Patents

Literature

82 results about "Flexure hinges" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multiple degree of freedom micro electro-mechanical system positioner and actuator

InactiveUS7451596B2Magnetic circuitElectrostatic generators/motorsSemiconductor materialsFlexure hinges

Owner:MASSACHUSETTS INST OF TECH

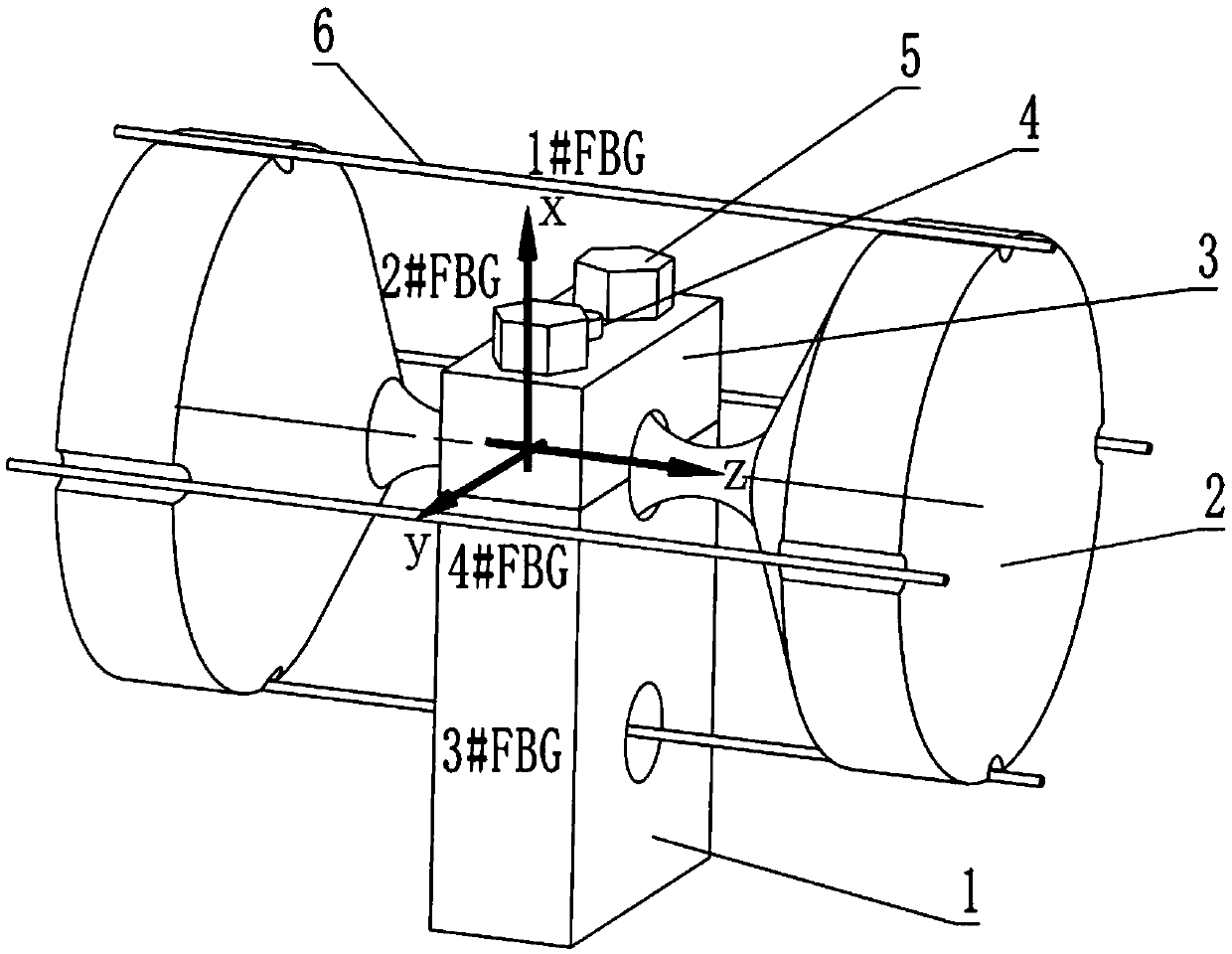

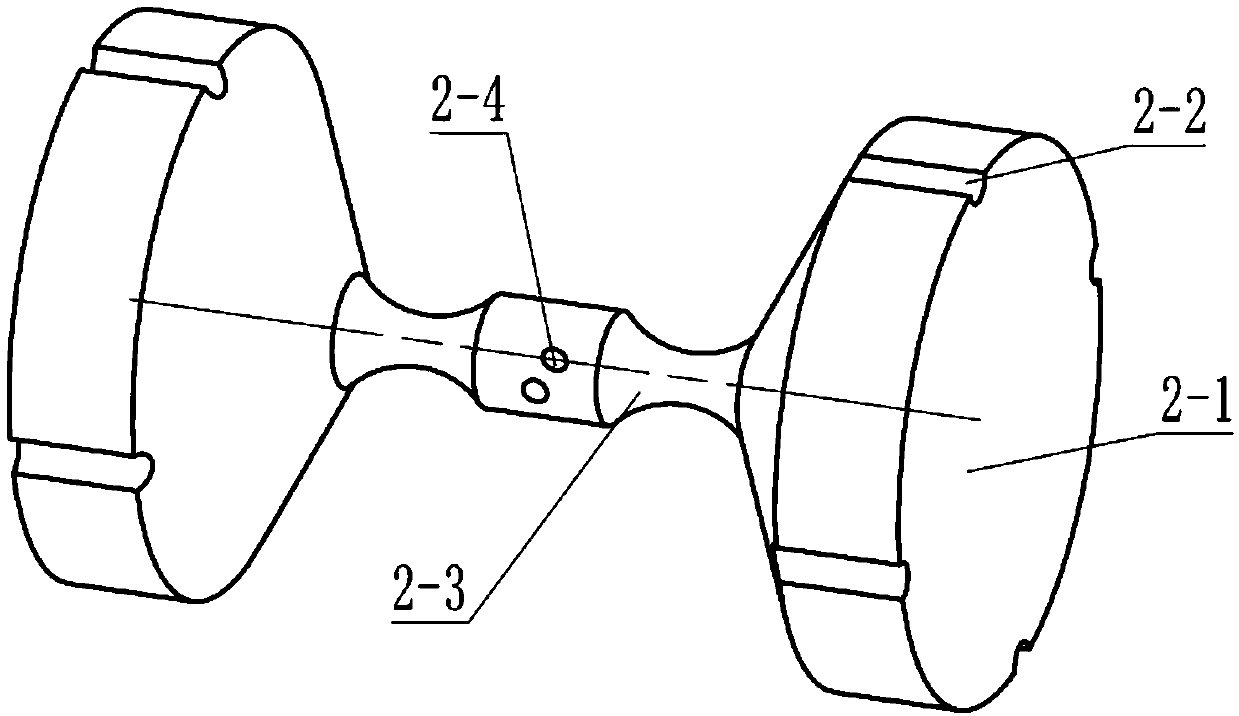

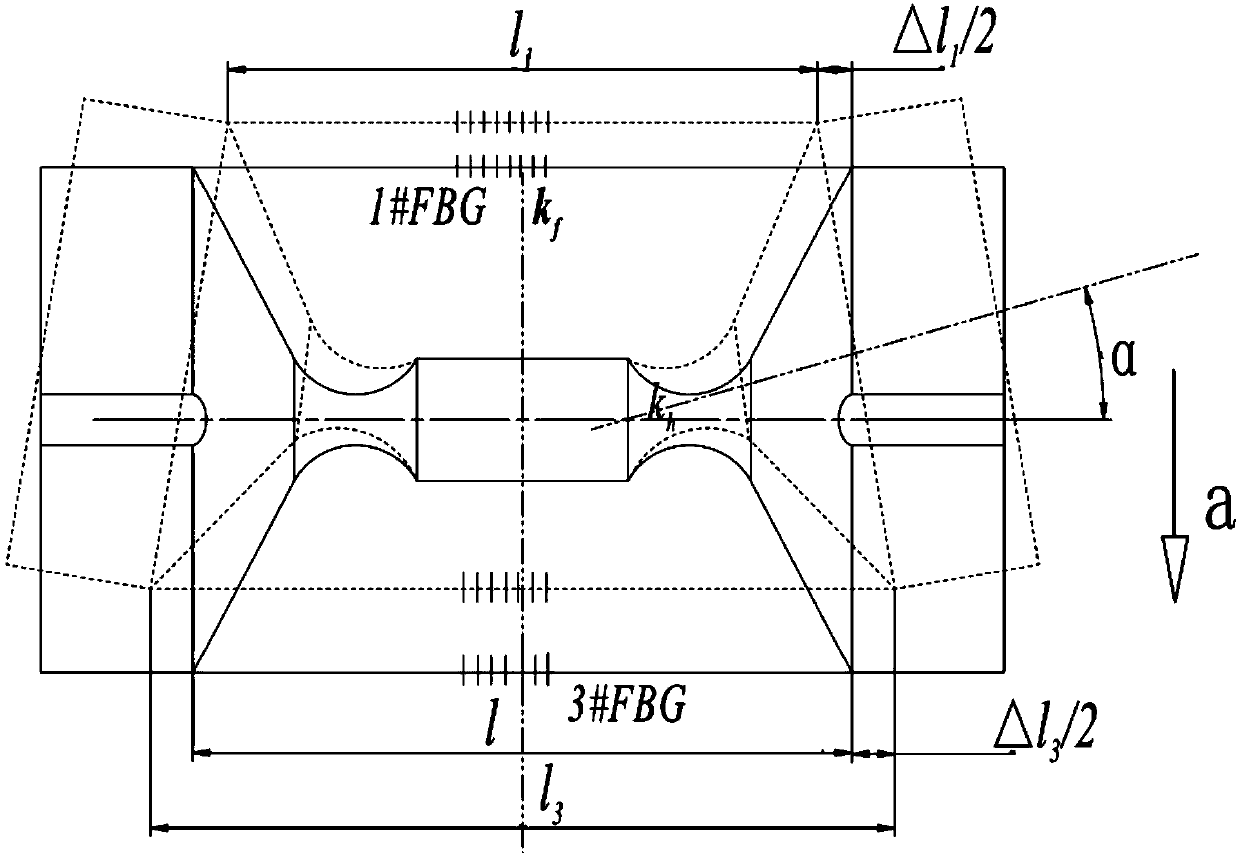

Three-dimensional FBG (fiber bragg grating) acceleration sensor based on flexure hinges

InactiveCN105116168ASimple structureEasy to assembleAcceleration measurement using interia forcesAcceleration measurement in multiple dimensionsGratingFiber Bragg grating

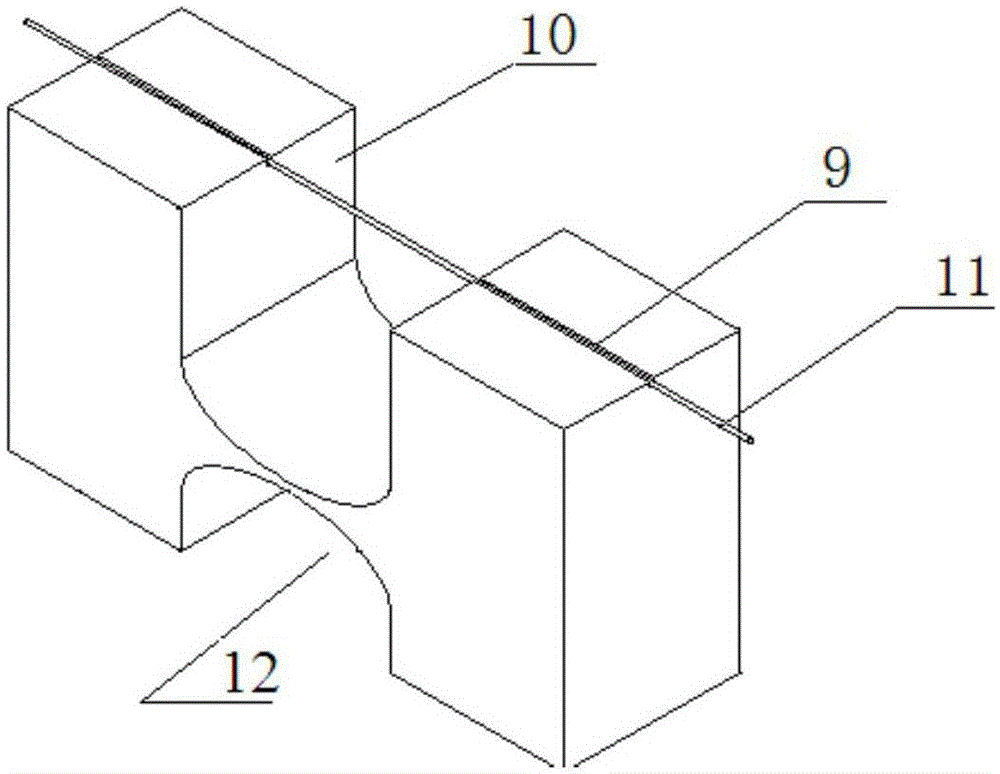

The invention discloses a three-dimensional FBG (fiber bragg grating) acceleration sensor based on flexure hinges. The three-dimensional FBG acceleration sensor comprises a casing, wherein an L-shaped base and three single-axis flexure hinges are arranged in the casing, two single-axis flexure hinges are fixed on a long arm of the L-shaped base, the other single-axis flexure hinge is fixed on a short arm of the L-shaped base, and sensitive axes of the three single-axis flexure hinges are perpendicular to one another; one end of each single-axis flexure hinge is a fixed end and fixed on the L-shaped base, and the other end is a free end; an optical fiber groove is formed in the upper surface, perpendicular to the direction of the sensitive axis, of each single-axis flexure hinge, and an optical fiber is fixed in the optical fiber groove; grooves are formed in the upper surface and the lower surface between the fixed end and the free end of each single-axis flexure hinge, and FBGs are arranged in the grooves; each groove of each single-axis flexure hinge comprises two symmetrical rectangular notches and a semielliptical notch connected with the rectangular notches. The three-dimensional FBG acceleration sensor based on the flexure hinges has high sensitivity and realizes measurement of acceleration in three directions.

Owner:山东山科安测光电科技有限公司

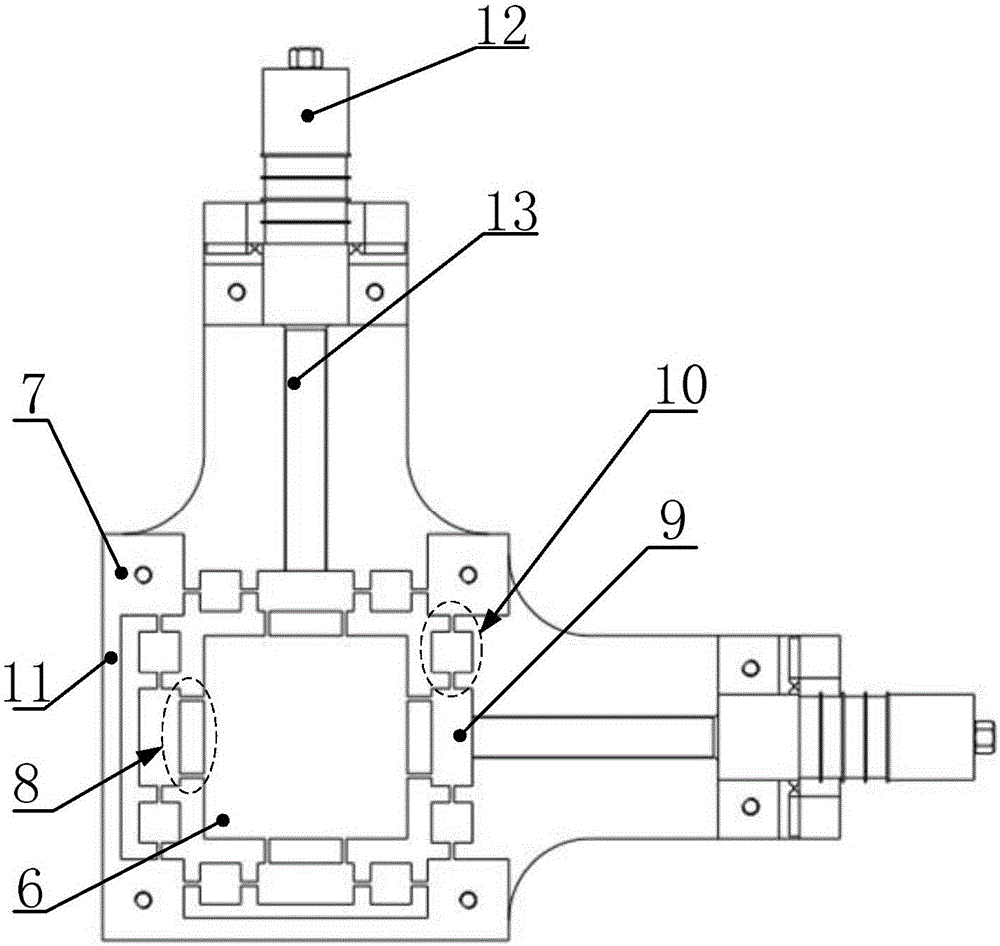

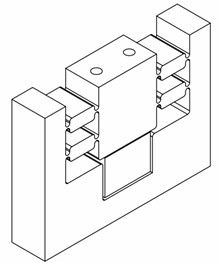

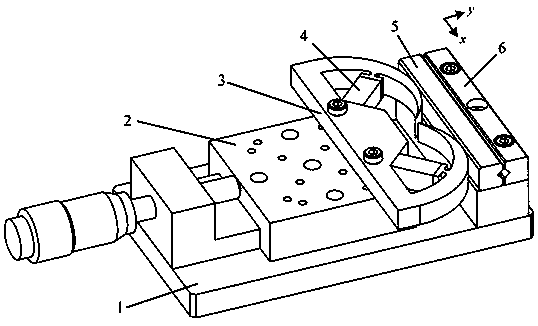

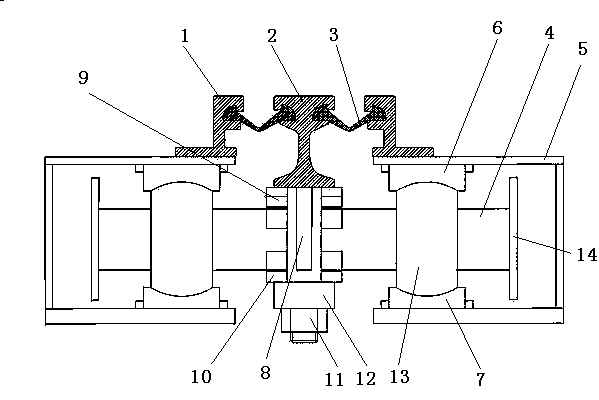

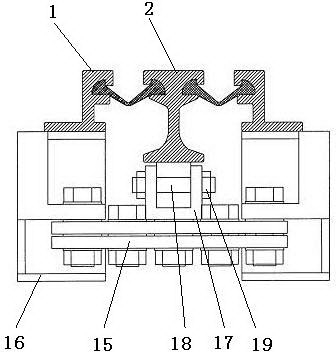

Two-dimensional ultrasonic vibration platform based on flexure hinge structure

InactiveCN105880140AAvoid changeMinor changesMechanical vibrations separationUltrasonic vibrationEngineering

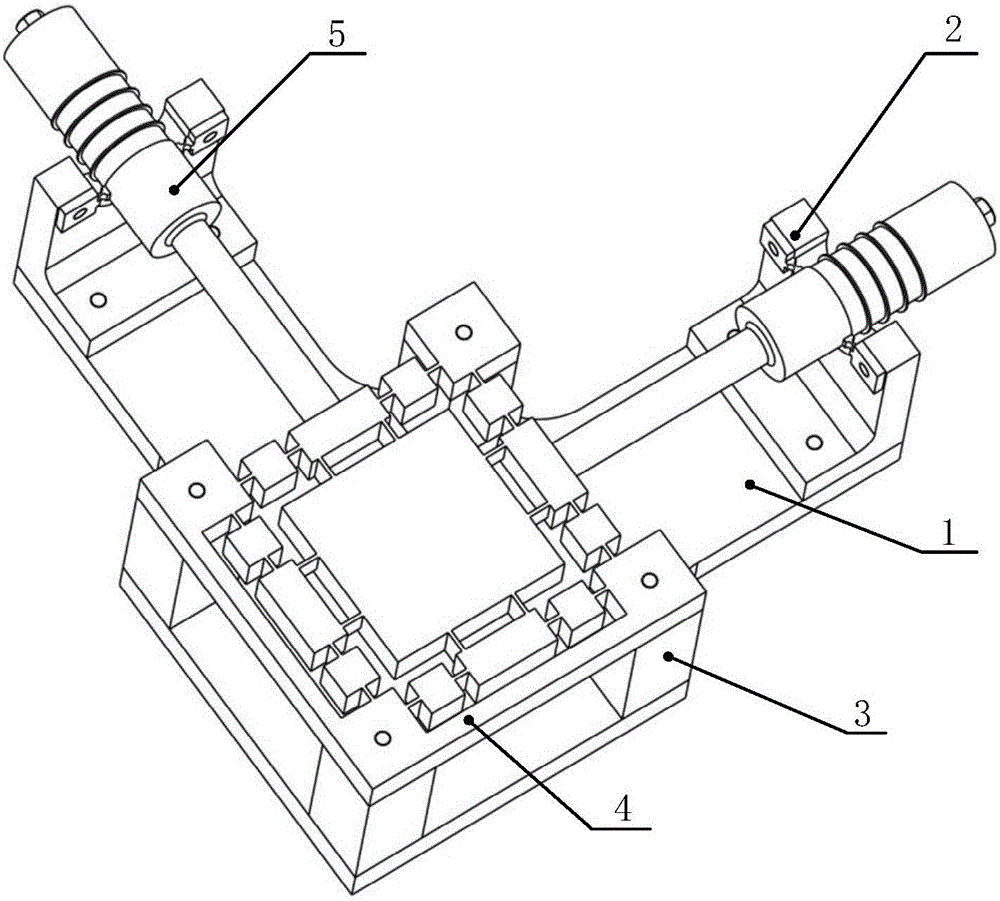

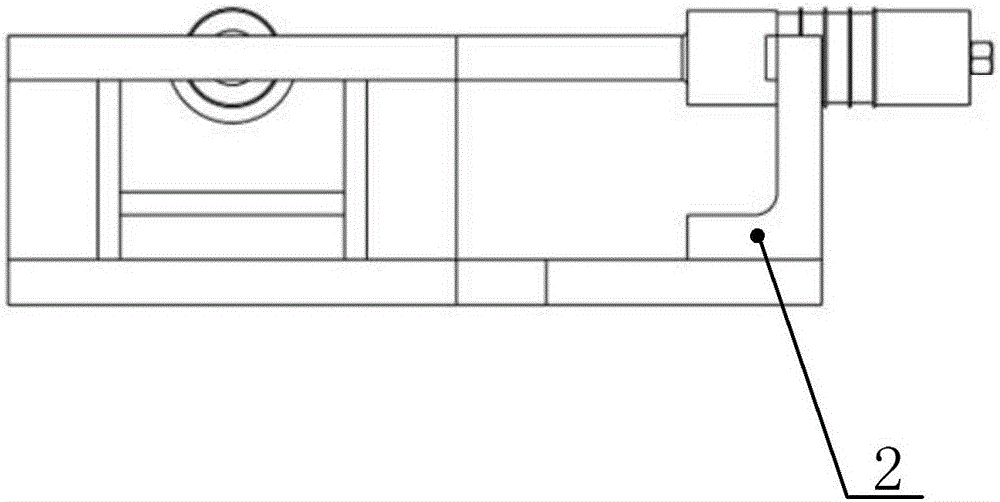

The invention discloses a two-dimensional ultrasonic vibration platform based on a flexure hinge structure. The two-dimensional ultrasonic vibration platform based on the flexure hinge structure comprises a two-freedom-degree movement decoupling flexible hinge platform body. The flexible hinge platform body comprises a square workbench arranged at the central position; four movement blocks are arranged around the square workbench and opposite to the four sides of the square workbench one by one; the inner side of each movement block is connected with one side of the square workbench opposite to the movement block through a rectangular flexible hinge of a parallel connection structure. The two ends of each movement block are connected with fixed blocks through rectangular flexible hinges of series connection structures. The fixed blocks are supported by supporting blocks which are fixed to a bearing plate. The supporting blocks are fixedly connected with the fixed blocks. Every two adjacent movement blocks in the four movement blocks are driven by two ultrasonic vibrators, and every two ultrasonic vibrators are perpendicularly arranged and supported by two supports; and the supports are fixed to the bearing plate. When micro milling is performed, and modification on a micro machine tool main shaft can be avoided by adopting the two-dimensional ultrasonic vibration platform based on the flexure hinge structure

