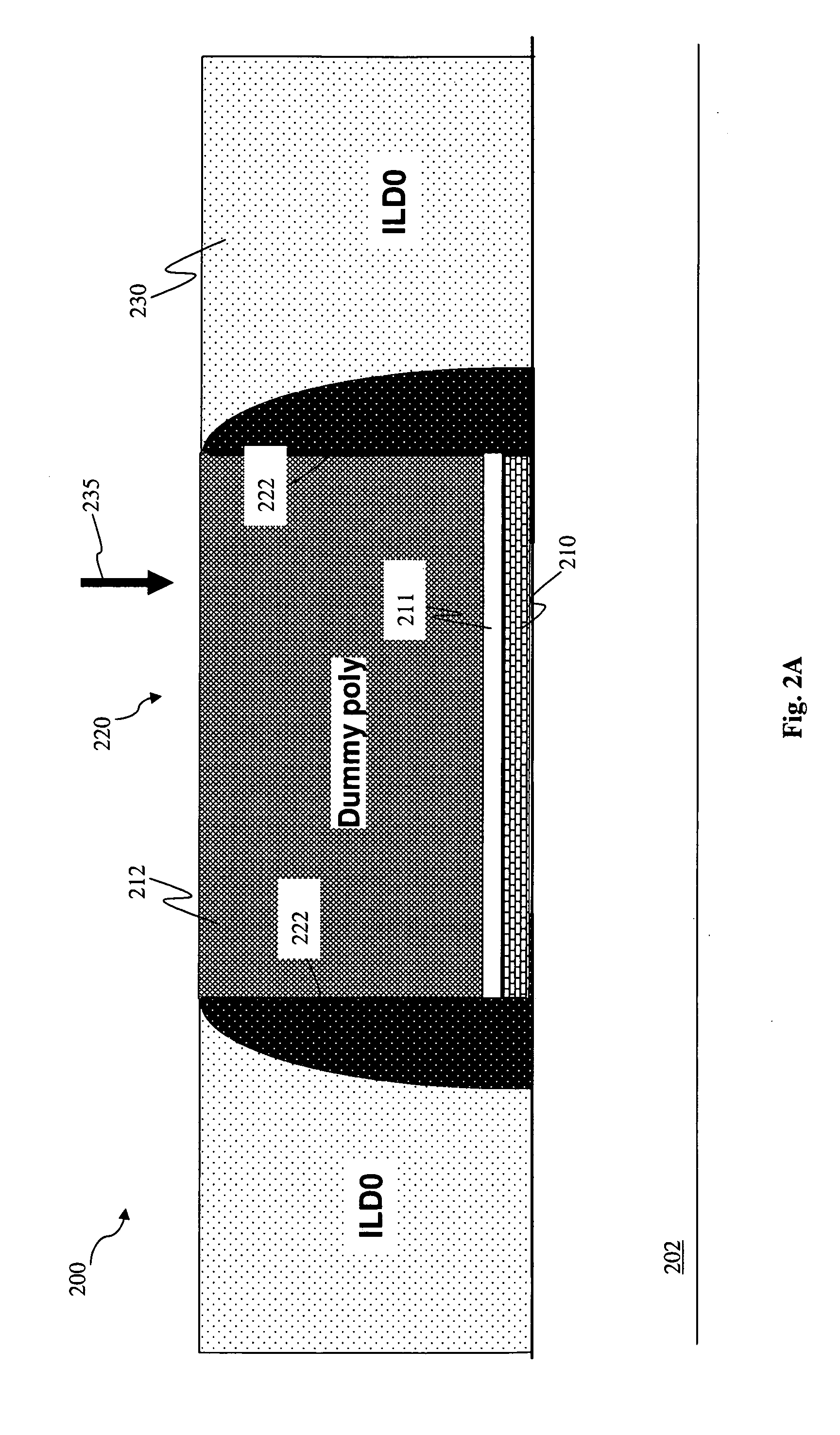

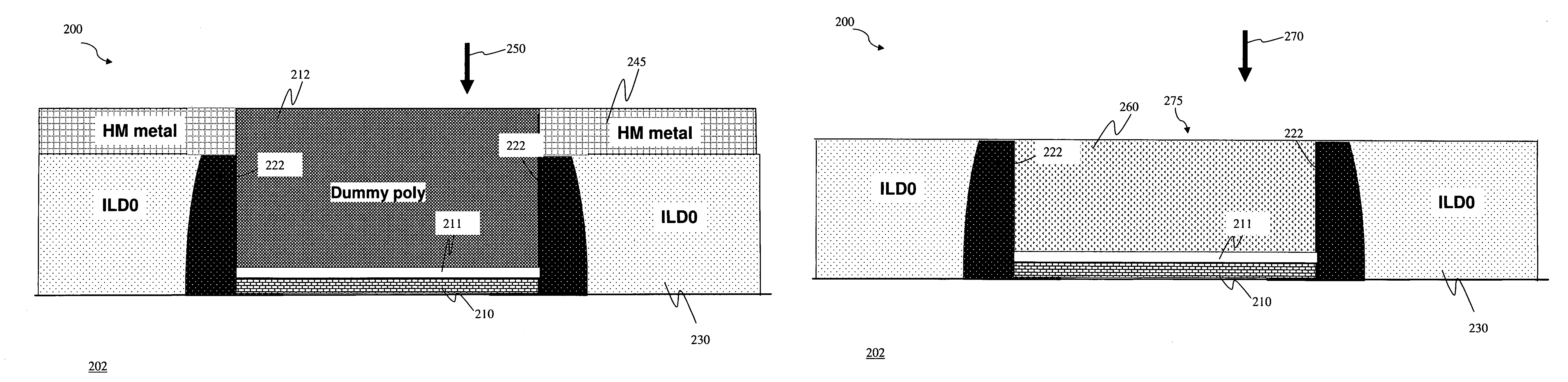

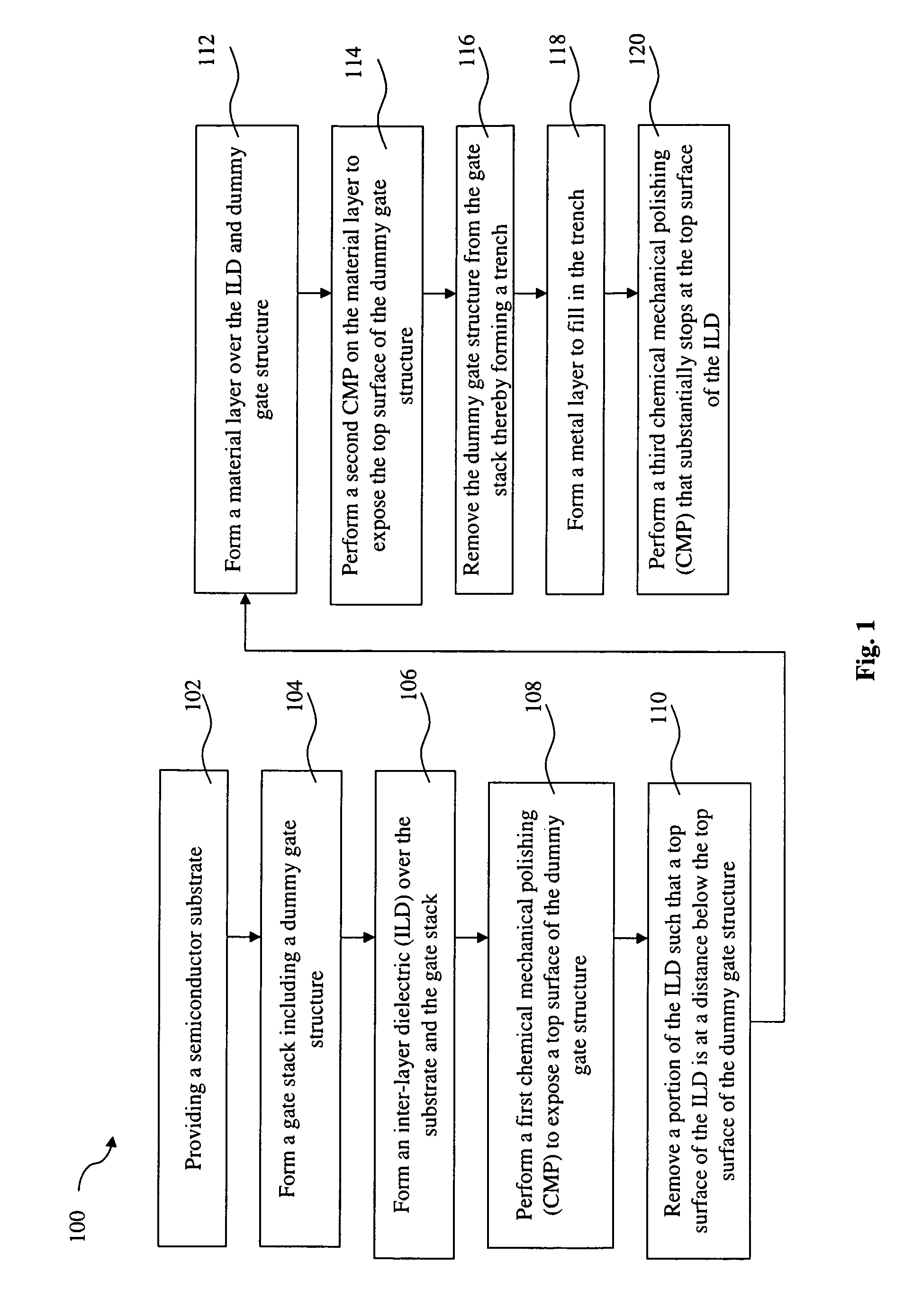

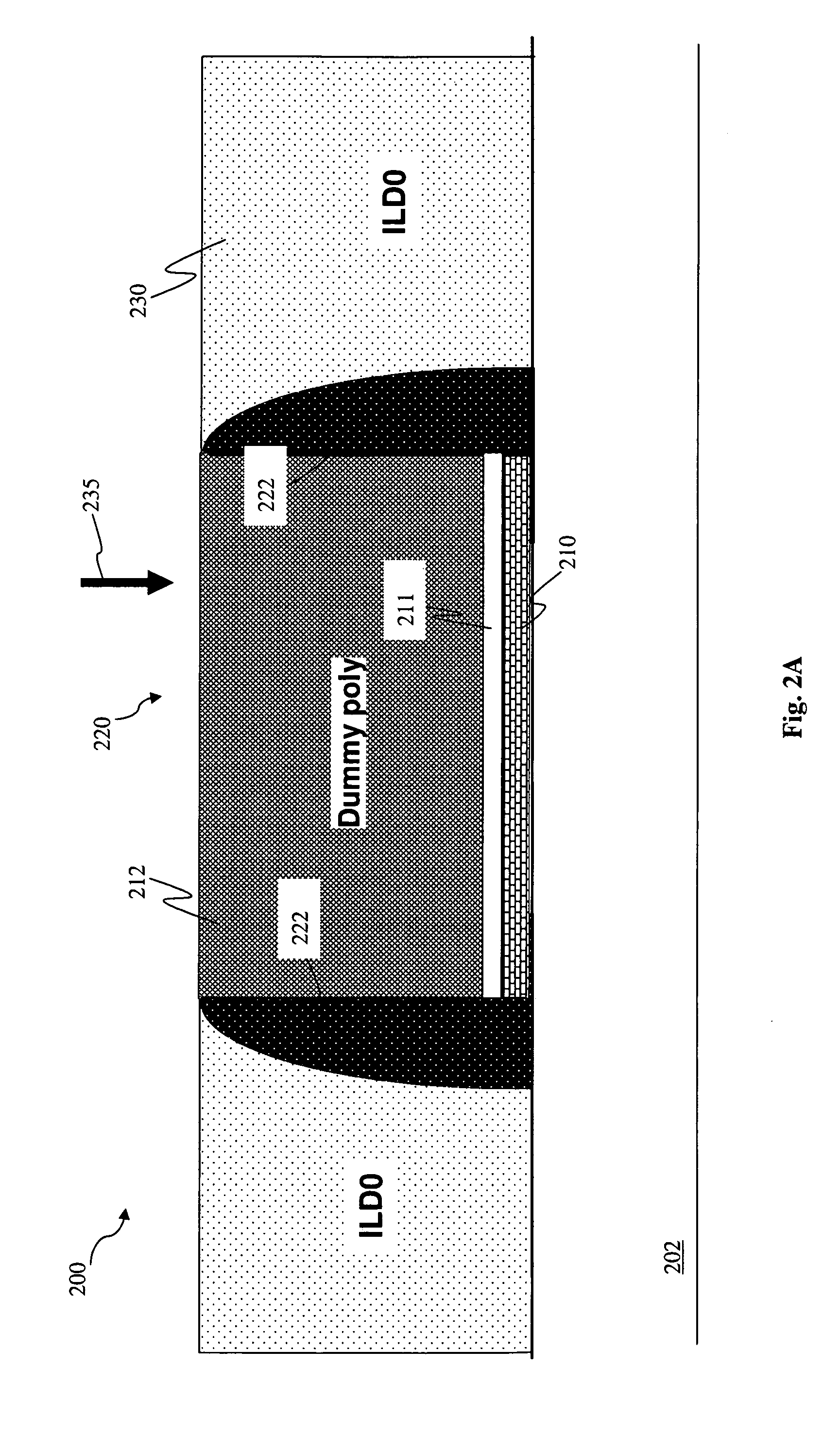

Method for gate height control in a gate last process

InactiveUS20100087056A1Improve device performanceSmall sizeSemiconductor/solid-state device manufacturingSemiconductor devicesDielectricInter layer

A method is provided for fabricating a semiconductor device that includes providing a semiconductor substrate, forming a transistor in the substrate, the transistor having a gate structure that includes a dummy gate structure, forming an inter-layer dielectric (ILD), performing a first chemical mechanical polishing (CMP) to expose a top surface of the dummy gate structure, removing a portion of the ILD such that a top surface of the ILD is at a distance below the top surface of the dummy gate structure, forming a material layer over the ILD and dummy gate structure, performing a second CMP on the material layer to expose the top surface of the dummy gate structure, removing the dummy gate structure thereby forming a trench, forming a metal layer to fill in the trench, and performing a third CMP that substantially stops at the top surface of the ILD.

Owner:TAIWAN SEMICON MFG CO LTD

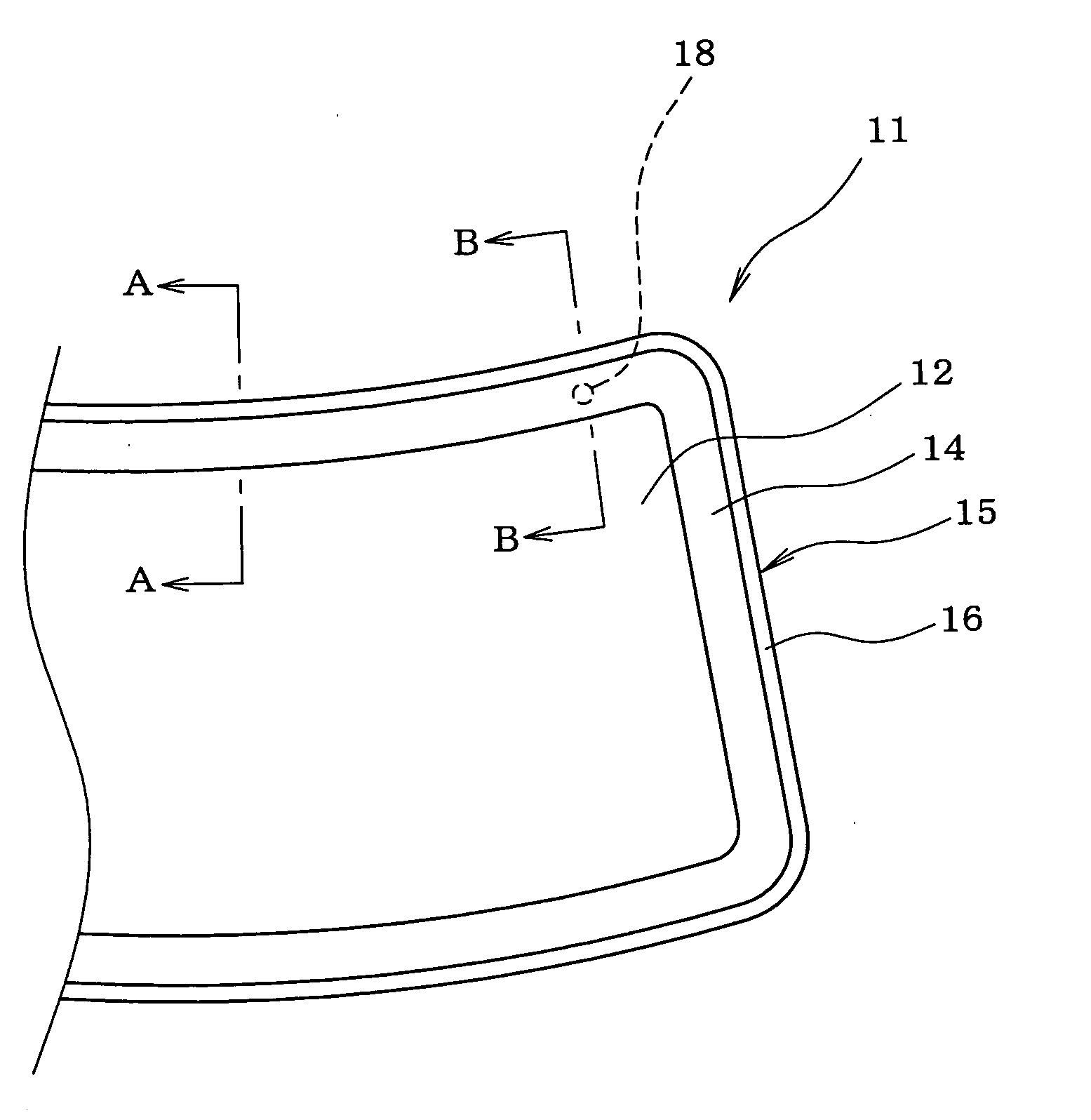

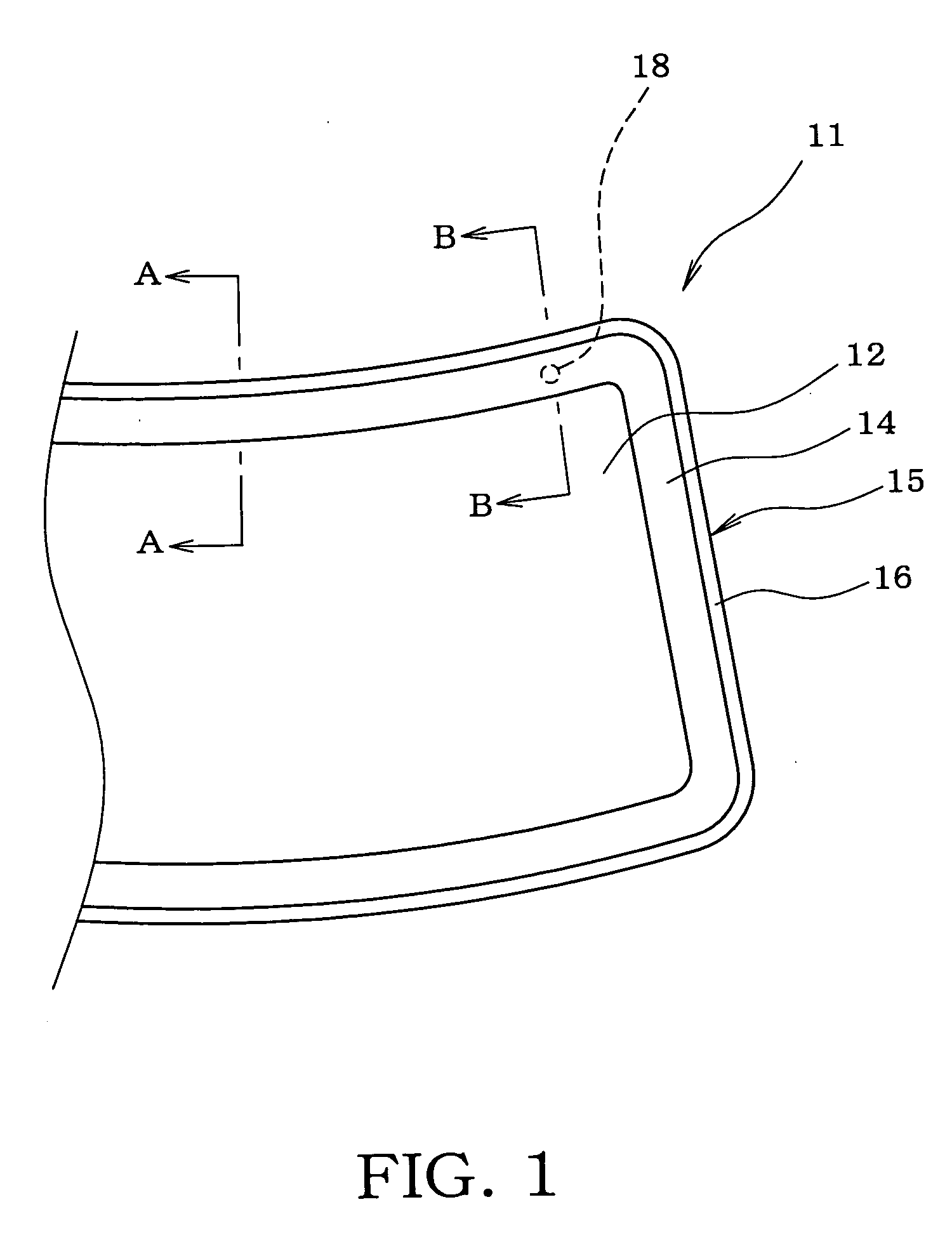

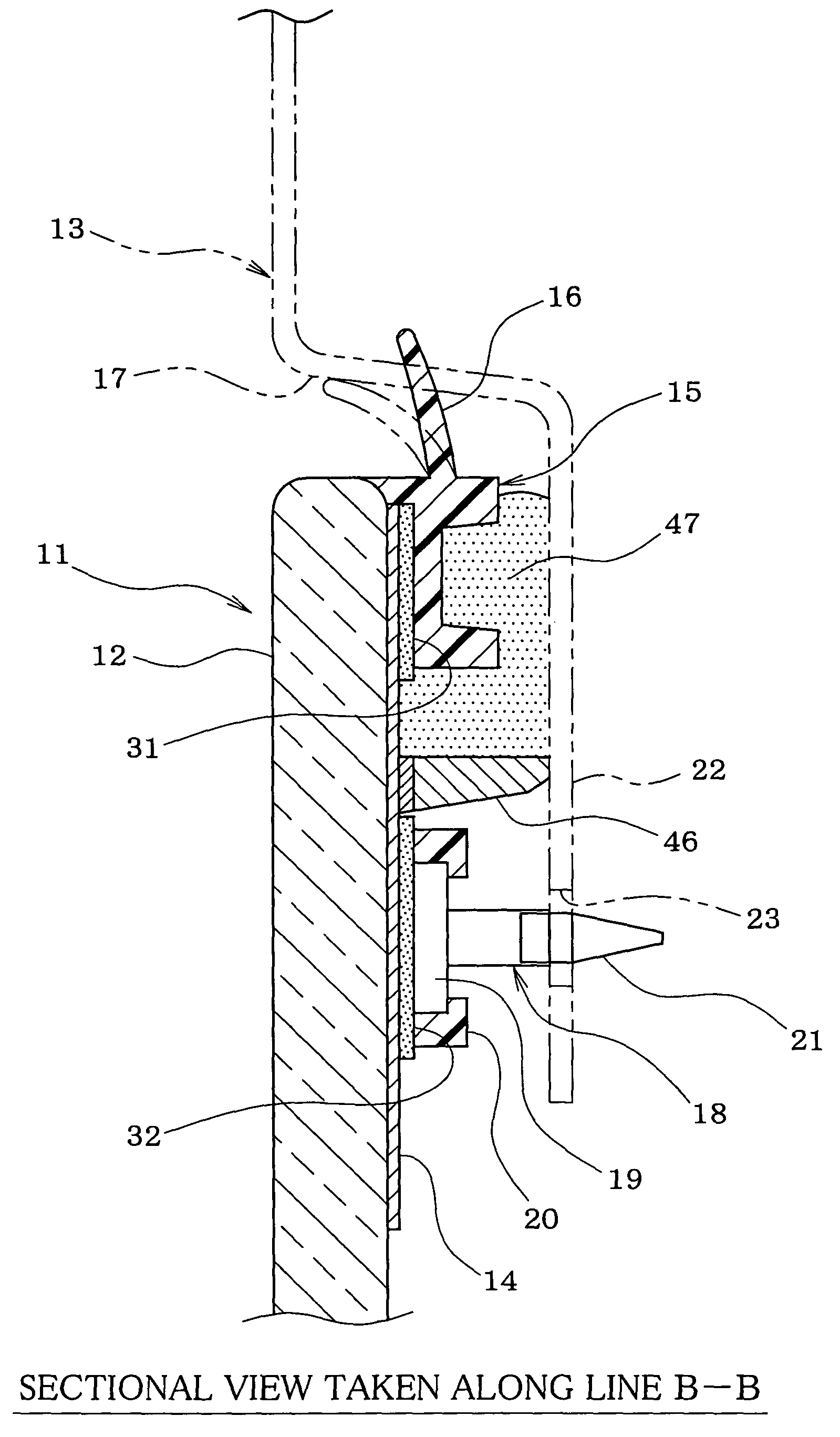

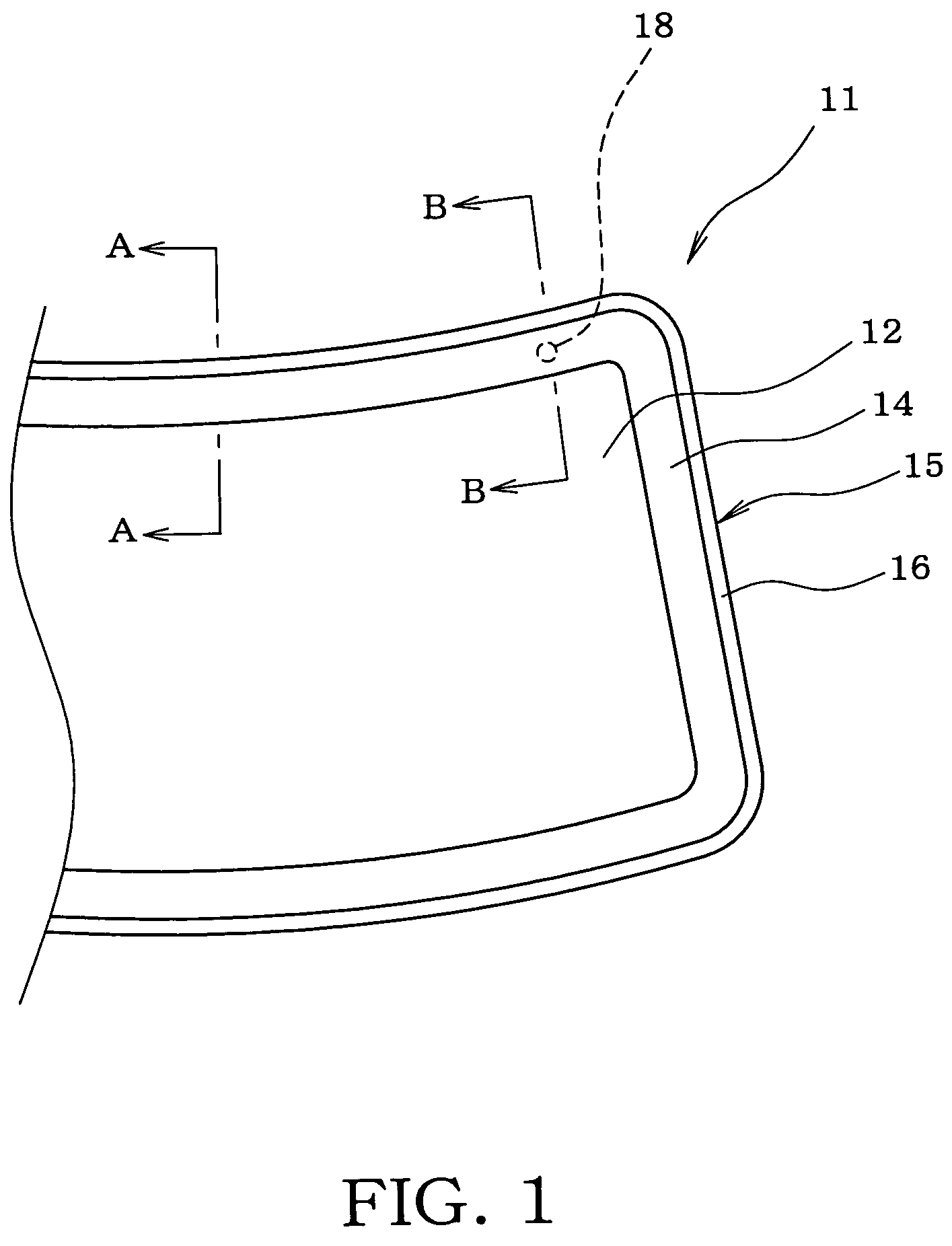

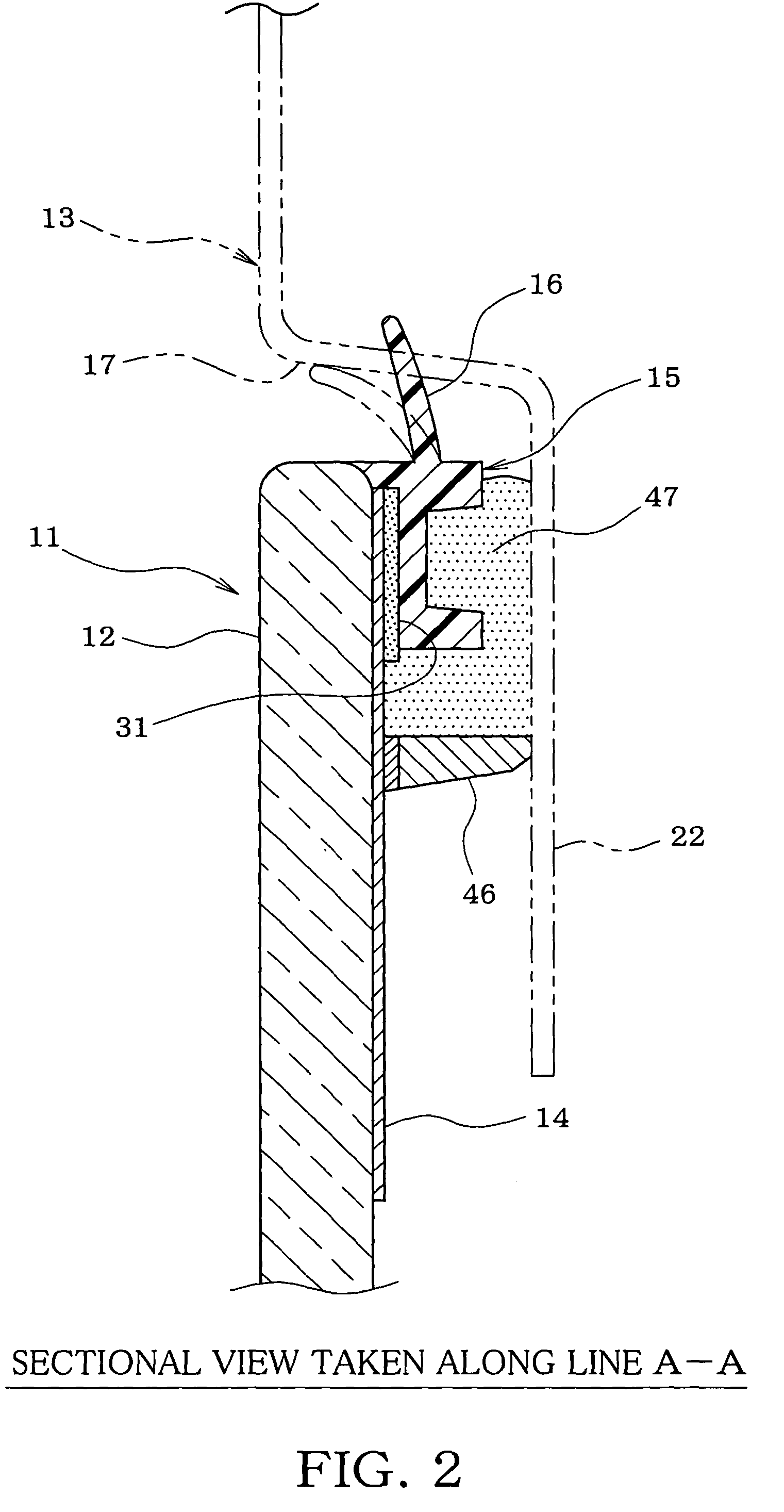

Window assembly-producing method and window plate

An adhesive agent is uniformly applied to a back surface of a window pane, the application made to an area where a covering member is planned to be adhered and to an area where a positioning fixture and a holding portion are planned to be adhered, the application is also made continuously such that adhesive agent layers of both planned adhesion areas being continuous with an adhesive agent continuous area in between. After that, the window pane and the positioning fixture are set in an injection mold and a polymer material is injected in the mold. This results that the covering member and the holding portion are formed into a shape where they are connected by a connection portion for material flow, which connection portion is formed at a position other than the adhesive agent continuous area. The forming results that the covering member and the holding portion are adhered and fixed to the back surface of the window pane with the adhesive agent layers in between. After the forming process above, the connection portion for material flow is removed.

