Anti-seepage multicolor zipper and processing technology thereof

A processing technology and anti-seepage technology, which is applied in the field of zippers, can solve problems such as low efficiency, misalignment of printing lines, processing bottlenecks, etc., and achieve the effect of improving production efficiency and eliminating overlap deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention in conjunction with the embodiments of the present invention:

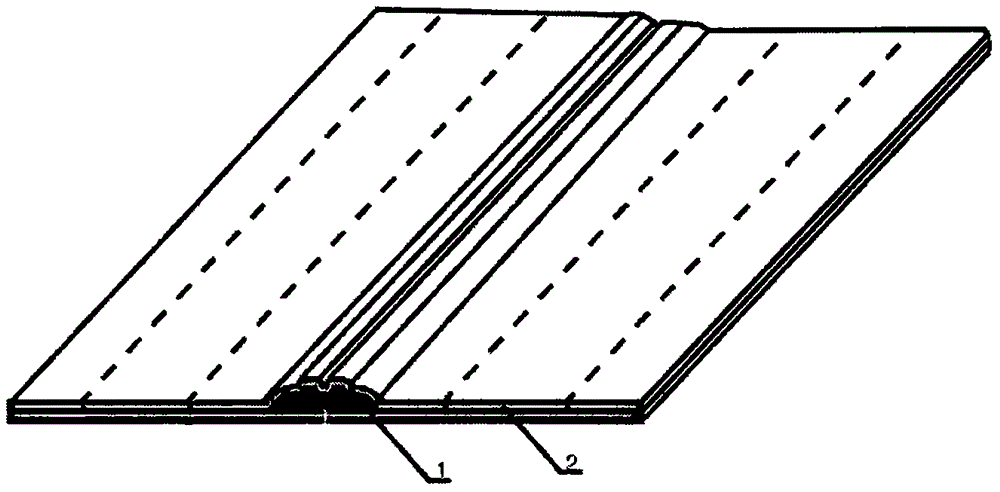

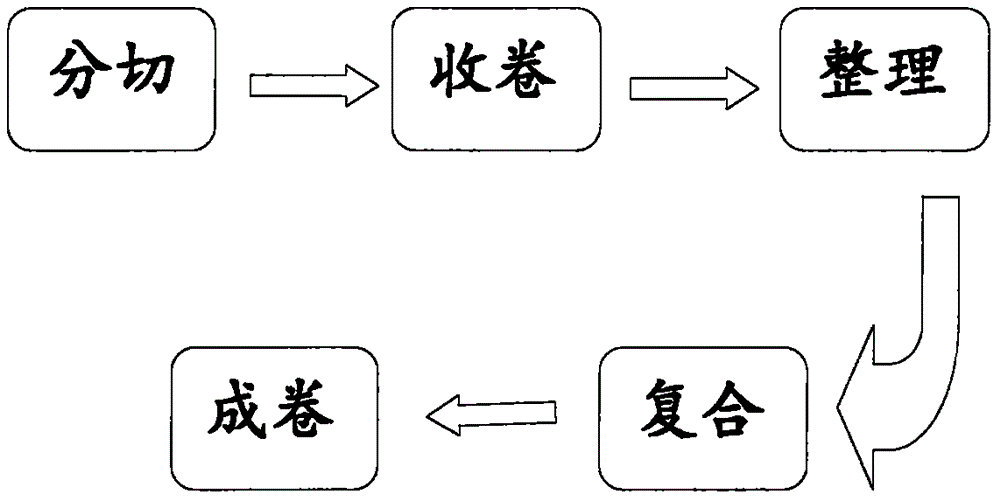

[0023] The anti-seepage multi-color zipper includes a zipper base layer (1) and a polyurethane waterproof layer (2), and its specific process steps are as follows:

[0024] ① Slitting: Cut one or several colored polyurethane films (a waterproof membrane) into strips by a slitting machine;

[0025] ②Winding: Wrap the waterproof polyurethane slit film cut into strips on a fixed turntable and roll it into a tube;

[0026] ③ Finishing: Use a linear mold to straighten and guide the outlet end of the multi-color waterproof polyurethane slitting film rolled into a tube;

[0027] ④Composite: introduce the straightened multi-color waterproof polyurethane slit film into the upper surface of the zipper base, and unwind the zipper base, so that the multi-color waterproof polyurethane slit film is atta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com