Owner:TIANJIN UNIV

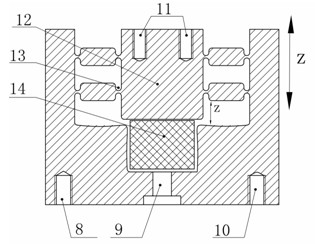

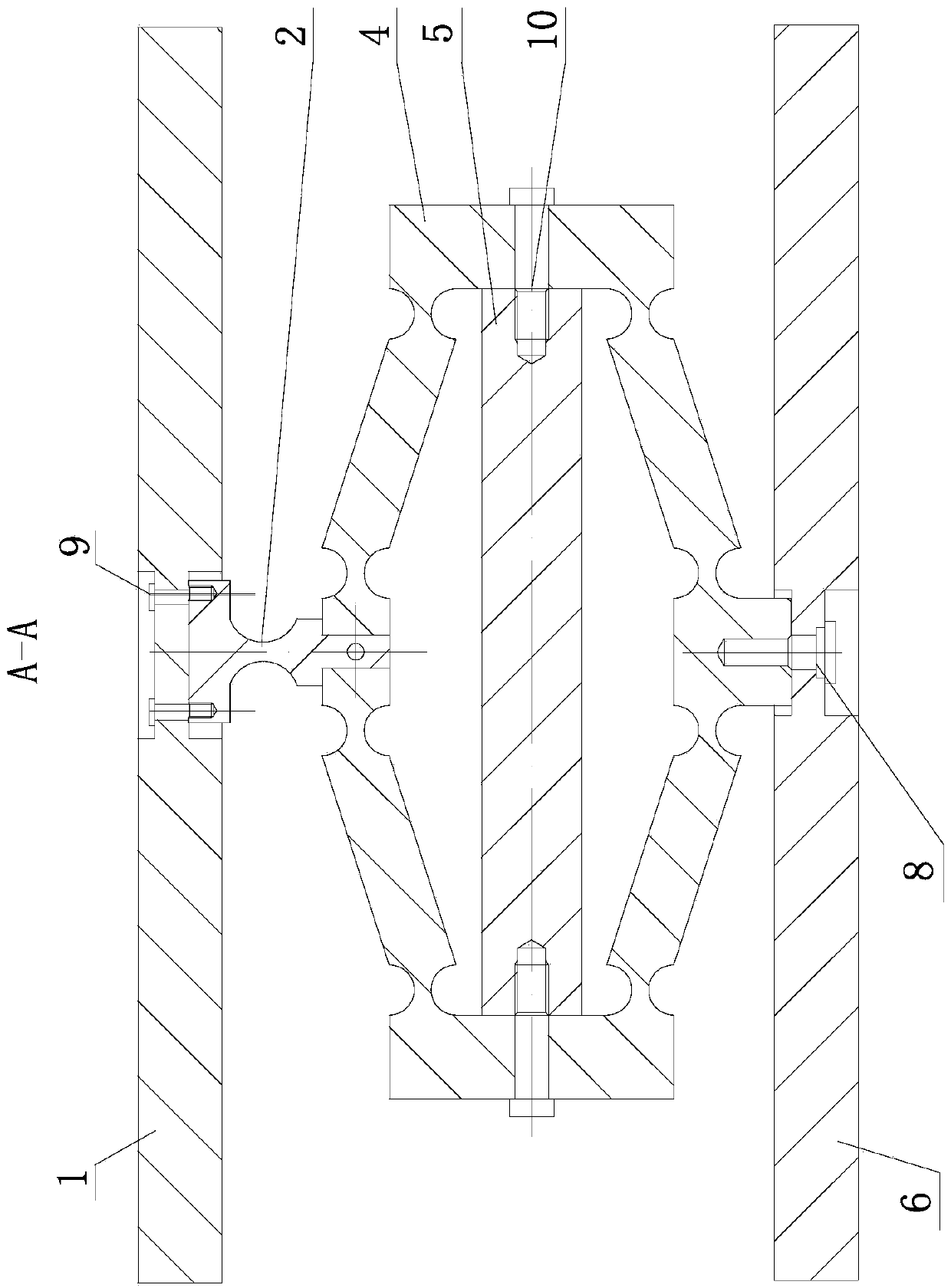

Multi-degree-of-freedom micromanipulator driven by multi-polarization mode piezoelectric actuator

InactiveCN102497129ARealize three-dimensional translationRealize high-precision micro-movementPiezoelectric/electrostriction/magnetostriction machinesCantilevered beamPiezoelectric actuators

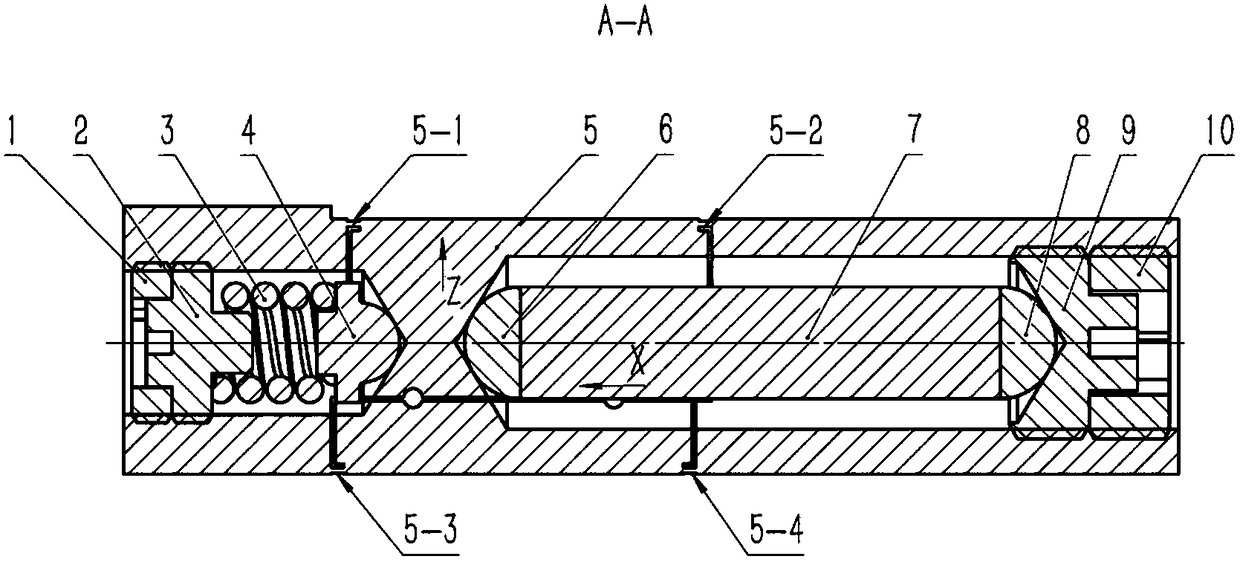

The invention discloses a multi-degree-of-freedom micromanipulator which is driven by a multi-polarization mode piezoelectric actuator. The micromanipulator comprises a substrate, a nested x and y axis translation micromotion mechanism, a Z axis translation micromotion mechanism, a Z axis turning micromotion mechanism and an end executive mechanism, wherein three-dimensional translation is realized by using a piezoelectric pile actuator with a piezoelectric strain constant d33 driving a flexure hinge; Z axis turning is realized by using a piezoelectric turning actuator with a piezoelectric strain constant d15 driving a reverse arm; and the end executive mechanism is a micro clamp holder consisting of a piezoelectric double-chip cantilever beam based on a piezoelectric strain constant d31 or a micro injection probe. High accurate micromotions such as the three-dimensional translation, turning around with a Z axis and swing around with an X axis are realized by the drive of the piezoelectric actuator in different polarization modes, and operations such as clamping, transport, probing, injection and the like are realized by different end executive arms. The micromanipulator has the advantages of freedom decoupling, compact structure, flexible operation, convenient control, high motion precision and the like, and the micromanipulator can be applied in the fields of biomedicine, micro electro mechanical engineering and the like.

Owner:ZHEJIANG UNIV

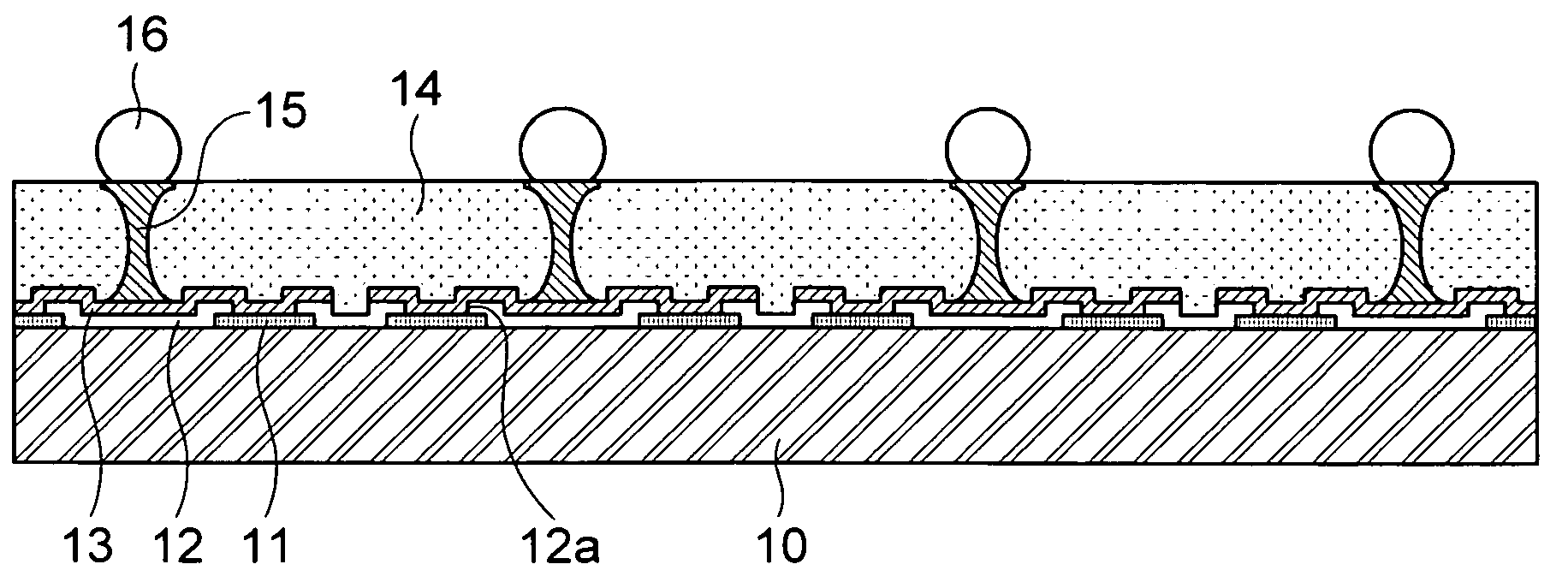

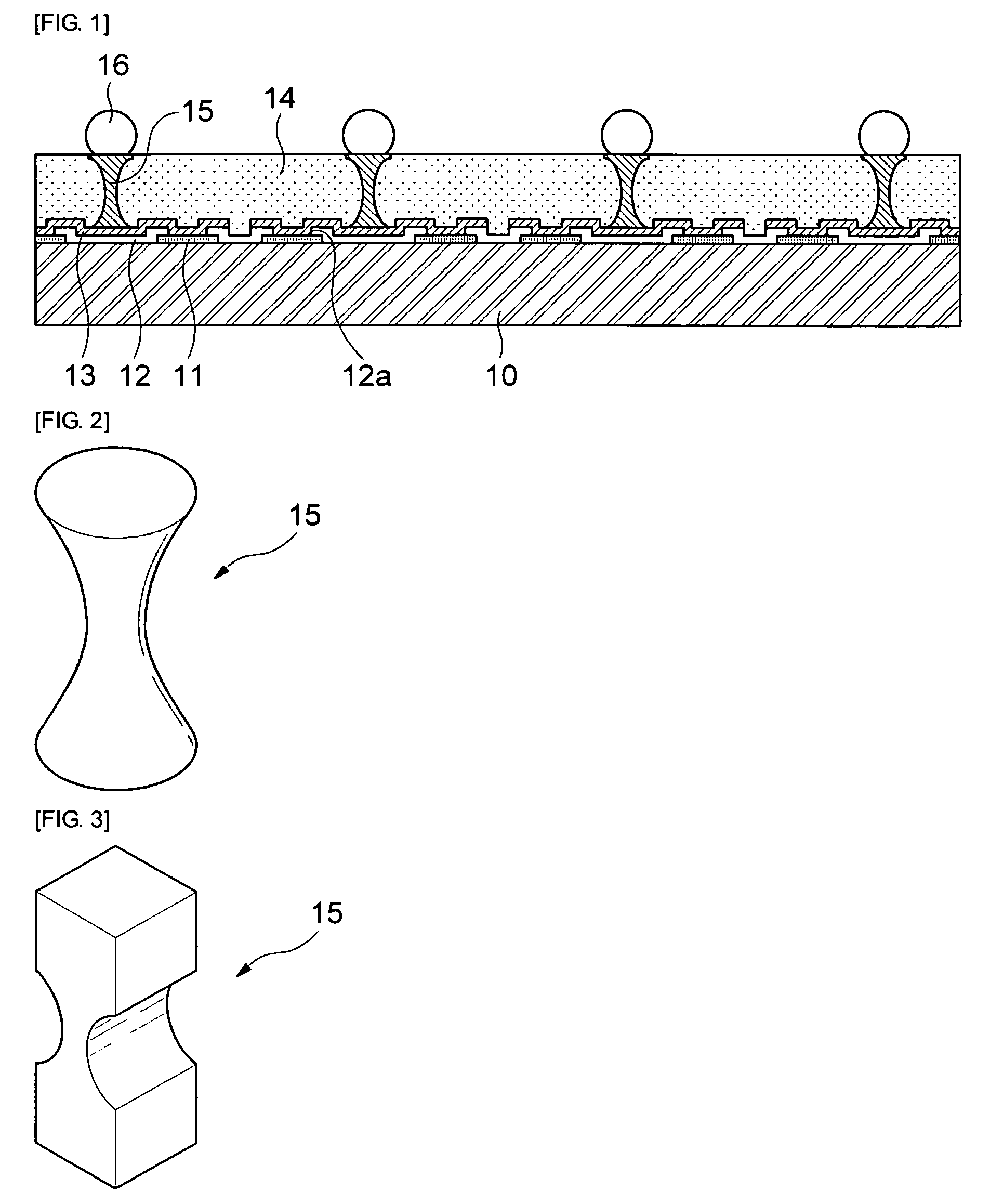

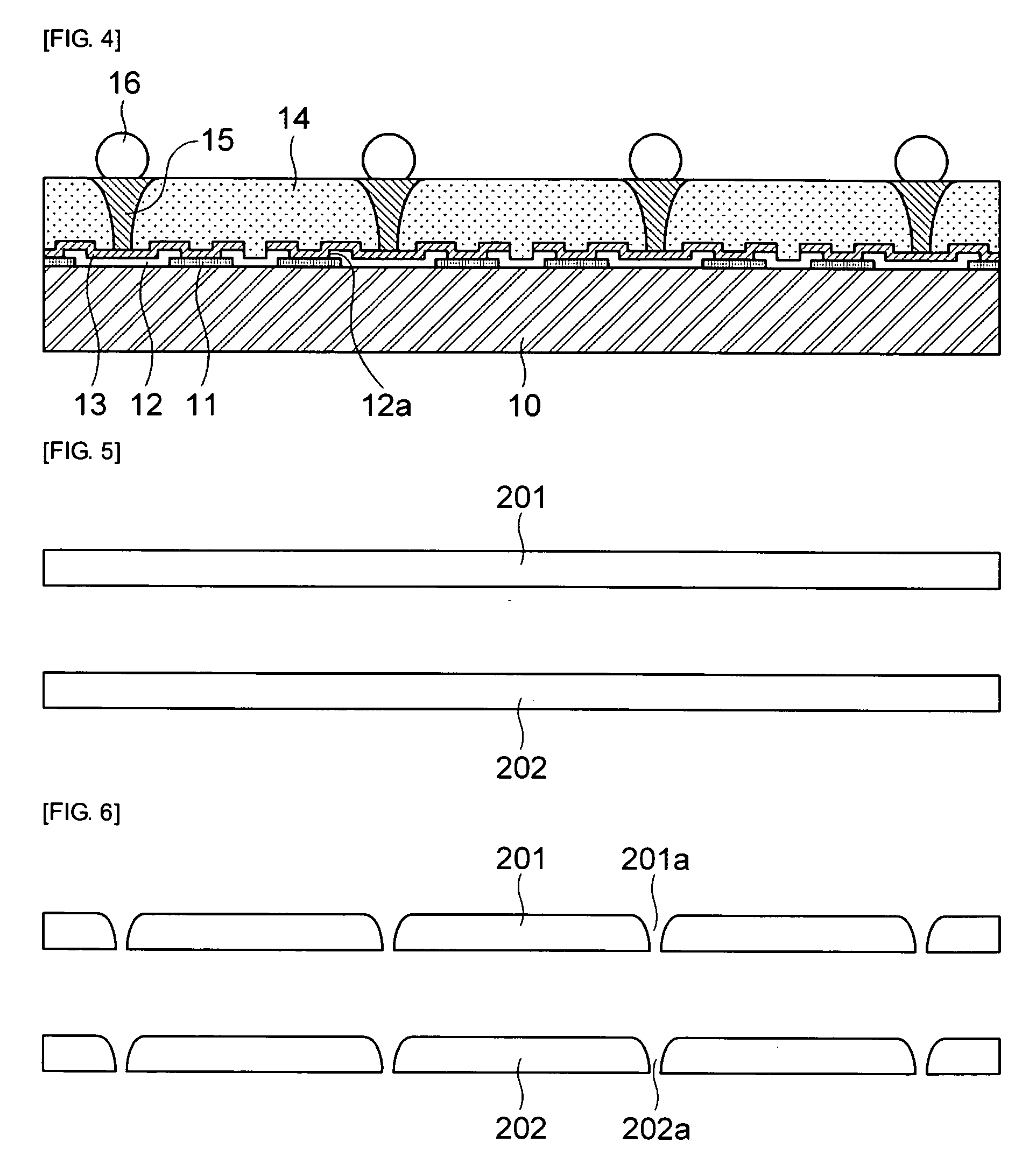

Wafer level package and method of manufacturing the same

InactiveUS20100052164A1Reduce processing costsSemiconductor/solid-state device detailsSolid-state devicesFlexure hingesMetal

The present invention relates to a wafer level package and a method of manufacturing the same and provides a wafer level package structure including a wafer having a die pad; a redistribution line formed to be connected on a top surface of the die pad; a metal post connected to a top surface of the redistribution line and formed in a flexure hinge structure; and a molding resin formed between the metal posts.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

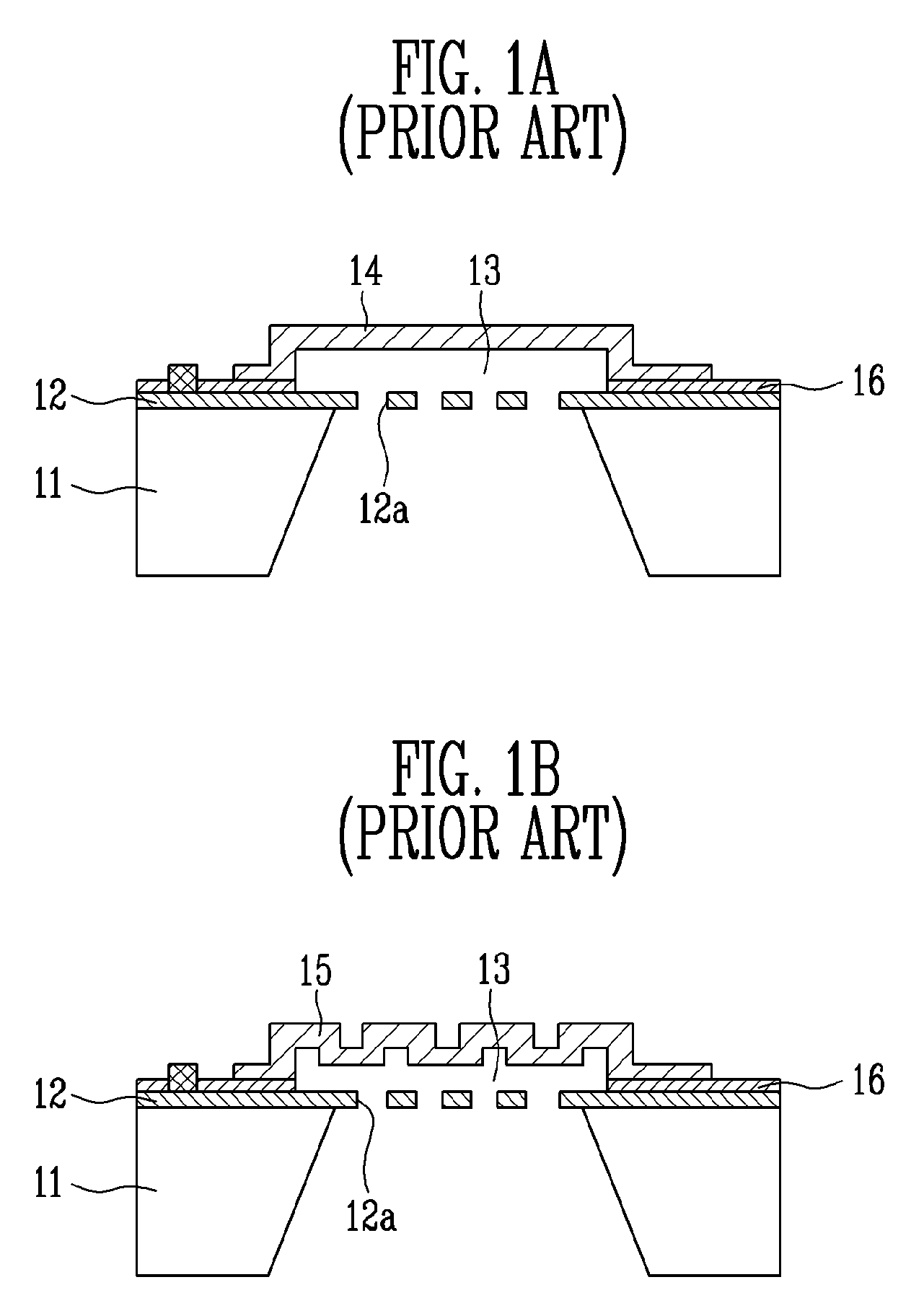

Condenser microphone having flexure hinge diaphragm and method of manufacturing the same

InactiveUS8422702B2Avoid deformationPiezoelectric/electrostrictive microphonesSemiconductor electrostatic transducersFlexure hingesEngineering

A micromini condenser microphone having a flexure hinge-shaped upper diaphragm and a back plate, and a method of manufacturing the same are provided.The method includes the steps of: forming a lower silicon layer and a first insulating layer; forming an upper silicon layer to be used as a back plate on the first insulating layer; forming a plurality of sound holes by patterning the upper silicon layer; forming a second insulating layer on the upper silicon layer; forming a conductive layer on the upper silicon layer having the sound holes, and forming a passivation layer on the conductive layer; forming a sacrificial layer on the passivation layer; depositing a diaphragm on the sacrificial layer, and forming a plurality of air holes passing through the diaphragm; forming electrode pads on the passivation layer and a region of the diaphragm; and etching the sacrificial layer, the passivation layer, the conductive layer, the upper silicon layer, the first insulating layer and the lower silicon layer to form an air gap between the diaphragm and the upper silicon layer.Consequently, due to the flexible diaphragm, a manufacturing process using semiconductor MEMS technology may improve the sensitivity of the condenser microphone and reduce the size of the condenser microphone, thereby enabling integration into a portable terminal.

