Production method of washable yarn-dyed knitted fabric

A technology of knitted fabric and production method, which is applied in the direction of fabric surface trimming, fabric elongation, textile and paper making, etc., can solve problems such as difficulty in grasping, increase the difficulty of enzymatic washing and grasping, etc., to eliminate internal stress, facilitate penetration effect, Beneficial for recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

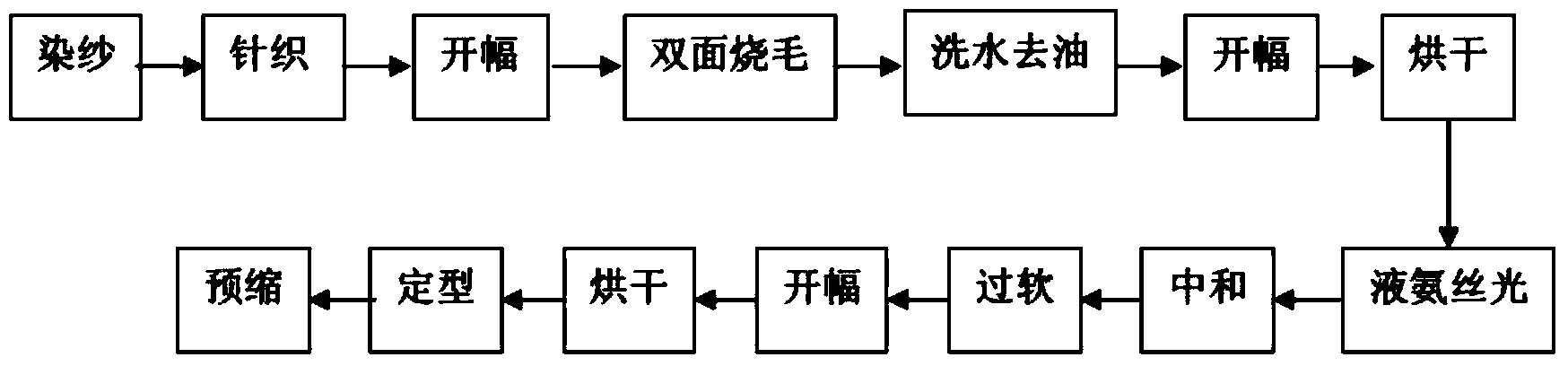

[0041] The present embodiment provides a kind of manufacture method of washable yarn-dyed knitted fabric, to produce the 26S / 1 pearl ground (Pique) fabric of finished product width 65inch, gram weight 200GM, CPI=70, WPI=28, such as figure 1 As shown in the technological process, it comprises the following steps:

[0042] Yarn dyeing: use 50S / 1 gray yarn to dye yarn according to the conventional process requirements, and make white and royal blue two-color dyed yarn;

[0043] Knitting: use the dyed yarn to weave blanks according to 20G30”50C=130MM;

[0044] Open width: Open width machine is used for open width inspection;

[0045] Double-sided singeing: use a singeing machine to singeing on both sides at a speed of 50m / min;

[0046] Washing and degreasing: with a bath ratio of 1:10, use 0.5g / L penetrating agent FKS (Dongguan Xianqiao Auxiliary Industrial Co., Ltd.), 1g / L degreasing agent Jinterge LCF-185 (Taiwan Fuying Technology Chemical Co., Ltd.) Co., Ltd.), 1g / L dispersa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com