Owner:TOKAI KOGYO CO LTD

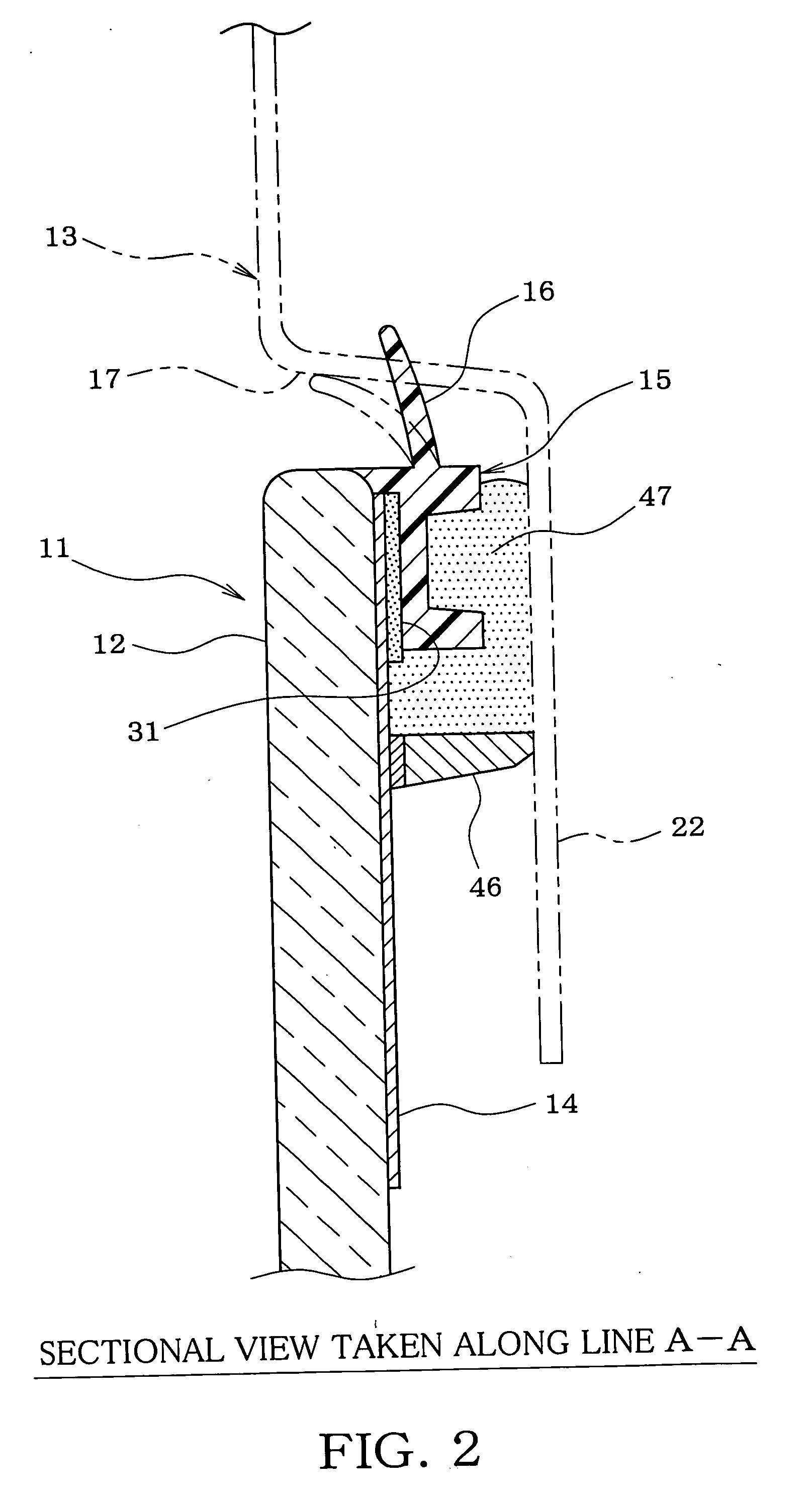

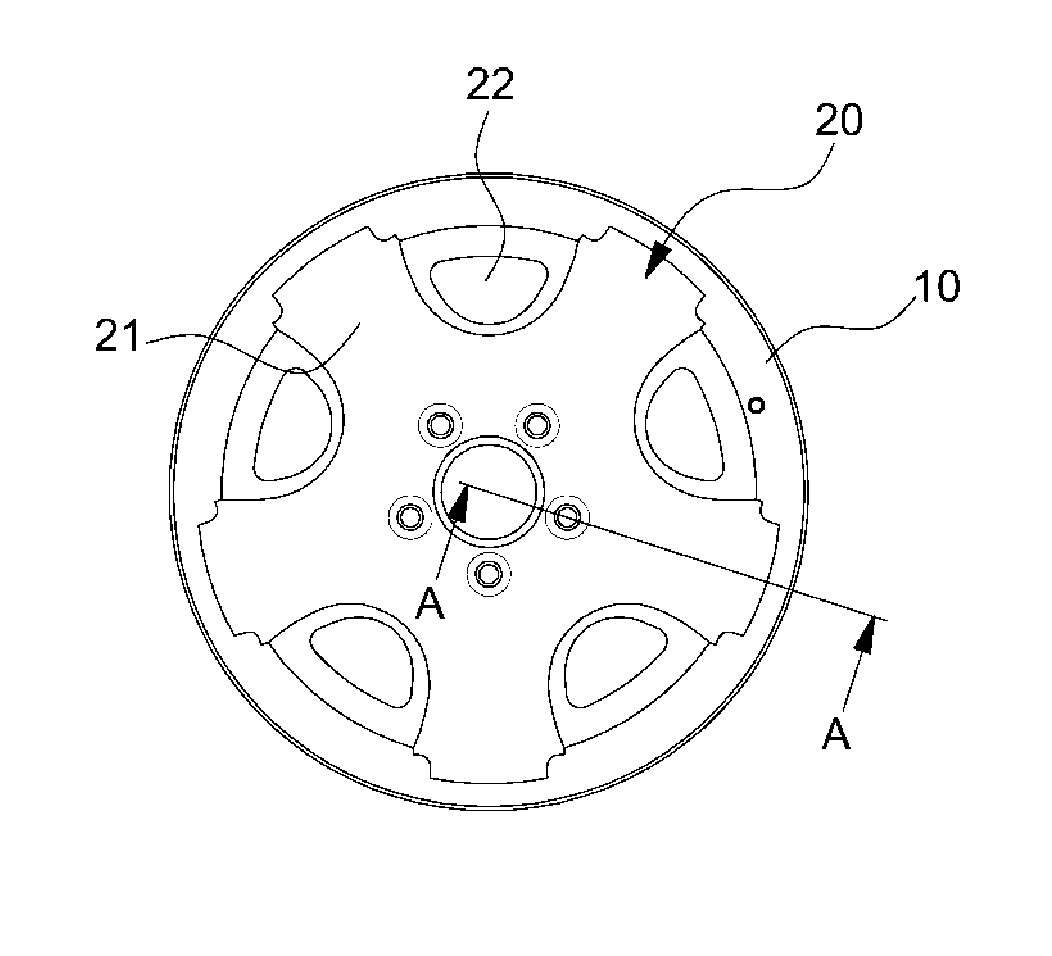

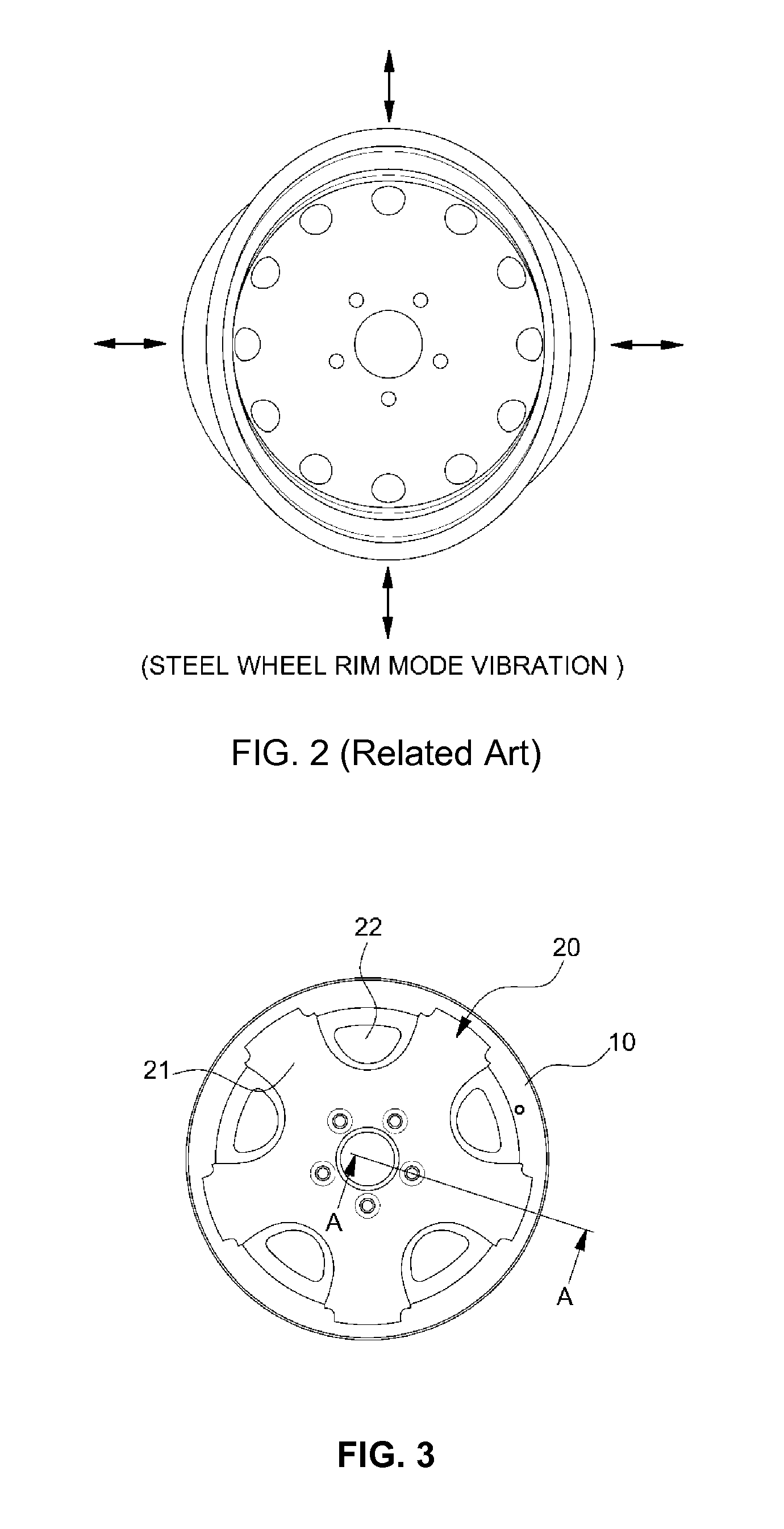

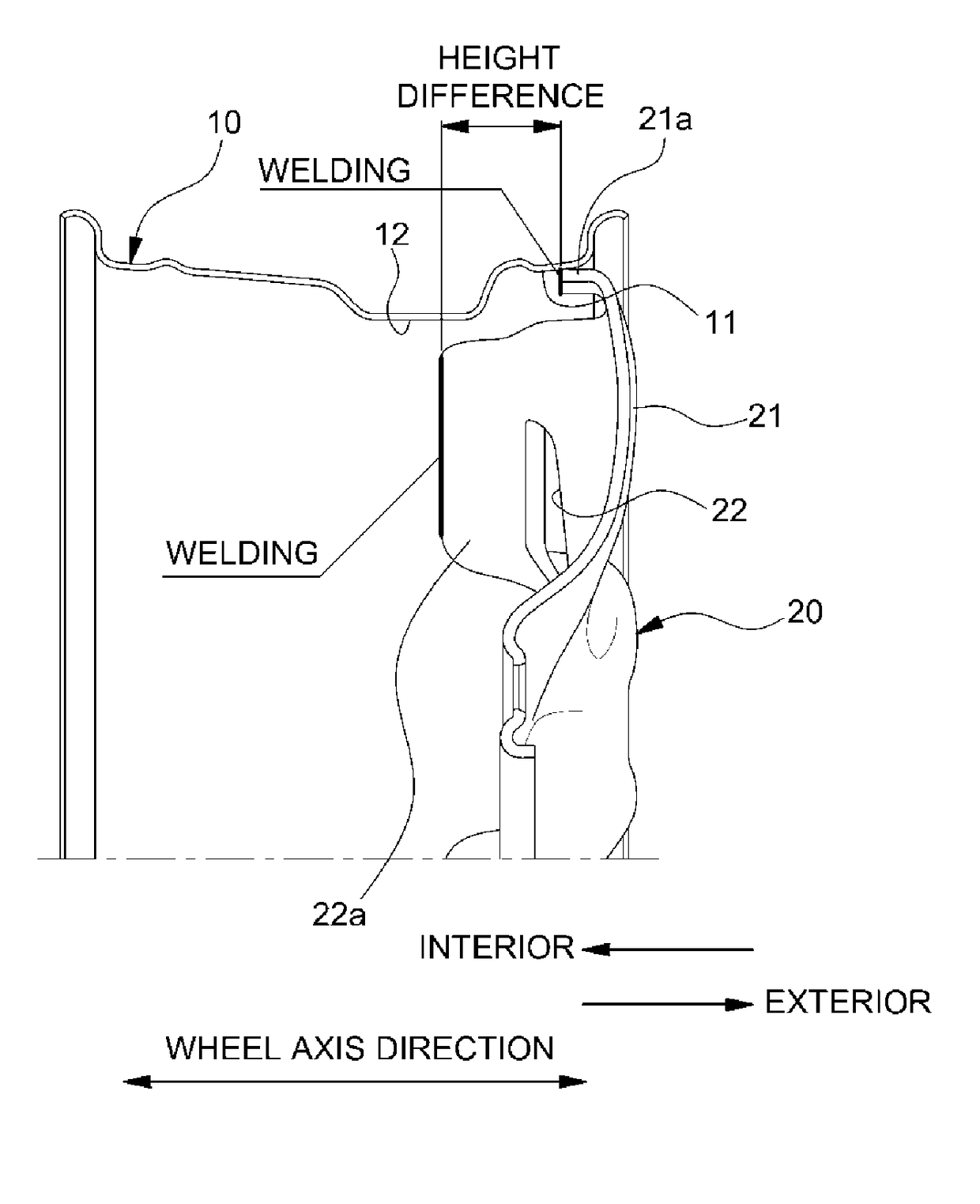

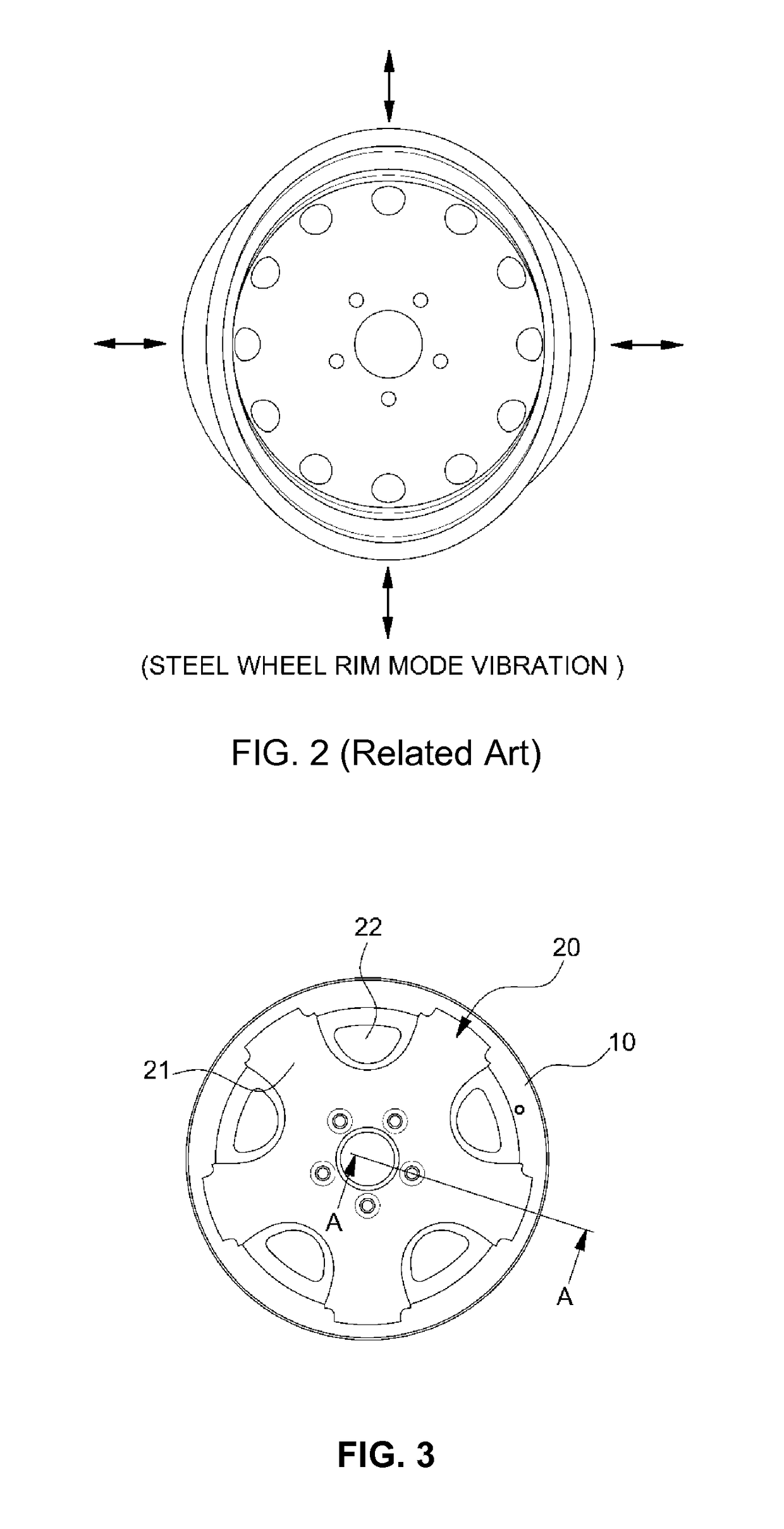

Wheel for vehicles and method for manufacturing the same

ActiveUS20160303895A1Simple designRaise the natural frequencyWheel manufactureSpoked wheelsCouplingEngineering

A wheel for vehicles may include a rim coupled to a tire, and a spoke-shaped disc including a spoke and a vent hole, the spoke-shaped disc being coupled to a side surface of the rim to support the rim, in which a coupling zone between the spoke of the spoke-shaped disc and the rim and a coupling zone between a portion of the spoke-shaped disc formed with the vent hole and the rim have a height difference in a wheel axis direction, to allow the spoke-shaped disc to support the rim at an interior and an exterior of the rim.

Owner:HYUNDAI MOTOR CO LTD +1

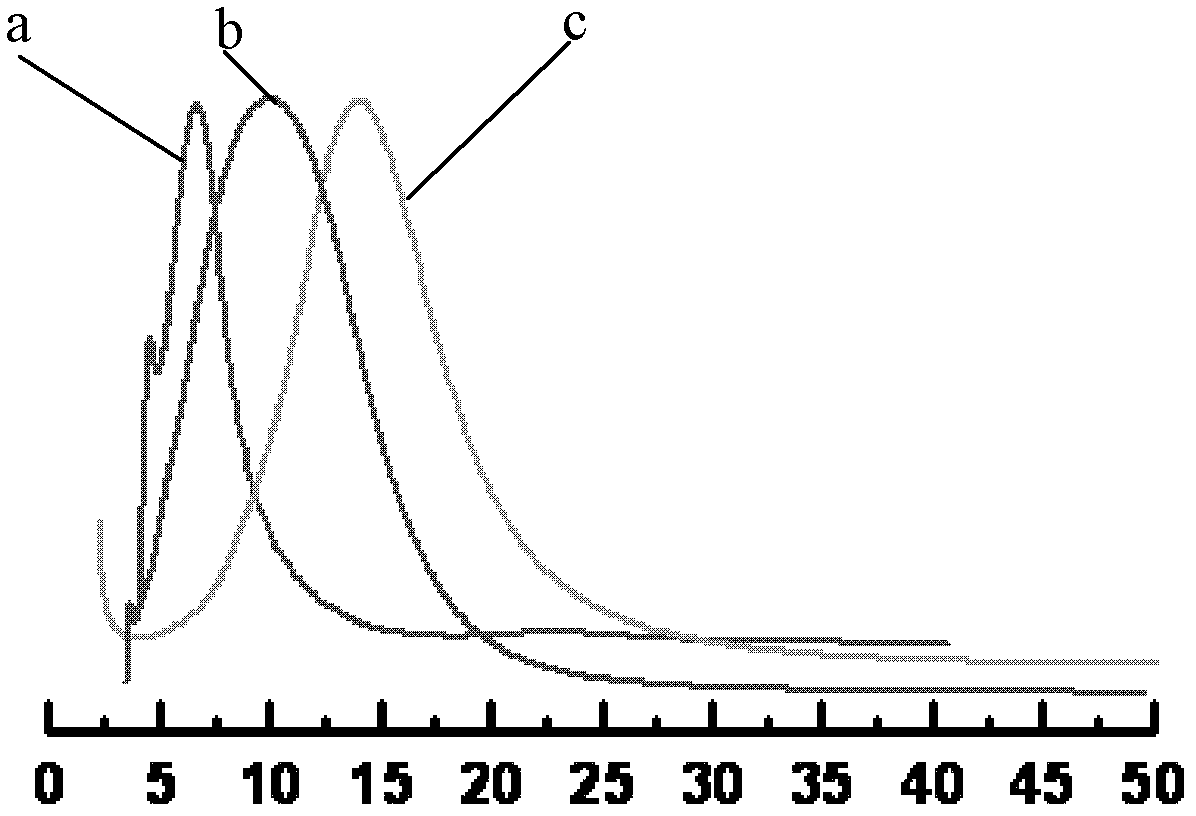

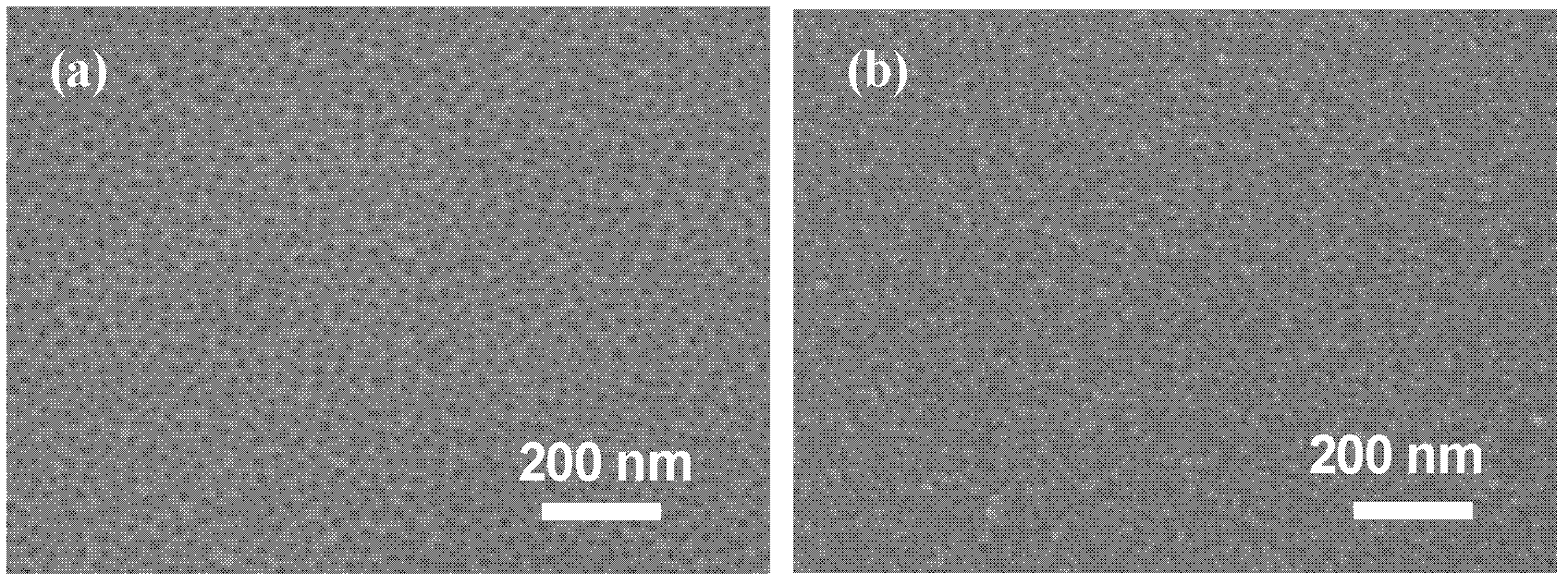

A preparation method of through-hole anodic aluminum oxide film with controllable pore size and thickness

The invention relates to a technique for preparing an anode alumina film, in particular to a method for preparing the anode alumina film which has small aperture, is ultra thin and is controllable in aperture and thickness. In the method, high-pure aluminum is used as an anode, a certain constant-voltage and direct-current power supply is applied onto a sulfuric acid electrolyte to perform anodicoxidation, proper voltages between the cathode and the anode, electrolyte concentration, electrolyte temperature and anode oxidization time are selected, and after the reaction, anode alumina with analuminum substrate is used as an anode and placed in mixed solution of perchloric acid and acetone, anode electrolysis treatment is performed under a voltage which is 5 to 15V higher than an anode oxidization voltage to make an alumina film separate from the aluminum substrate and to remove a baffle layer, and thus, the small-aperture through-hole anode alumina film with controllable aperture andthickness is obtained. When the method is used, the mass, simple, nondestructive, uniform and large-scale preparation of small-aperture and through-hole anode alumina film is realized, and the technical problem that the small-diameter and ultra-thin through hole anode alumina film is not available at present is solved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