Owner:ELECTRONICS & TELECOMM RES INST

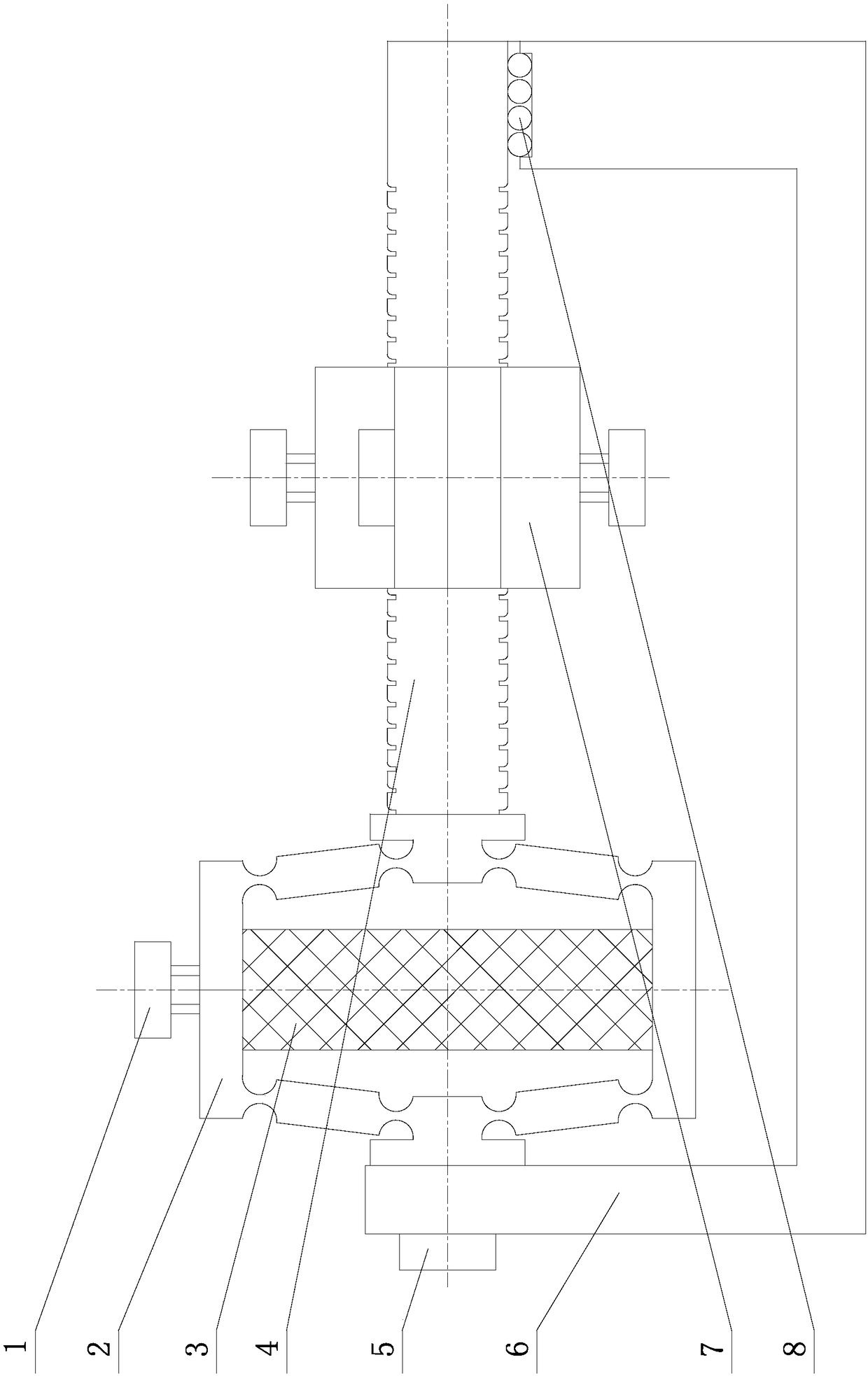

Symmetrical piezoelectric-driven two-dimensional directional adjusting mechanism and rotating platform angle adjusting method

ActiveCN109546887AWide range of angle adjustmentHigh precisionPiezoelectric/electrostriction/magnetostriction machinesElectricitySpace environment

A symmetrical piezoelectric-driven two-dimensional directional adjusting mechanism and a rotating platform angle adjusting method are provided. The invention relates to a piezoelectric driving deviceand an adjusting method. The symmetrical piezoelectric-driven two-dimensional directional adjusting mechanism comprises a rotating platform, a base, universal flexure hinges and four displacement amplifying units. Each displacement amplifying unit is mainly composed of a triangular amplifying structure and a piezoelectric ceramic actuator. The universal flexure hinges and the triangular amplifyingstructures are arranged between the rotating platform and the base. The rotating platform angle adjusting method comprises the following steps: gasless connection is carried out on the symmetrical piezoelectric-driven two-dimensional directional adjusting mechanism, and after installation, the initial height displacement deviation of the two symmetrical universal flexure hinges of the rotating platform is measured by using a laser displacement sensor; and then, the angle of the rotating platform is adjusted, and when the work is finished, the piezoelectric ceramic actuators are powered off and restored to the initial state. The symmetrical piezoelectric-driven two-dimensional directional adjusting mechanism and the rotating platform angle adjusting method are applied to the field of precision directional positioning and laser communication in a space environment.

Owner:HARBIN INST OF TECH

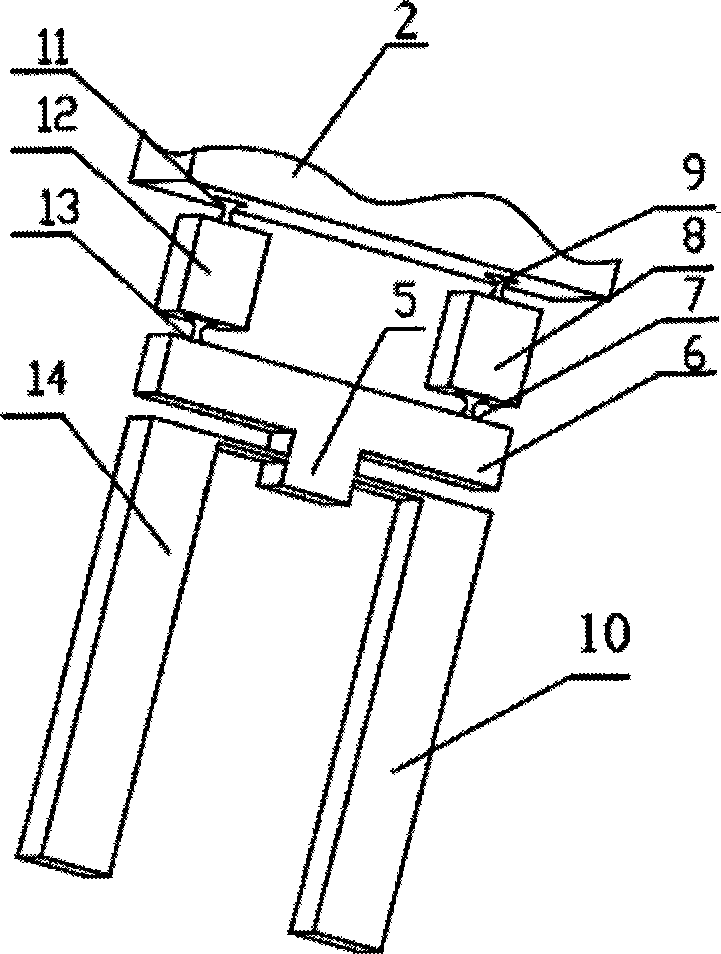

Piezoelectric on-off valve type jetting dispensing head

The invention discloses a piezoelectric on-off valve type jetting dispensing head, and relates to a dispensing device mainly for the quick assembly of electronic chips. The jetting dispensing head is provided with a base, two piezoelectric ceramics, pull rods, a triangular block, a heating block, stop blocks, a nozzle, a firing pin, a flexure hinge and a liquid supply device, wherein the base is provided with the flexure hinge, two piezoelectric ceramics are pre-tensioned on two arms of the flexure hinge respectively through stop blocks, the stop blocks are arranged in the front end of the piezoelectric ceramics respectively, and are fixed on the base by the pull rods and embedded in stop blocks guide groove of the inner frame edge of the base; the nozzle is fixed on the front end under the base; cover plates are arranged on two sides of the base respectively, the rear ends of two cover plates are fixed on two arms of the flexure hinge by bolts, and the triangular block are fixed on the front end of two cover plates; the firing pin is arranged on the front end of the triangular block; the heating block is fixed on the lower part of the base; the liquid supply device is provided with a colloidal runner, an inlet conversion adapter and an inlet hose; and the liquid supply device is arranged on the lower part of the base, a heat-insulating groove is arranged between the base and the liquid supply device, and the colloidal runner is externally connected with the liquid supply device through the inlet conversion adapter and the inlet hose.

Owner:XIAMEN UNIV

Optical-fiber-grating acceleration sensor based on double-axis flexure hinge and measuring method

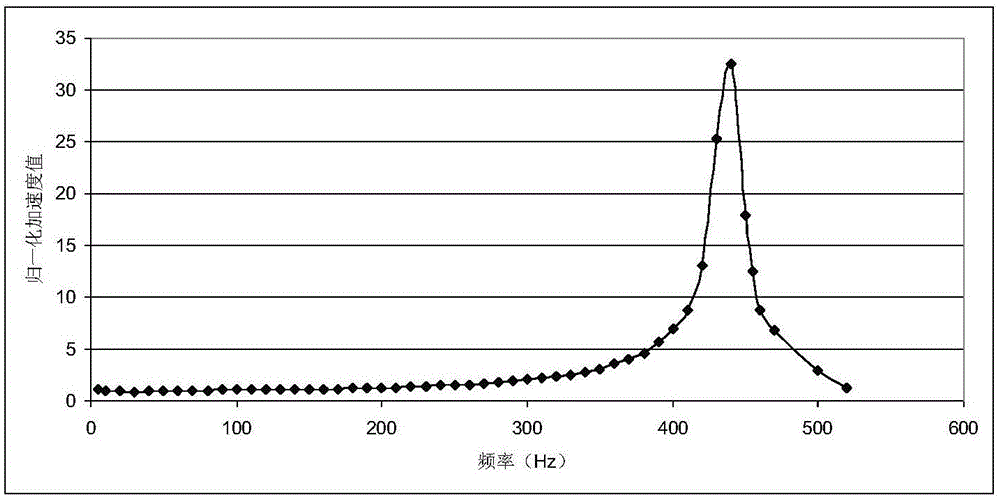

InactiveCN108663110AAccurate measurementHigh sensitivityAcceleration measurement using interia forcesSubsonic/sonic/ultrasonic wave measurementGratingElastic component

The invention provides an optical-fiber-grating acceleration sensor based on a double-axis flexure hinge. The optical-fiber-grating acceleration sensor comprises a supporting piece capable of being installed on a measured body, a lower groove is formed in the upper end face of the supporting piece, a sensing core penetrates through the lower groove, and is fixed to the supporting piece through a pressing block with an upper groove, and the upper groove is matched with the lower groove; the sensing core comprises a flexure hinge penetrating through the upper groove and the lower groove, the twoends of the flexure hinge are each provided with a coasting body integrated with the flexure hinge, four optical fiber grooves are evenly formed in the circumferential direction of each coasting body, four optical fibers are mutually non-interactive and are put into the optical fiber grooves of the two coasting bodies at certain pre-tightening force, the two ends of each optical fiber are fixed,and the suspension part, located between the two coasting bodies, of each optical fiber is provided with a grating. According to the optical-fiber-grating acceleration sensor, the double-axis flexurehinge is an elastic component, the high natural frequency is kept while the sensitivity is improved, and in the two-dimensional plane of the measured acceleration, all directional sensitivities are same, the two-phase acceleration can be accurately measured, and the optical-fiber-grating acceleration sensor also has the temperature compensation effect.

Owner:WUHAN UNIV OF TECH

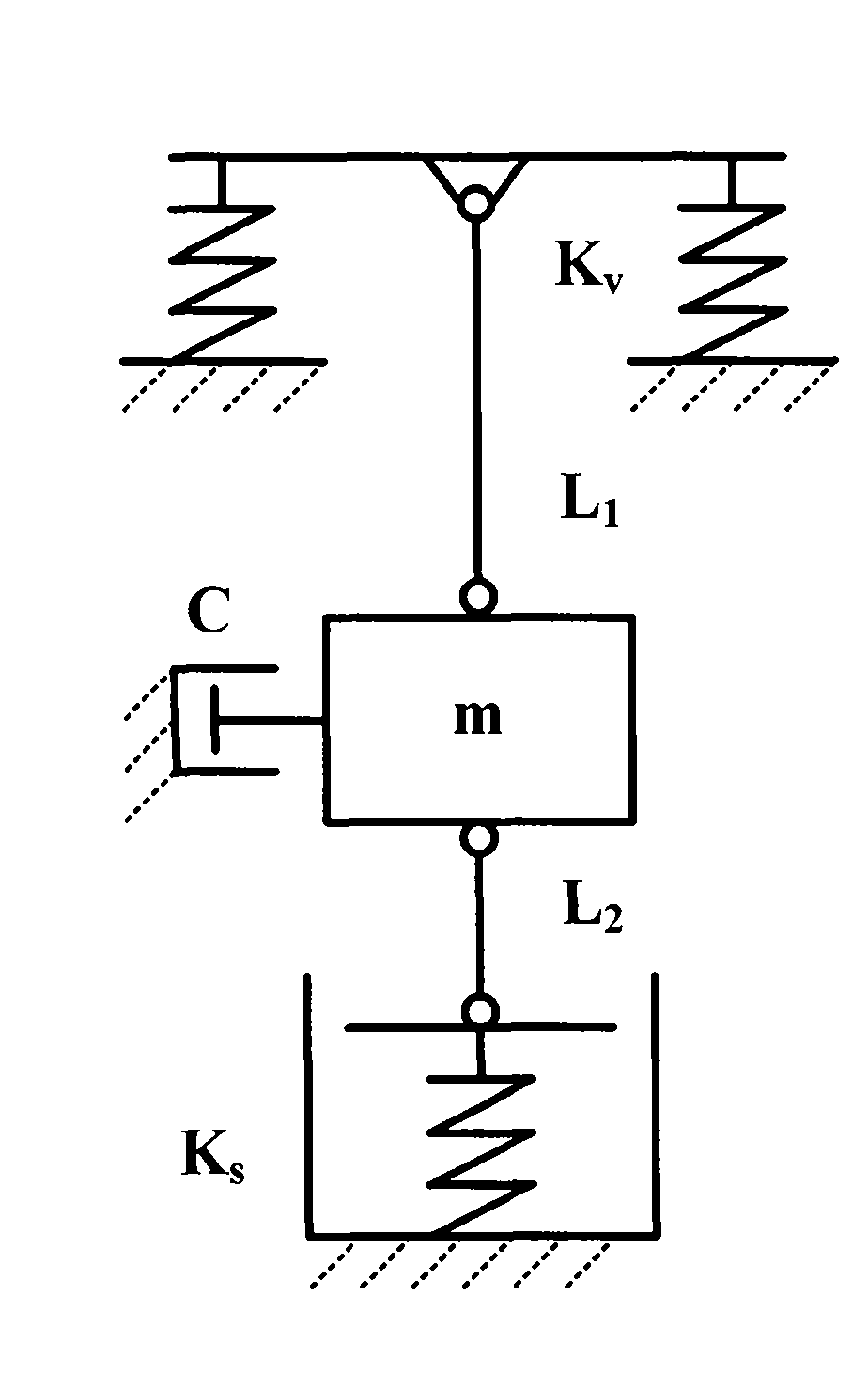

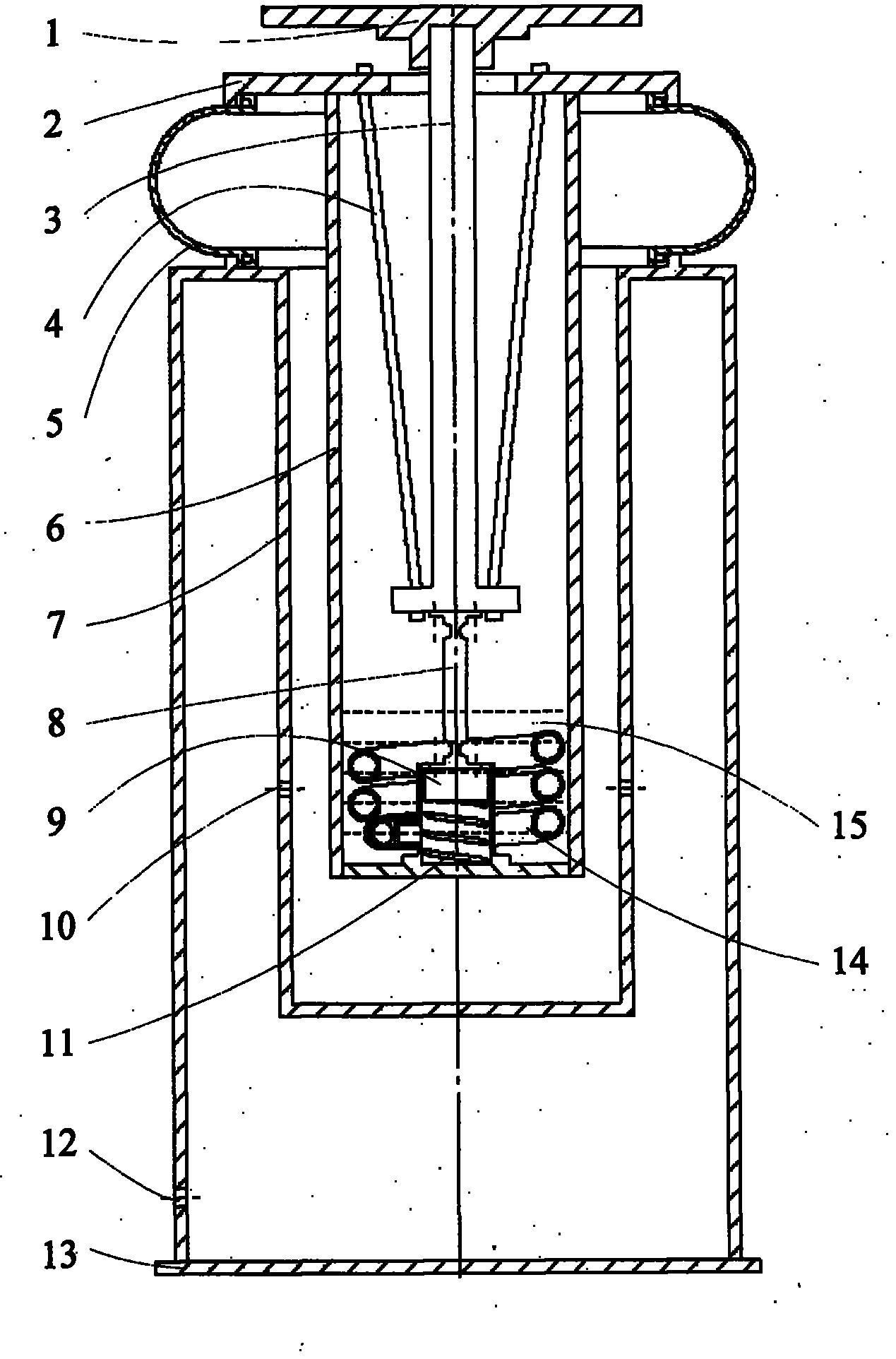

Air spring vibration isolator based on piston type liquid viscous damping action

ActiveCN102338188AGood effectReasonable useSpringsShock absorbersViscous dampingReciprocating motion

The invention discloses an air spring vibration isolator based on piston type liquid viscous damping action, and belongs to the field of ultra-precise measurement and processing. The upper end and the lower end of a cable-stayed steel wire rope of the vibration isolator are fixedly connected with an annular cover plate and the lower end of a supporting rod respectively to form a simple pendulum mechanism; a steel spring is arranged at the bottom of an inner cylinder; a piston is contacted and matched with the steel spring; the upper end and the lower end of a flexure hinge are arranged at thelower end of the supporting rod and the upper end face of the piston respectively to form an inverted pendulum mechanism; a spiral damper tube is arranged outside a piston cavity; damping oil is injected into the bottom of the inner cylinder to enclose the spiral damper tube; and one port of the spiral damper tube is communicated with the interior of the piston, and the other end of the spiral damper tube is communicated with the damping oil. The air spring vibration isolator provides damp for a positive-inverted pendulum serial mechanism by using the liquid viscous damping action and the reciprocating motion of the piston, obtains different liquid viscous damping by selecting the damping oil with different viscosities, and can provide the optimal damping under the condition that strong vibration, micro vibration and shock loads exist in the horizontal direction of the vibration isolator.

