Anti-pilling finishing method of cationic wool napping fabrics

A cationic, anti-pilling technology, applied in the direction of fabric surface trimming, wear-resistant fibers, roughening, etc., can solve the problem of anti-pilling performance staying at a certain level, limited effect of anti-pilling additives, and color fastness of fabrics To achieve the effect of reducing the probability of pilling, optimizing the fabric process and improving the pilling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Fabric name: 6S{22N / 1 shrink-resistant wool+500D(CDP+ATY black)} ply yarn+150D / 144F CDP cationic brushed fabric.

[0035] The specific implementation process is as follows:

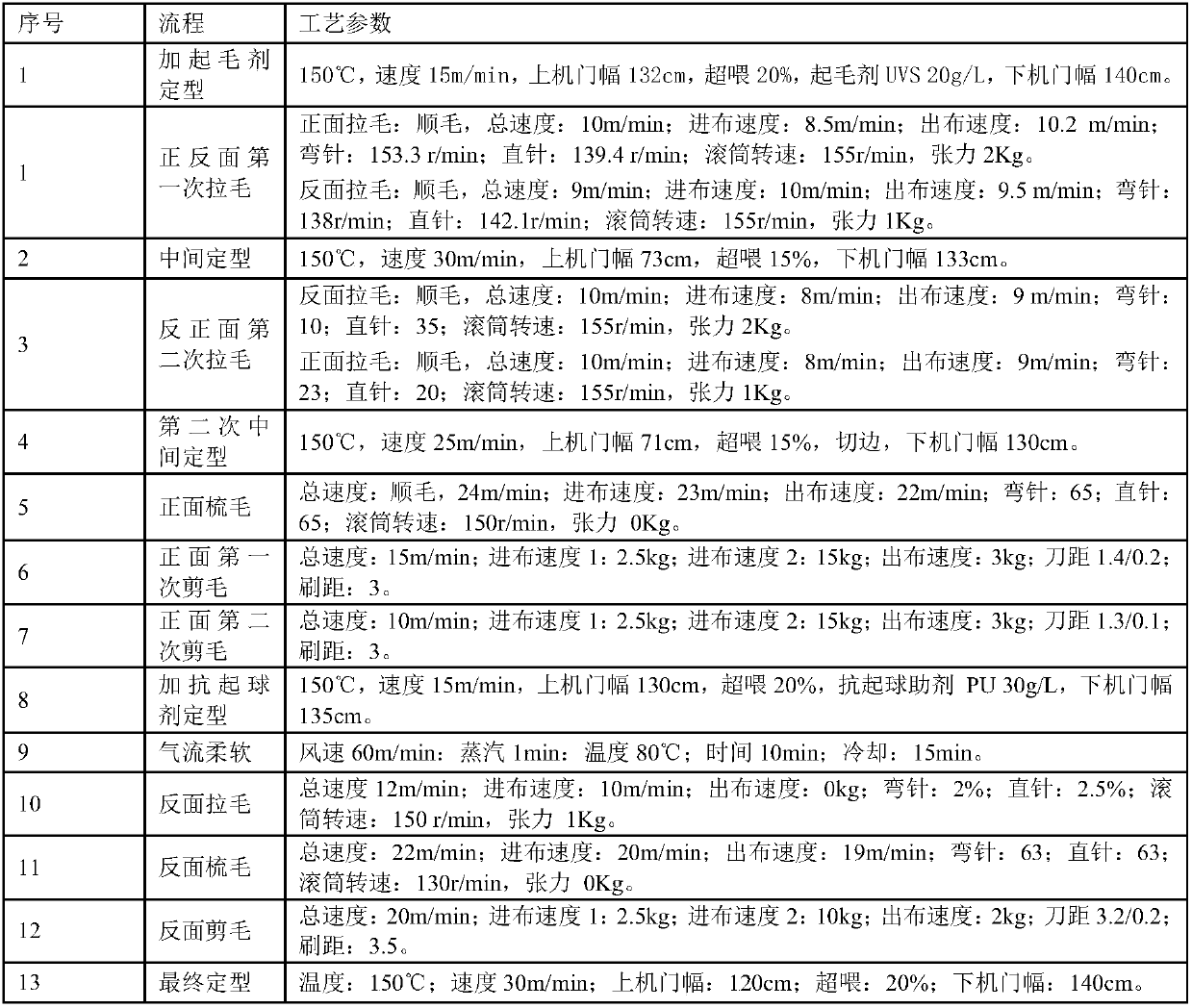

[0036]

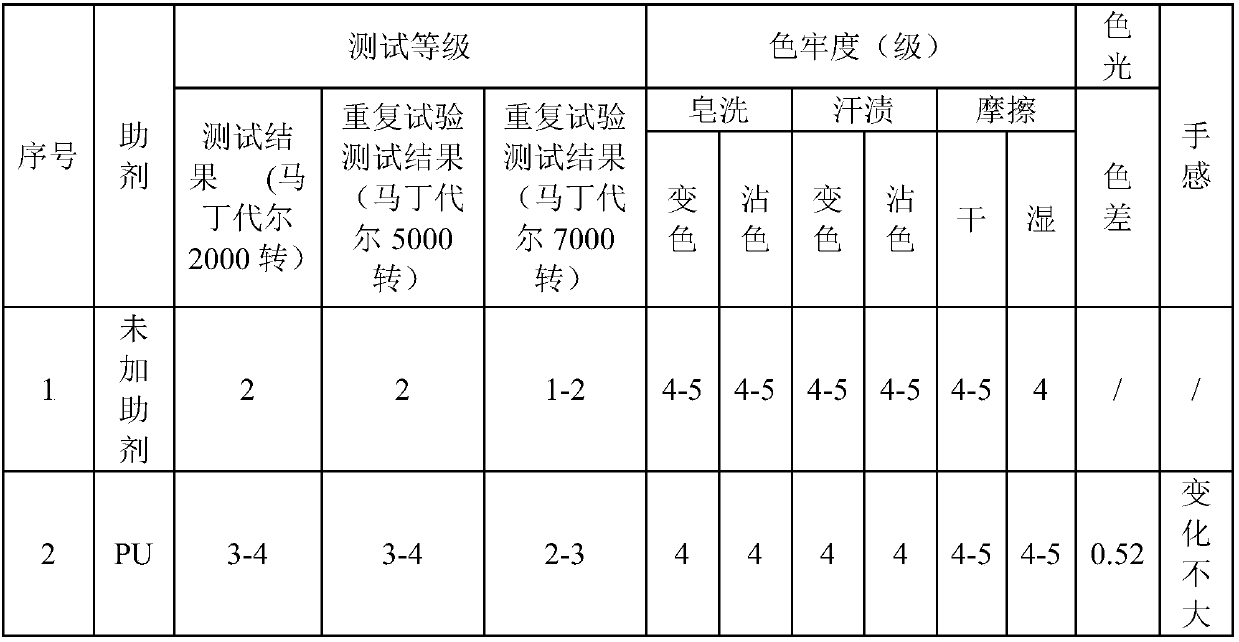

[0037] If the general napping process is adopted, although the napping style is guaranteed, it will bury hidden dangers for the improvement of the anti-pilling performance in the rear channel, so that the improvement of the anti-pilling performance is always at a general level, which cannot meet the needs of the market. According to the idea of the present invention, special modifications have been made to the napping, carding and shearing processes of this fabric, and further improvements have been made in the process flow. On the basis of meeting the requirements of the original style, the anti-pilling performance of the fabric has been improved. . Using this finishing method together with the anti-pilling agent makes the fabric surface cleaner than ordinary finishing, with fewer f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com