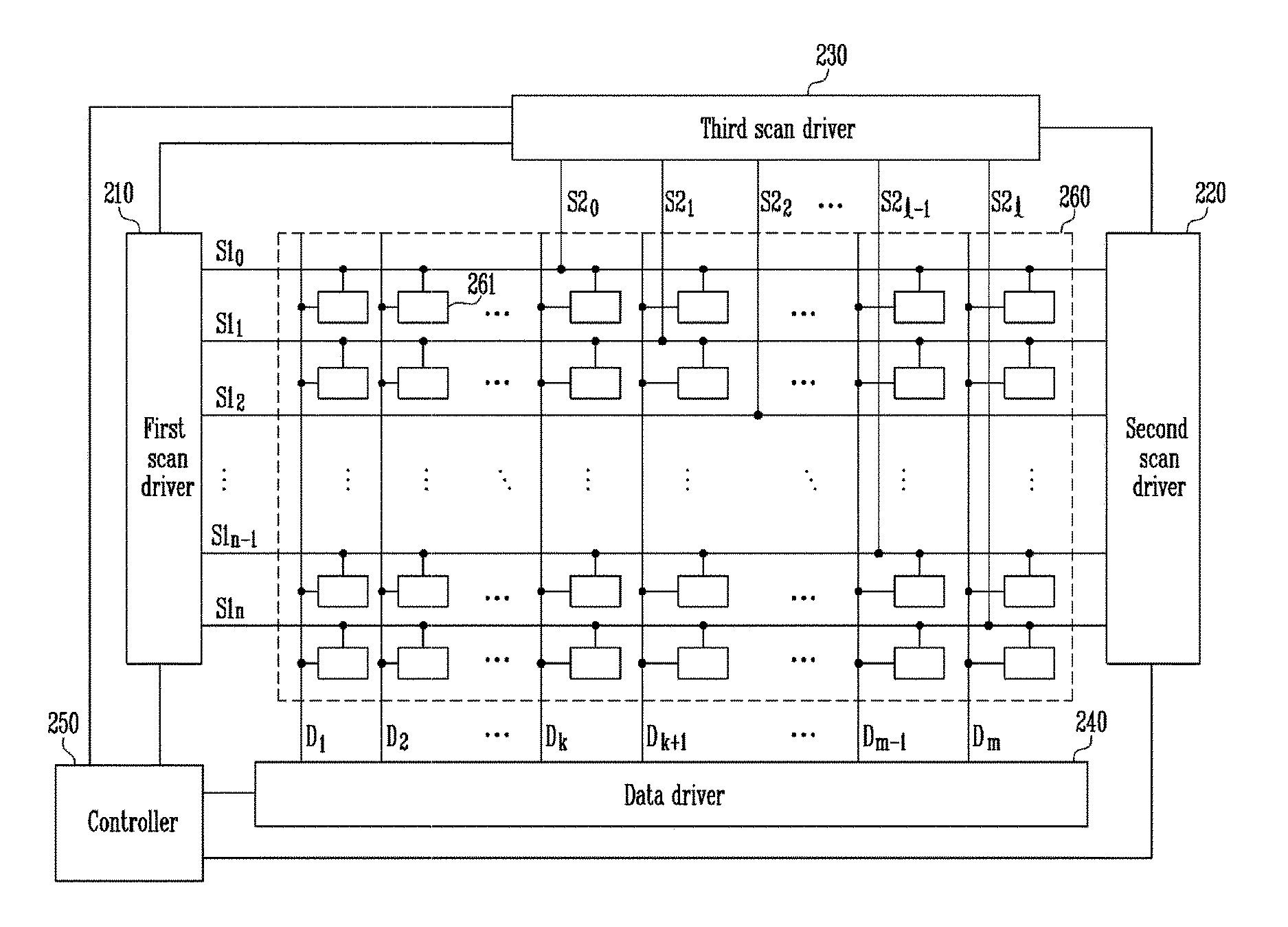

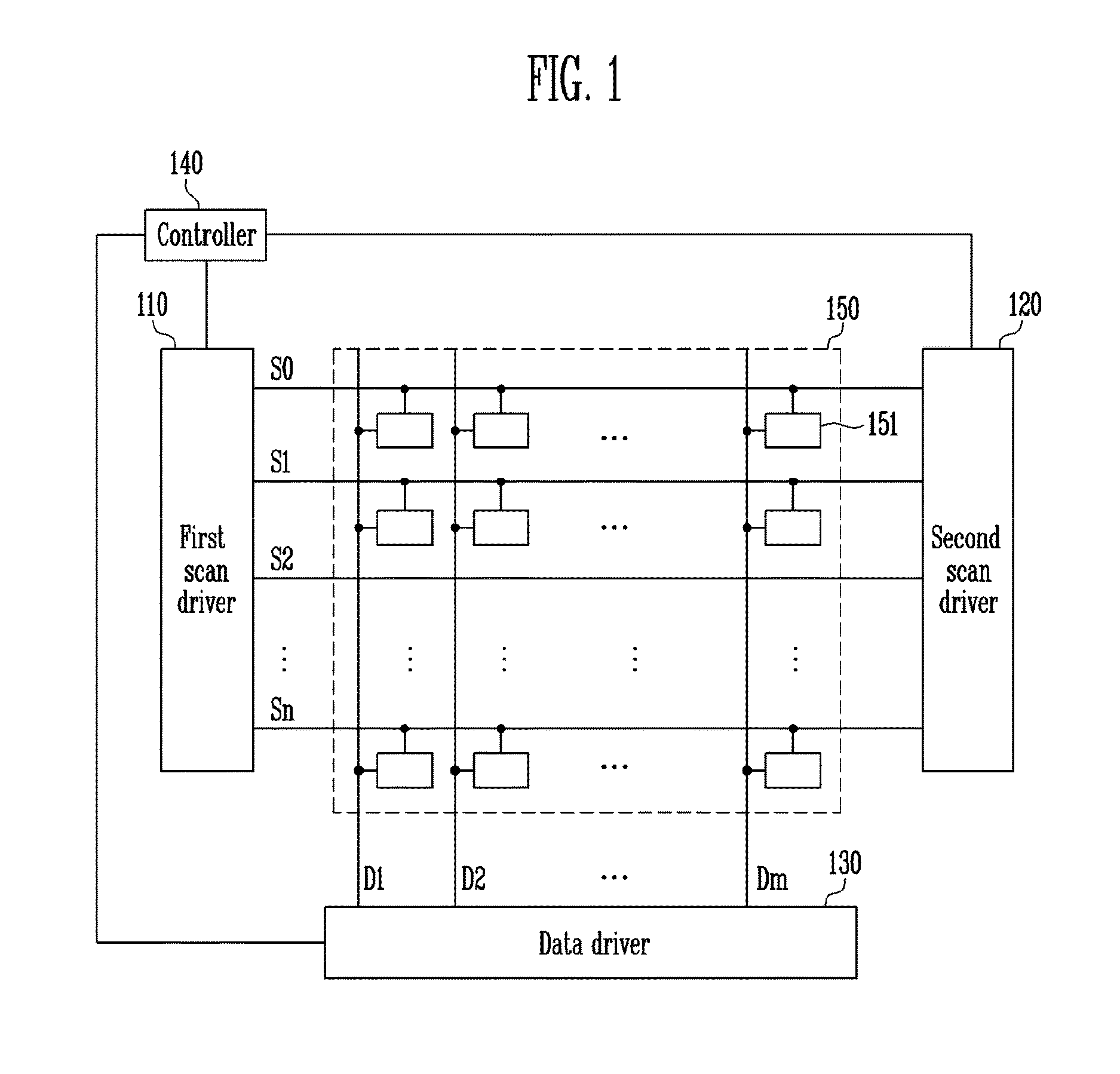

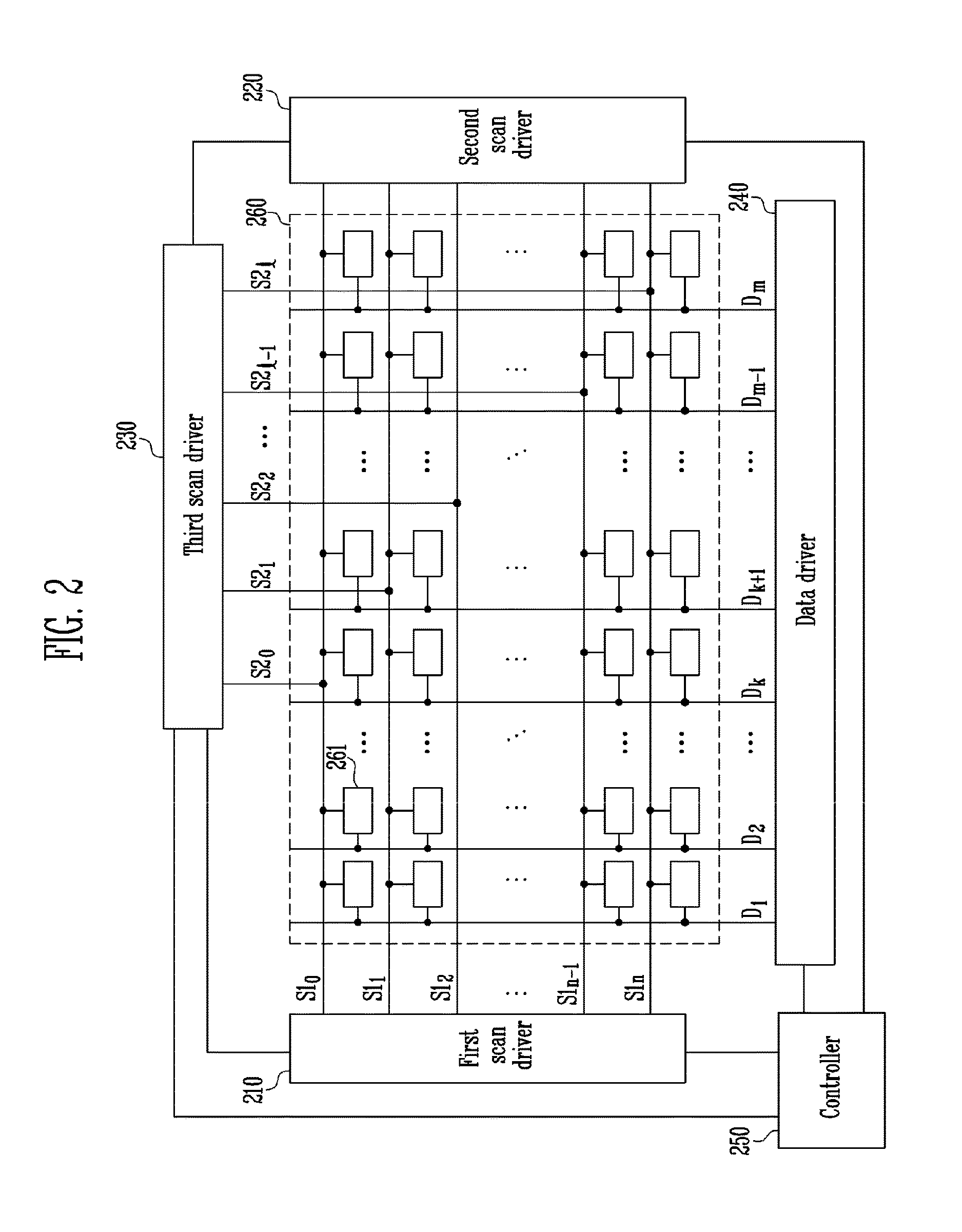

Display device having reduced scan signal delay and driving method therefor

InactiveUS20170046999A1Reduce response delayReducing total RCStatic indicating devicesData signalDisplay device

A display device according to an exemplary embodiment of the present invention may include: a display unit including a plurality of pixels; a first scan driver positioned at a first side of the display unit and arranged to output at least one first scan signal to the display unit; a second scan driver positioned at a second side of the display unit and arranged to output at least one second scan signal to the display unit; a third scan driver positioned along at least a portion of a third side of the display unit and arranged to output at least one third scan signal to the display unit; and a data driver positioned at a fourth side of the display unit and arranged to transmit a data signal to the display unit.

Owner:SAMSUNG DISPLAY CO LTD

Method for gate height control in a gate last process

InactiveUS7939392B2Improve device performanceSmall sizeSemiconductor/solid-state device manufacturingSemiconductor devicesDielectricInter layer

A method is provided for fabricating a semiconductor device that includes providing a semiconductor substrate, forming a transistor in the substrate, the transistor having a gate structure that includes a dummy gate structure, forming an inter-layer dielectric (ILD), performing a first chemical mechanical polishing (CMP) to expose a top surface of the dummy gate structure, removing a portion of the ILD such that a top surface of the ILD is at a distance below the top surface of the dummy gate structure, forming a material layer over the ILD and dummy gate structure, performing a second CMP on the material layer to expose the top surface of the dummy gate structure, removing the dummy gate structure thereby forming a trench, forming a metal layer to fill in the trench, and performing a third CMP that substantially stops at the top surface of the ILD.

Owner:TAIWAN SEMICON MFG CO LTD

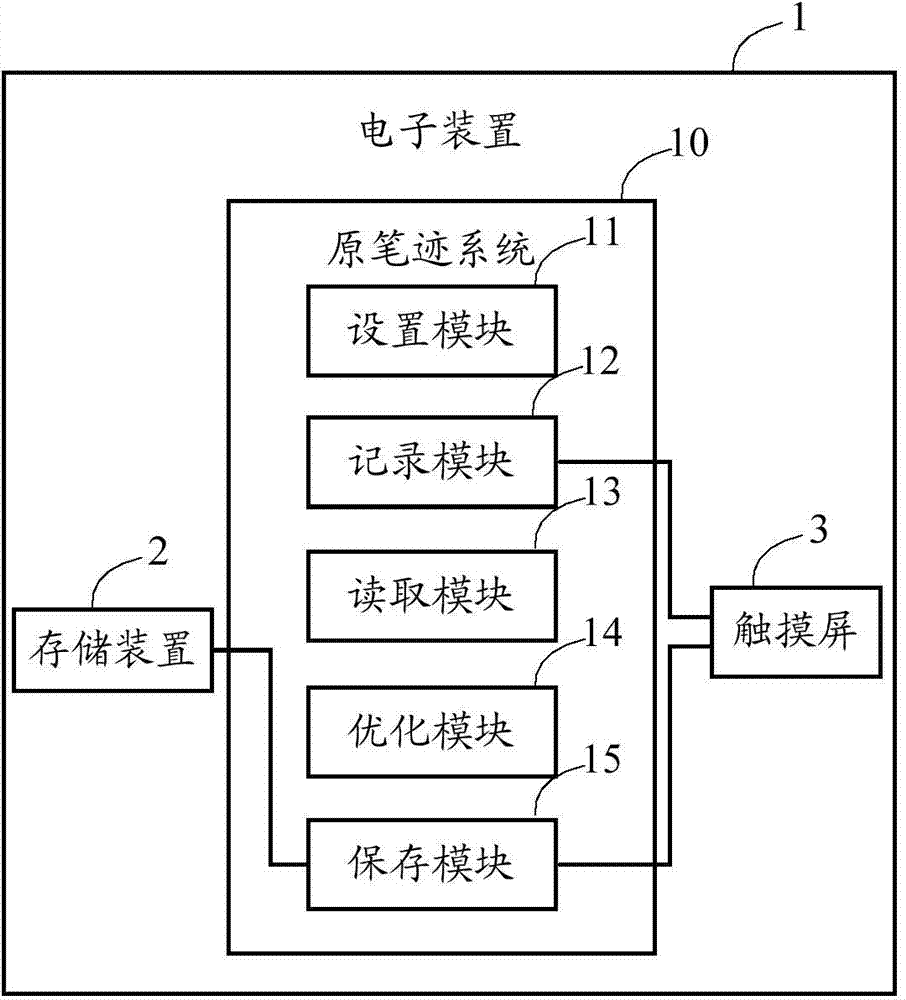

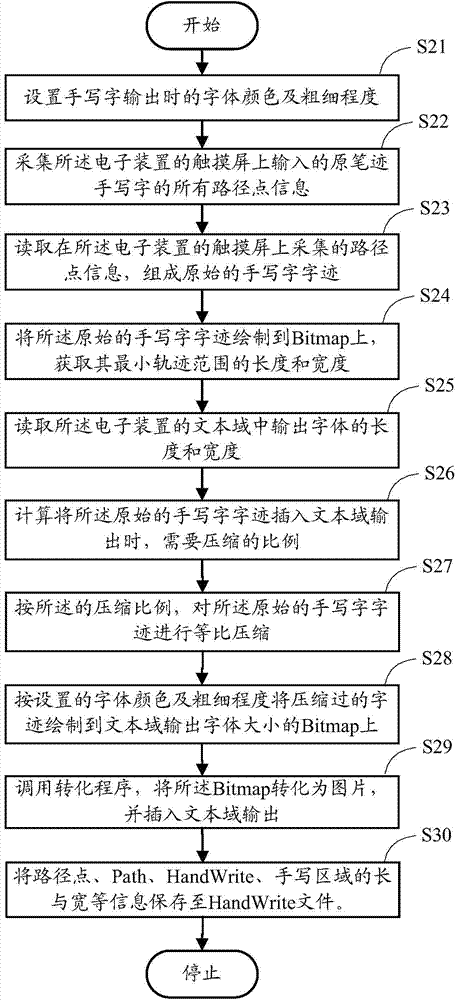

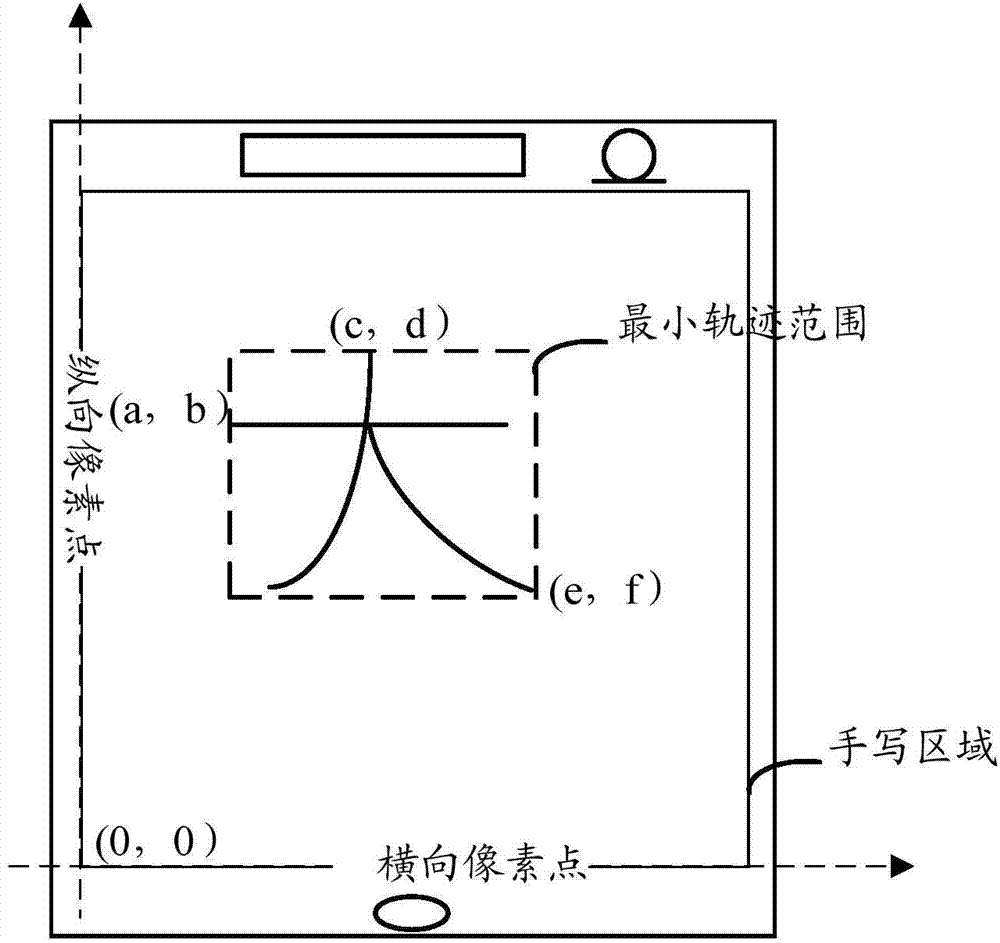

System and method for saving original handwriting

InactiveCN104731390AImprove handwriting input experienceSame thicknessInput/output to record carriersDigital ink recognitionHandwritingAlgorithm

In a method for an electronic device to output handwriting fonts, a thickness and a color is chosen for lines of handwriting fonts. Coordinates of touch points in response to a handwriting operation on the touch screen are recorded and one or more handwriting fonts are generated based on the recorded touch points. A first bitmap including the generated handwriting fonts is generated and a compression ratio between a minimum area of the generated handwriting fonts in the first bitmap and a area of a font in a text box of the electronic device is calculated. The generated handwriting fonts are compressed according to the compression ratio and a second bitmap including the compressed handwriting fonts is generated. The second bitmap is converted into a figure, and the figure is outputted in the text box of the electronic device.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD +1

Wheel for vehicles and method for manufacturing the same

A wheel for vehicles may include a rim coupled to a tire, and a spoke-shaped disc including a spoke and a vent hole, the spoke-shaped disc being coupled to a side surface of the rim to support the rim, in which a coupling zone between the spoke of the spoke-shaped disc and the rim and a coupling zone between a portion of the spoke-shaped disc formed with the vent hole and the rim have a height difference in a wheel axis direction, to allow the spoke-shaped disc to support the rim at an interior and an exterior of the rim.

Owner:HYUNDAI MOTOR CO LTD +1

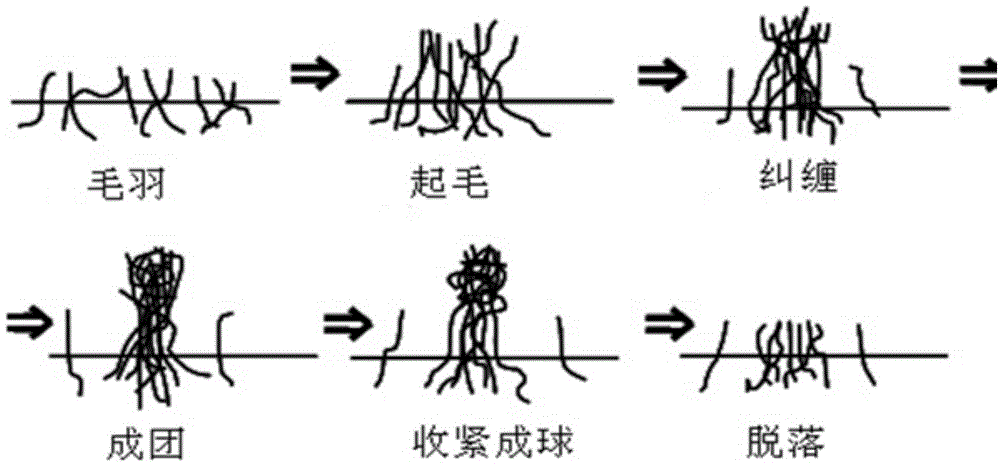

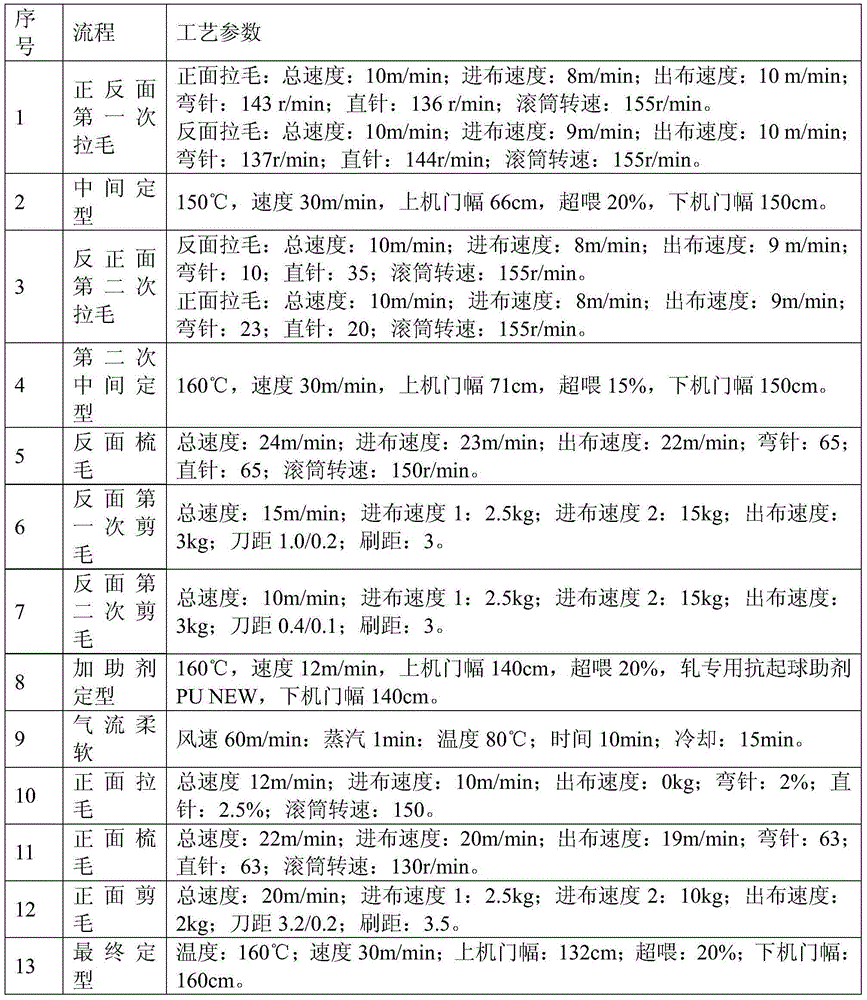

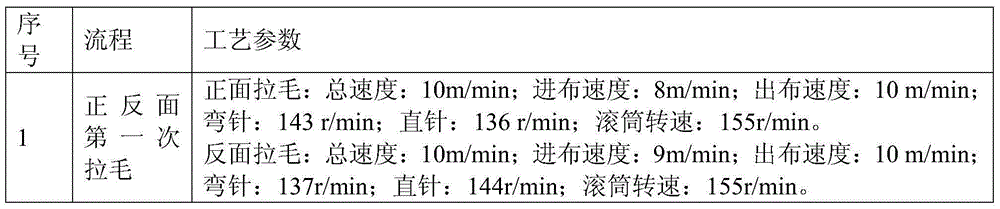

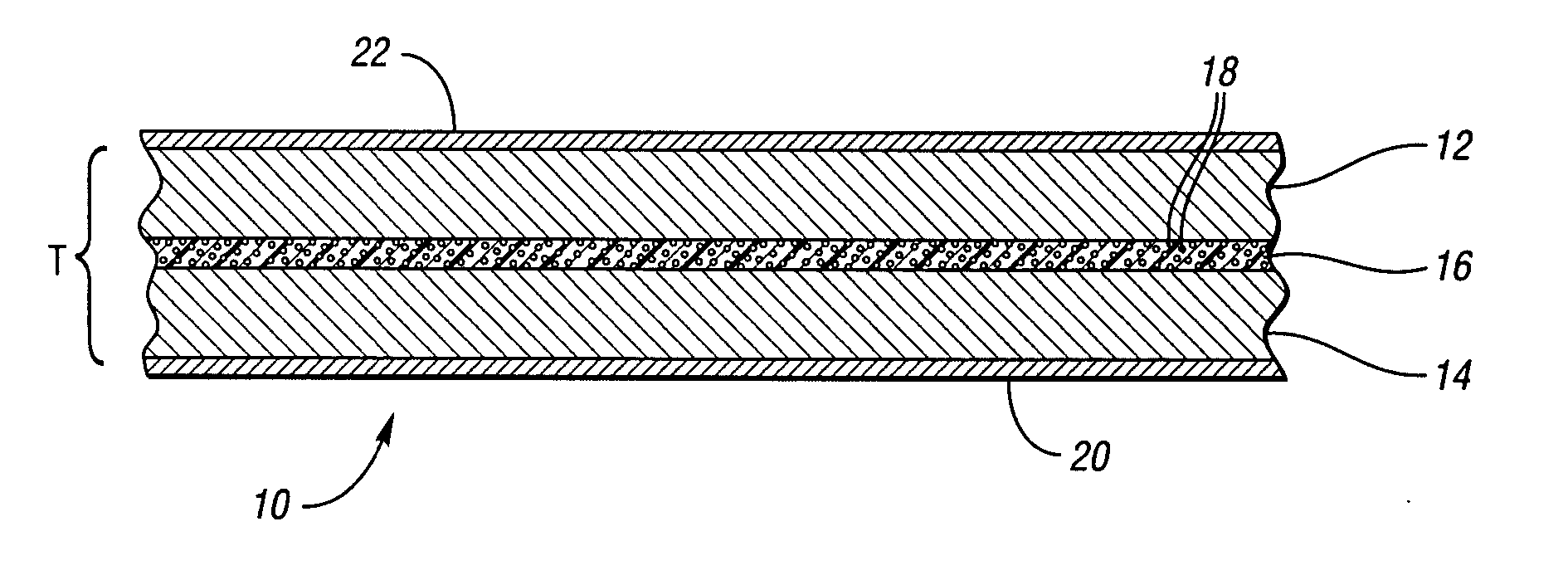

Anti-pilling finishing method of large needle gage loop-raised fabric

ActiveCN104480665AImprove anti-pilling performanceImproved pilling resistanceFabric breaking/softeningHeating/cooling textile fabricsFiberYarn

The invention relates to an anti-pilling finishing method of large needle gage loop-raised fabric. The anti-pilling finishing method comprises following steps: (1) galling processing, used for pulling fluff out of fiber yarn; (2) carding processing, used for carding the fluff to be vertical; and (3) shearing processing, used for removing the float fluff obtained via carding. The anti-pilling finishing method is capable of improving anti-pilling performance of large needle gage loop-raised fabric to half to one grade. The anti-pilling finishing method is simple; original style of the processed fabric is not changed; and no extra processing process is increased.