Owner:HARBIN INST OF TECH

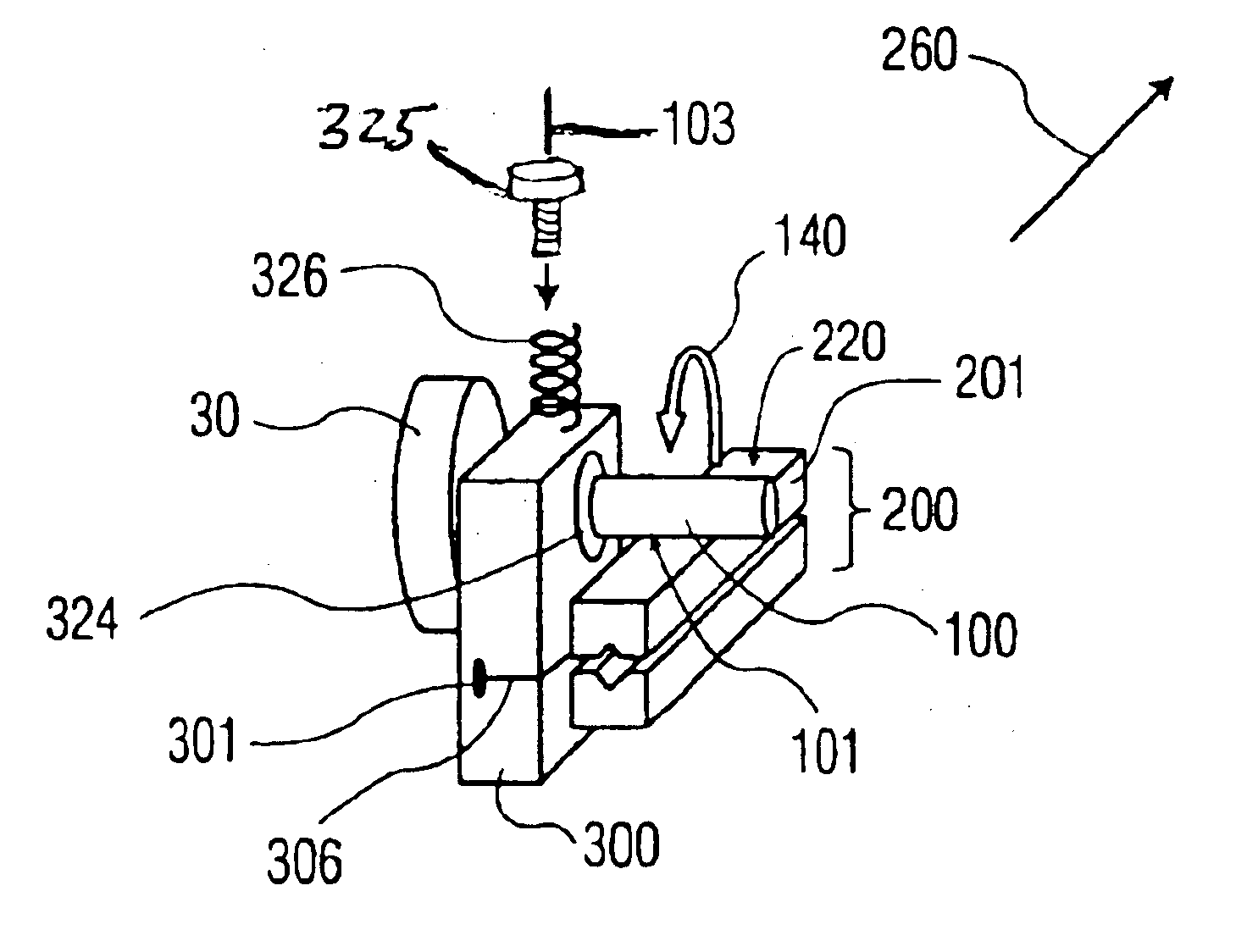

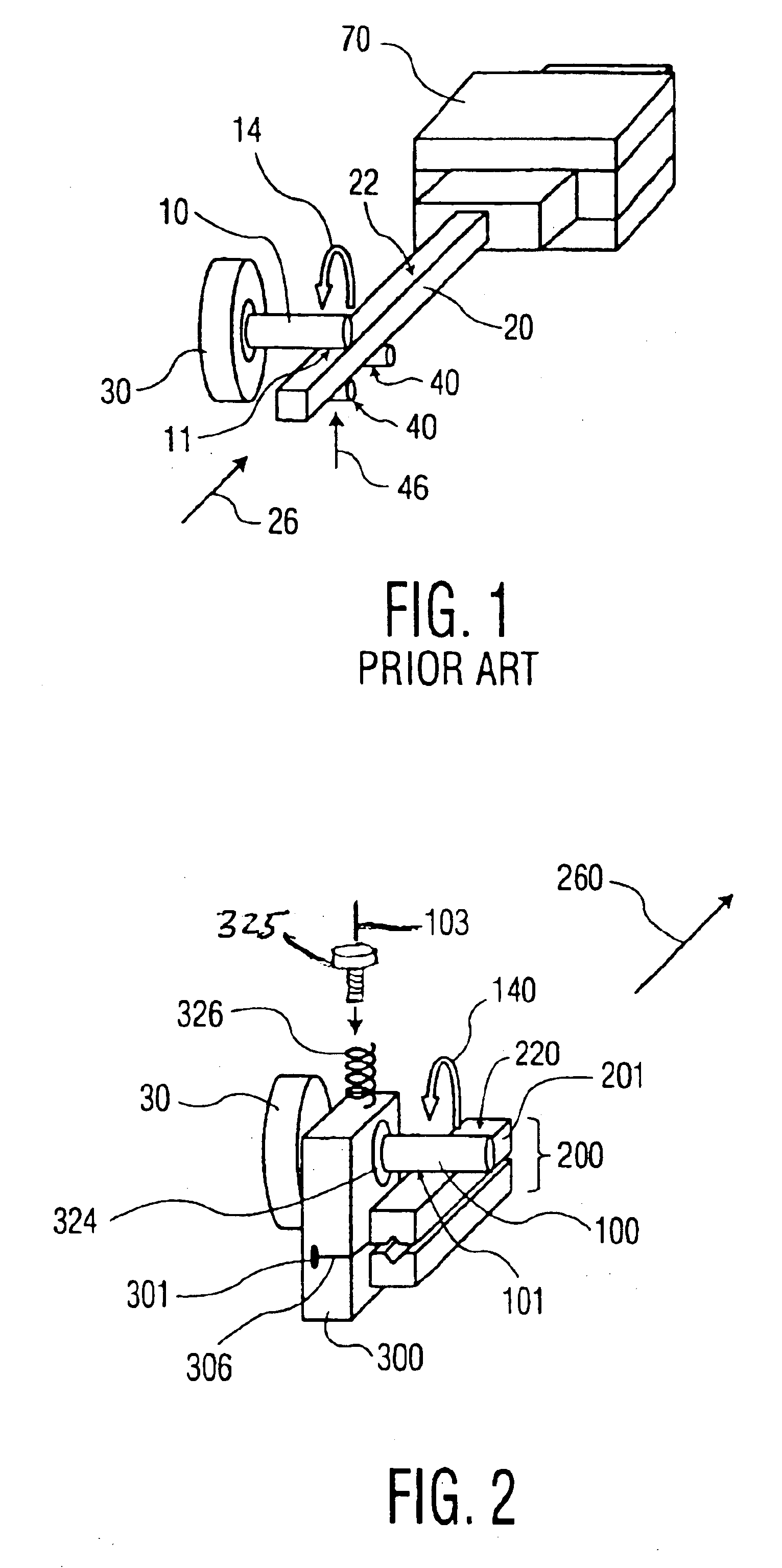

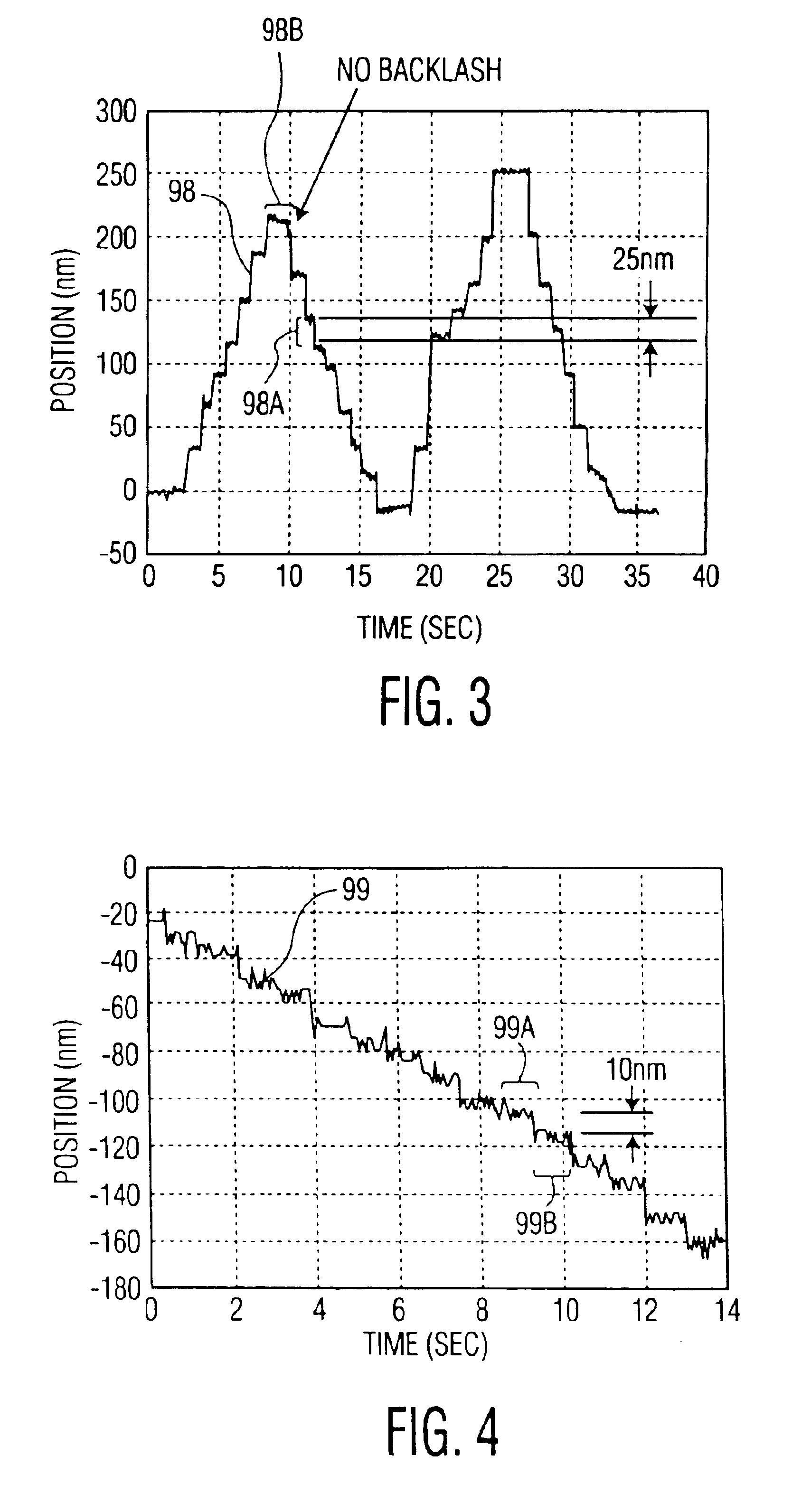

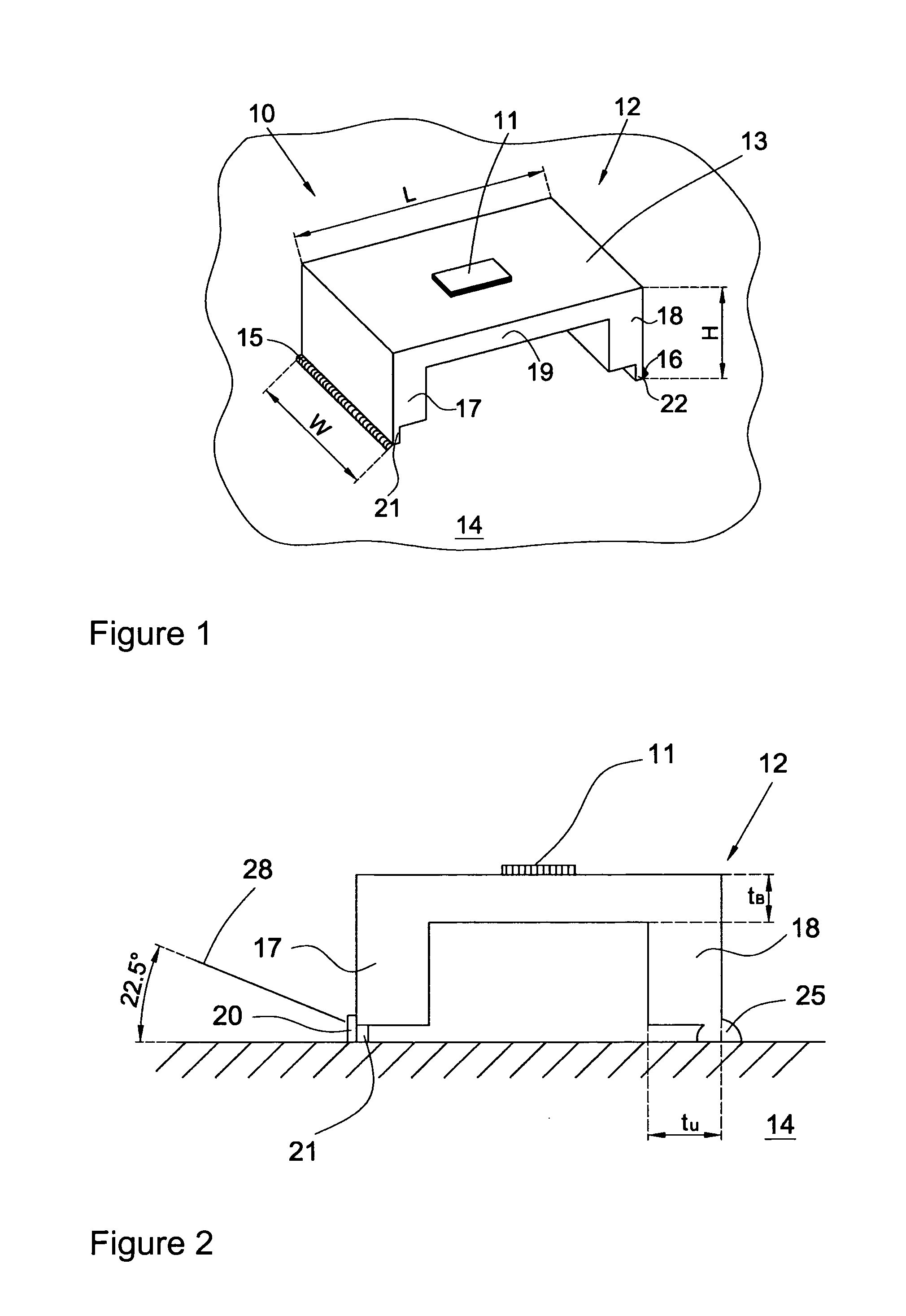

Method and apparatus for a low cost, high speed, and compact nanometer precision motion stage using friction drive and flexure hinge

InactiveUS6840886B2Prevent movementPiezoelectric/electrostriction/magnetostriction machinesPortable liftingDrive shaftConstant force

A friction drive including a drive shaft that is in rotational motion and in frictional contact with a follower at a contact area. The drive shaft transfers a thrust at the contact area. The follower receives the thrust and provides motion in response to the thrust. A flexure hinge couples the drive shaft to the follower with a constant force while restraining movement of the contact area in the direction of the thrust.

Owner:PANASONIC HEALTHCARE HLDG CO LTD

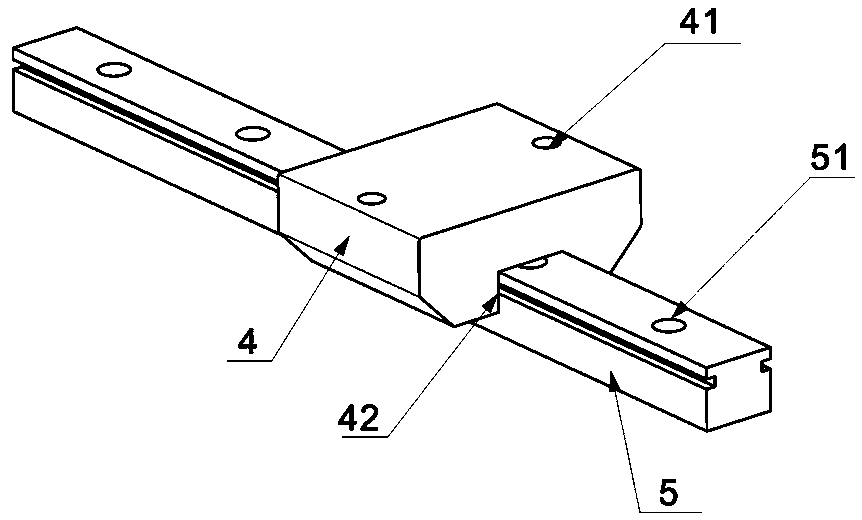

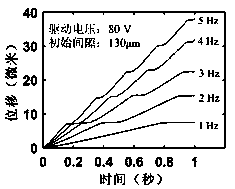

A sticky-slip inertial linear actuator based on surface inclination friction control

ActiveCN109150002ALarge output displacementHigh outputPiezoelectric/electrostriction/magnetostriction machinesFlexure hingesLinear actuator

The invention relates to a sticky-slip inertial linear actuator controlled by surface inclination friction, which relates to an actuator, comprising a flexure hinge amplifying mechanism, a piezoelectric stack actuator 1, a guide rail, a base and a mover; The flexure hinge amplifying mechanism is fixed on the base, the piezoelectric stack actuator 1 is installed in the flexure hinge amplifying mechanism, the piezoelectric stack actuator 1 is pre-tightened by a pre-tightened connector which is screwed on the flexure hinge amplifying mechanism, and the guide rail is a hollow structure which is closed at both ends; The guide rail is internally machined with a triangular amplifying mechanism in which a piezoelectric stack actuator (2) capable of adjusting the inclination angle of the guide railis mounted, a mover is arranged on the guide rail, and a friction material layer with self-lubricating characteristics in contact with the guide rail is fixedly connected on the surface of the mover.The invention has the advantages of large output force and displacement, compact structure, stable operation and bi-directional operation with load, and has wide application prospect.

