Cement trowelling device for municipal roads

A technology of municipal roads and cement, which is applied in the municipal field, can solve the problems of undisclosed operation steps, large labor input, and poor leveling effect, so as to improve the operation effect and ensure the uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

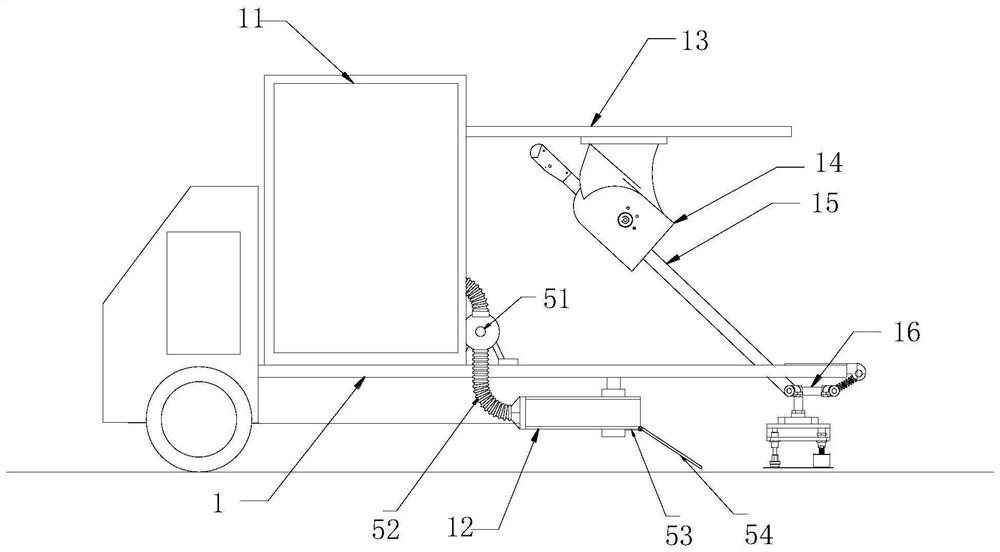

[0028] see figure 1 , a cement troweling device for municipal roads, comprising a vehicle frame 1, a material box 11 is arranged on the vehicle frame 1, a feeding frame 12 is provided at the bottom of the vehicle frame 1, and the rear side of the material box 11 A rear frame 13 is provided, the bottom of the rear frame 13 is provided with a mounting seat 14, a push plate 15 is movably installed on the mounting seat 14, and an operating mechanism 16 is provided at the bottom end of the push plate 15, The material feeding frame 12 is provided with a feeding tube 53, and the discharge end of the feeding tube 53 is provided with a material guide plate 54, and the material guide plate 54 is located directly in front of the operating mechanism 16; the material box 11 A material delivery pump 51 is arranged at the material outlet, and the material delivery pump 51 is connected with a material delivery cylinder 53 through a material delivery pipeline 52 .