Owner:上海嘉麟杰纺织科技有限公司

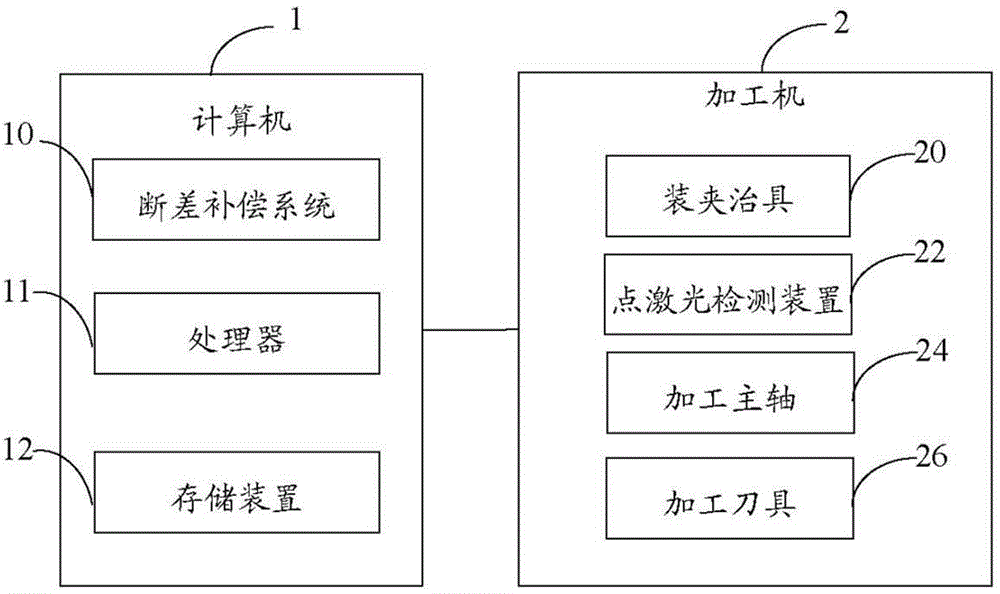

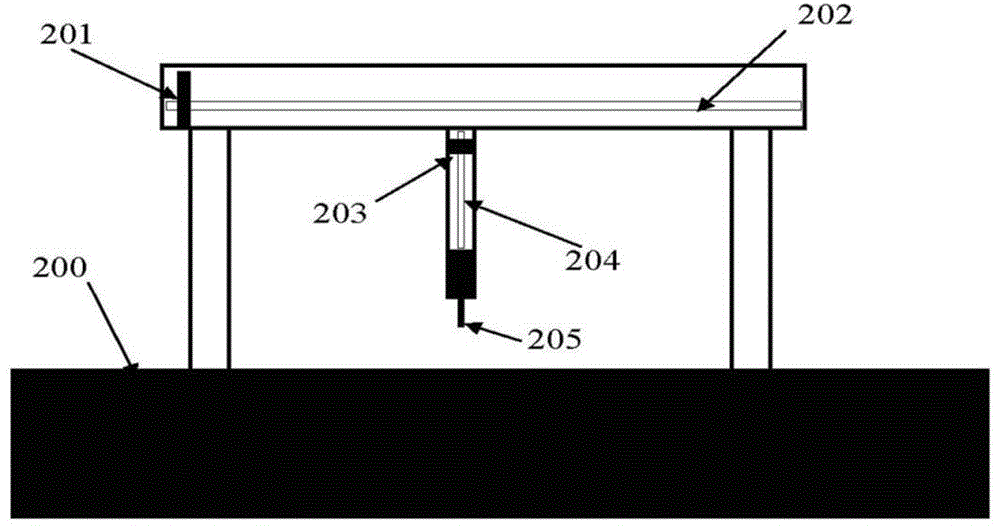

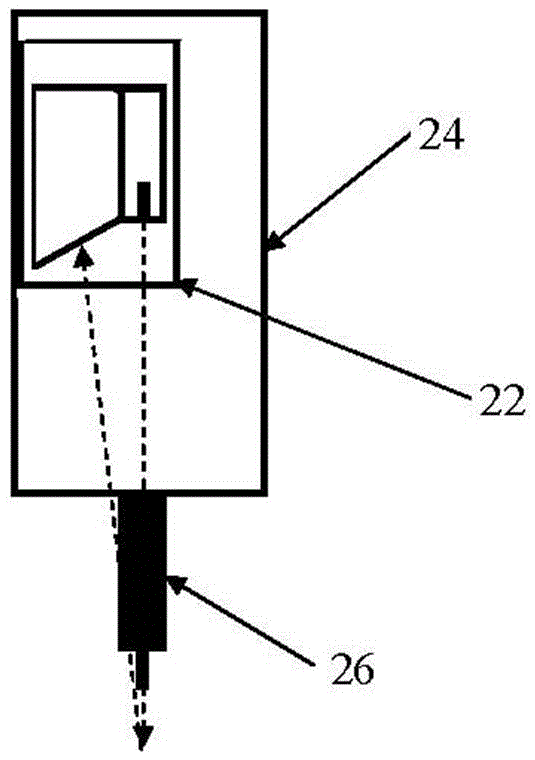

System and method for compensating inner offset of machining device

InactiveCN104416419ASame thicknessProgramme controlAutomatic control devicesZ-CoordinateLaser detection

In a method for compensating step value of a processing product placed on a machining device using a computing device, a machining tool of the machining device is controlled to be moved to each benchmark point in sequence. Actual coordinate values of each benchmark point is calculated by a laser detection device of the machining device. The acquired actual coordinate values are fitted to be a benchmark plane. New coordinate values of each machining point in a machining program is acquired by rotating each of the machining points to the benchmark plane. The machining tool is controlled to move to each machining point according to the calculated new coordinate values and an actual z coordinate value of each machining point is acquired using the laser detection device. The step compensation value in Z-axis of the each machining point is calculated and transmitted to the machining device.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

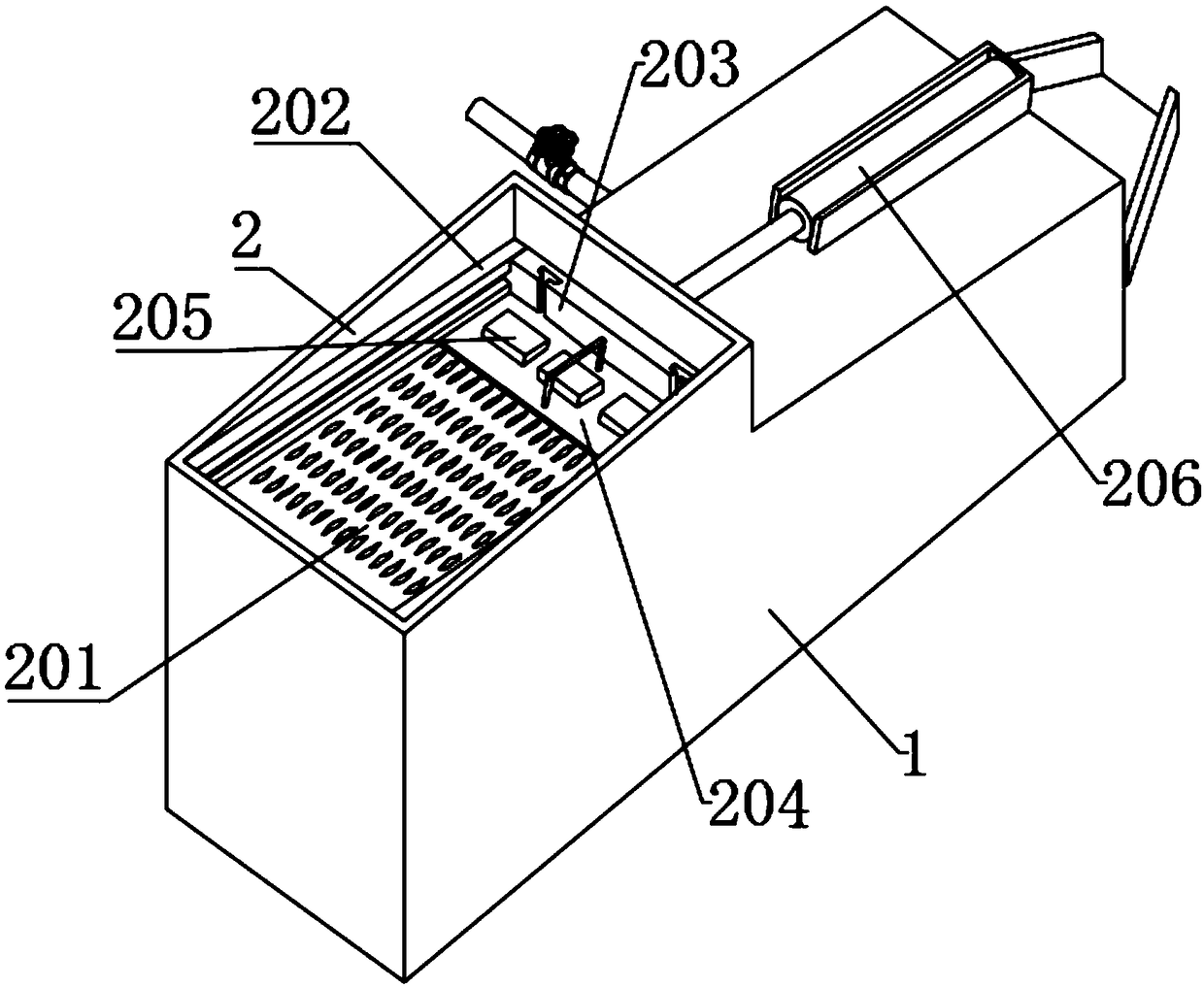

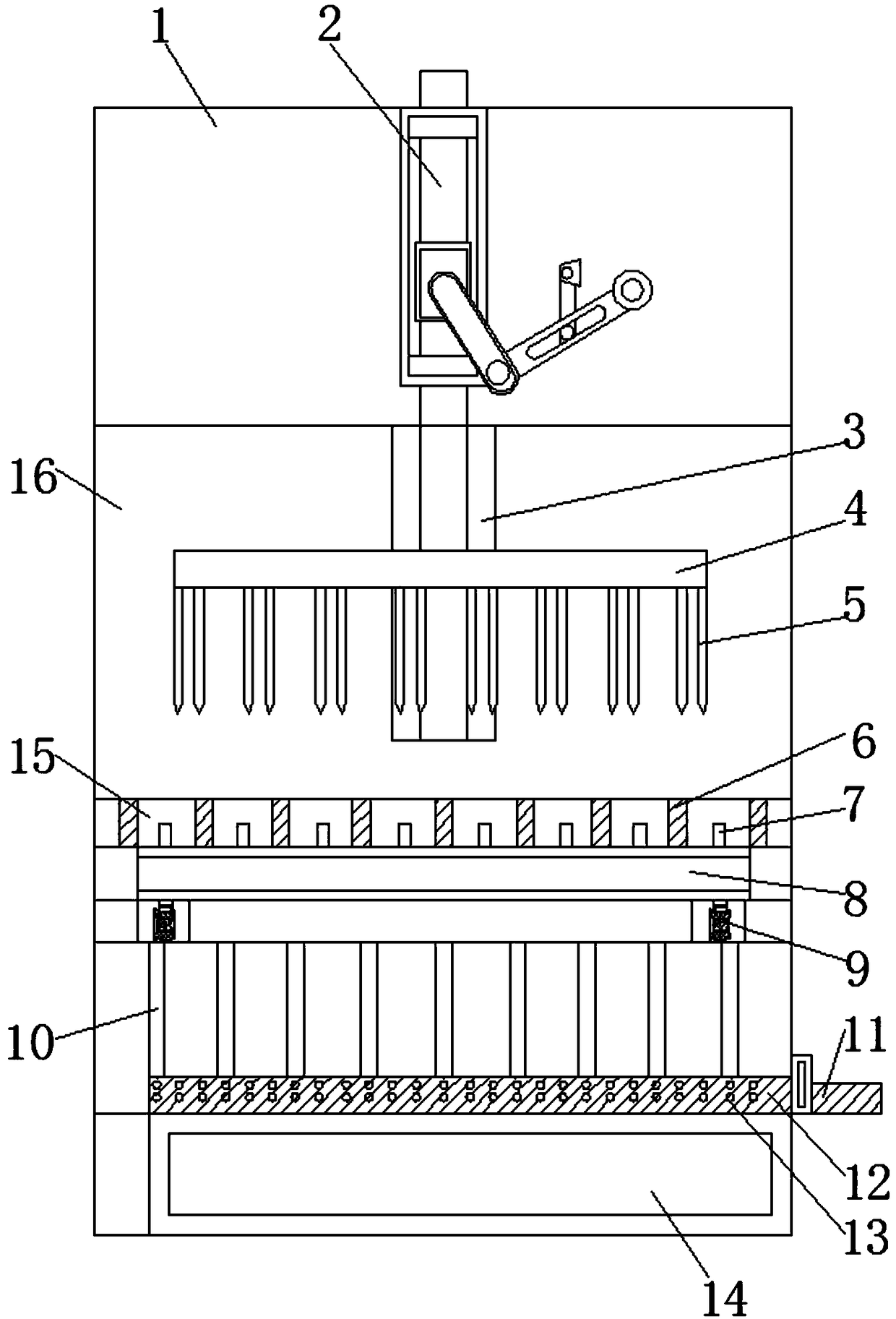

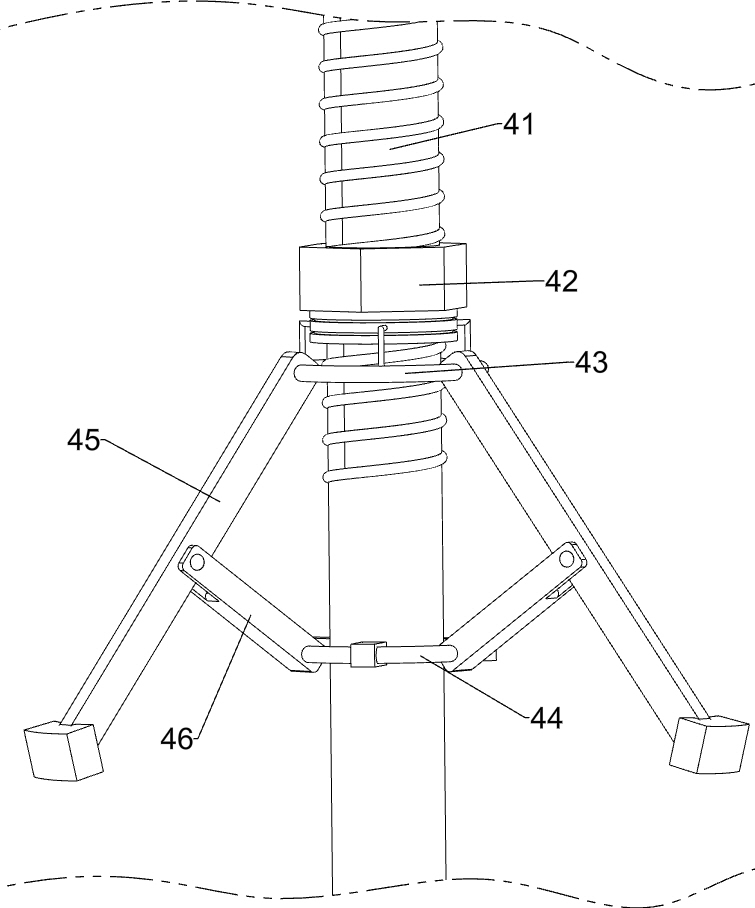

Potato shredding and cleaning device for agricultural food processing

InactiveCN109366535ASame thicknessLabor savingMetal working apparatusFood treatmentAgricultural engineeringSlide plate

The invention provides a potato shredding and cleaning device for agricultural food processing. The potato shredding and cleaning device for agricultural food processing comprises a shredding hole plate, a push plate, a pressing plate, a material receiving sliding plate, cleaning hood heads and a cleaning hole plate; and the shredding hole plate is inlaid at the upper end of the inner side of a shredding cavity, the two ends of the upper side of the shredding hole plate are connected with sliding rails respectively, the two ends of the push plate are respectively inserted into slide grooves ofthe slide rail, the pressing plate is arranged at the front end of the push plate in a sliding mode through a T-shaped block at the rear end of the pressing plate, a material receiving sliding plateis further arranged on the lower side of the shredding hole plate, the cleaning hole plate is rotationally arranged at the bottom end of a discharging square hole, the inner side end of the cleaning hole plate is arranged on a limiting plate, the top of a cleaning cavity is provided with two groups of cleaning hood heads, and an upper water pipe is in communication with the two groups of cleaninghood heads. The weight of a balancing weight on the pressing plate is utilized to enable the potato to be tightly attached to the shredding hole plate, the push plate is pushed by a shredding push rodto move forwards and backwards according to the direction of the shredding hole plate, the potatoes can be cut into shreds, and the thickness of the shredded potatoes after shredding can be ensured to be the same.

Owner:王友锋

Anti-pilling finishing method of cationic wool napping fabrics

InactiveCN108018666AImprove anti-pilling performanceGuaranteed feel changeAbrasion resistant fibresAnimal fibresCardingEngineering

The invention relates to an anti-pilling finishing method of cationic wool napping fabrics. The method comprises a napping process, a carding process, a shearing process and an accessory ingredient adding and design finalizing process, wherein the pulling process includes reverse side pilling finishing napping and front side napping after reverse side anti-pilling treatment; the accessory ingredient adding and design finalizing process includes design finalizing finishing with fuzzy agents and design finalizing finishing with anti-pilling agents. The anti-pilling properties of the cationic wool napping fabrics treated by the finishing method can be improved by 2 levels, and hand feels are comfortable; the method is simple in process and does not change original fabric styles, the anti-pilling properties of the cationic wool napping fabrics are greatly enhanced, ornamental value and comfort of clothes made from such fabrics are improved, and the method has good application prospects.