Owner:NINGBO UNIV

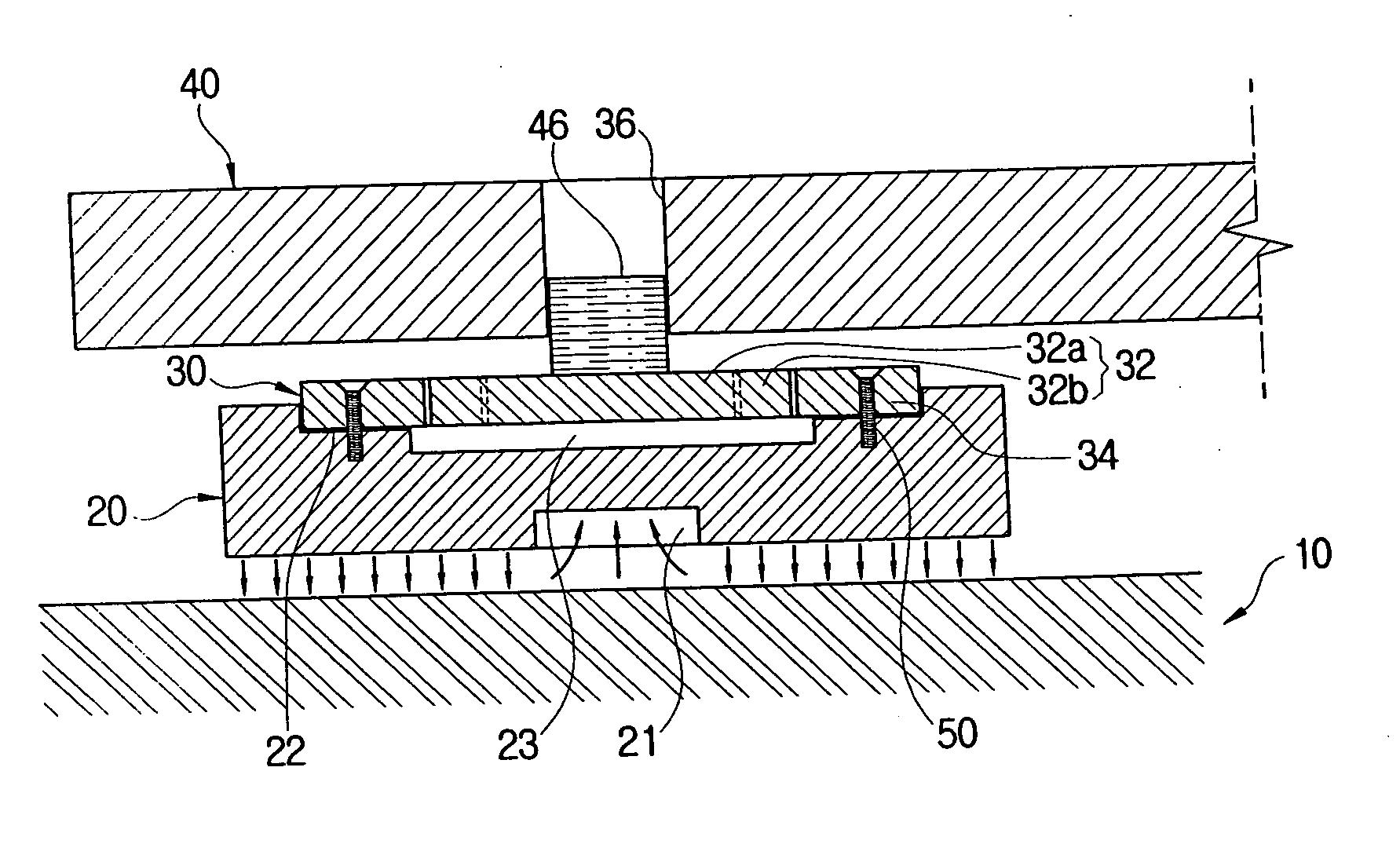

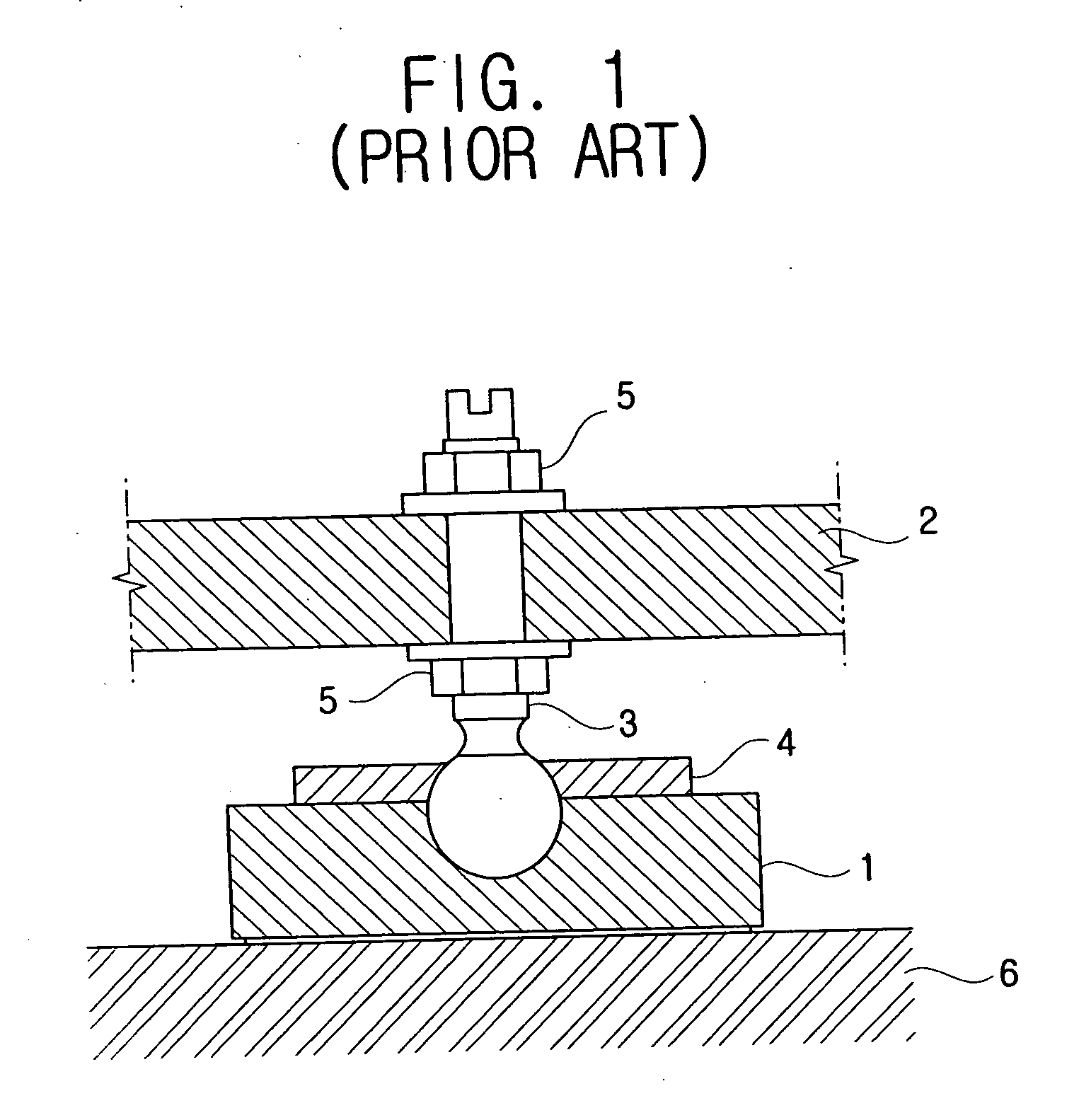

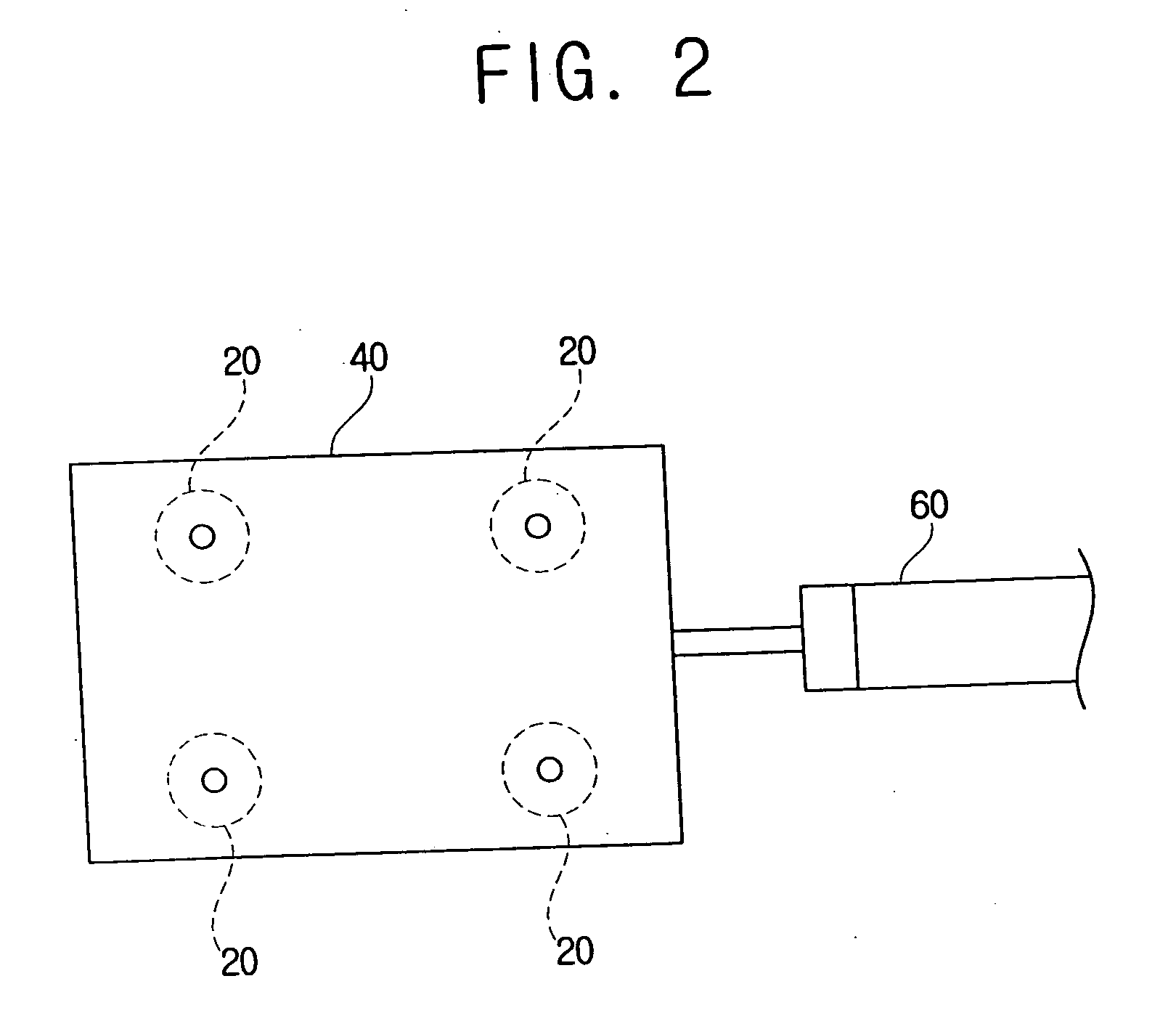

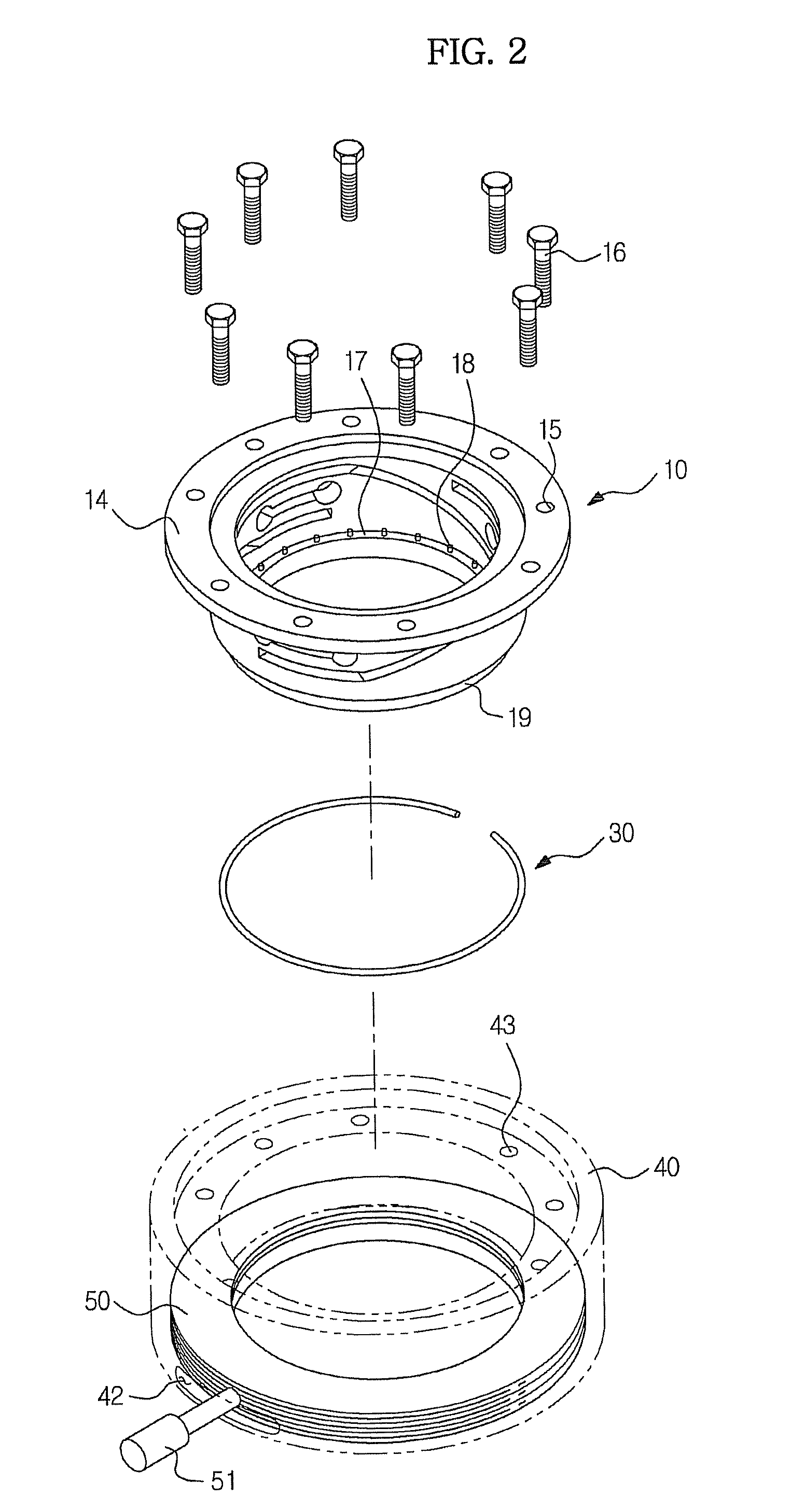

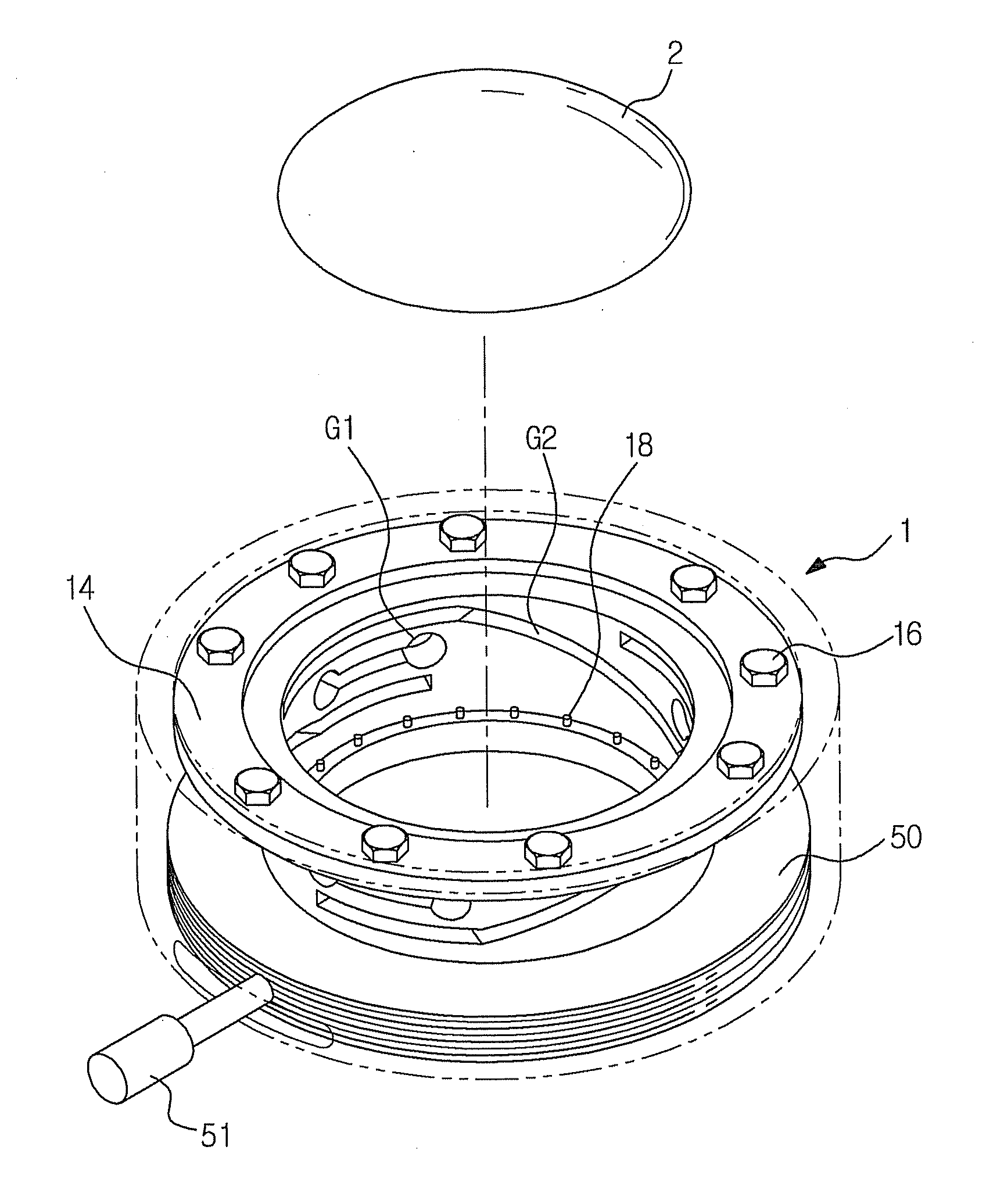

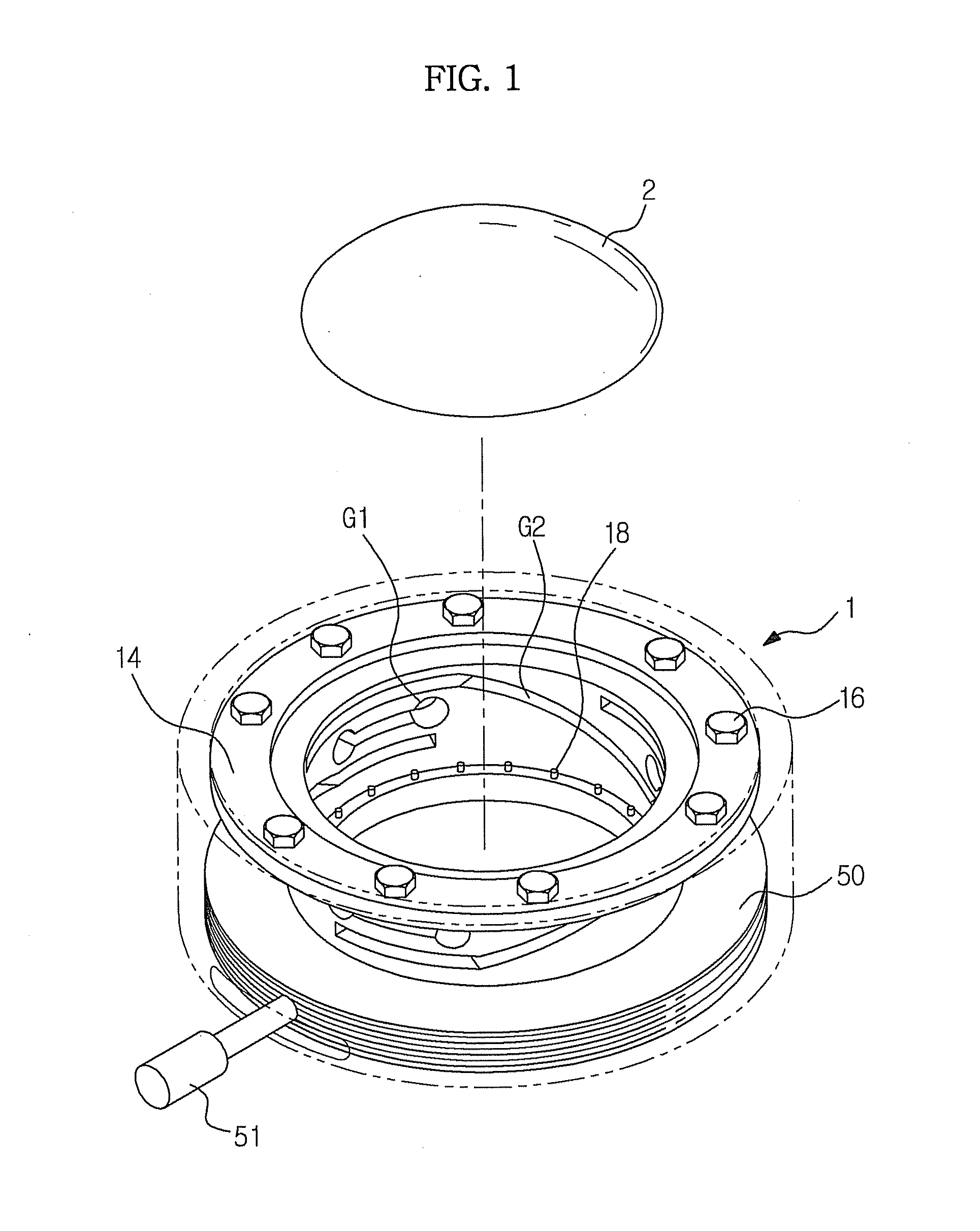

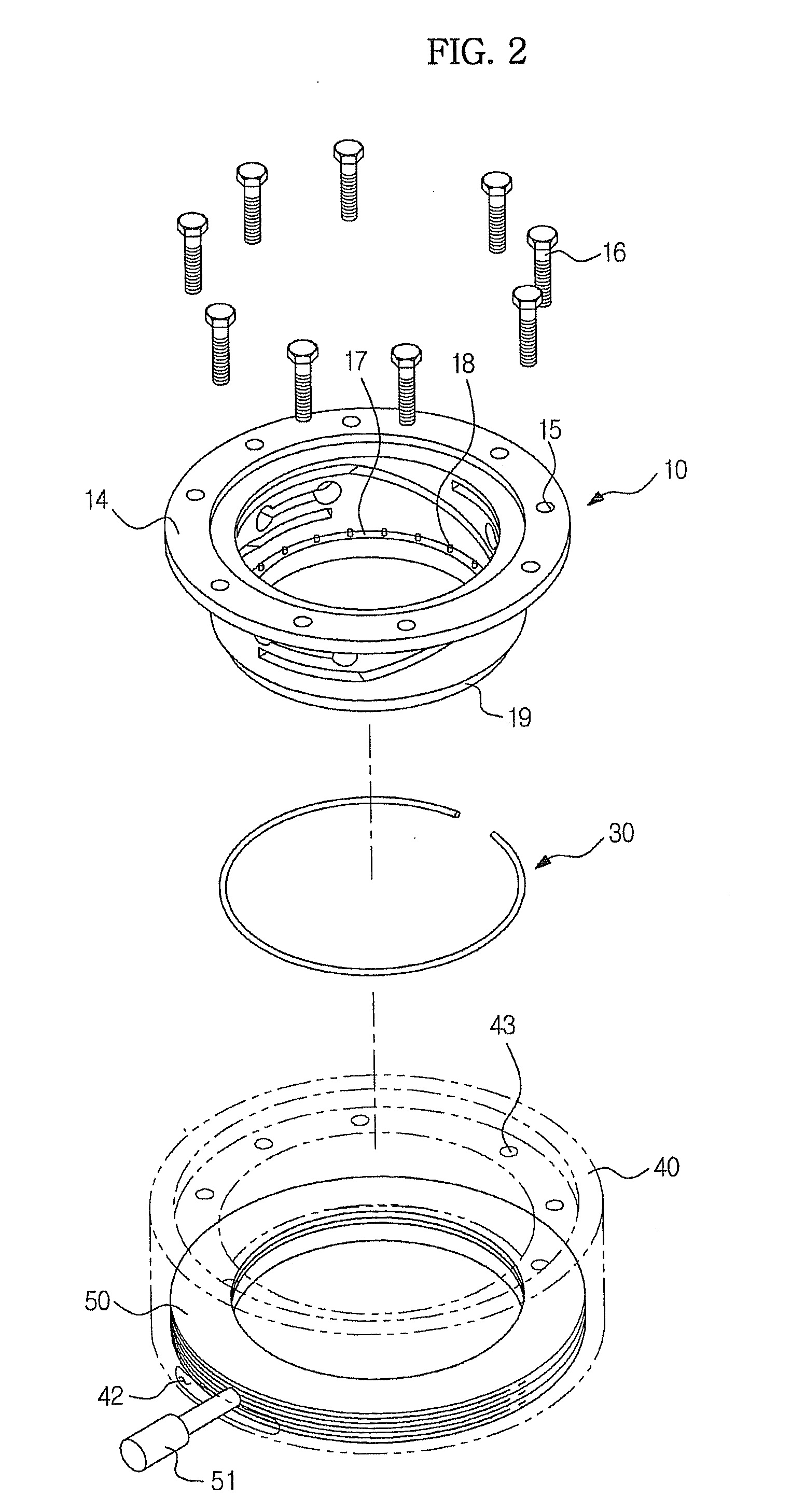

Transporting apparatus

ActiveUS20050180666A1Reduce the overall heightLinear bearingsGas cushion bearingsAir bearingFree rotation

A transporting apparatus which can horizontally transport a carrier using an air bearing of which a rotational degree of freedom is kept relative to a surface of a base. The transporting apparatus is movable along a surface of a base and includes an air bearing placed on a base, a connector connected to an upper part of the air bearing and provided with a supporter in a center thereof, the supporter having a flexure hinge structure to allow the air bearing to be freely rotated relative to the base, and the carrier supported by the supporter of the connector to be transported while keeping a level with respect to the surface of the base. With this configuration, a movement of the air bearing does not affect the carrier, thereby improving accuracy and reliability of the transporting apparatus.

Owner:SEAGATE TECH INT

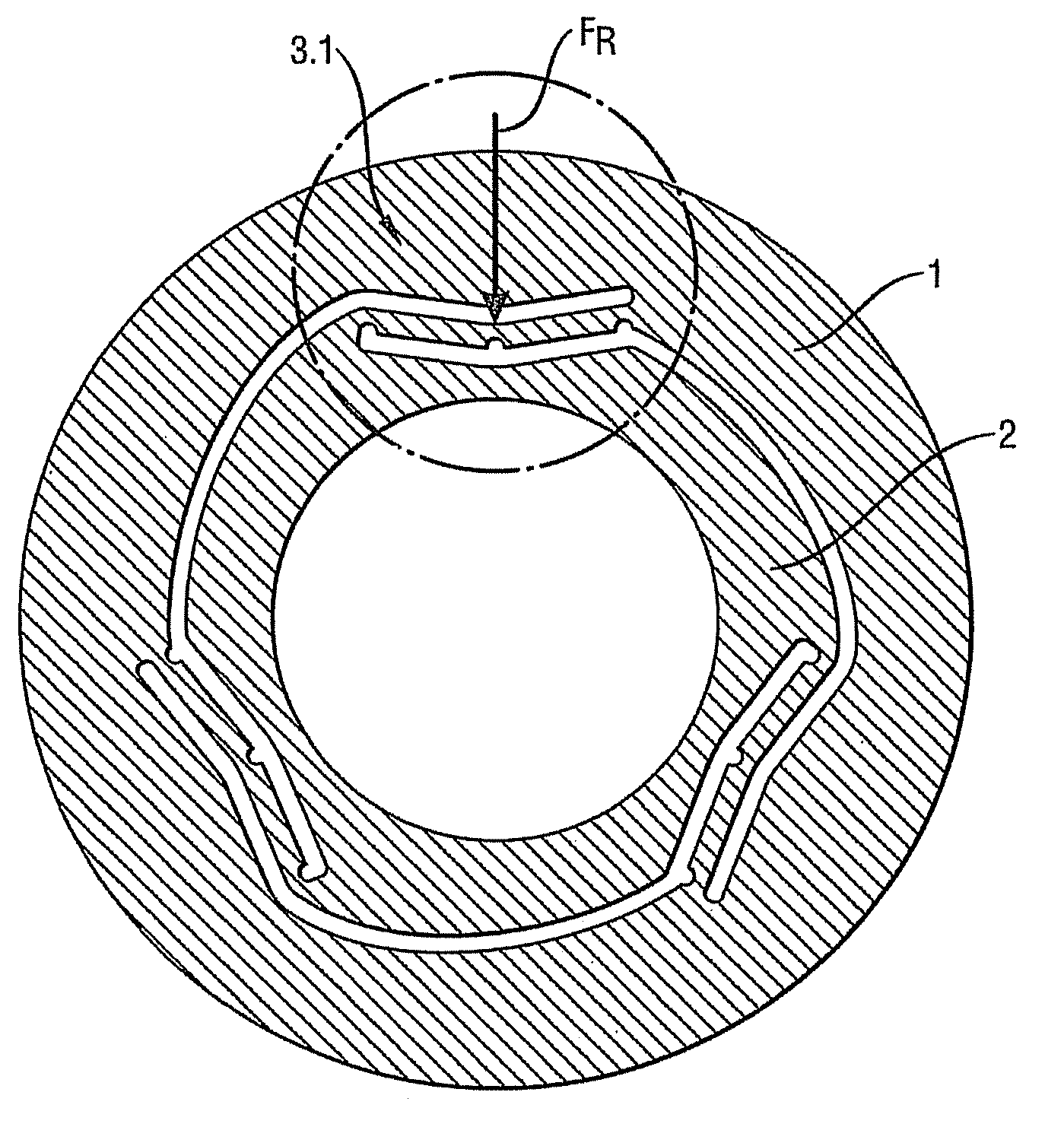

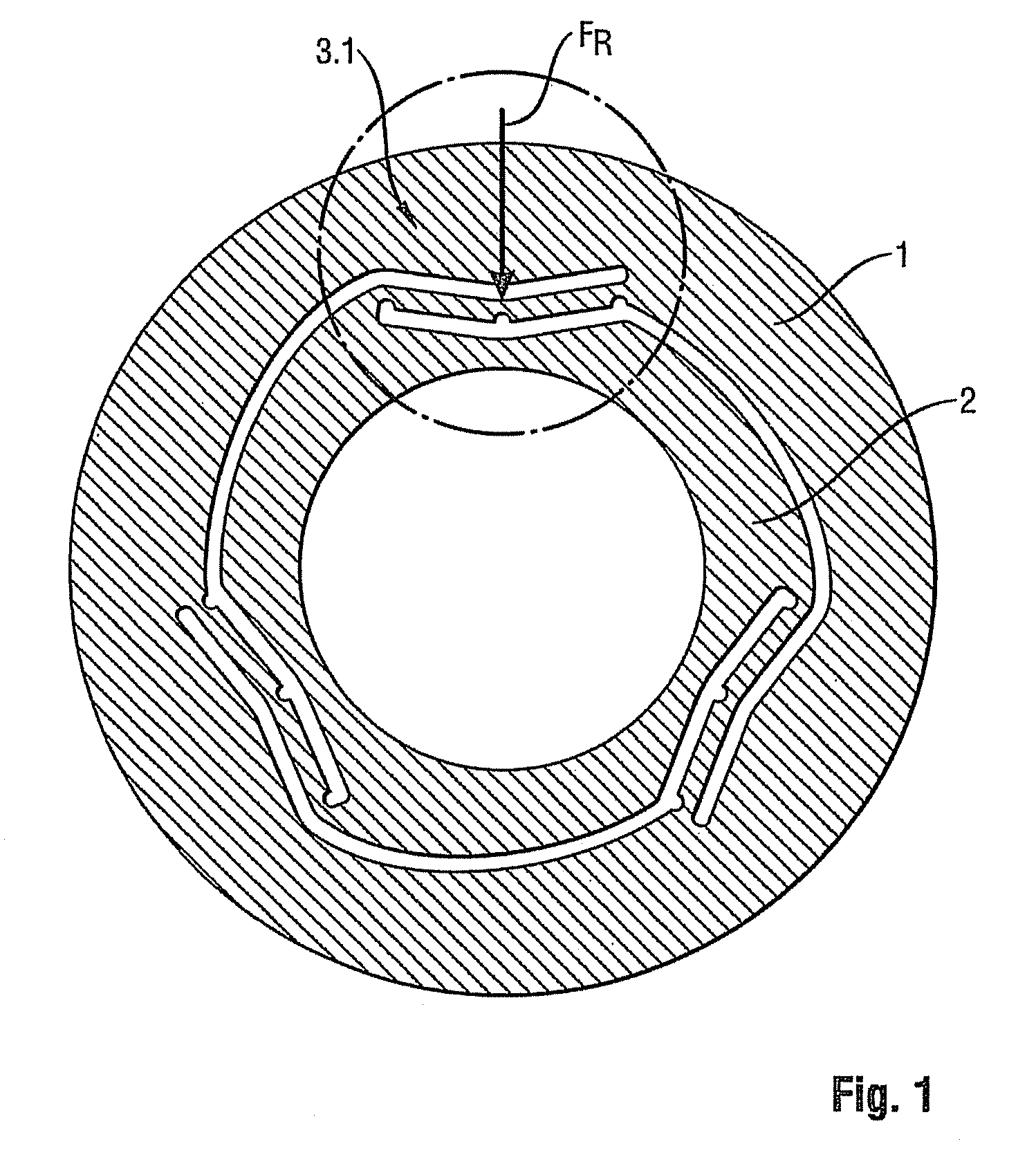

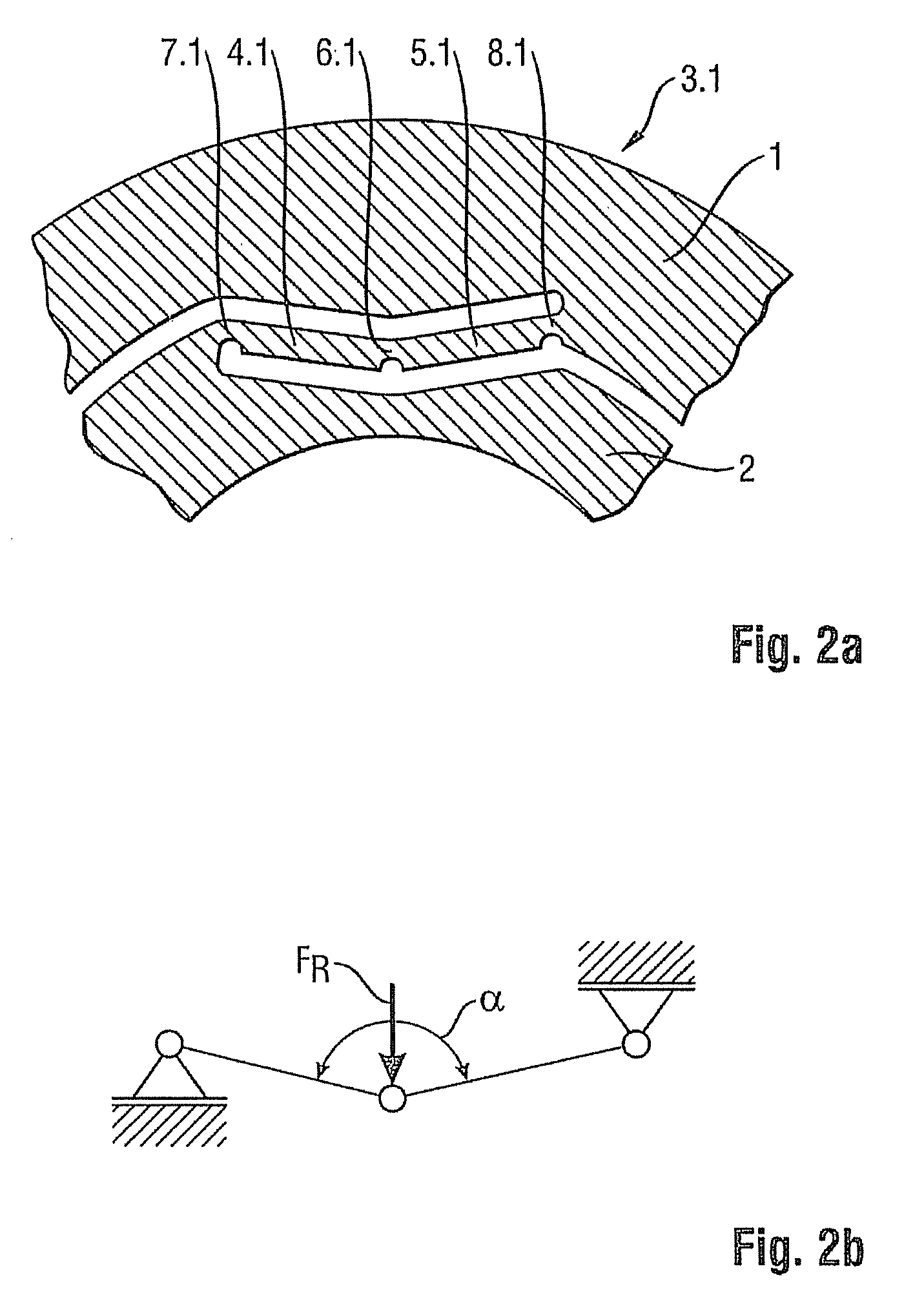

Laterally adjustable optical mount with bent lever manipulator units

The present invention relates to an optical mount, in particular a lens mount, which is divided by a plurality of cuts in the mount material into a stationary outer mounting ring, a laterally adjustable inner mounting ring and three bent lever manipulator units which are offset by 120° relative to one another and which comprise a bent lever having a first element, one end of which is connected by way of a bent lever flexure hinge to one end of a second element, the other end of the first element being connected to the inner mounting ring, the other end of the second element being connected to the outer mounting ring, and with the first and second elements enclosing a bent angle smaller than 180°. By manipulating the three bent lever manipulator units, any center position of the inner mounting ring can be adjusted relative to the center of the outer mounting ring within an intended displacement range.