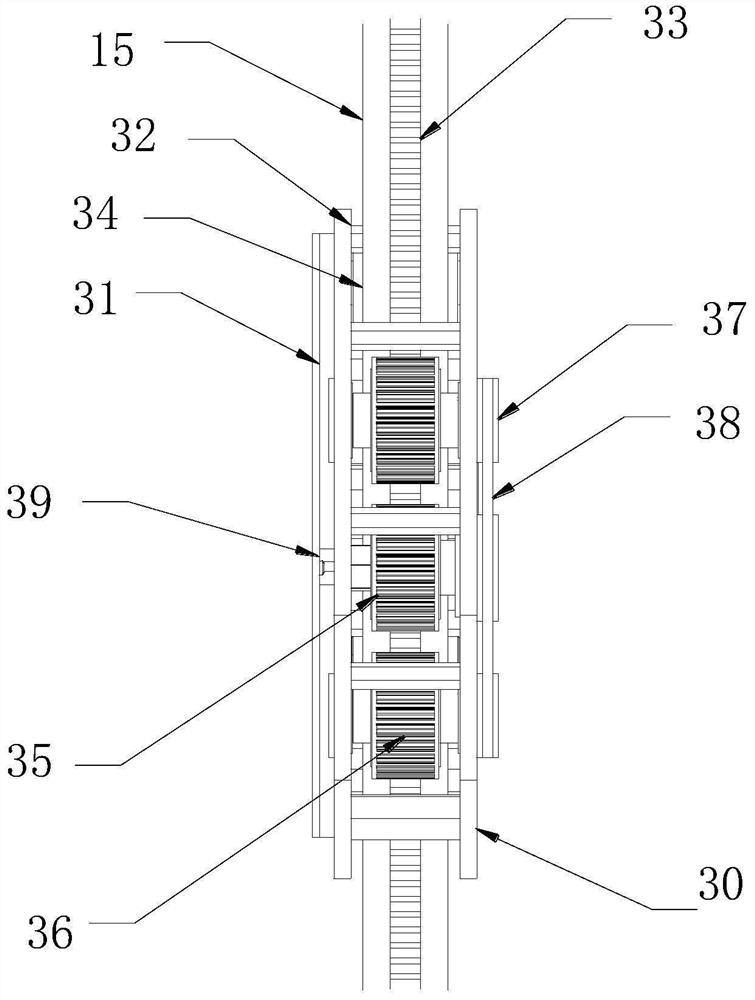

[0029] see image 3 , the...

Embodiment 2

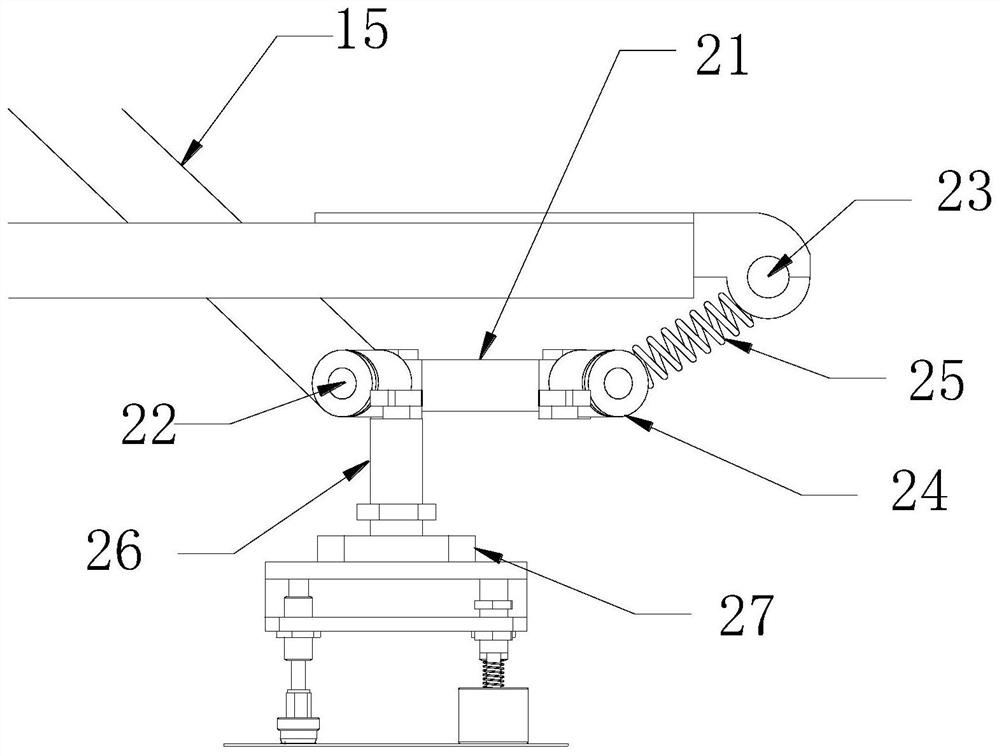

[0034] see image 3 with Figure 5 , this embodiment is further optimized as Embodiment 1, on the basis of which, the said wiping device 27 is provided with a mounting substrate 41, and the bottom of said mounting substrate 41 is provided with a wiping board 40, and said mounting substrate 41 The inside of the board is provided with a mounting groove 42, and the mounting groove 42 is respectively provided with a front mounting rod 43 and a rear mounting rod 44, and the front mounting rod 43 and the rear mounting rod 44 are respectively fixed by locking bolts. In the installation groove 42 , a lower support rod 45 is provided at the bottom end of the front rack rod 43 , and the bottom rod end of the lower support rod 45 is connected with the wiper plate 40 through a fixing bolt 46 . The bottom end of the rear frame rod 44 is provided with a movable support rod 47, and a support tube 48 is provided in the rear area of the bottom plane of the wiper plate 40, and the movable su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com