Owner:SHANGHAI CHALLENGE TEXTILE

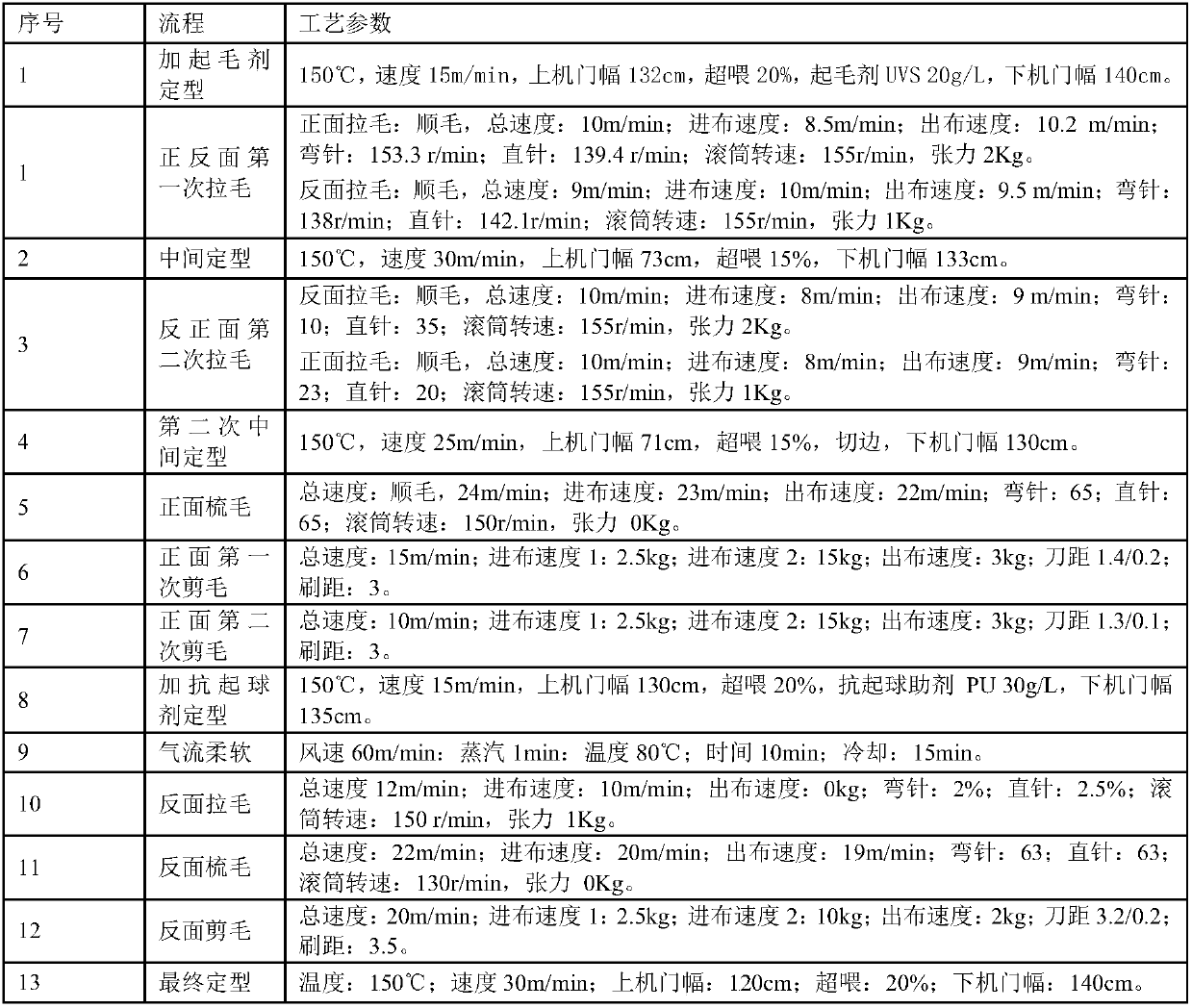

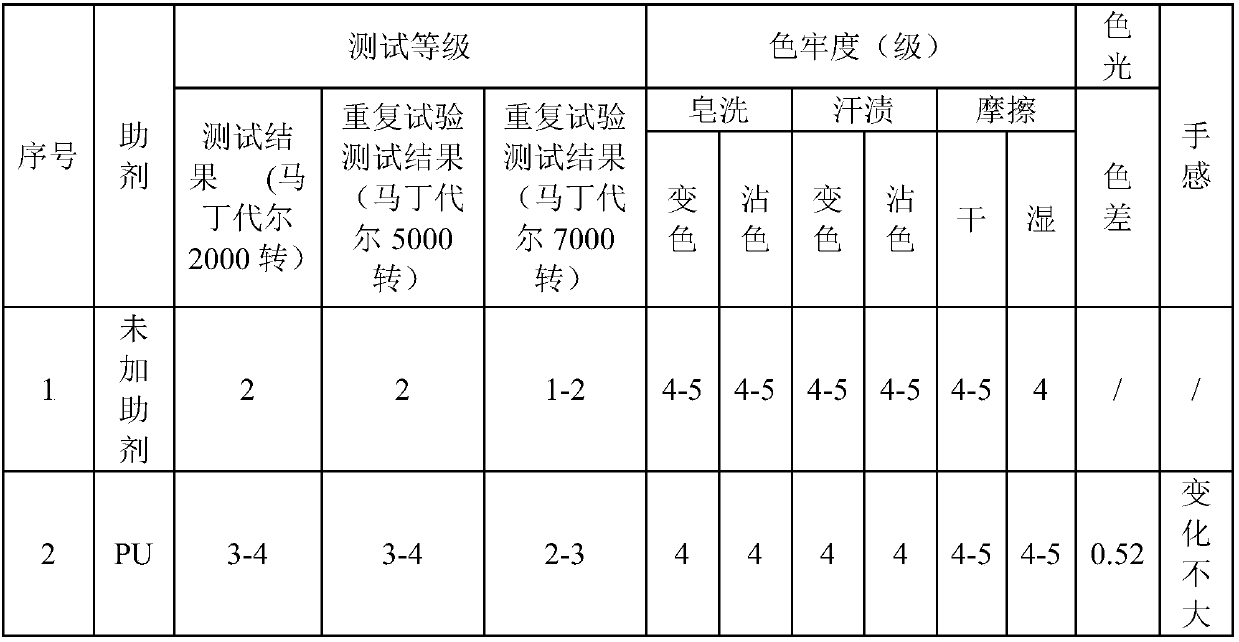

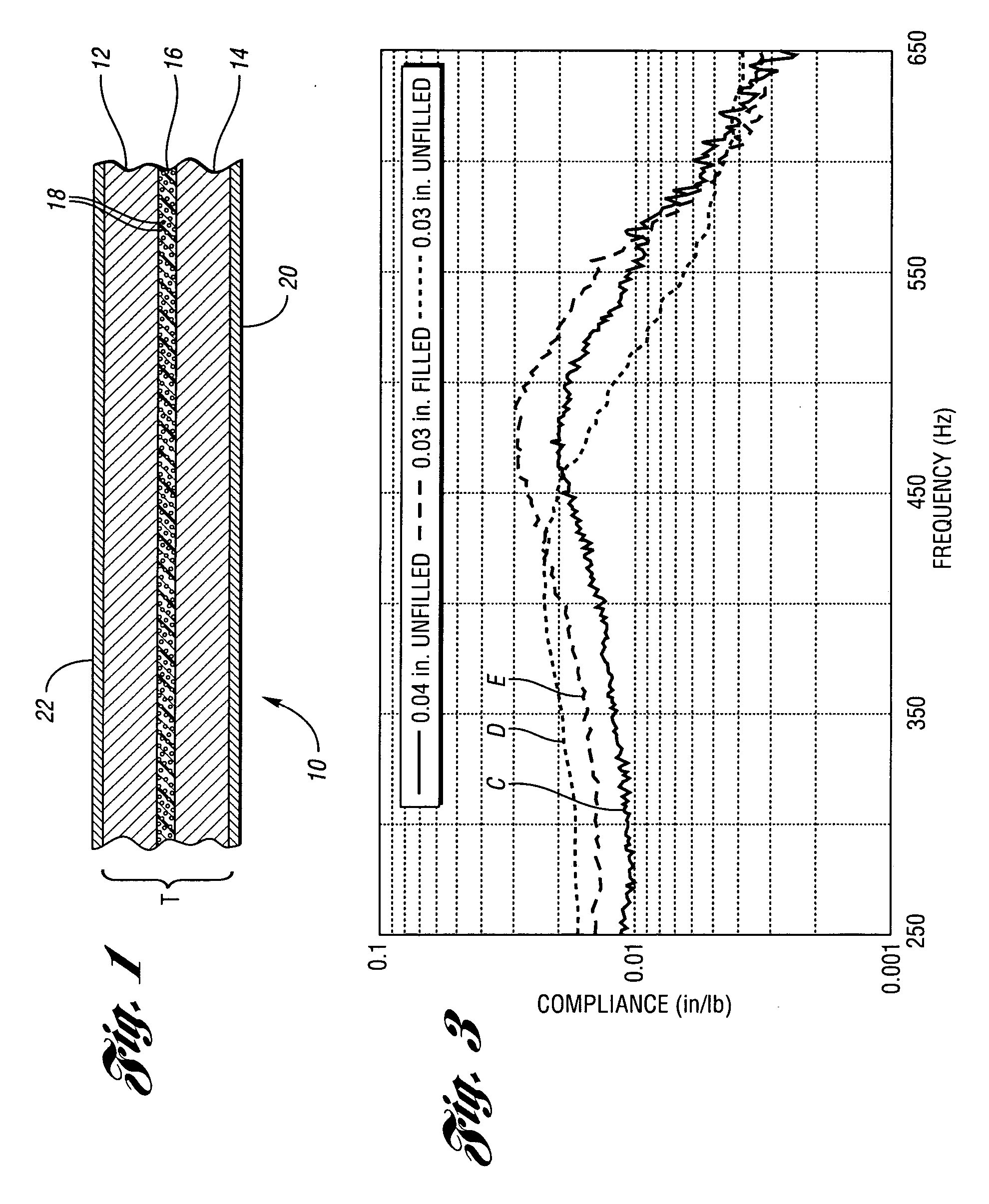

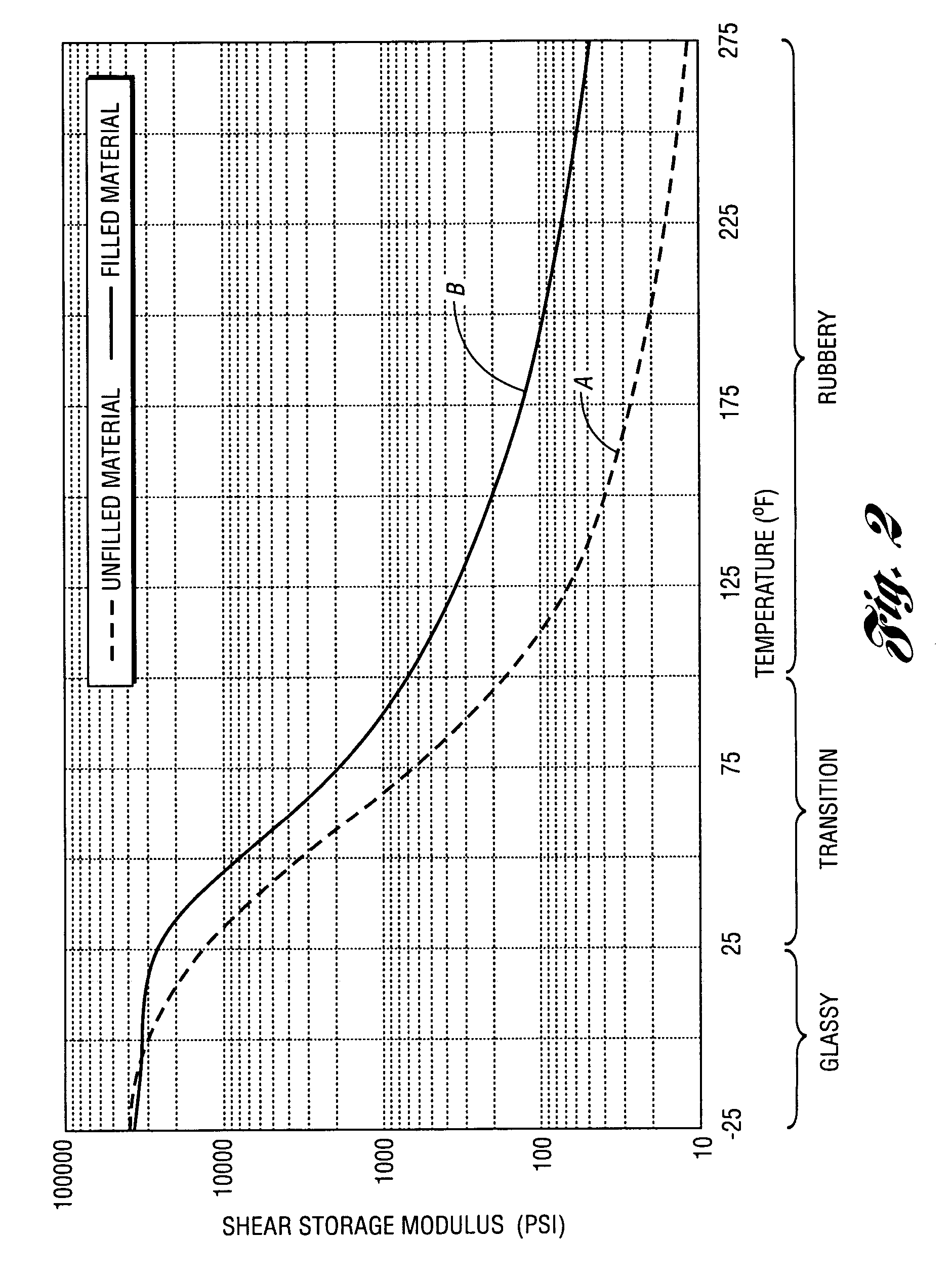

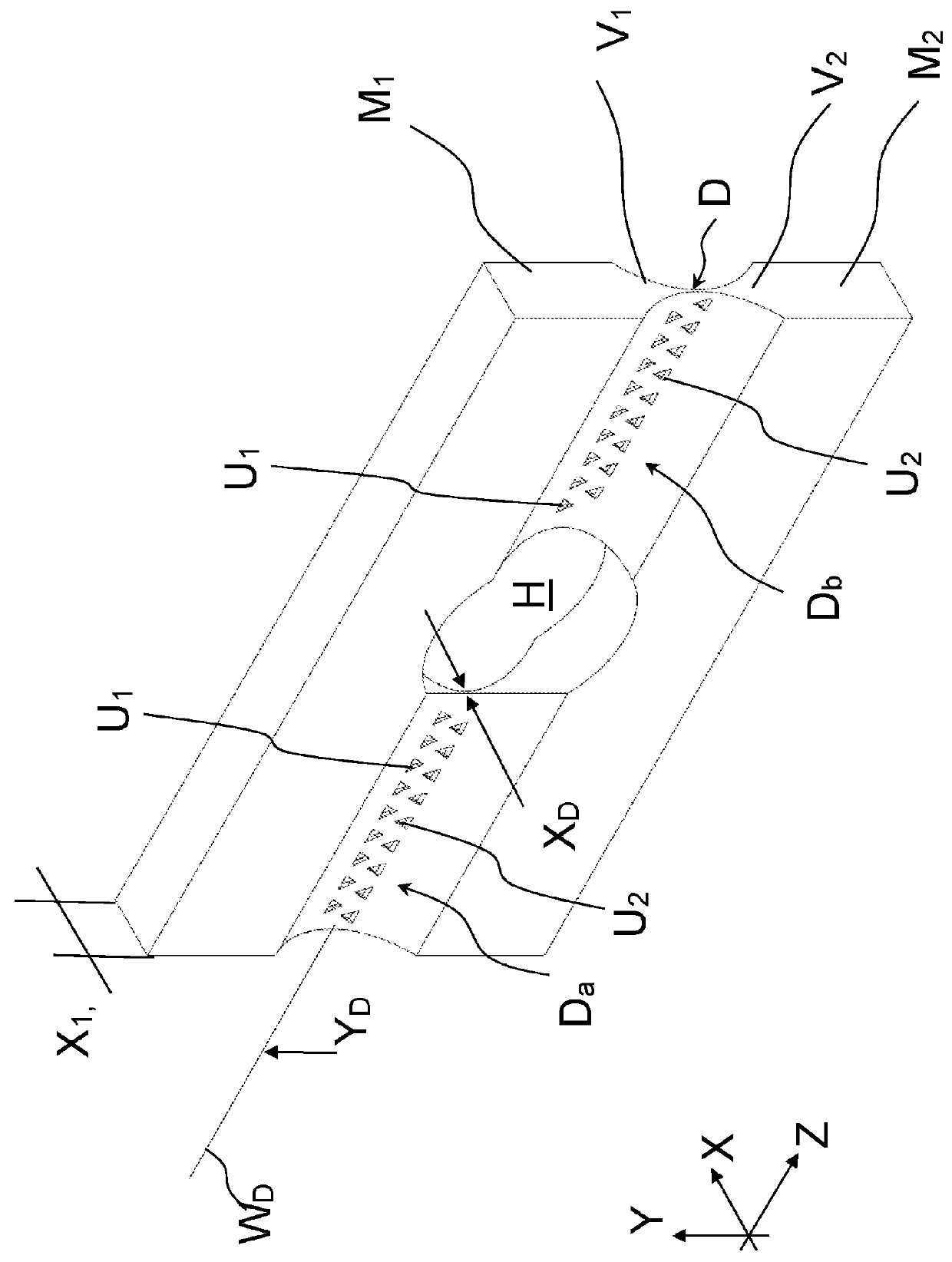

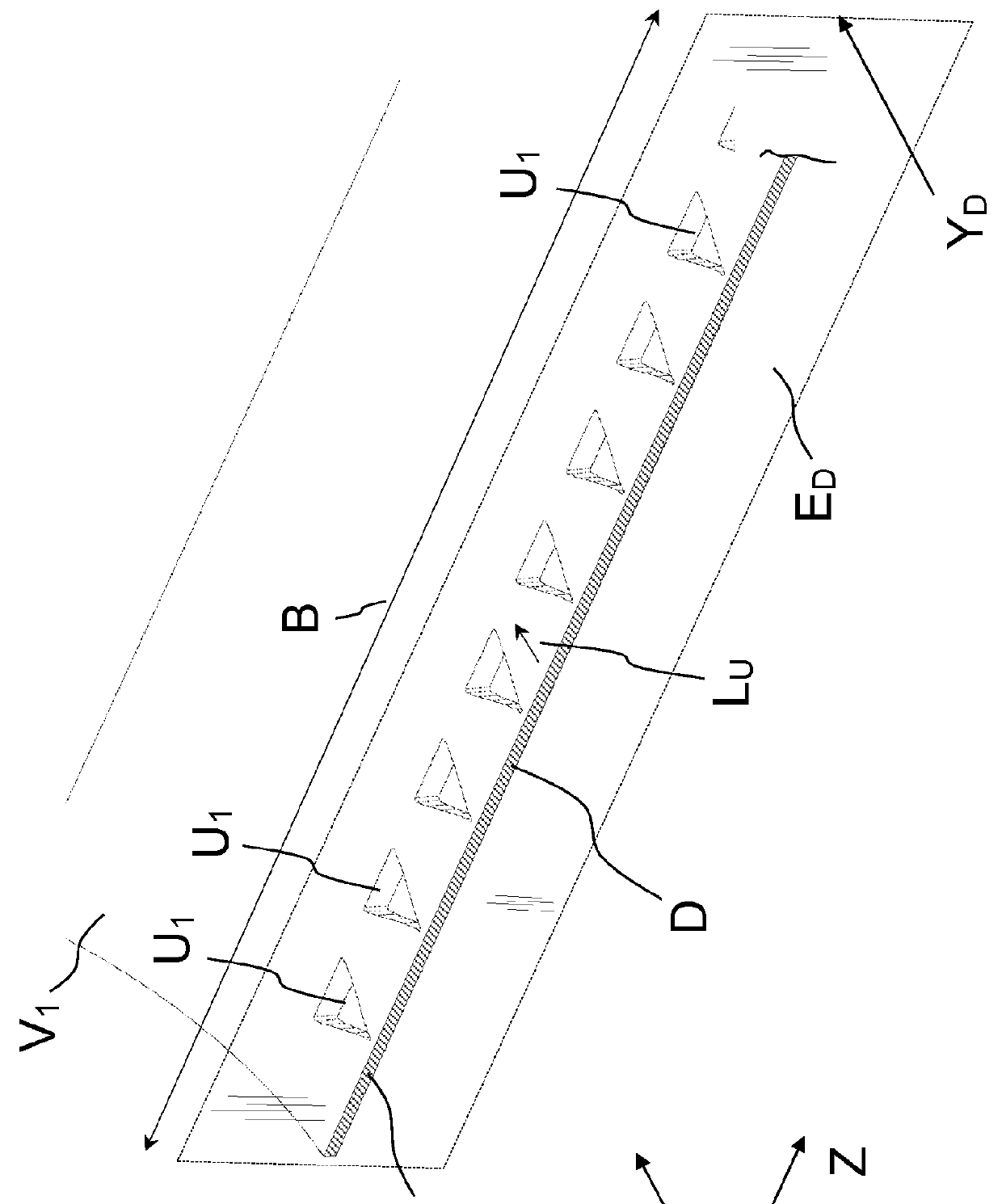

Laminated structure with a filled viscoelastic layer and method

InactiveUS20070026212A1Improve static stiffnessSame stiffnessSynthetic resin layered productsCeramic layered productsVibration attenuationFilling materials

The present invention provides a panel providing improved noise and vibration attenuation. The panel is formed from a constrained layer viscoelastic laminate material having at least two constraining layers and at least one viscoelastic layer therebetween spanning the entirety of the constraining layers. Included within the viscoelastic layer is an effective amount of filler material operable to increase the static stiffness of the panel. A method of increasing the static stiffness of constrained layer viscoelastic materials is also provided.

Owner:MATERIAL SCIENCES CORPORATION

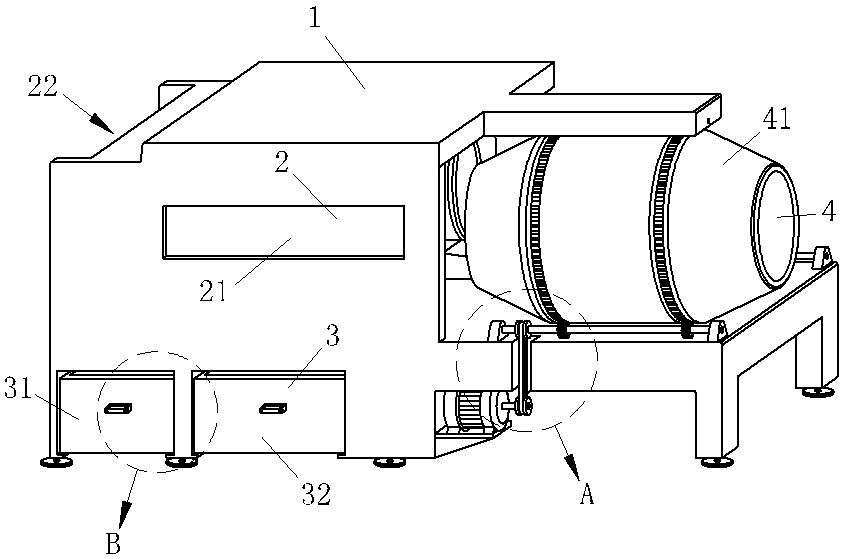

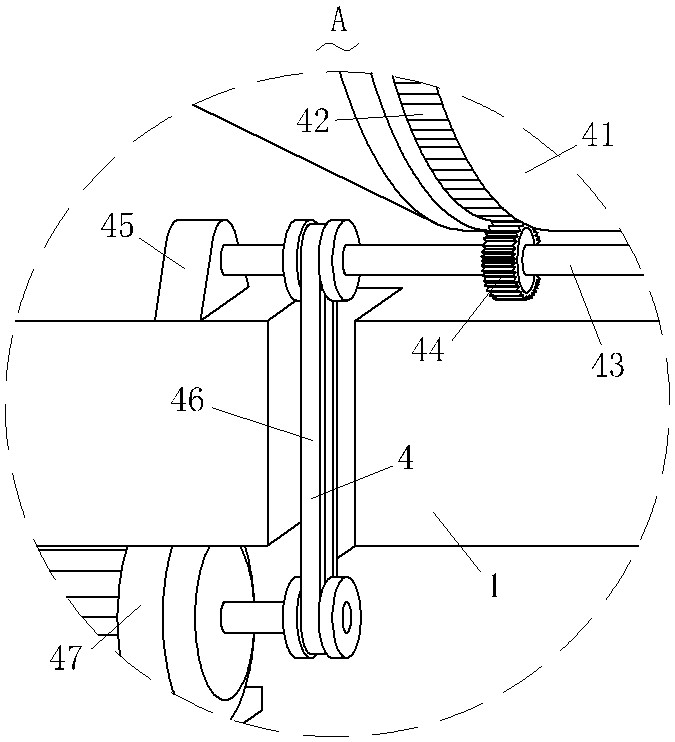

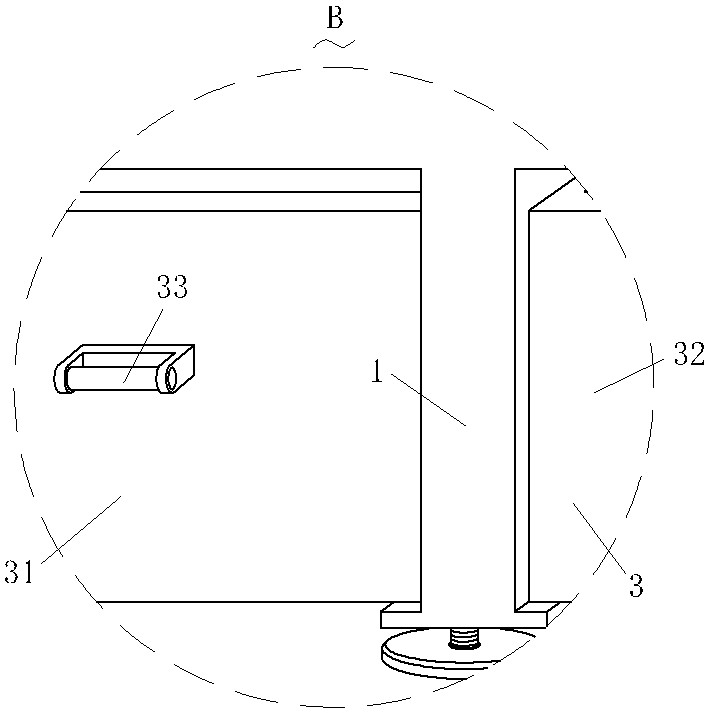

Asphalt pavement paving material mixing device

ActiveCN111877091AEasy accessGood removal effectRoads maintainenceRoad surfaceMechanical engineering

The invention relates to the technical field of asphalt pavement laying, in particular to an asphalt pavement laying material mixing device. The device comprises a shell, a feeding mechanism, a collecting mechanism, a stirring mechanism, a first screening mechanism, a second screening mechanism and a shaking mechanism. Materials are prevented from sliding down and being blocked through the feedingmechanism, the materials are preliminarily screened and filtered through the first screening mechanism, fine gravel is removed, the screened gravel is further screened under the action of the secondscreening mechanism, resource waste is reduced, the first screening mechanism is prevented from being blocked under the action of the shaking mechanism, and the screening efficiency is improved. Through work of the second screening mechanism, fallen gravel particles fall in a classified mode and are collected and stored under the action of the collecting mechanism, subsequent use is facilitated, mixing, stirring and blending of materials are facilitated under the action of the stirring mechanism, and subsequent pavement laying is facilitated; meanwhile, the stirring mechanism is beneficial toproviding power for the first screening mechanism to rotate.

Owner:福建省华实建工集团有限公司 +1

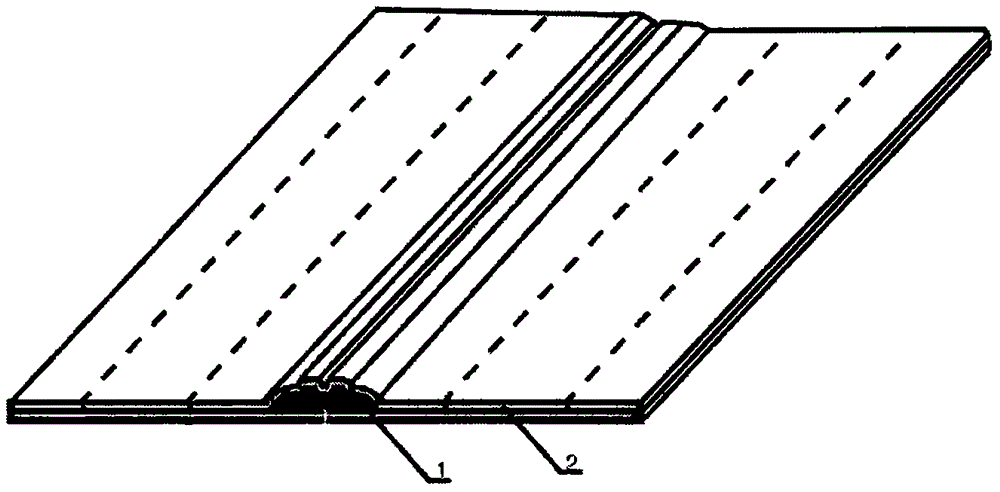

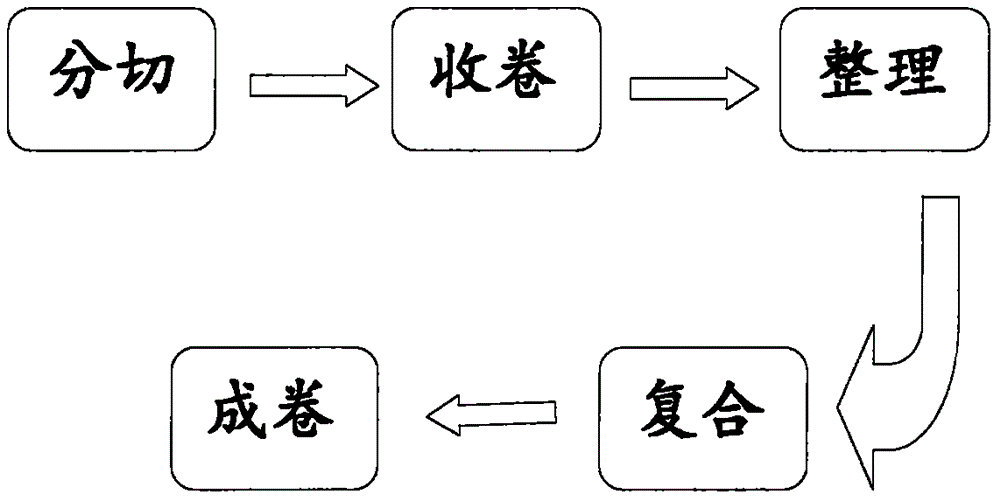

Anti-seepage multicolor zipper and processing technology thereof

InactiveCN106626682AIncrease productivitySame color intervalSlide fastenersLamination ancillary operationsEngineeringMechanical engineering

The invention relates to an anti-seepage multicolor zipper and a processing technology thereof. The anti-seepage multicolor zipper comprises a zipper basement layer and a polyurethane waterproof layer. The processing technology comprises the following concrete technological steps: firstly, slitting, namely cutting one or several kinds of colored polyurethane film (one waterproof membrane) into stripes by virtue of a slitting machine; secondly, rolling, namely winding waterproof polyurethane slit films slit into the stripes on a fixed rotary table and rolling into a tube shape; thirdly, straightening out and guiding an outlet end of multicolor waterproof polyurethane slit films rolled into the tube shape with a linetype mould; fourthly, introducing the straightened out multicolor waterproof polyurethane slit films into the upper surface of the zipper basement layer, and compounding by virtue of a thermal compounding machine, so that the anti-seepage multicolor zipper is obtained; and fifthly, rolling. The processing technology provided by the invention has the advantages that production efficiency of the anti-seepage colored zipper is greatly improved, and multiple color splicing choices can be provided, so that the same color interval and thickness are guaranteed and parallel straight lines are presented, and overlap deviation of the same color in different printing lengths is also eliminated.