Owner:JENOPTIK OPTICAL SYST

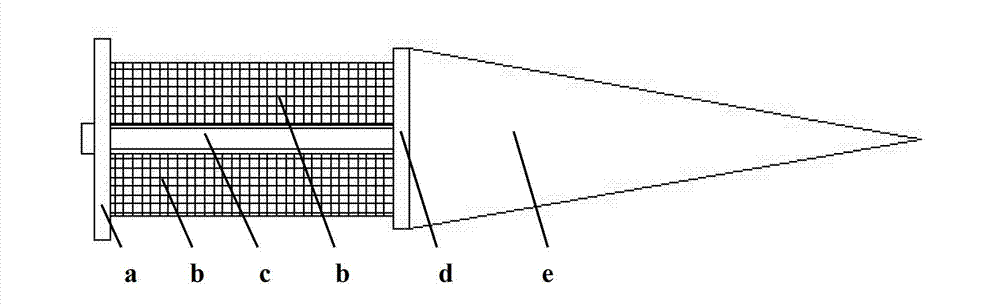

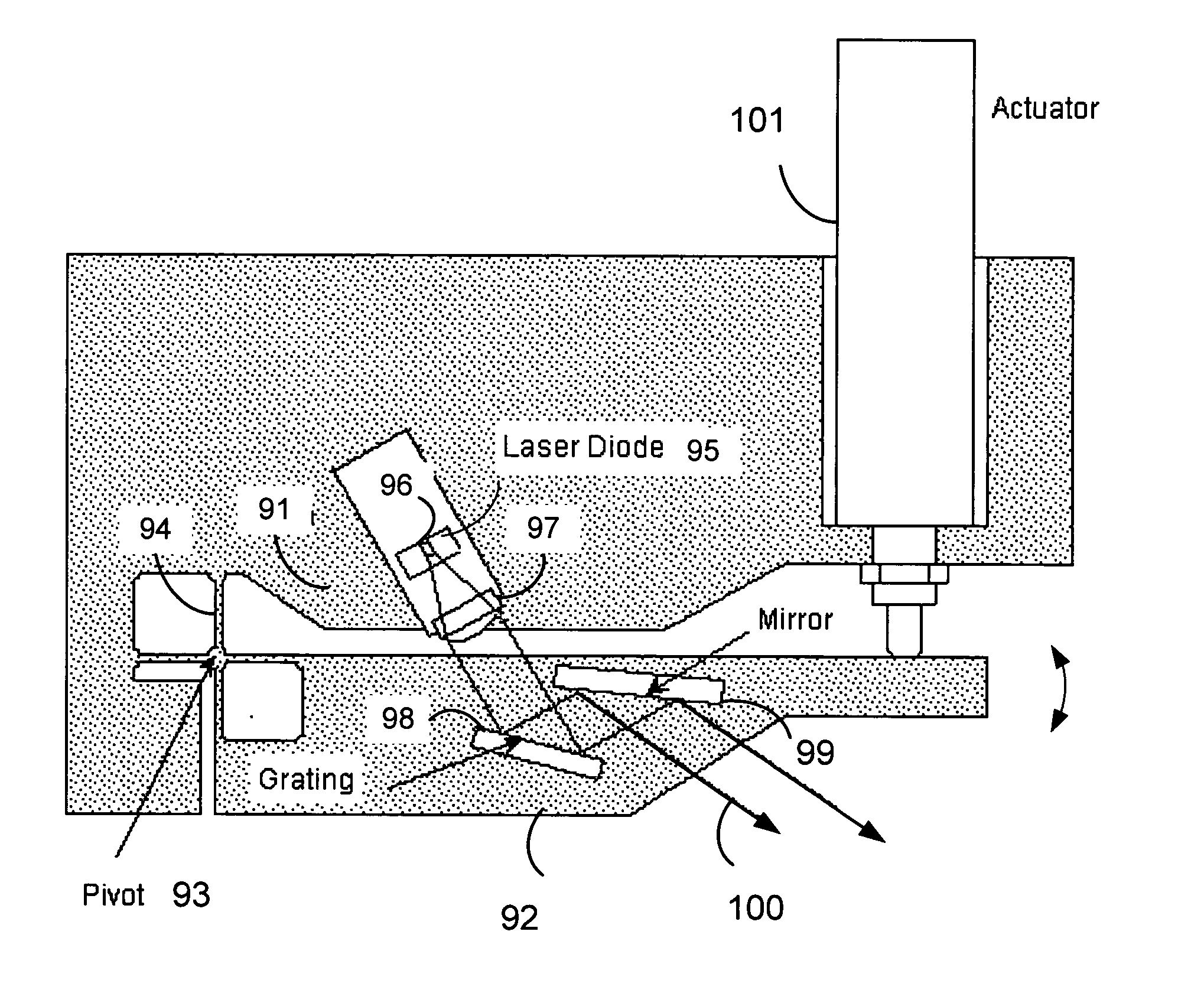

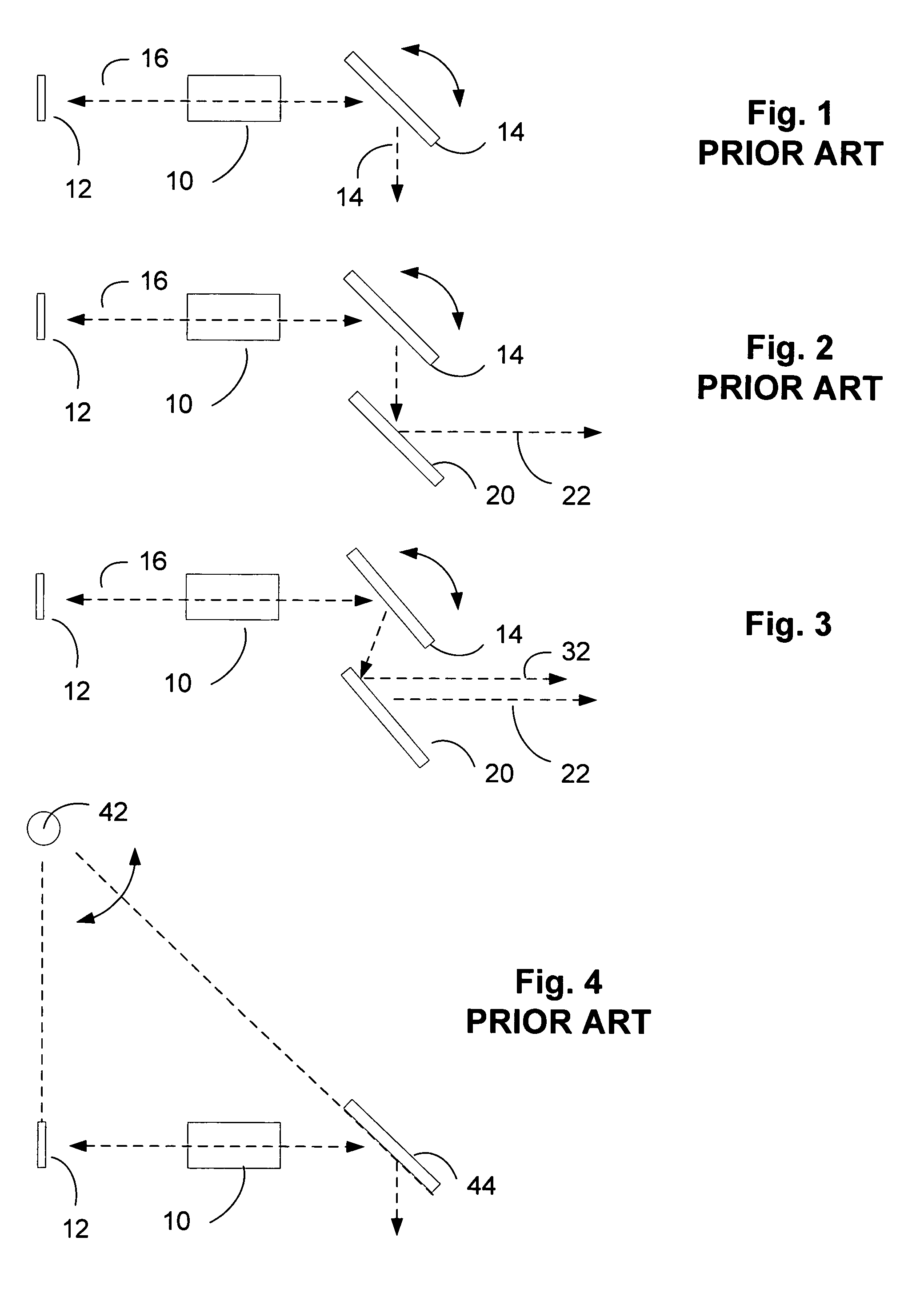

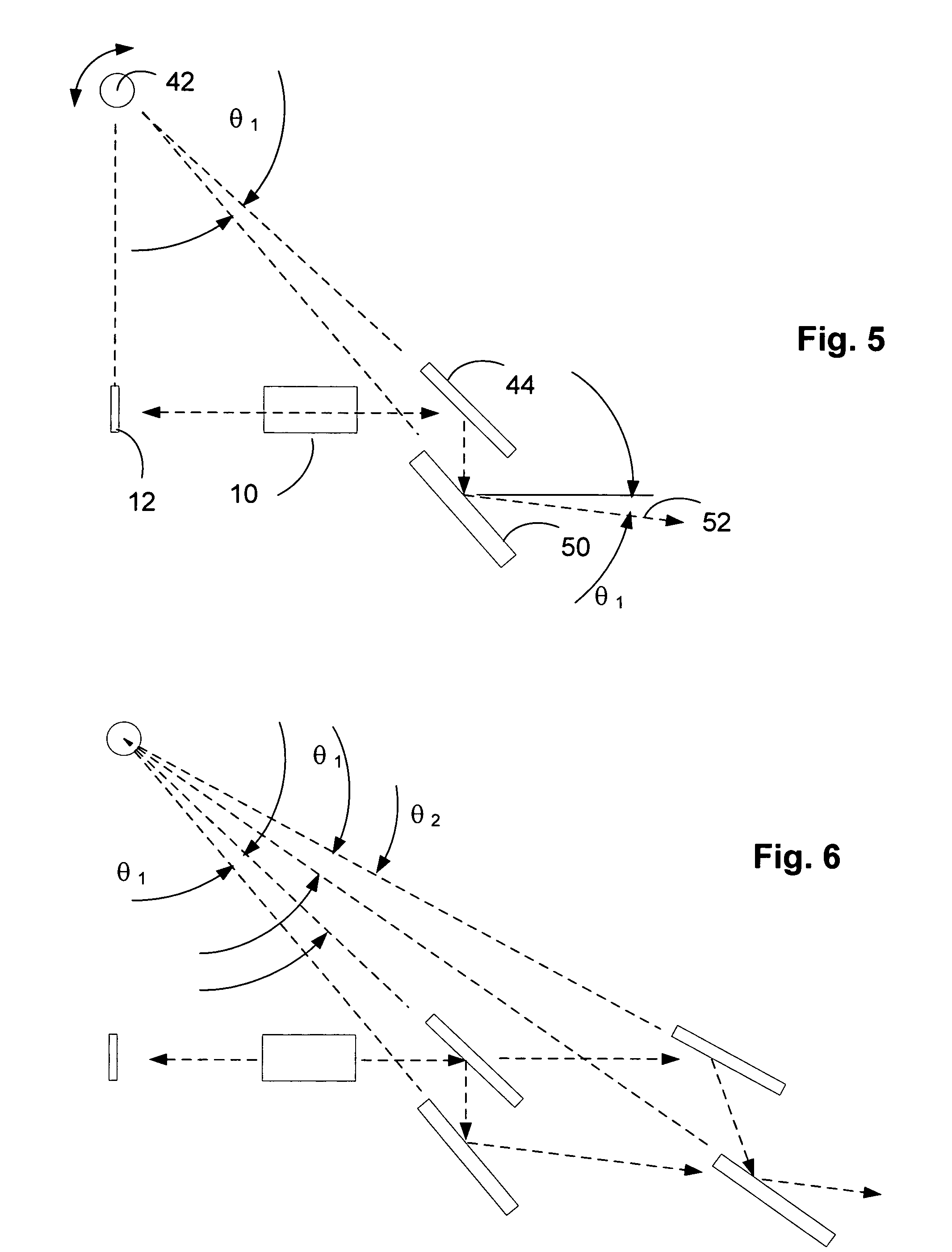

Tunable laser

InactiveUS20060227821A1Wide tuning rangeFew and with closely controlled mode hopLaser detailsSemiconductor lasersGratingFlexure hinges

Owner:COHERIX

Inertial linear piezoelectric motor

ActiveCN109039149AImprove efficiencyReduce unwanted frictionPiezoelectric/electrostriction/magnetostriction machinesHarmonicEngineering

The invention relates to an inertial linear piezoelectric motor. Comprises a bottom plate, a slider, a sliding rail, two mass blocks and a piezoelectric stack; The bottom plate is an elongated plate,one end of which is connected with a slider, and the other end of which is connected with a vertical structure part and a horizontal structure part through a flexure hinge. The vertical structure andthe horizontal structure are hollow rhombus structure with the same structure. The piezoelectric stack is arranged in the hollow rhombus structure of the vertical structure part; the piezoelectric stack is arranged in the hollow rhombus structure of the vertical structure part; The slider is fitted on the slide rail to realize linear sliding along the slide rail. When a harmonic signal of a firstorder frequency is inputted to the piezoelectric stack to produce a first order resonant mode, the whole inertial linear piezoelectric motor moves to the right, and when a harmonic signal of a secondorder frequency is inputted to the piezoelectric stack to produce a second order vibration mode, the whole inertial linear piezoelectric motor moves to the left; As that frequency of the harmonic signal apply to the piezoelectric stack is changed, different vibration mode of the motor can be generated and the movement direction of the motor can be changed.

Owner:HEFEI UNIV OF TECH

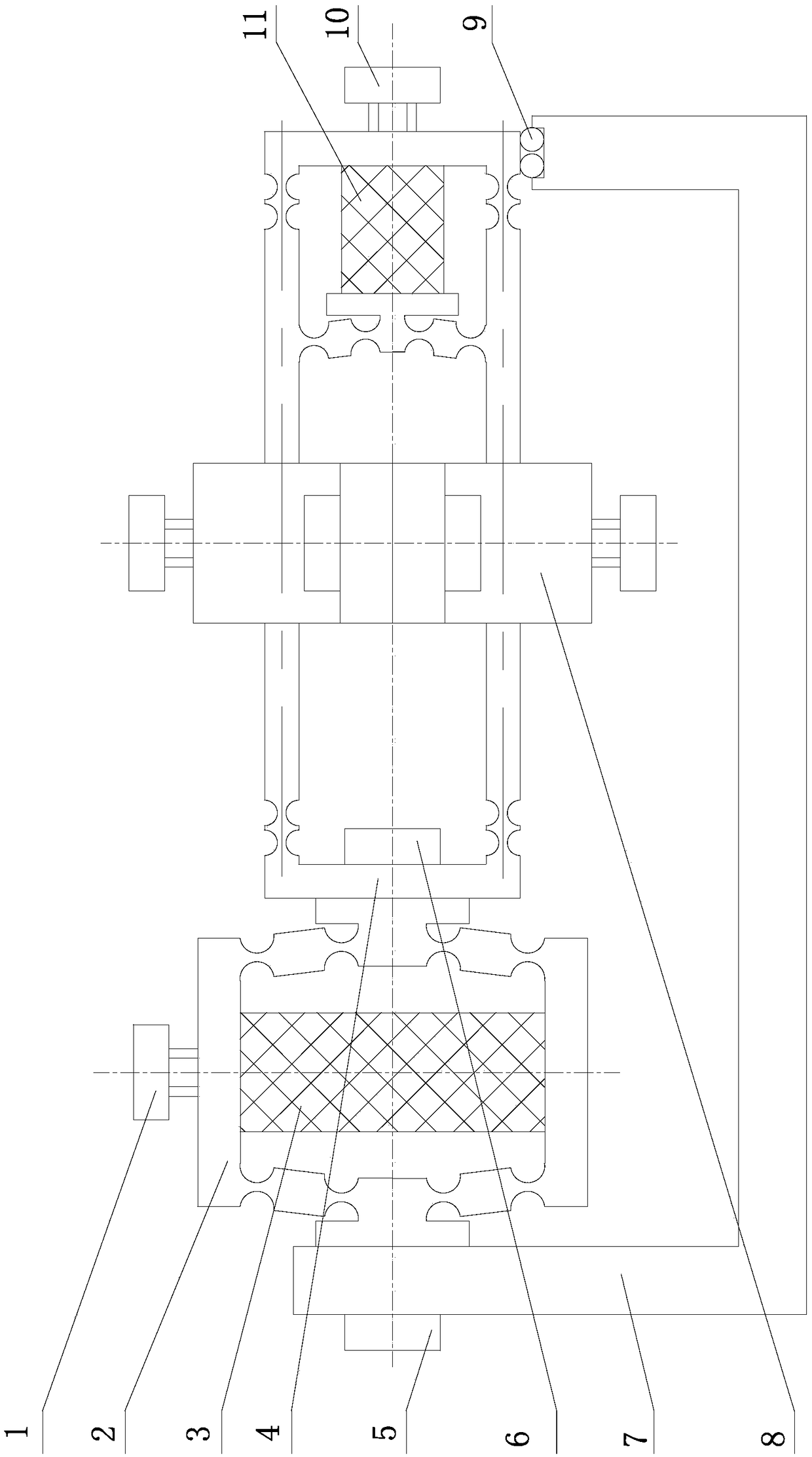

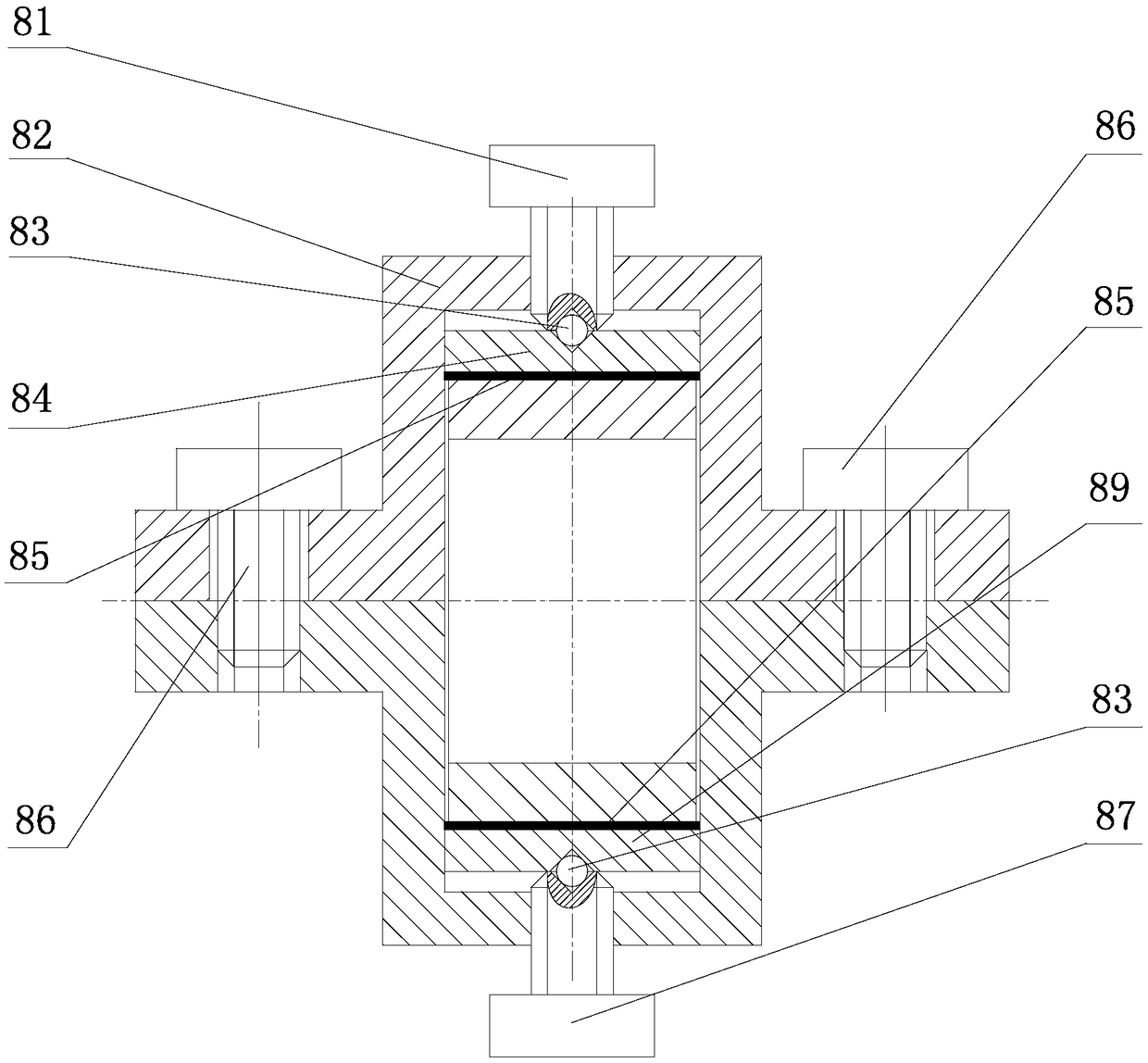

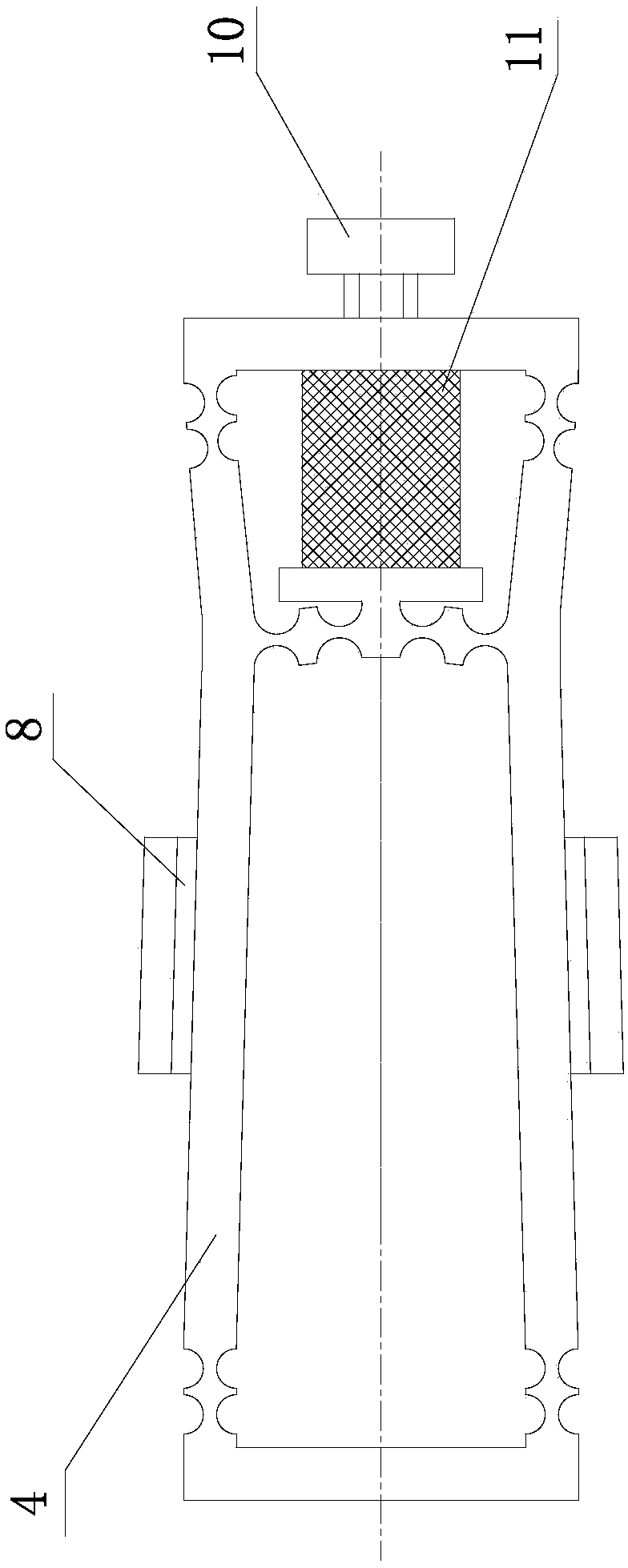

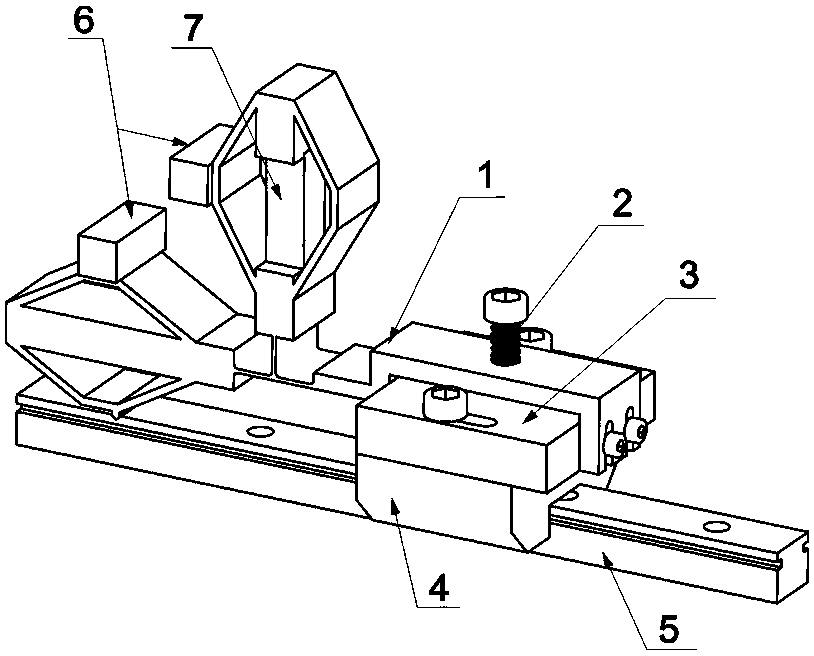

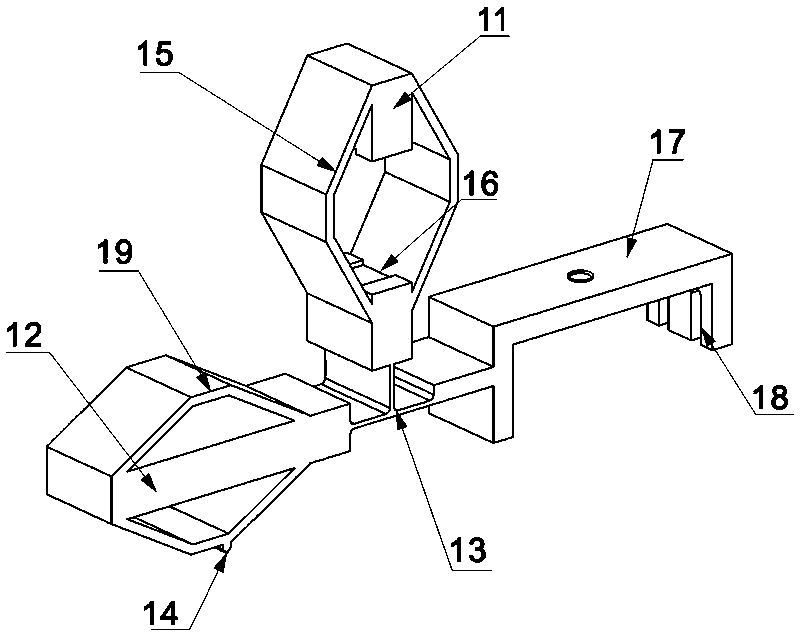

A device and a method for restraining the backward motion of a parasitic piezoelectric actuator by an arc-shaped structure hinge