Owner:SHANGHAI TONGMAO NEW MATERIAL TECH CO LTD

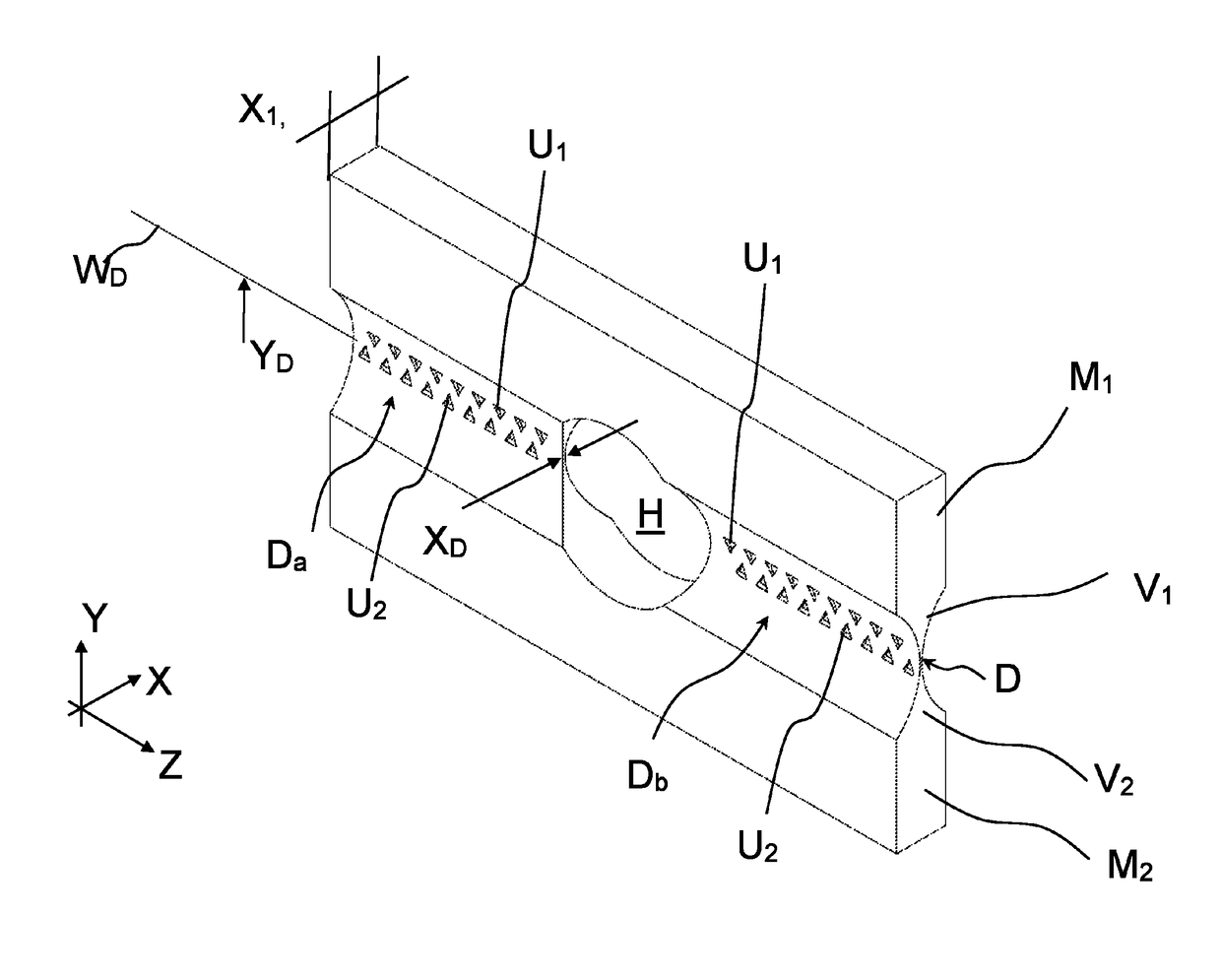

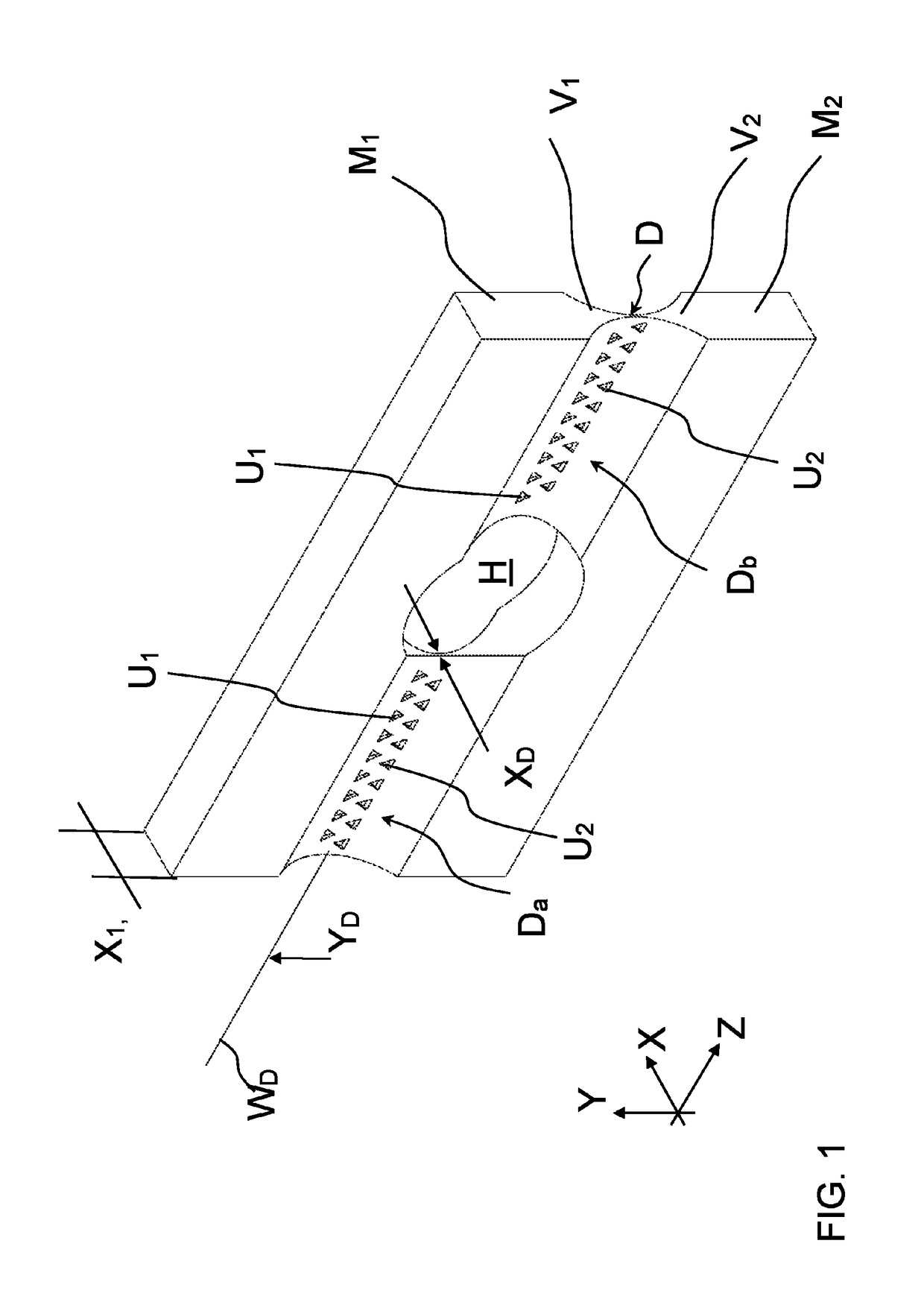

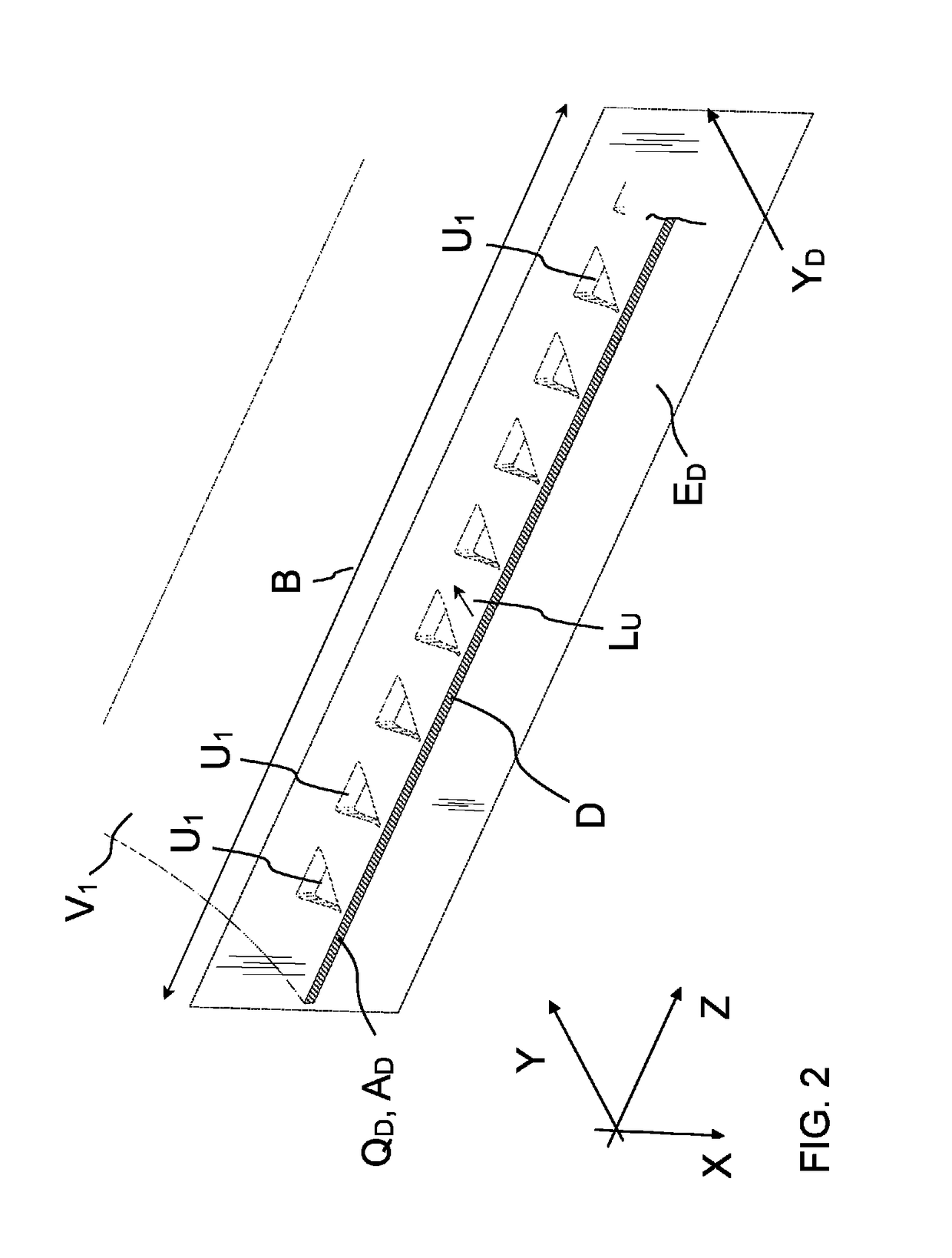

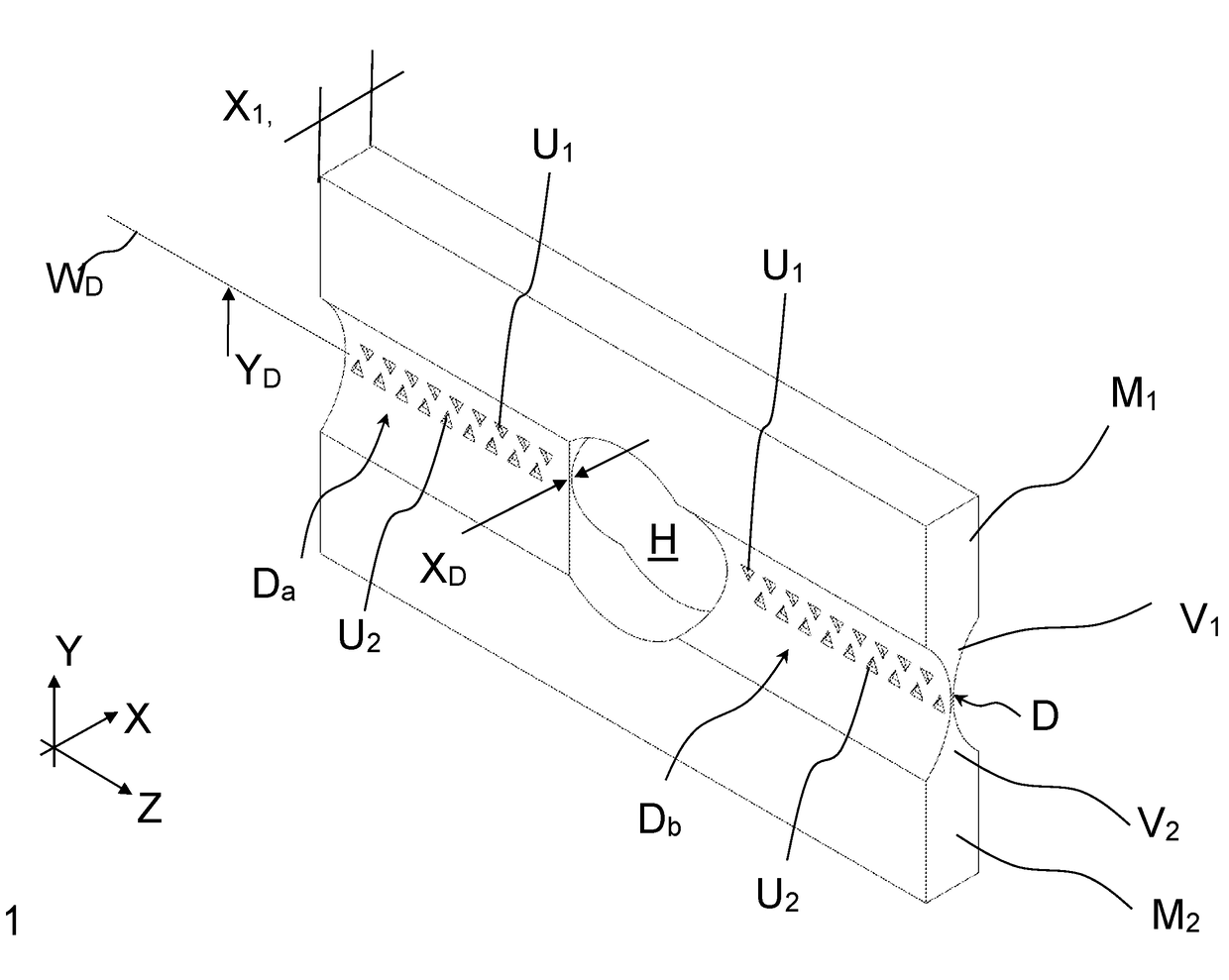

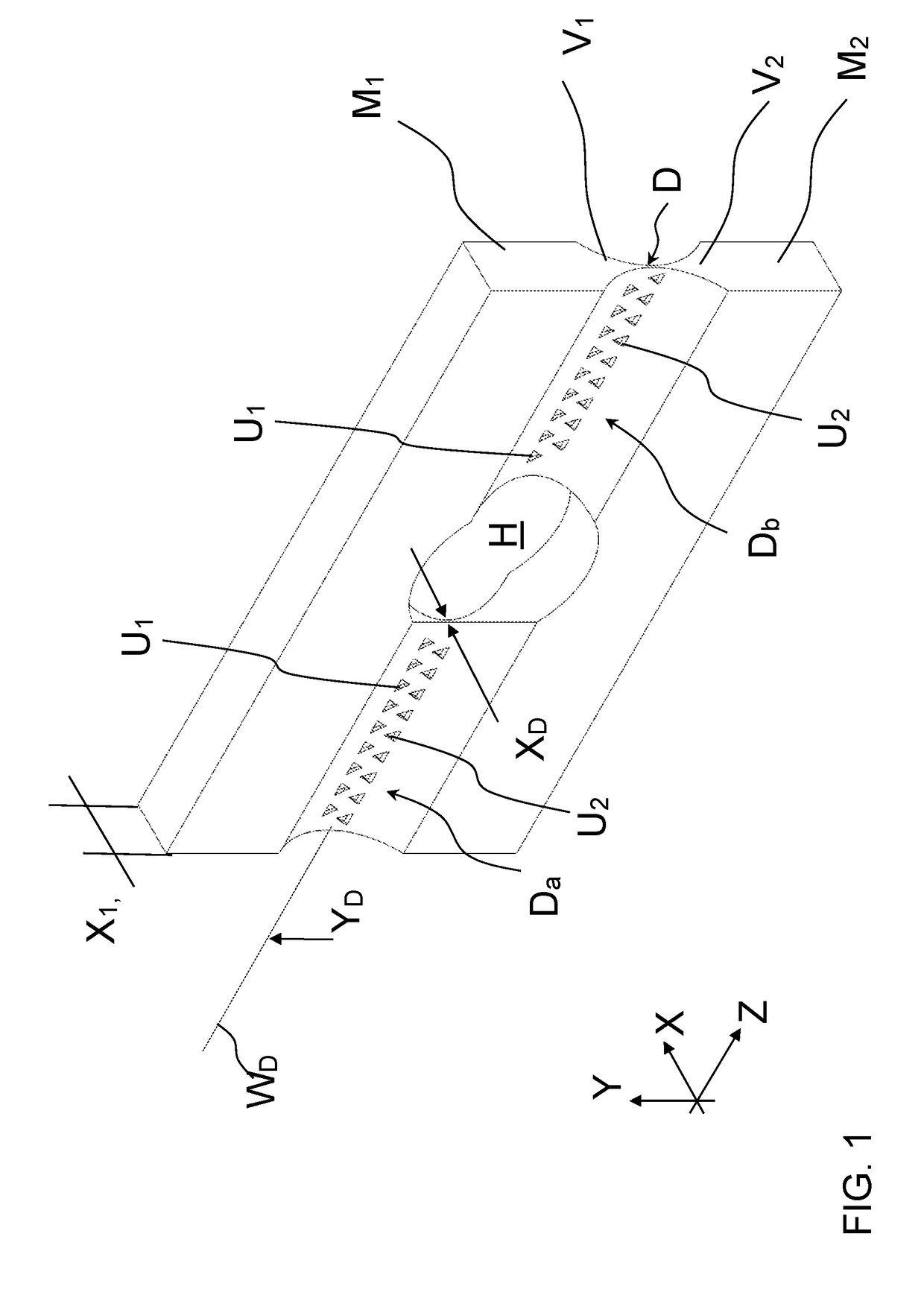

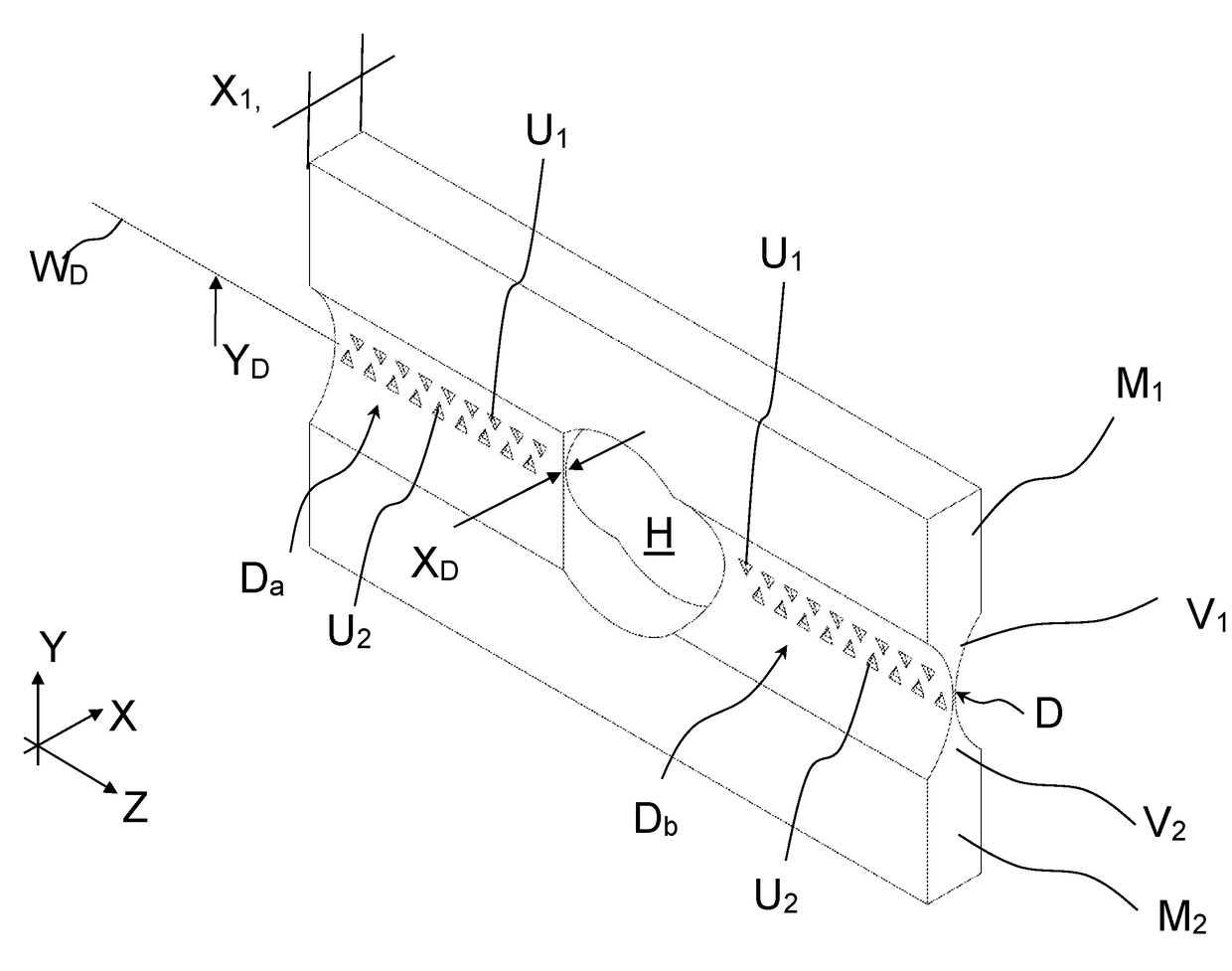

Flexure hinge

ActiveUS9964142B2Improve responsivenessLow bending stiffnessWeighing apparatus detailsPivotal connectionsFlexure hingesEngineering

Owner:WIPOTEC GMBH

Window assembly manufacturing method and window pane

An adhesive agent is uniformly applied to a back surface of a window pane, the application made to an area where a covering member is planned to be adhered and to an area where a positioning fixture and a holding portion are planned to be adhered, the application is also made continuously such that adhesive agent layers of both planned adhesion areas being continuous with an adhesive agent continuous area in between. After that, the window pane and the positioning fixture are set in an injection mold and a polymer material is injected in the mold. This results that the covering member and the holding portion are formed into a shape where they are connected by a connection portion for material flow, which connection portion is formed at a position other than the adhesive agent continuous area. The forming results that the covering member and the holding portion are adhered and fixed to the back surface of the window pane with the adhesive agent layers in between. After the forming process above, the connection portion for material flow is removed.

Owner:TOKAI KOGYO CO LTD

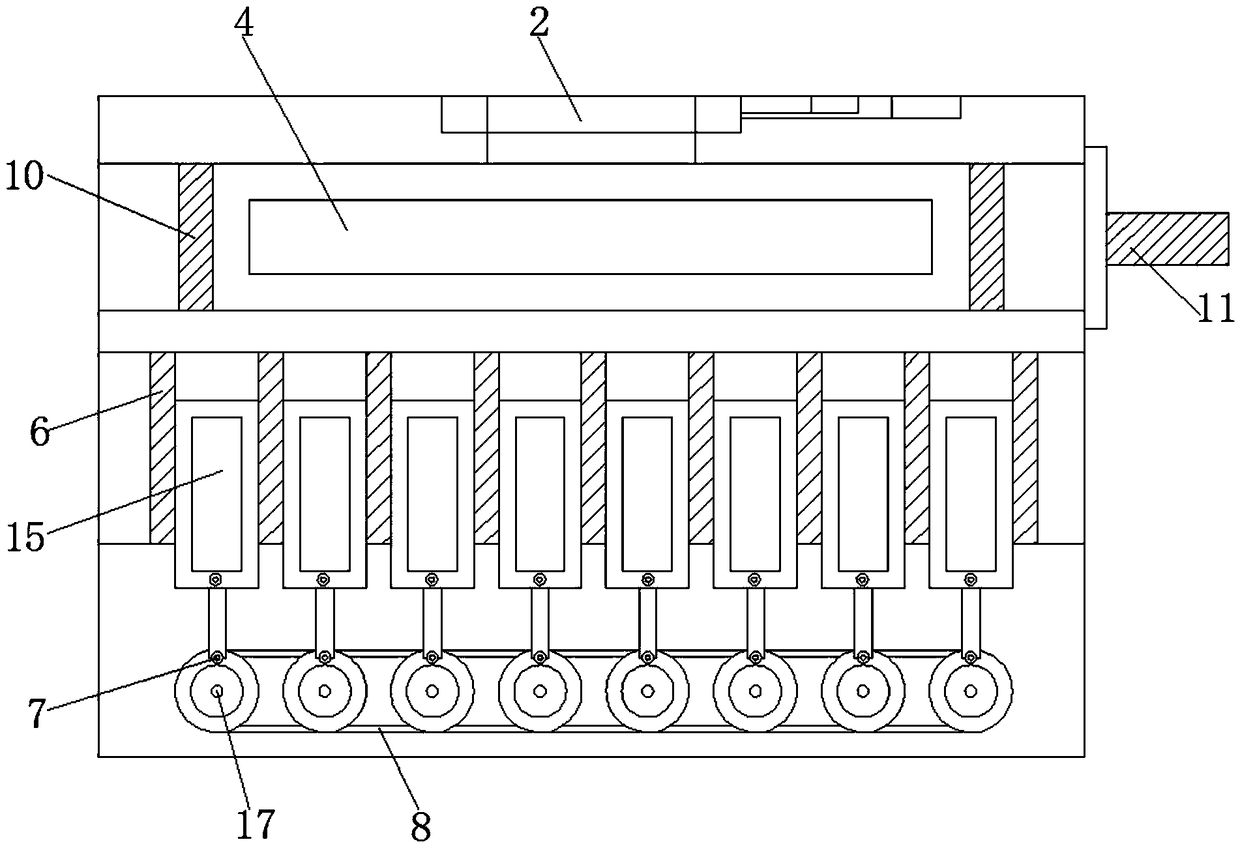

Automatic slicing device for mushroom machining

InactiveCN109434896AImprove delivery efficiencyIncrease salesMetal working apparatusSurface mountingElectric machinery

The invention discloses an automatic slicing device for mushroom machining. The automatic slicing device comprises a device box, a pushing block and a slicing box; an automatic device is fixedly arranged at the inner top end of the device box, a connecting block is connected to the bottom end of the automatic device, a sliding groove is formed in the surface of the bottom end of the automatic device, a slicing cutter is fixed at the bottom end of the connecting block, a storage baffle is arranged at the bottom end of the slicing cutter, and the pushing block is connected to the inner side of the storage baffle; and the front side of the pushing block is provided with a hinge rod, the bottom end of the hinge rod is provided with a belt, and the bottom end of the belt is connected with an output end of a first motor. The slicing device is provided with the automatic device and the slicing baffle, a large number of mushrooms can be cut at the same time, and thus the automatic slicing canbe achieved; and through the pushing block, the mushrooms can be automatically conveyed, in addition, reserved holes can carry out the slicing adjustment on the mushrooms with different kinds and different sizes, so that the thickness of mushroom slices is the same by means of the consolidated slicing, and the selling of mushroom dry goods is improved.

Owner:郑州智锦电子科技有限公司

Flexure hinge

ActiveUS10012262B2Improve responsivenessLow bending stiffnessWeighing apparatus detailsPivotal connectionsFlexure hingesUltimate tensile strength

Owner:WIPOTEC GMBH

Flexure Hinge

ActiveUS20170350443A1Simple calculationSolve the complicated productionWeighing apparatus detailsPivotal connectionsEngineeringFlexure hinges

Owner:WIPOTEC GMBH

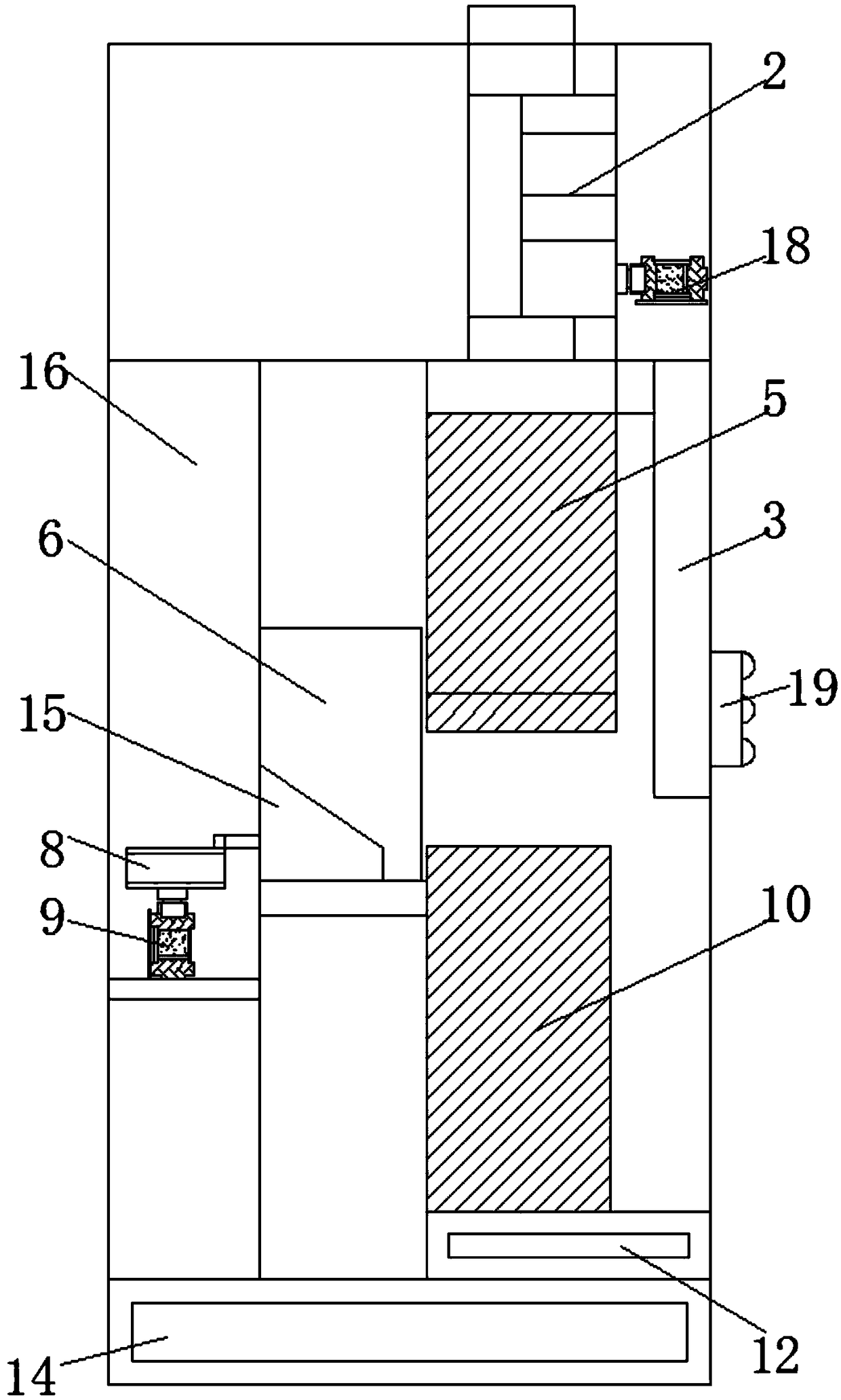

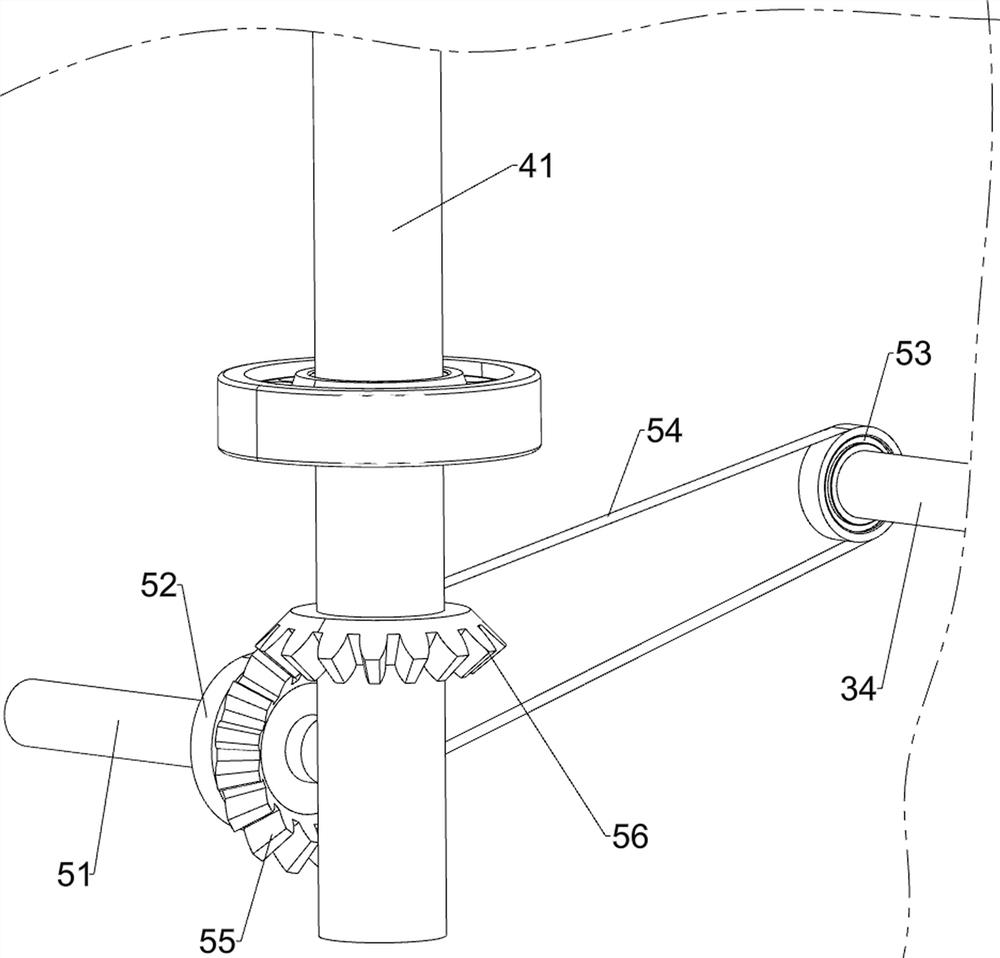

Rice steamer planing device

ActiveCN112157729APlaned evenlySame thicknessFlat surfacing machinesBark-zones/chip/dust/waste removalAgricultural scienceAgricultural engineering

The invention relates to planing equipment, and particularly relates to a rice steamer planing device. The rice steamer planing device can automatically plane a rice steamer without wasting labor or hurting hands. The rice steamer planing device comprises a support, a planing assembly, a pushing assembly and a placing assembly, wherein the planing assembly is installed on the support, the pushingassembly is installed on the support, and the placing assembly is installed on the support. The rice steamer planing device is provided with a rotating assembly, so that the rice steamer can be planedmore uniformly, the thickness degree is the same, and the quality of the rice steamer is better; the rice steamer planing device is provided with a collecting frame, so that falling wood chips can becompletely collected, the trouble of later cleaning is reduced, and a user is more free from worry; and the rice steamer planing device is simple and convenient to operate, the hands do not need to be in contact with an edge tool, and people are not prone to being injured.