PendingCN109217717AOvercoming fallbackImprove motion stabilityPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric actuatorsFlexure hinges

The invention relates to a device and a method for restraining the backward motion of a parasitic piezoelectric actuator by an arc-shaped structure hinge, belonging to the field of precision positioning. The driving unit and the initial gap adjusting unit of the device are respectively connected with the base through screws. The initial clearance between the arc-shaped flexure hinge in the drive unit and the guide slider can be adjusted by rotating the knob of the horizontal fine-tuning mechanism. When the driving voltage of the piezoelectric stack drops rapidly in a certain initial gap, the frictional force of the arc-shaped flexure hinge caused by elastic recovery can balance the frictional force of the arc-shaped flexure hinge, thereby effectively restraining the backward motion and greatly improving the motion stability of the piezoelectric actuator. The invention has the advantages of simple structure, convenient control and high resolution of the parasitic motion principle inherited driver, effectively eliminates the backward phenomenon, realizes the horizontal steady movement, and improves the overall output performance of the parasitic motion principle piezoelectric driver.

Owner:JILIN UNIV

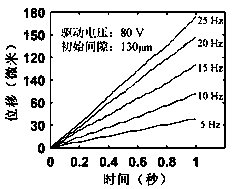

Bionic soft dexterous hand

The invention relates to a bionic soft dexterous hand. The bionic soft dexterous hand comprises a palm and five fingers. A plurality of palm side oval groove openings are arranged on the palm sides ofa forefinger, a middle finger, a ring finger and a small finger. A lateral oval groove opening is evenly arranged on the heels of the forefinger, the ring finger and the small finger facing the middle finger. The palm side oval groove opening is arranged on the side of a tiger mouth, and a lateral oval groove opening is arranged on the heel of a big toe. The palm side oval groove openings and thelateral oval groove openings are evenly flexible hinges and provided with threading holes. The threading holes penetrate traction lines. One end of the traction lines are fixed at a fingertip, the other end of the traction lines are gathered in a palm center and are led out from a wrist after bypassing a threading block set in the palm center. The flexure hinges are deformed by the stretching ofthe traction lines to achieve the bending movement of five fingers laterally or toward the palm center. Compared with the prior art, the bionic soft dexterous hand achieves manipulation actions and releases of hand objects such as grasping, holding, pinching and clamping by means of the coordination between fingers, has a rigid and soft combination, and is simple and convenient to control

Owner:TONGJI UNIV

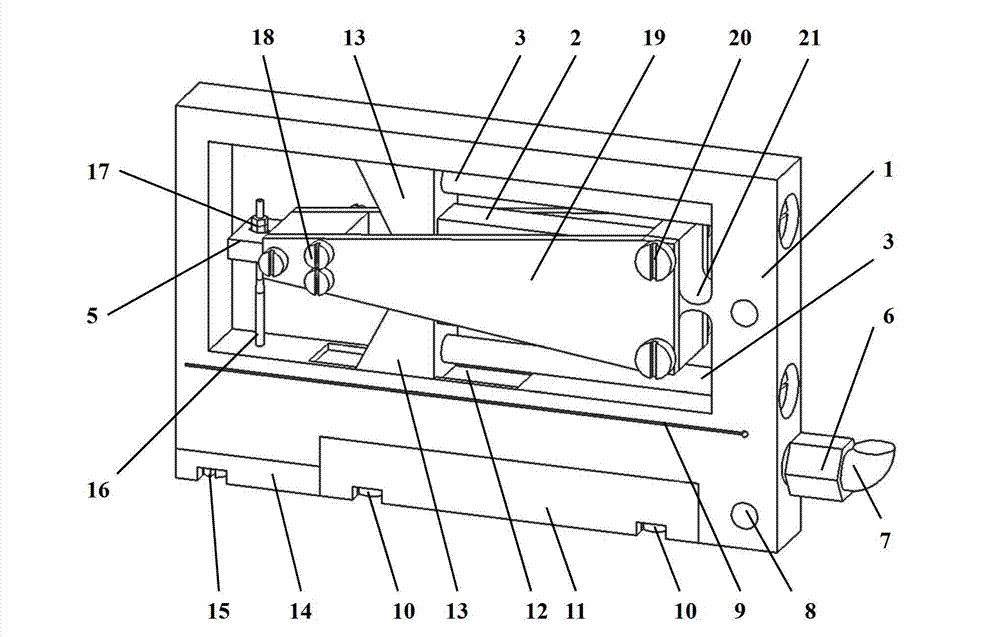

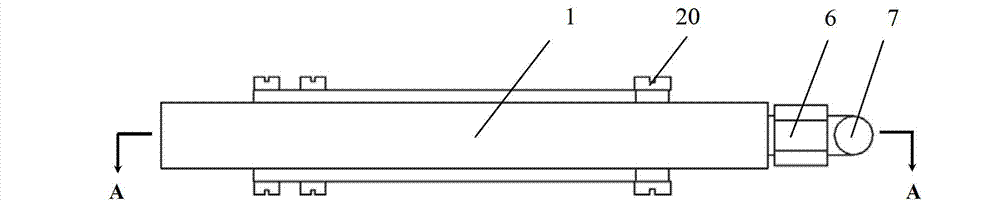

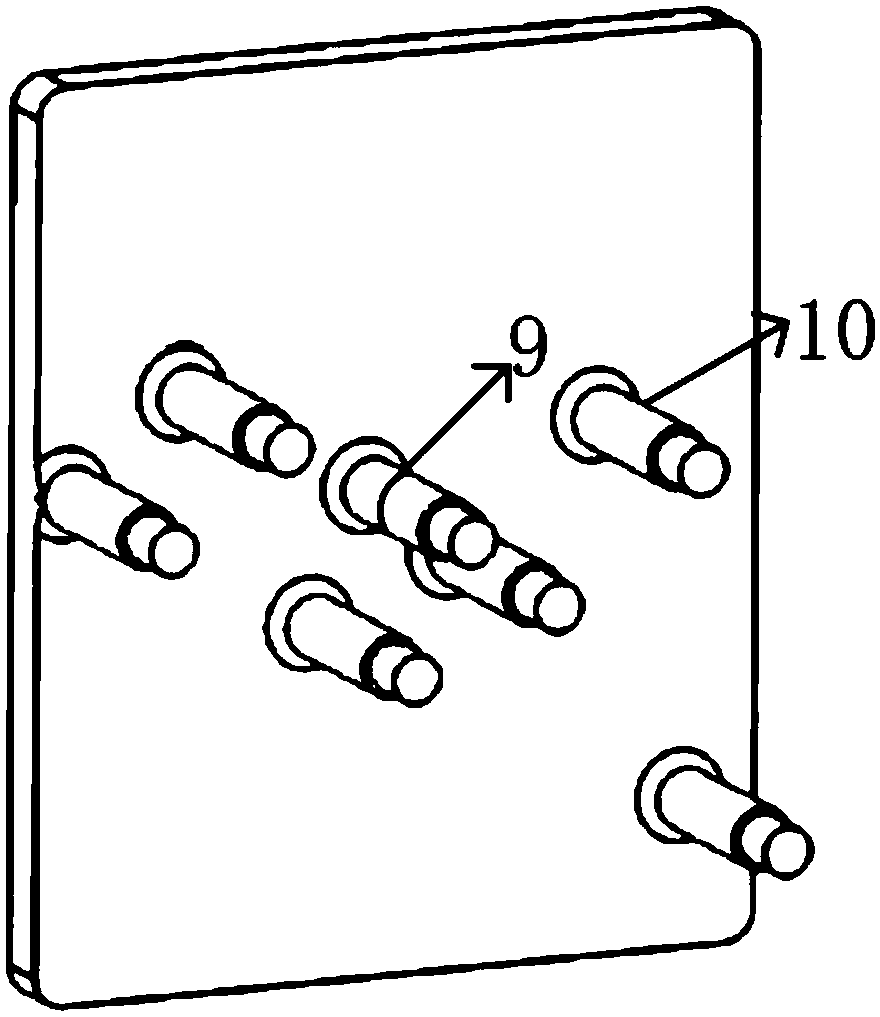

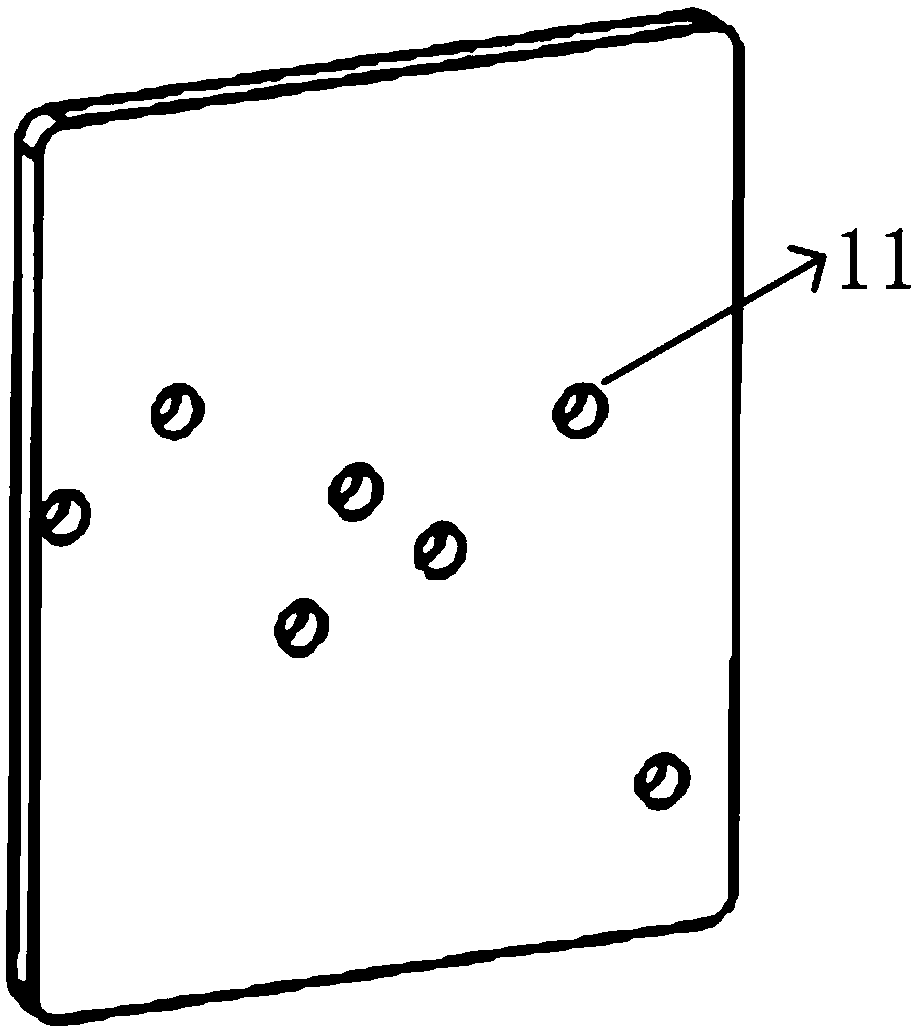

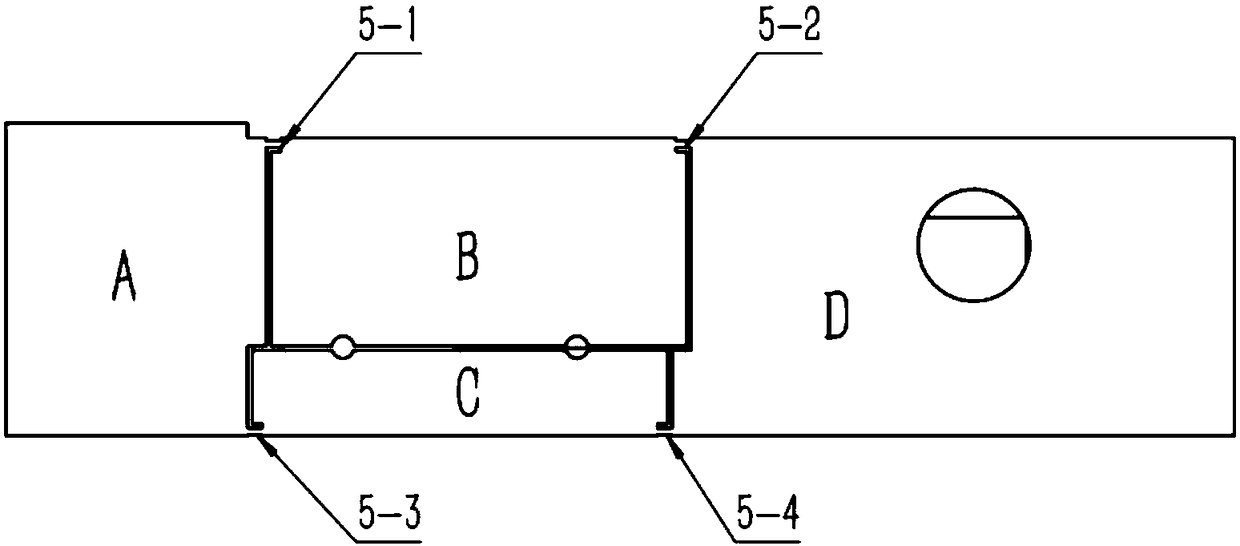

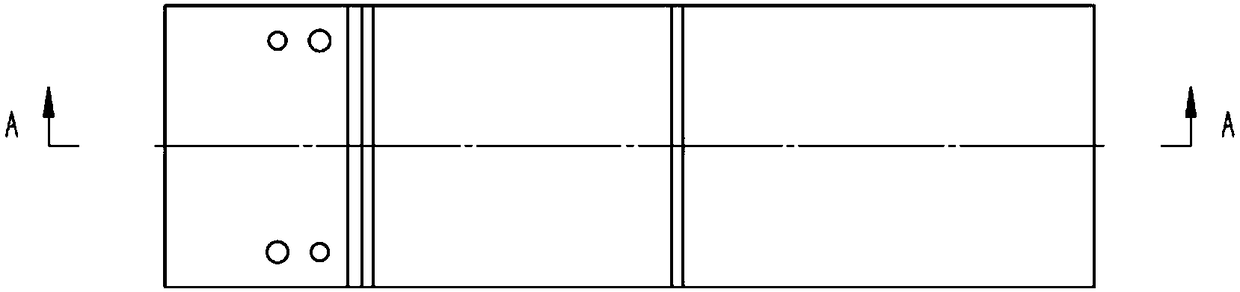

Single freedom degree large-stroke nanometer displacement positioning platform based on flexure hinges

ActiveCN108198588AReduce vertical sizeSmall vertical spaceInstrumental componentsCircular coneEngineering

The invention provides a single freedom degree large-stroke nanometer displacement positioning platform based on flexure hinges. The single freedom degree large-stroke nanometer displacement positioning platform based on the flexure hinges includes a platform main body, wherein the four flexure hinges are arranged on the platform main body, and the platform main body is divided into four parts bythe four hinges, specifically, the area A, the area B, the area C and the area D. The area A is a mobile area, the area B and the area C are stress deformation areas, and the area D is a fixed area. Aleft blind hole and a right blind hole are formed in the two ends of the platform main body, the bottom portion of the left blind hole is a smooth circular cone surface, and a spring pretightening assembly is installed in the left blind hole. The bottom portion of the right blind hole is also a smooth circular cone surface, and a piezoceramic assembly is installed in the right blind hole. The spring pretightening assembly and the piezoceramic assembly constitute an amplifying mechanism. A relatively large vertical displacement under the condition of a small vertical platform size is achieved,and the demand for a large vertical stroke with a small space occasion can be satisfied.