Owner:临沂临港国有资产运营集团有限公司

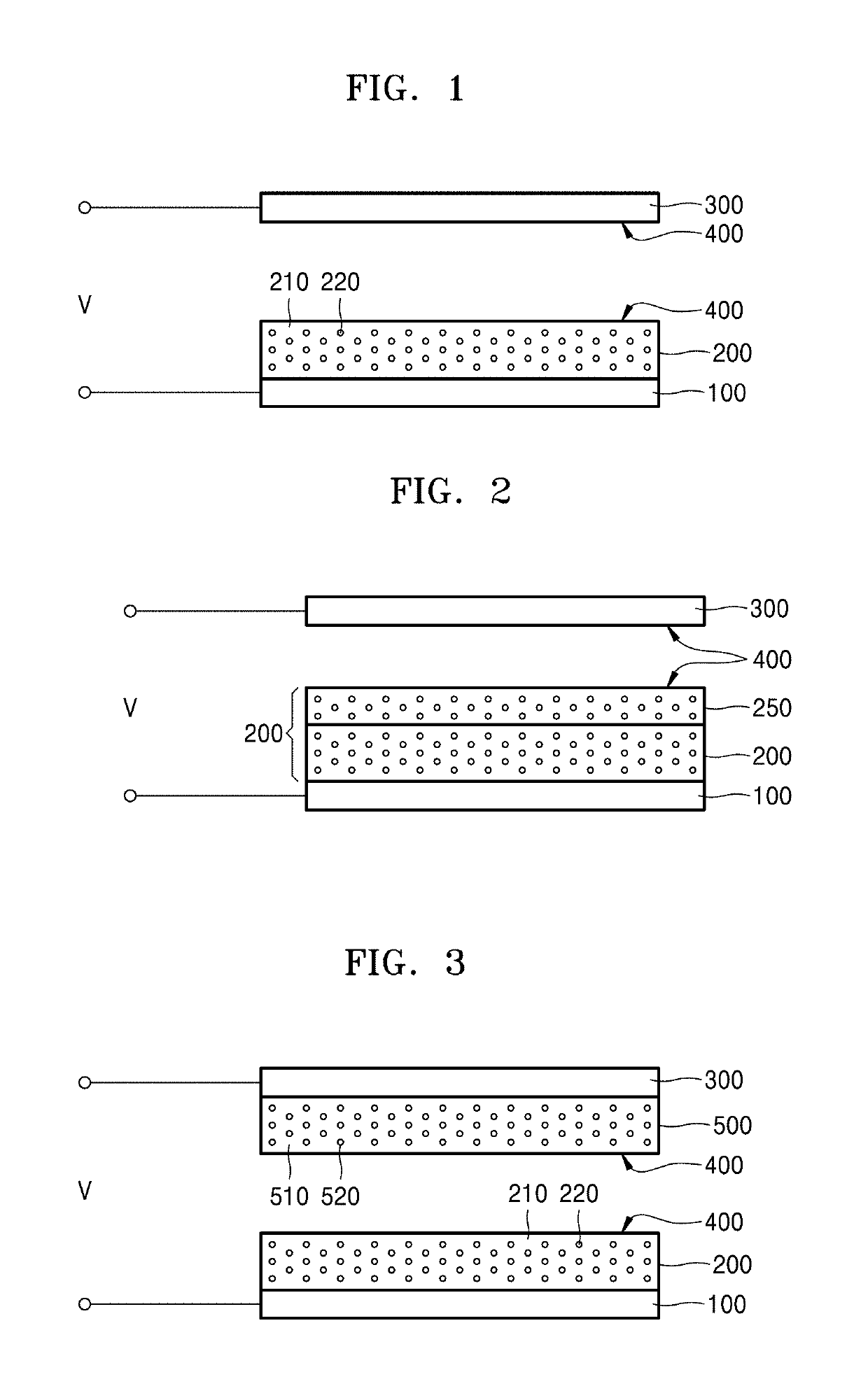

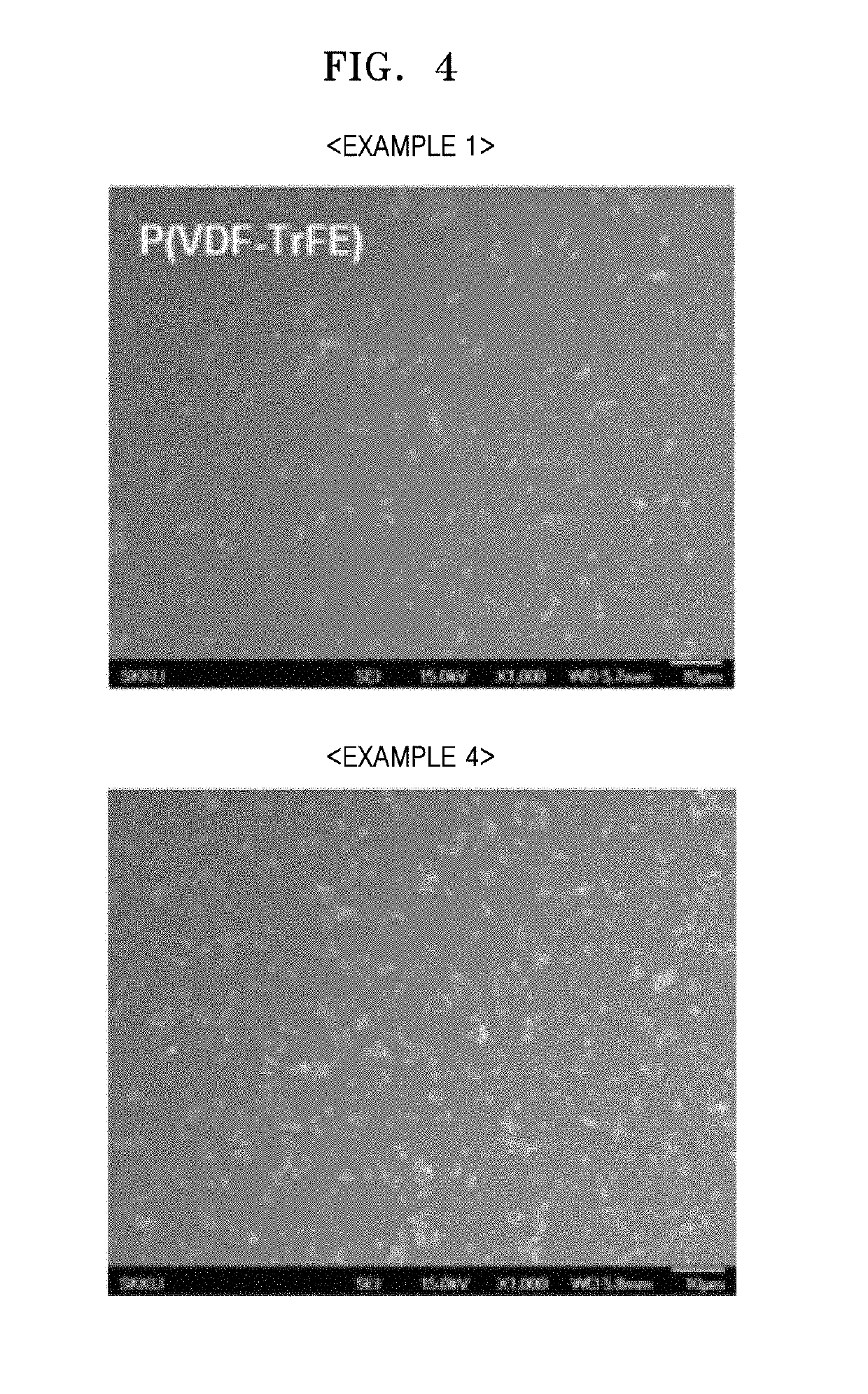

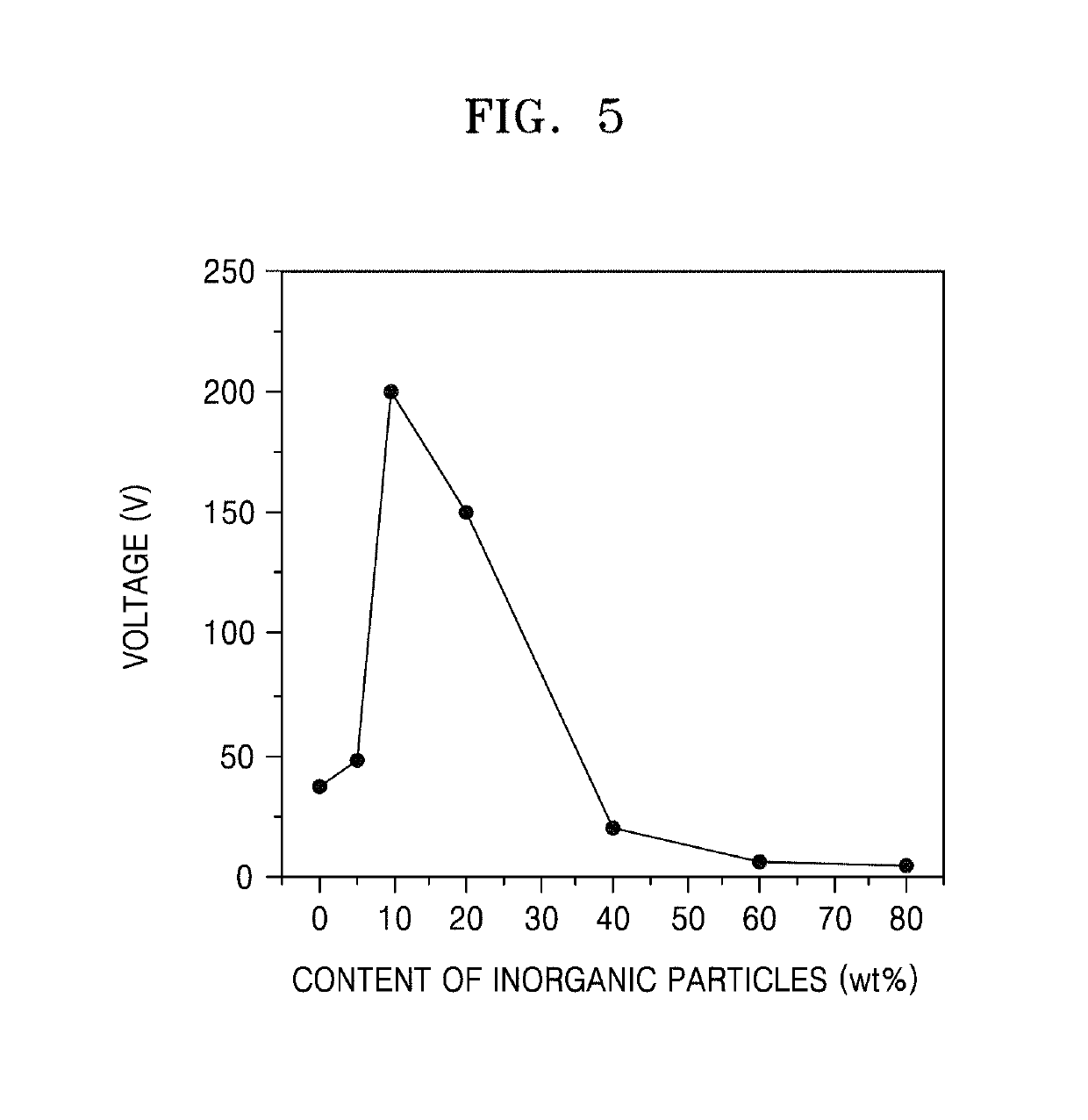

Triboelectric generation device

InactiveUS10468996B2High outputIncrease productionNon-conductive material with dispersed conductive materialInfluence generatorsFerroelectric polymersInorganic particle

The present disclosure enables materials of a triboelectric charging member to exhibit a characteristic of increased surface charge density, thereby improving output of a triboelectric generating device. Accordingly, the present disclosure provides a triboelectric generating device showing improved output without increasing a size of the triboelectric generating device or without increasing amounts of materials required for the triboelectric generating device. An embodiment of a triboelectric generating device provided according to a first aspect of the present disclosure includes a first electrode; a first charging layer formed on the first electrode; and a second electrode disposed on the first charging layer, wherein the first charging layer and the second electrode are arranged such that an interface between the first charging layer and the second electrode forms a frictional interface, and the first charging layer includes a ferroelectric polymer matrix and ferroelectric inorganic particles dispersed in the ferroelectric polymer matrix.

Owner:SAMSUNG ELECTRONICS CO LTD +1

Flexure hinge

ActiveUS20170350442A1Simple calculationSolve the complicated productionWeighing apparatus detailsPivotal connectionsEngineeringFlexure hinges

Owner:WIPOTEC GMBH

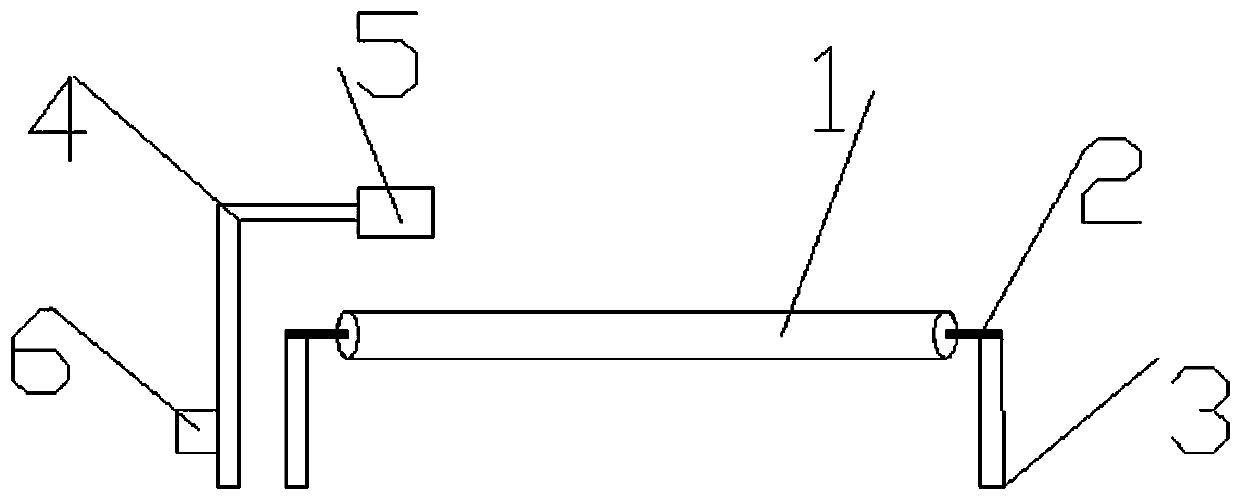

Intelligent precise release film rolling system

The invention relates to an intelligent precise release film rolling system. The system comprises a recycling roller, a roller shaft, a supporting frame, a thickness sensor, a controller and a fixingframe; the roller shaft is fixedly mounted in the center of the recycling roller; the roller shaft is connected with the supporting frame; the thickness sensor is arranged at the upper end of the fixing frame; and the controller is arranged at the bottom end of the fixing frame. The intelligent precise release film rolling system has the advantages of simple structure and intelligent operation. The thickness of roll films can be accurately measured through the ultrasonic sensor, it is guaranteed that the thicknesses of the roll films can be constant, enterprises can sell the roll films with uniform standards to the outside, and the product benefits of the enterprises are increased.

Owner:江苏诺迪新材料科技有限公司

Method for slicing wild kudzuvine roots

InactiveCN109463487APromote brain developmentImprove appearancePre-extraction tea treatmentFlavorPUERARIA LOBATA ROOT

The invention aims to provide a method for slicing wild kudzuvine roots. The method is simple in operation and pickles wild kudzuvine root slices to obtain wild kudzuvine root slices unique in taste,and substantially uniform in thickness and size; and the method includes the following steps: first cleaning the kudzuvine roots; washing and air-drying the kudzuvine roots to ensure sufficient watercontent inside the kudzuvine roots; differently slicing different kudzuvine roots; and finally pickling the slices. In the method, the washed and air-dried kudzuvine roots are classified and sliced according to diameters, and the size and thickness of the kudzuvine root slices after slicing are basically the same, thereby avoiding poor taste due to excessive loss of water or raw and astringency due to less loss of water in the post-treatment of the kudzuvine root slices, and avoiding destroy of the taste and flavor of the kudzuvine root slices. The sliced kudzuvine roots are sealed with special seasoning; the inner flavor of the kudzuvine root slices matches the seasoning to enhance the single original taste of the kudzuvine root slices; and sialic acid capable of promoting brain development and effectively helping the body to resist virus is added to greatly enhance the appearance of the kudzuvine root slices.

Owner:安徽金龙山葛业有限公司

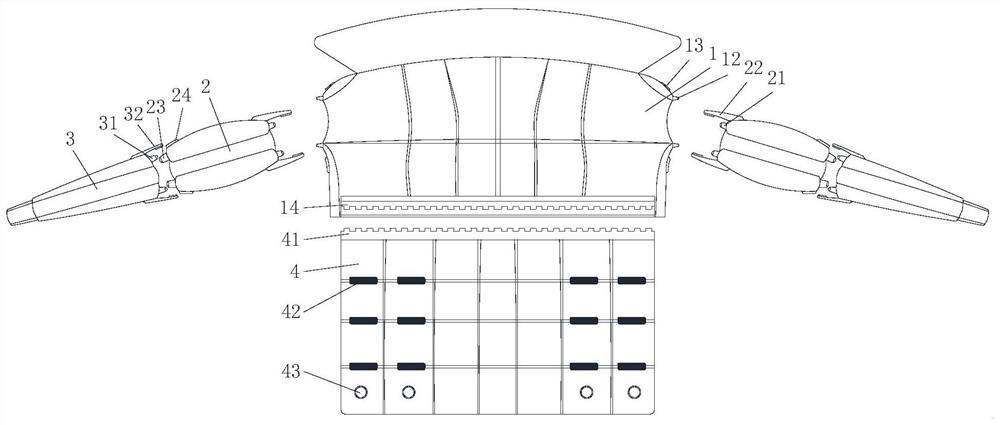

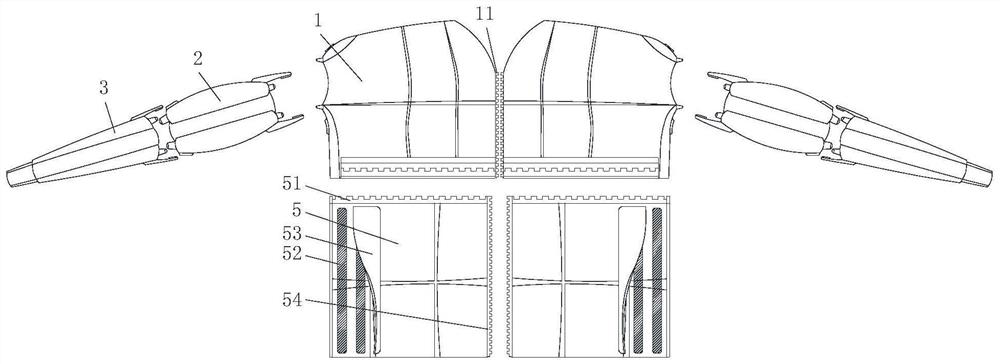

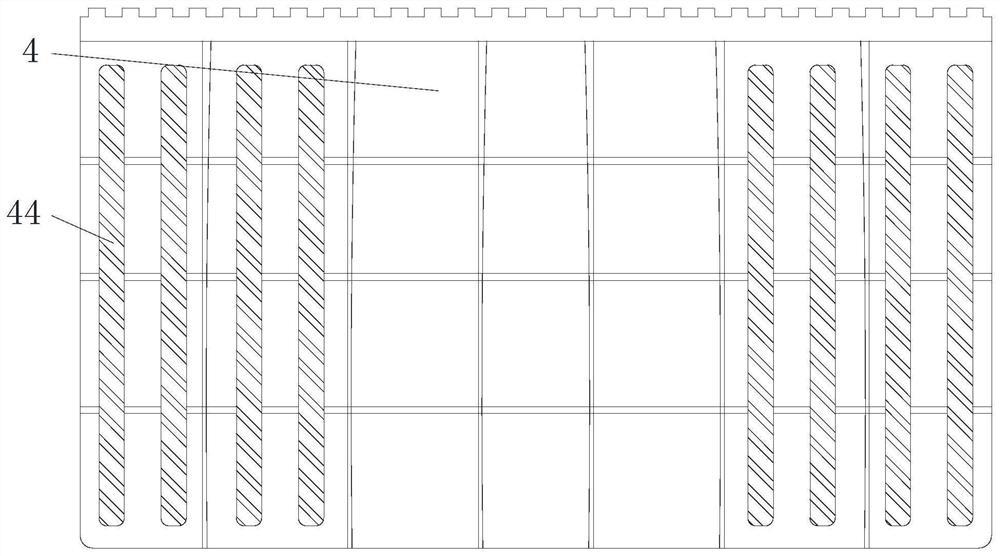

Down jacket with adjustable model

PendingCN113907460ASame thicknessPrevent misfitsGarment special featuresConvertible garmentStructural engineeringLower body part

The invention relates to the technical field of down jackets, and discloses a down jacket with an adjustable model, which comprises an upper half body part, symmetrically arranged large arm parts, symmetrically arranged small arm parts, a back part and symmetrically arranged lower half body parts. The large arm parts and the upper half body part are connected through annularly arranged zippers, the tail ends of the small arm parts and the large arm parts are connected through annular zippers, the back part is connected to the bottom of the upper half body part through a zipper, and the back part and the side edges of the lower half body parts are bonded to form a cylindrical structure. By detachably arranging the large arm parts, the small arm parts, the back part and the lower body parts, a user can protect parts needing warm keeping according to different external temperature environments, and by arranging a down filling block, a magnetic strip sealing opening and a down filling opening in the back part, at the connected and overlapped parts of the back part and the lower body parts, the single-layer down feather is formed by taking out the redundant down feather filler, and it is guaranteed that the overall thickness of the down jacket is the same on the premise that warm keeping is not affected.

Owner:ANHUI GUIGU E COMMERCE

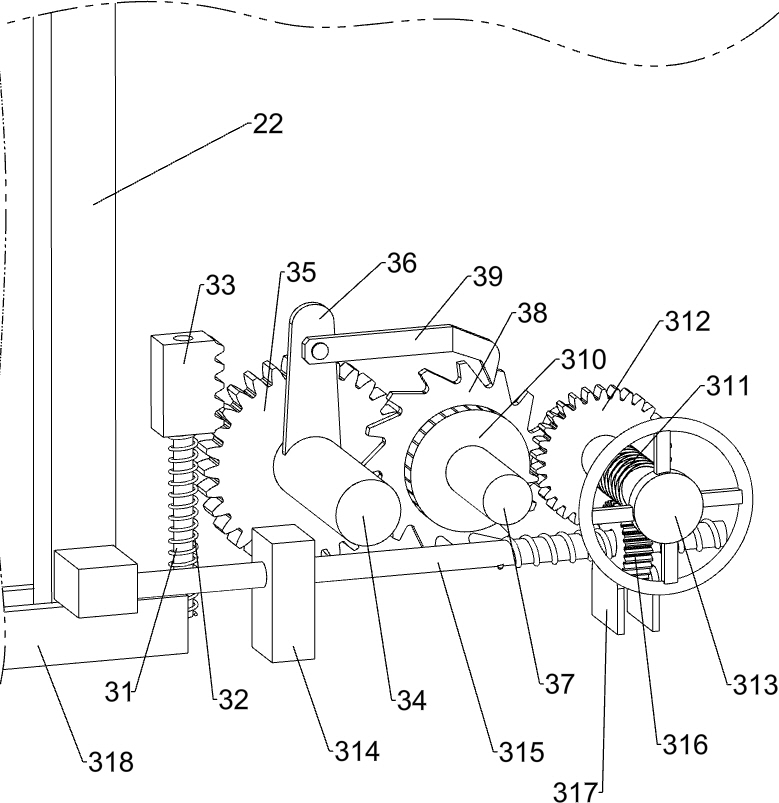

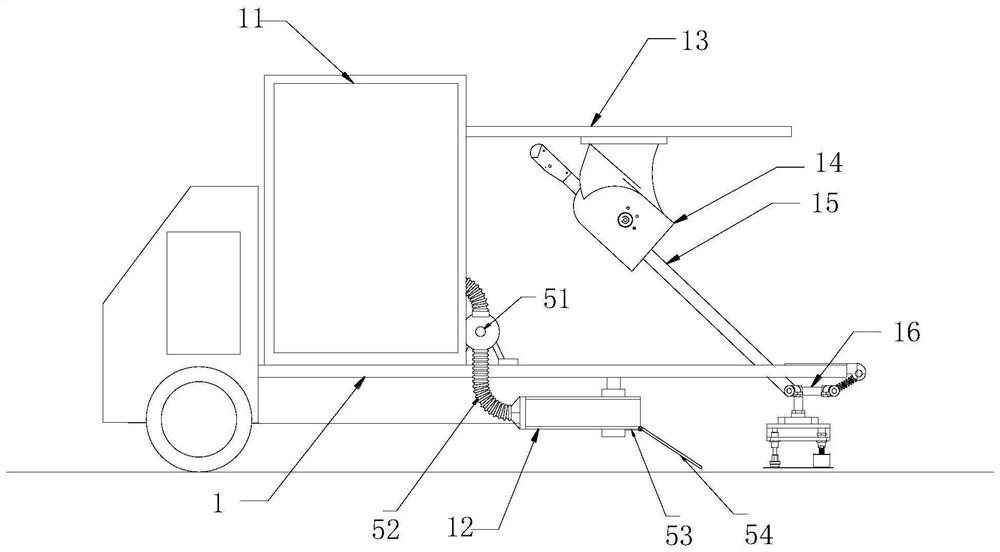

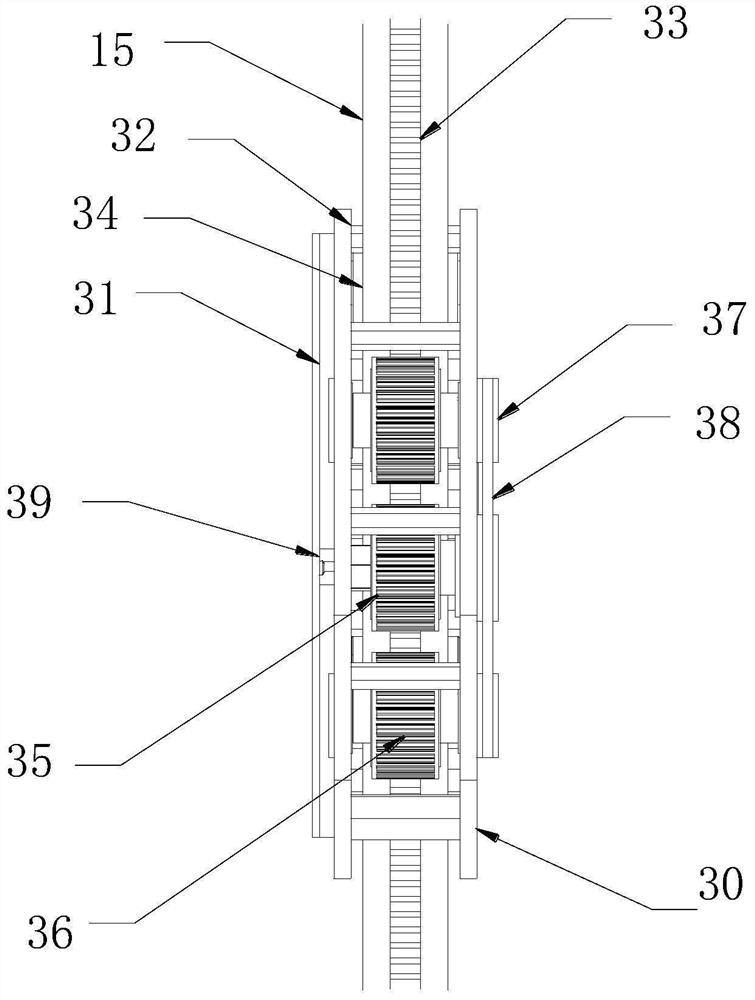

Cement trowelling device for municipal roads

InactiveCN112376363AEfficient moppingGuaranteed trowelingRoads maintainenceVehicle frameArchitectural engineering

The invention relates to the technical field of municipal administration, and especially relates to to a cement trowelling device for municipal roads. The device comprises a frame, a material box is arranged on the frame, a conveying frame is arranged at the bottom of the frame, a rear frame is arranged on the rear side of the material box, a mounting seat is arranged at the bottom of the rear frame, and a pushing plate is movably mounted on the mounting seat. An operation mechanism is arranged at the bottom end of the pushing plate and comprises a supporting base plate, a fixed connecting bolt is installed on one side of the supporting base plate, the fixed connecting bolt and the bottom end of the pushing plate are fixedly installed, a spring connecting bolt is installed on the other side of the supporting base plate, and a positioning base is arranged at the tail end of the frame. The spring connecting bolt is connected with the positioning base through a tension spring, a lower edge straight rod is arranged on the bottom plane of the supporting base plate, and a material smearing device is installed at the bottom end of the lower edge straight rod. Cement can be effectively smeared from front to back, and the uniformity of the cement is further guaranteed.

Owner:刘传

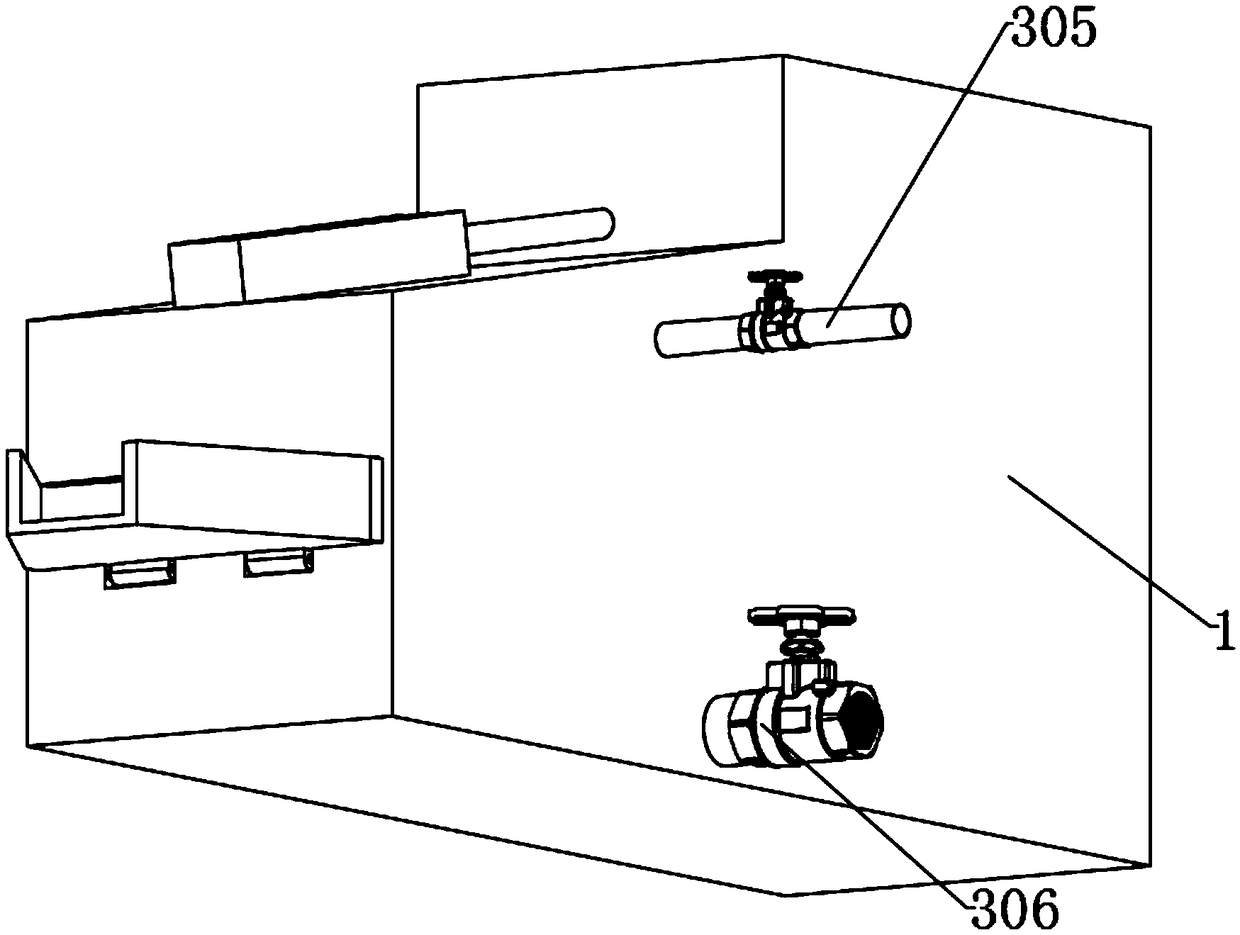

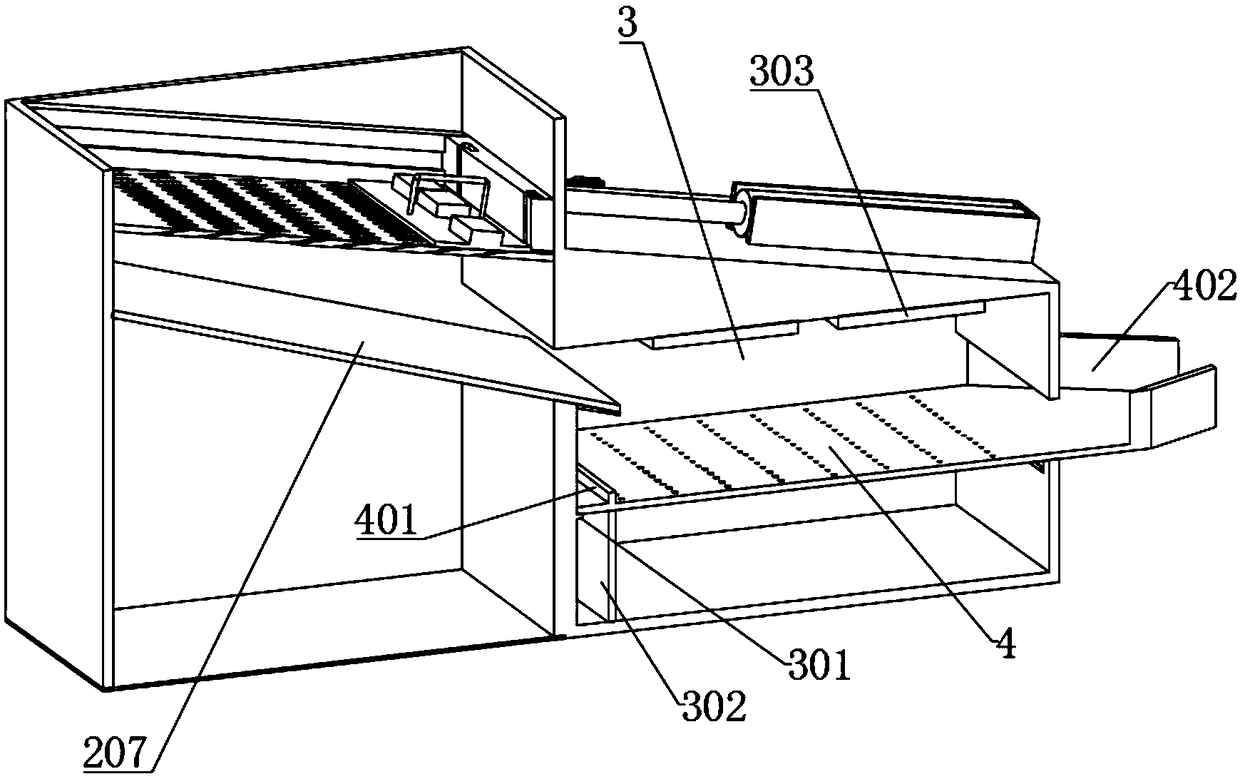

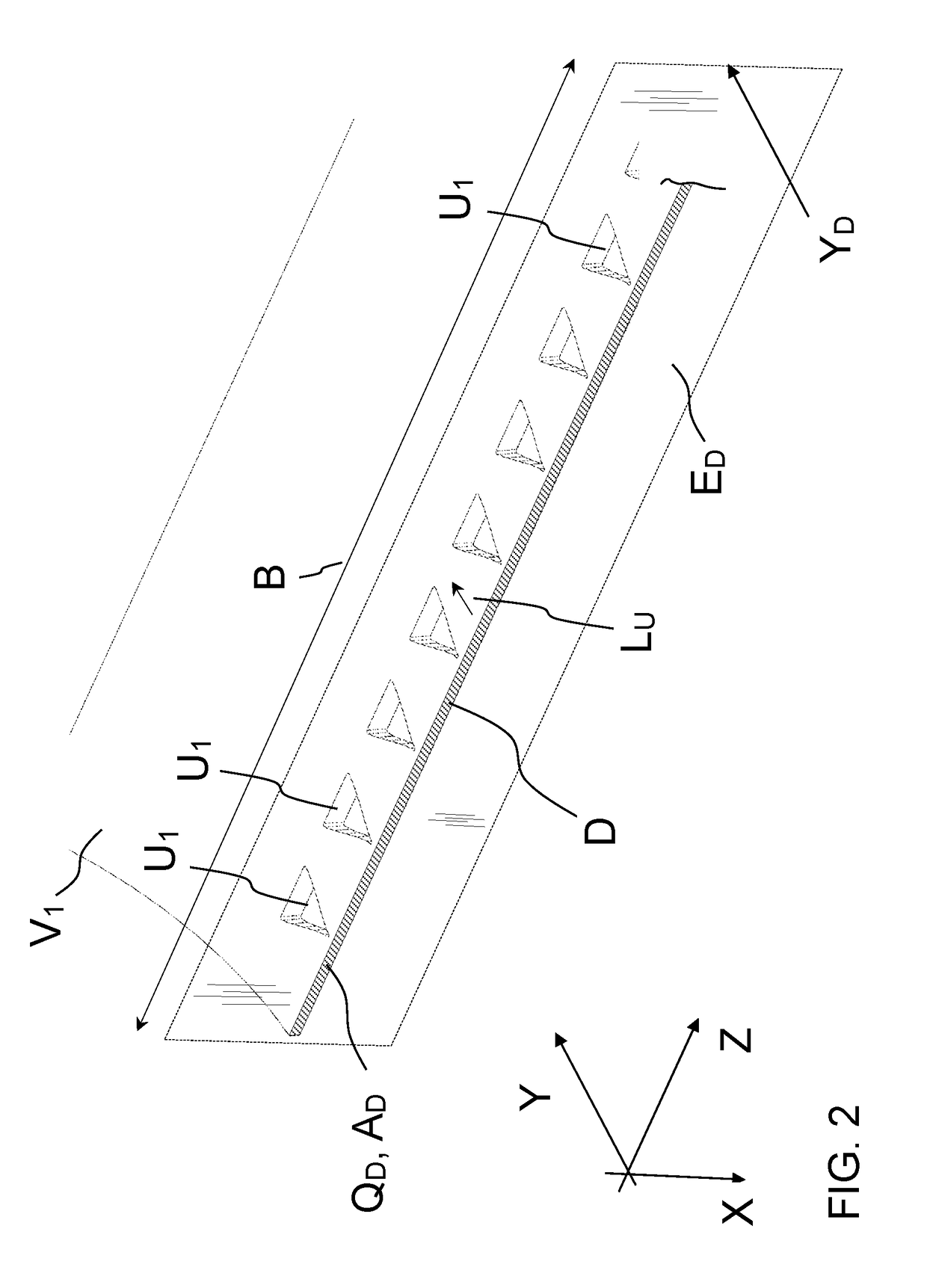

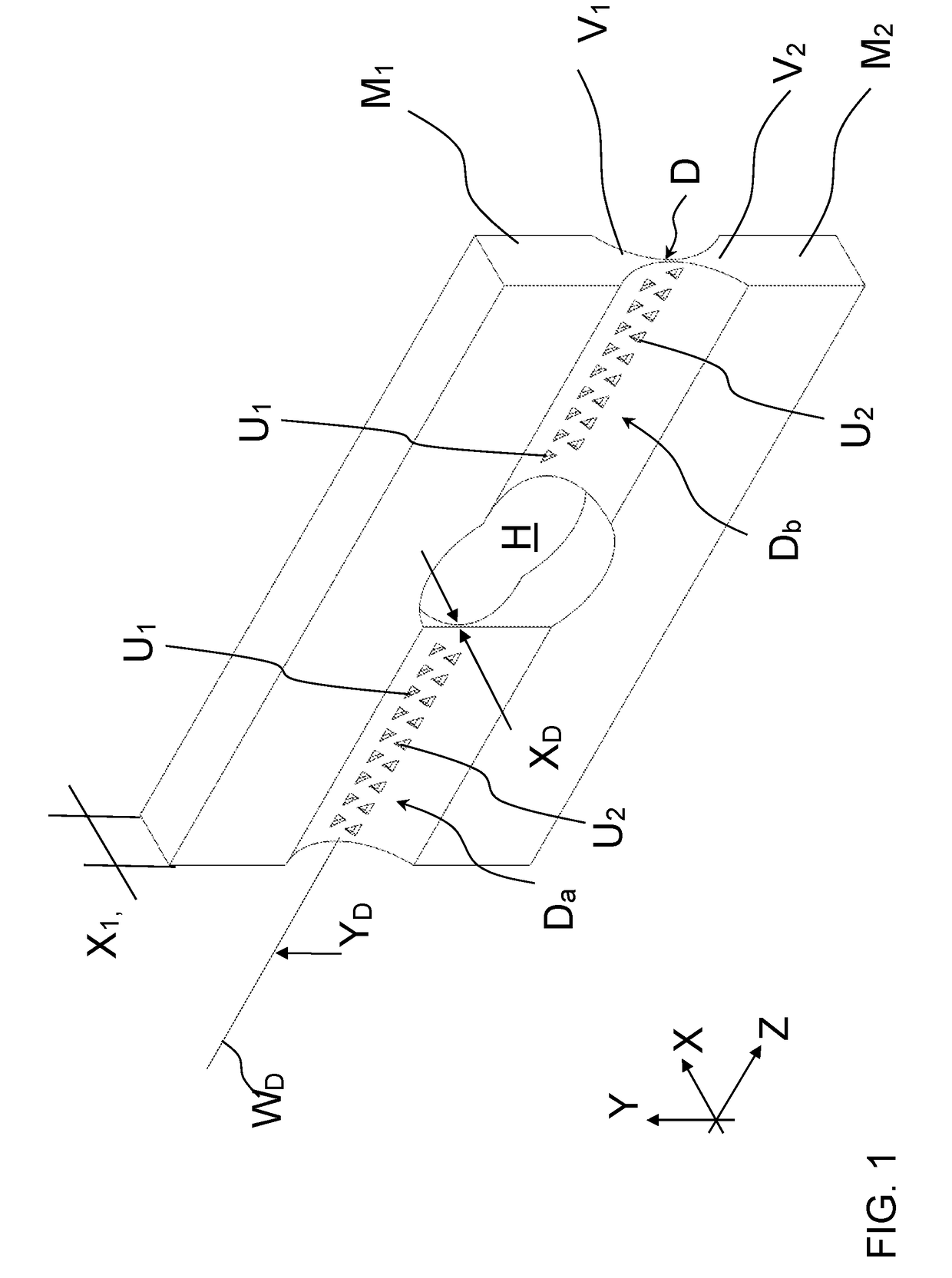

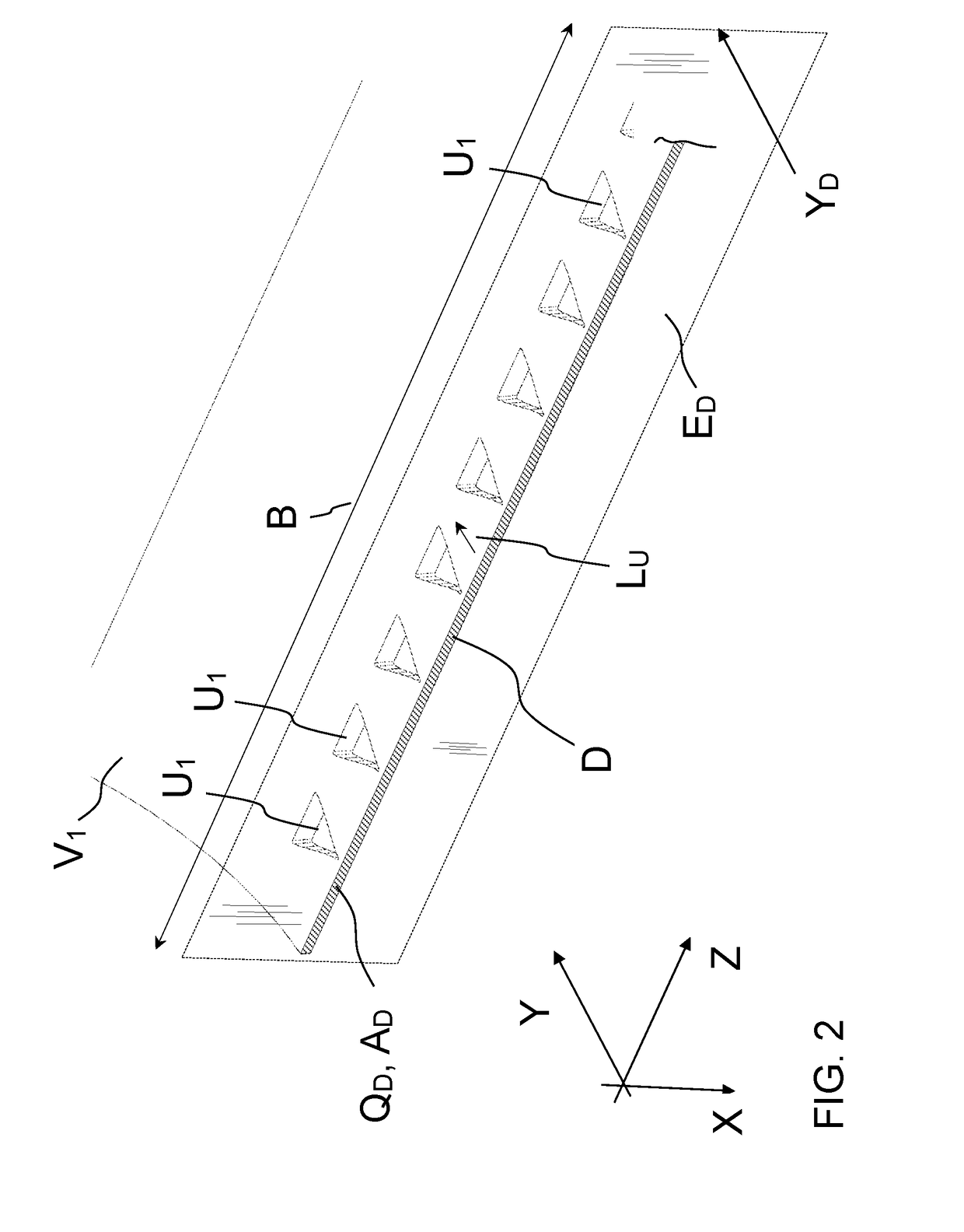

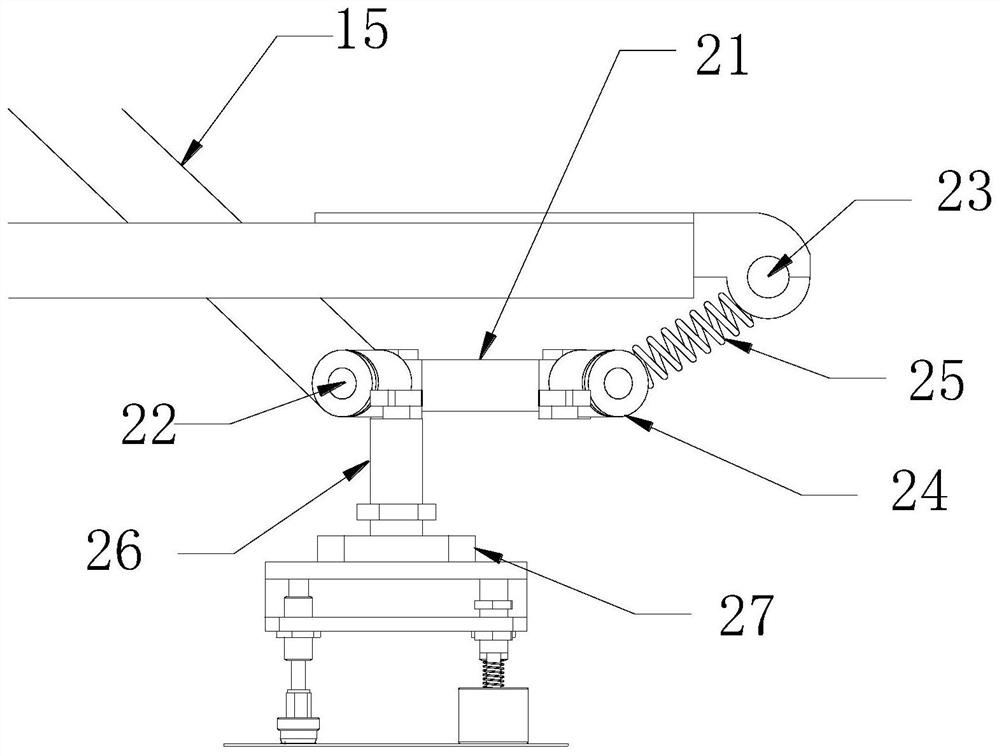

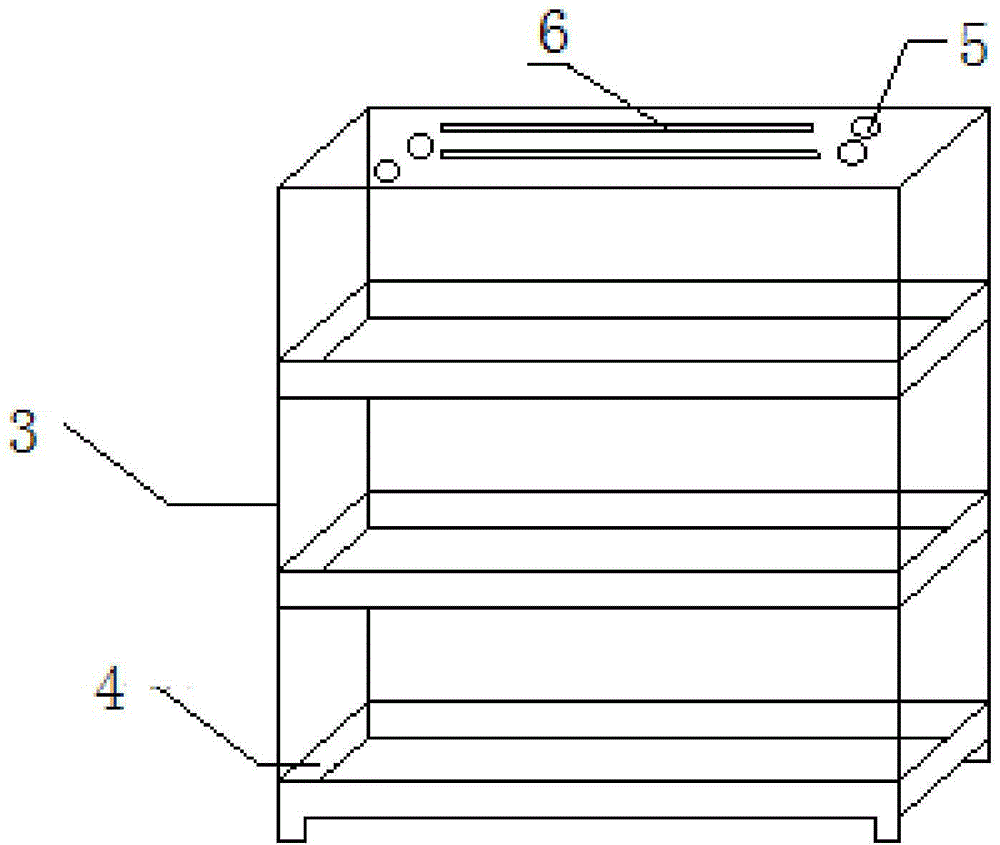

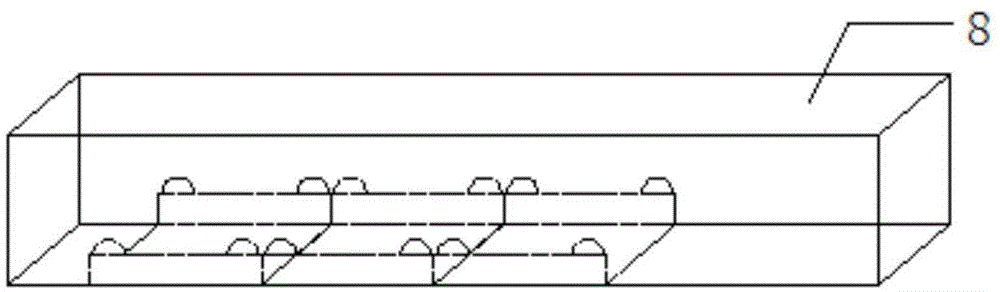

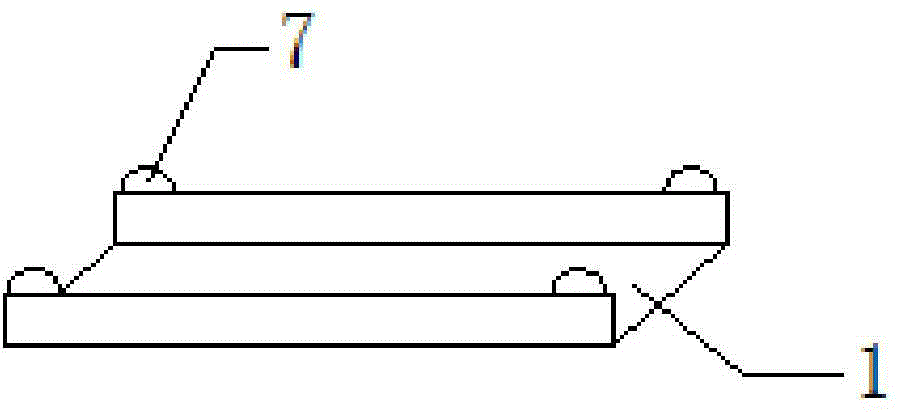

Ecological slope experiment system and using method thereof

The invention relates to an ecological slope experiment system and a using method thereof. The experiment system comprises a culture system and an experiment system body. The culture system comprises a support, culture groove racks and a plurality of culture grooves which are formed in the culture groove racks. The experiment system body comprises an experiment groove. Sliding wheels are arranged at the bottoms of the culture groove racks, the support is provided with sliding rails corresponding to the sliding wheels, and the culture groove racks are arranged on the sliding rails in a sliding mode. According to the system, the culture grooves containing experiment planted grasses are regularly watered and cultivated, grouping can be conducted in the cultivation process according to the growth condition of the planted grasses, and thus it can be guaranteed that the coverage rate of the planted grasses and the rhizome dense degree are the same when experiment soil is selected.

Owner:SHANDONG UNIV

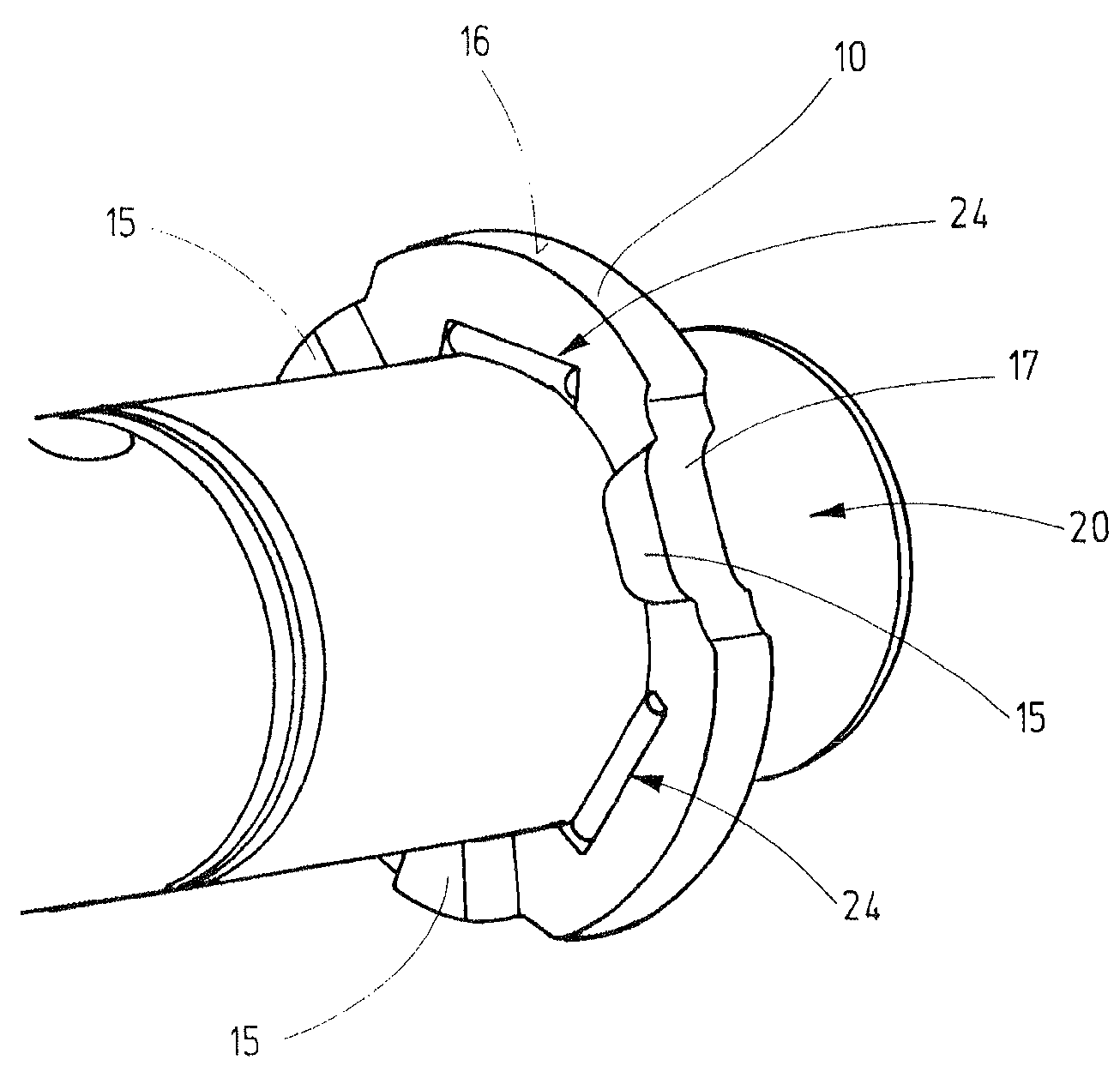

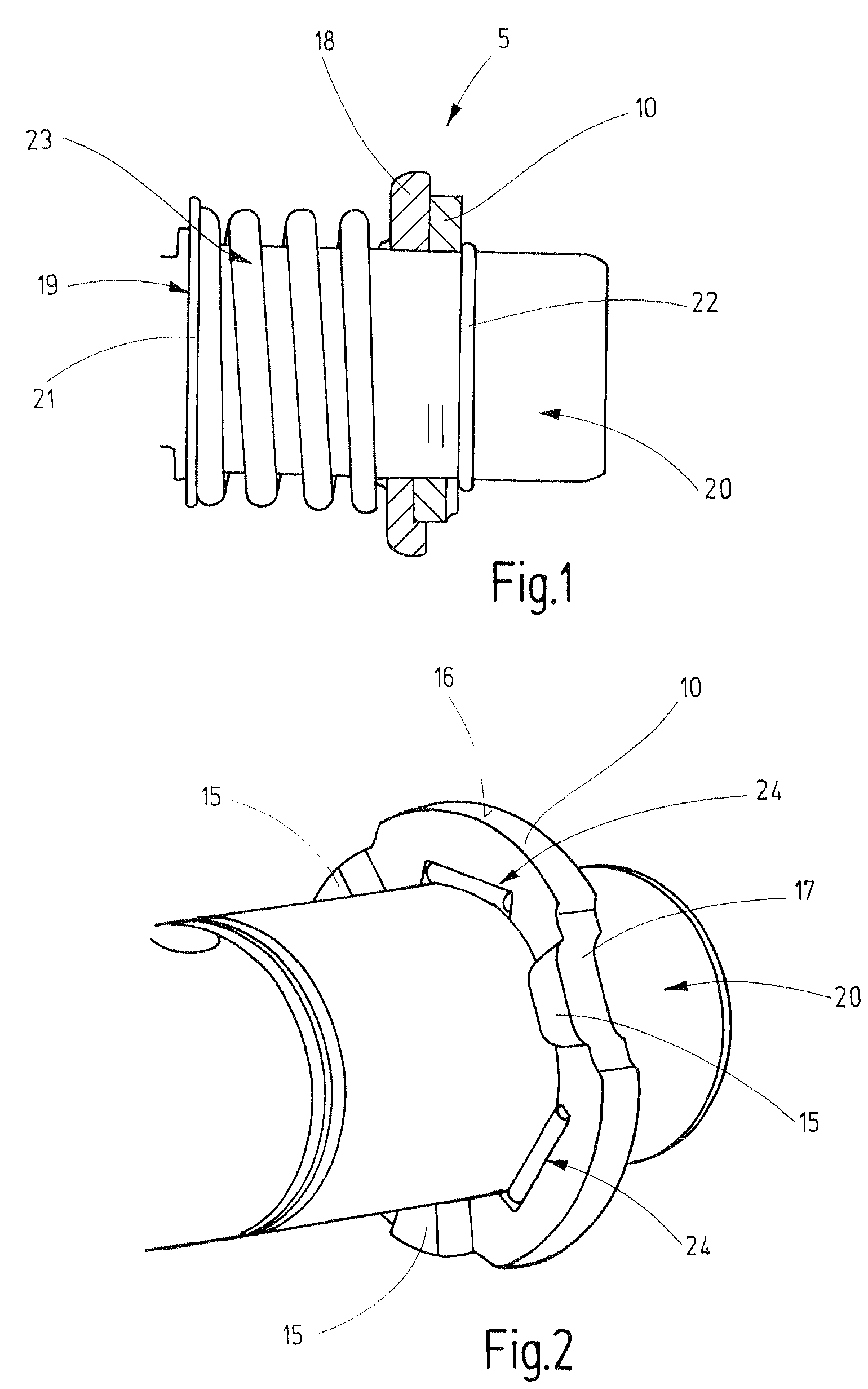

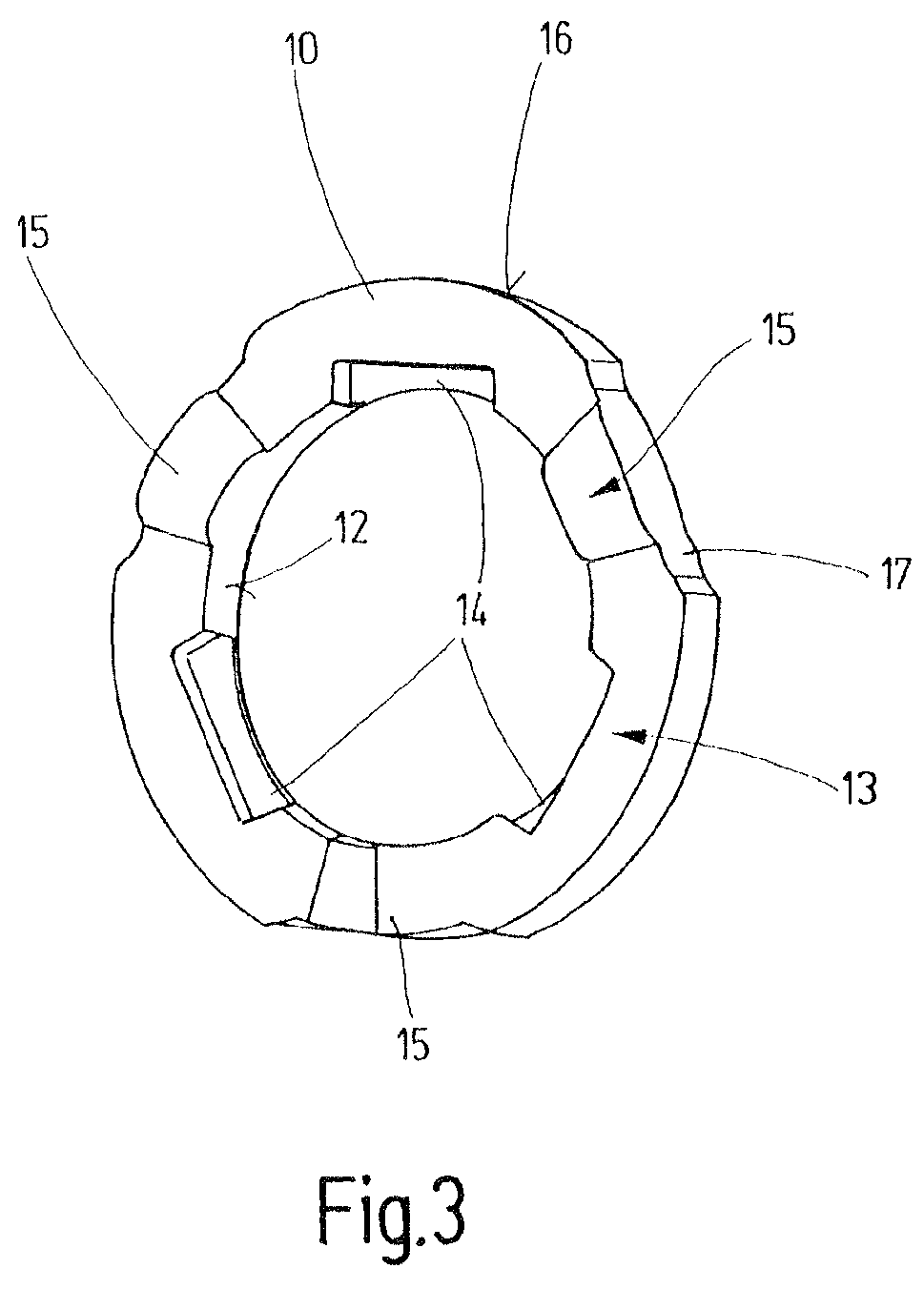

Snap-in disk and overload clutch with a snap-in disk

Owner:ROBERT BOSCH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com