Owner:SANYING MOTIONCONTORL TIANJIN INSTR CO LTD

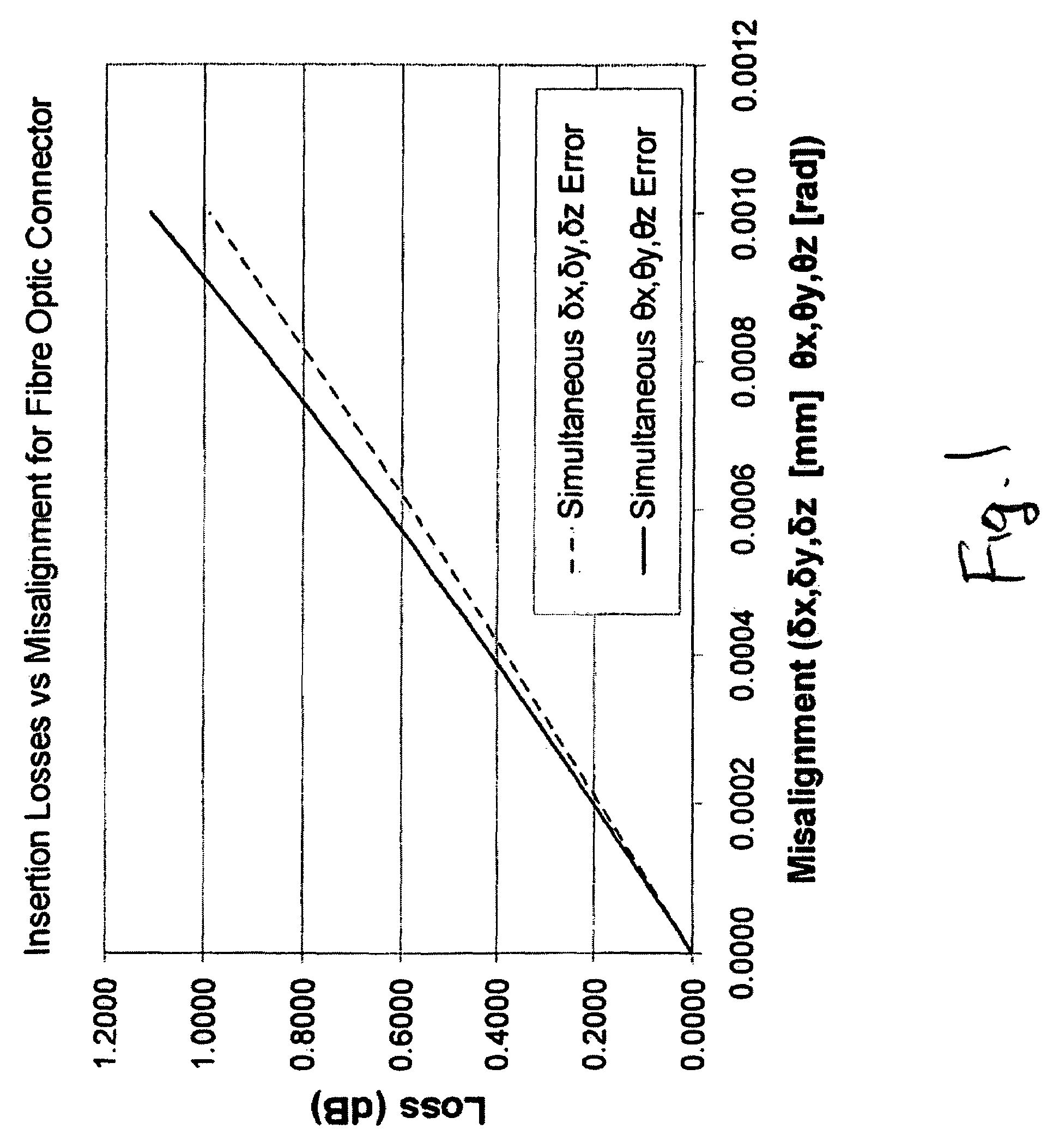

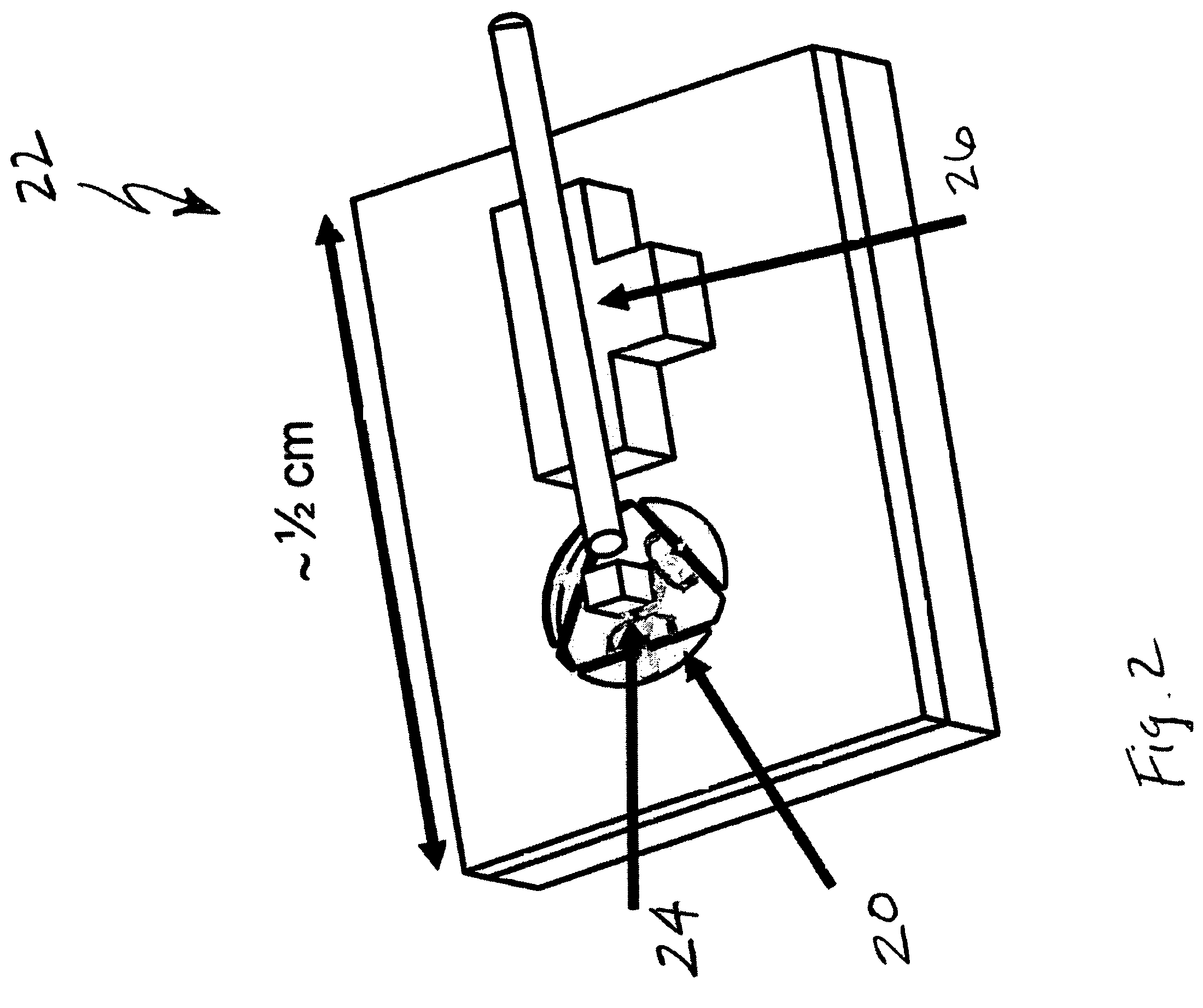

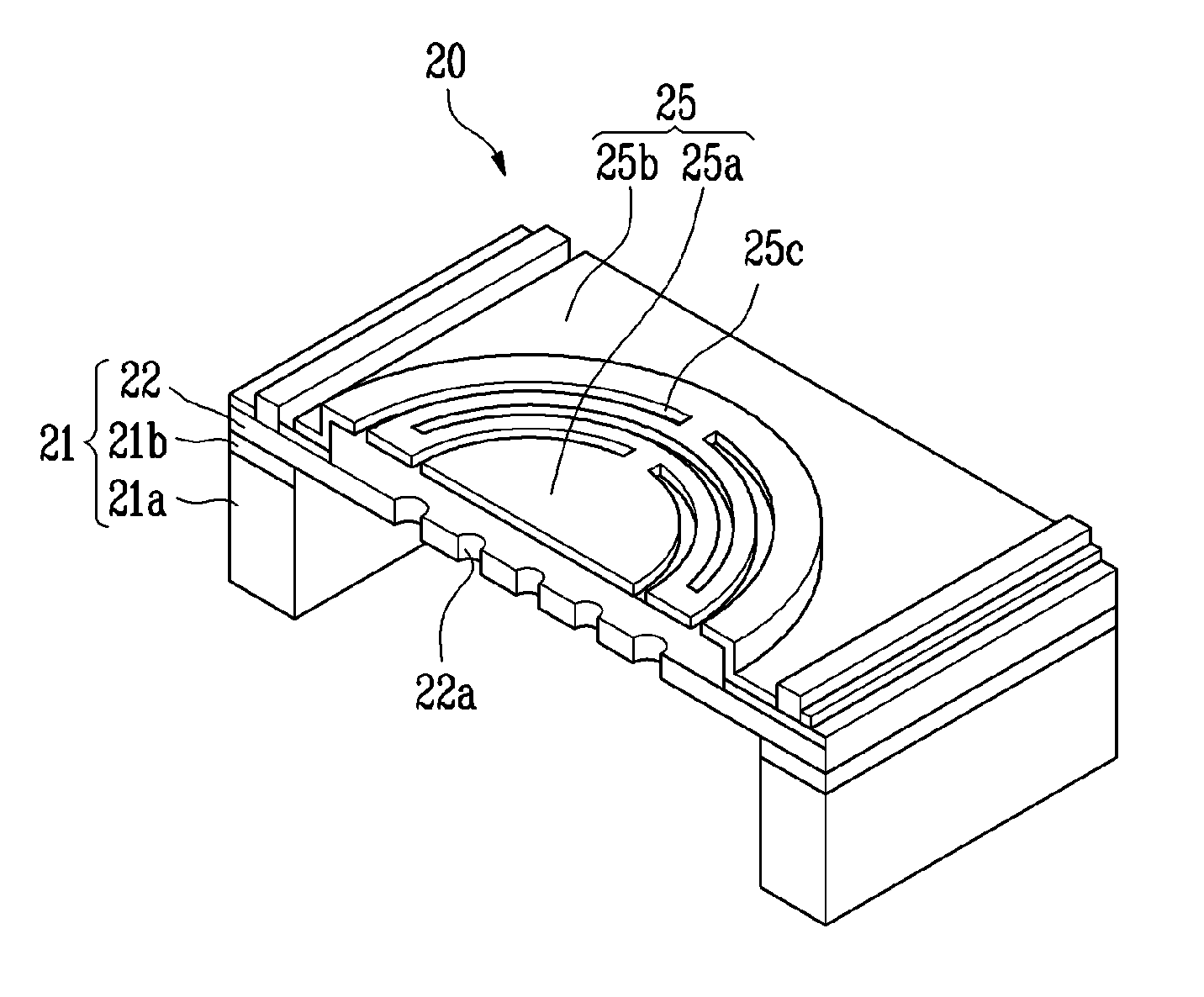

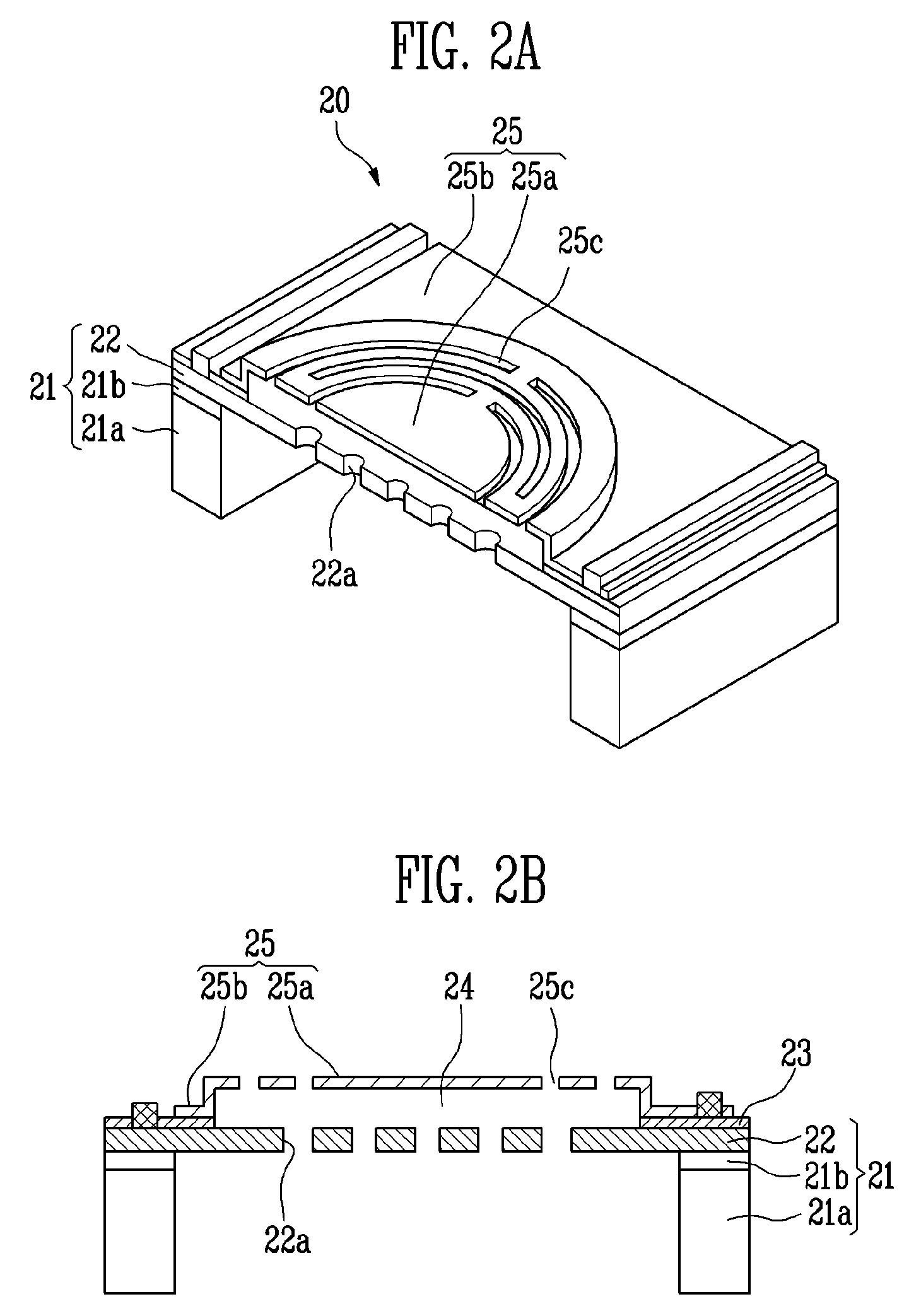

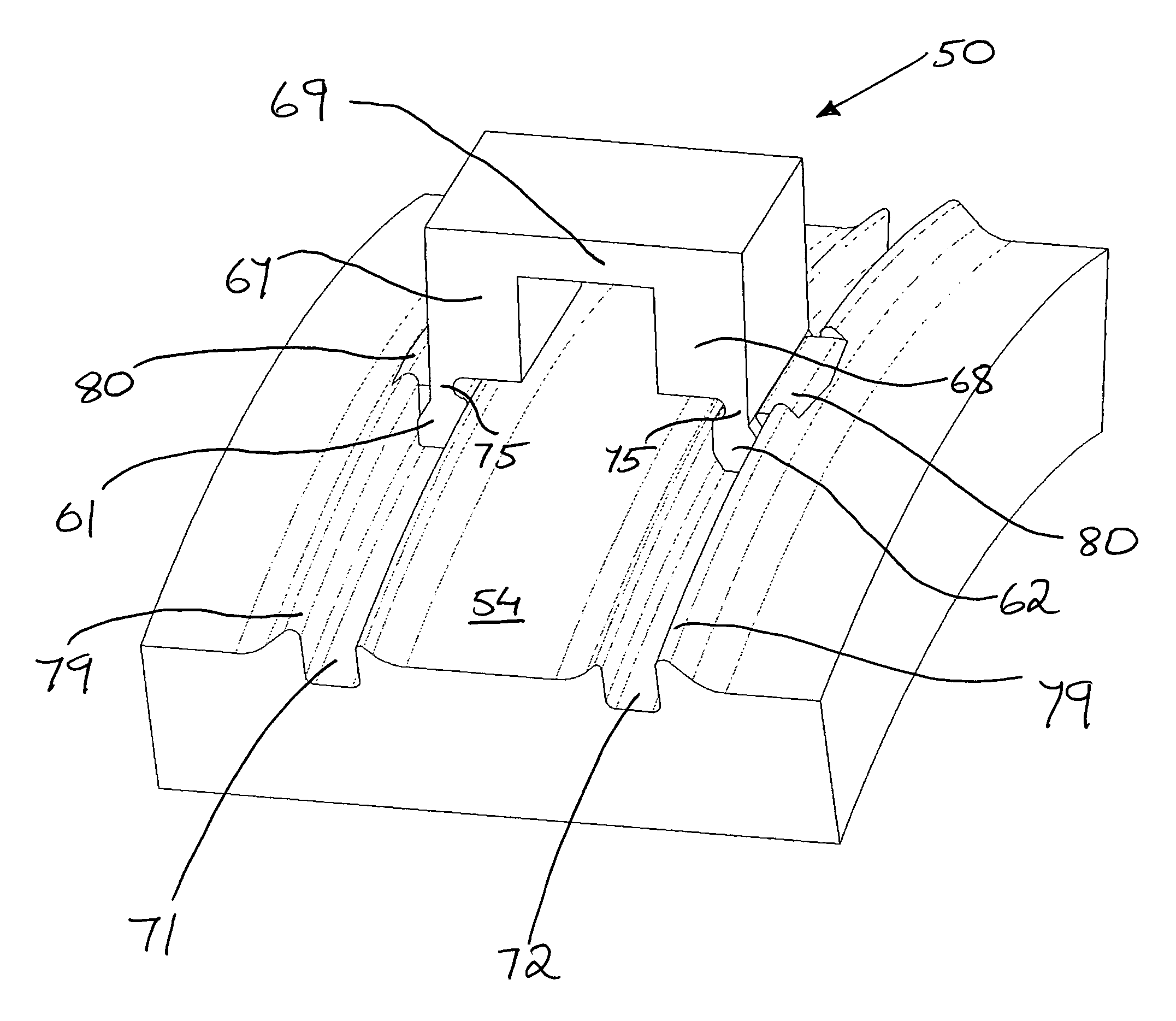

Multiple degree of freedom micro electro-mechanical system positioner and actuator

InactiveUS20060156722A1Magnetic circuitElectrostatic generators/motorsSemiconductor materialsFlexure hinges

A micro electro-mechanical system (MEMS) positioner, including an actuator and method for making the same, includes a stage formed within a first layer of semiconductor material, along with a series of beams, flexure hinges and controlled input thermal actuators. The actuators are operatively engaged with a second layer, and are selectively actuatable to effect longitudinal expansion thereof, so that relative actuation between individual ones of actuators spaced in the planar direction relative to one another is configured to generate controlled movement of the stage within the planar direction, and relative actuation between individual ones of actuators spaced orthogonally to the planar direction relative to one another is configured to generate controlled movement of the stage out of the planar direction. The relative position between the stage and the support is adjustable in each of six degrees of freedom, so that the compliant mechanism forms a quasi-static precision manipulator.

Owner:MASSACHUSETTS INST OF TECH

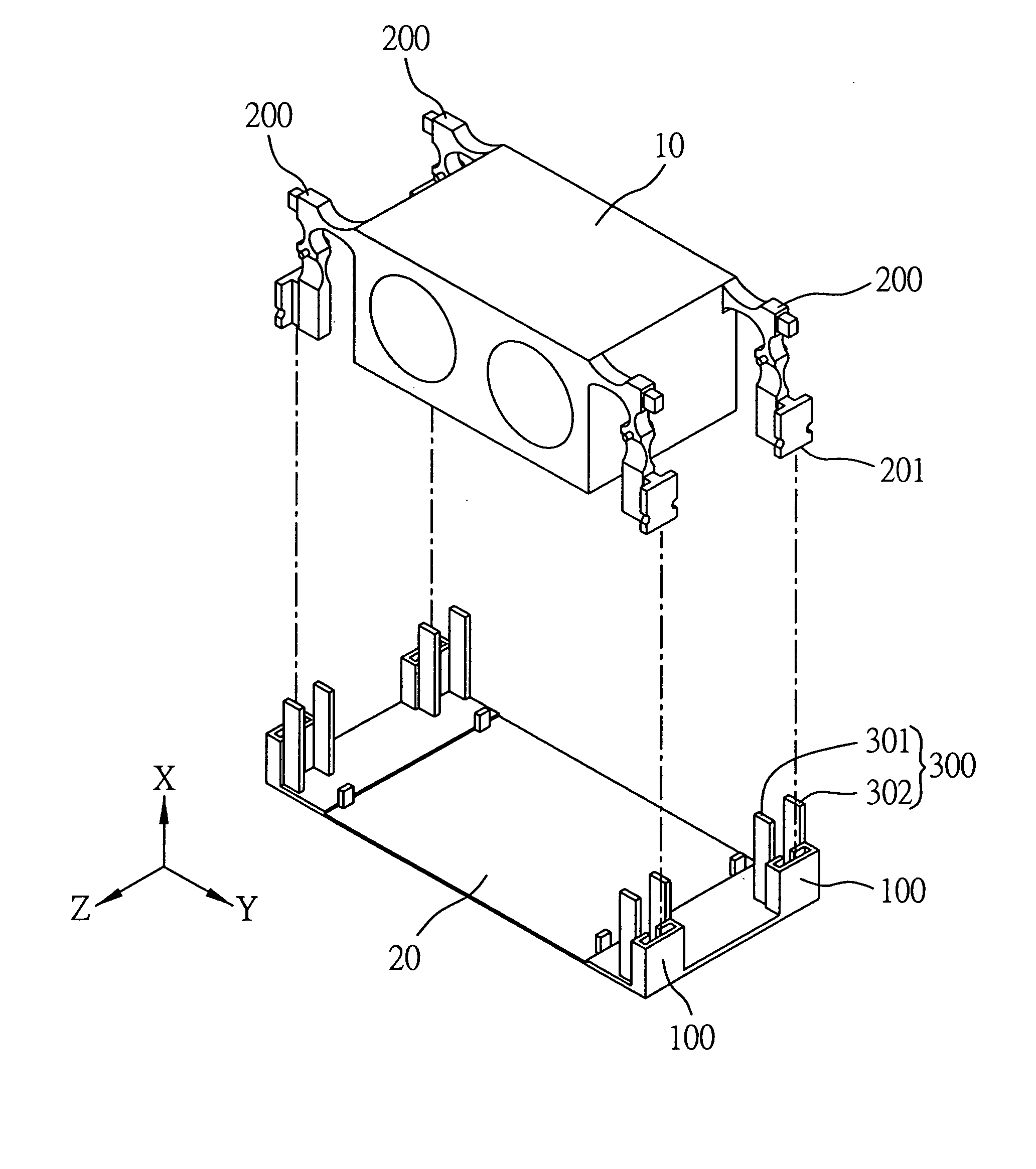

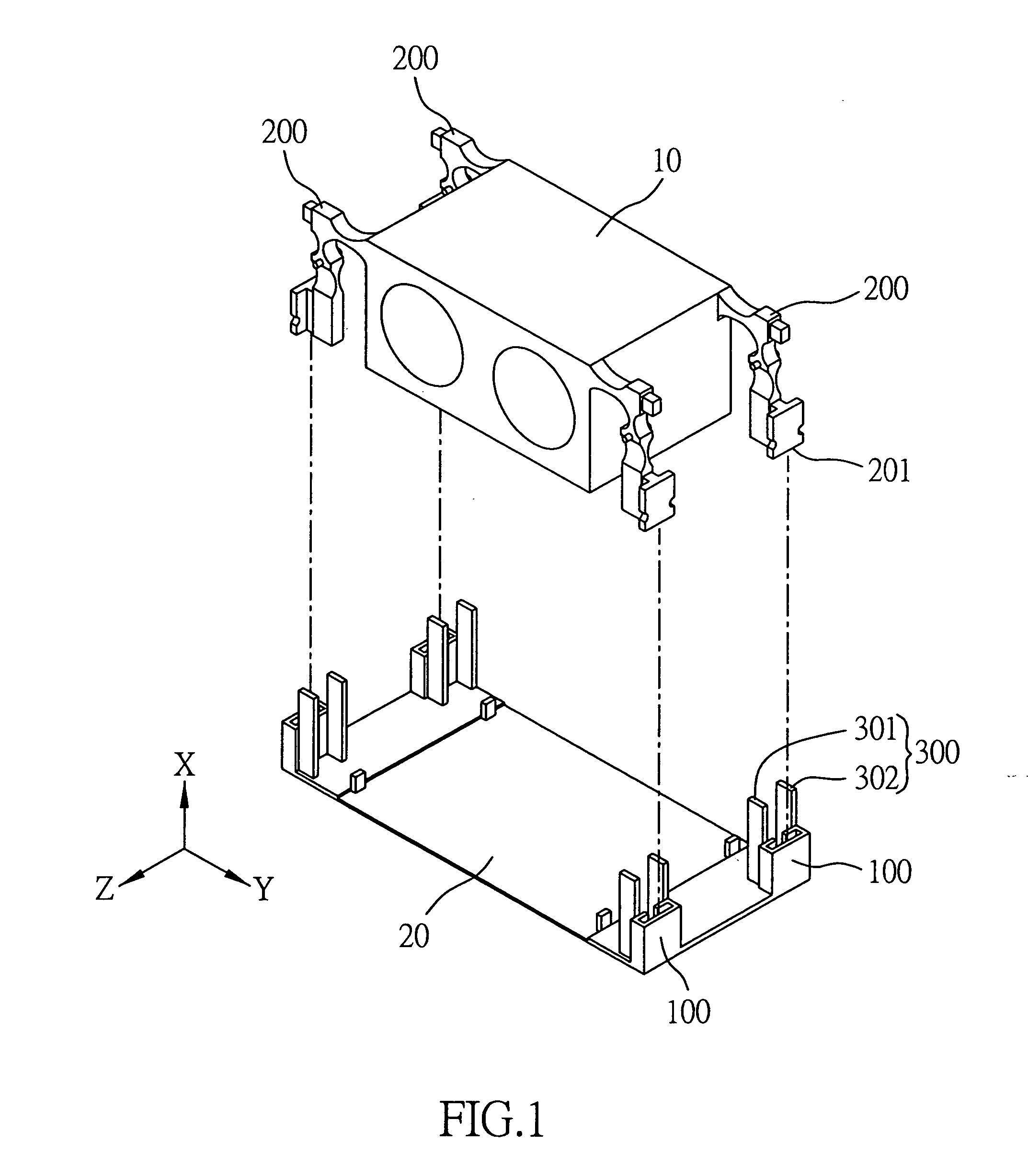

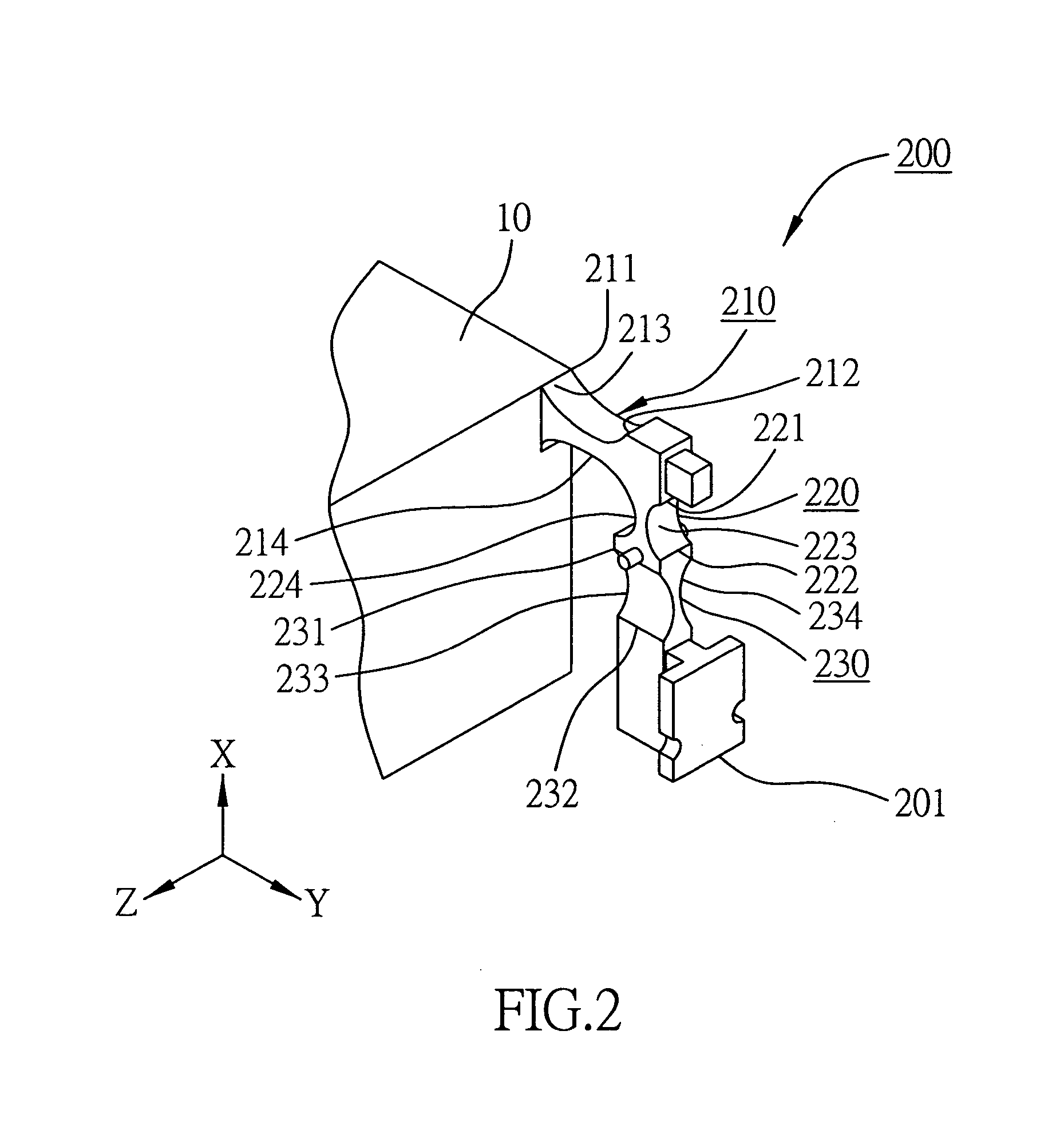

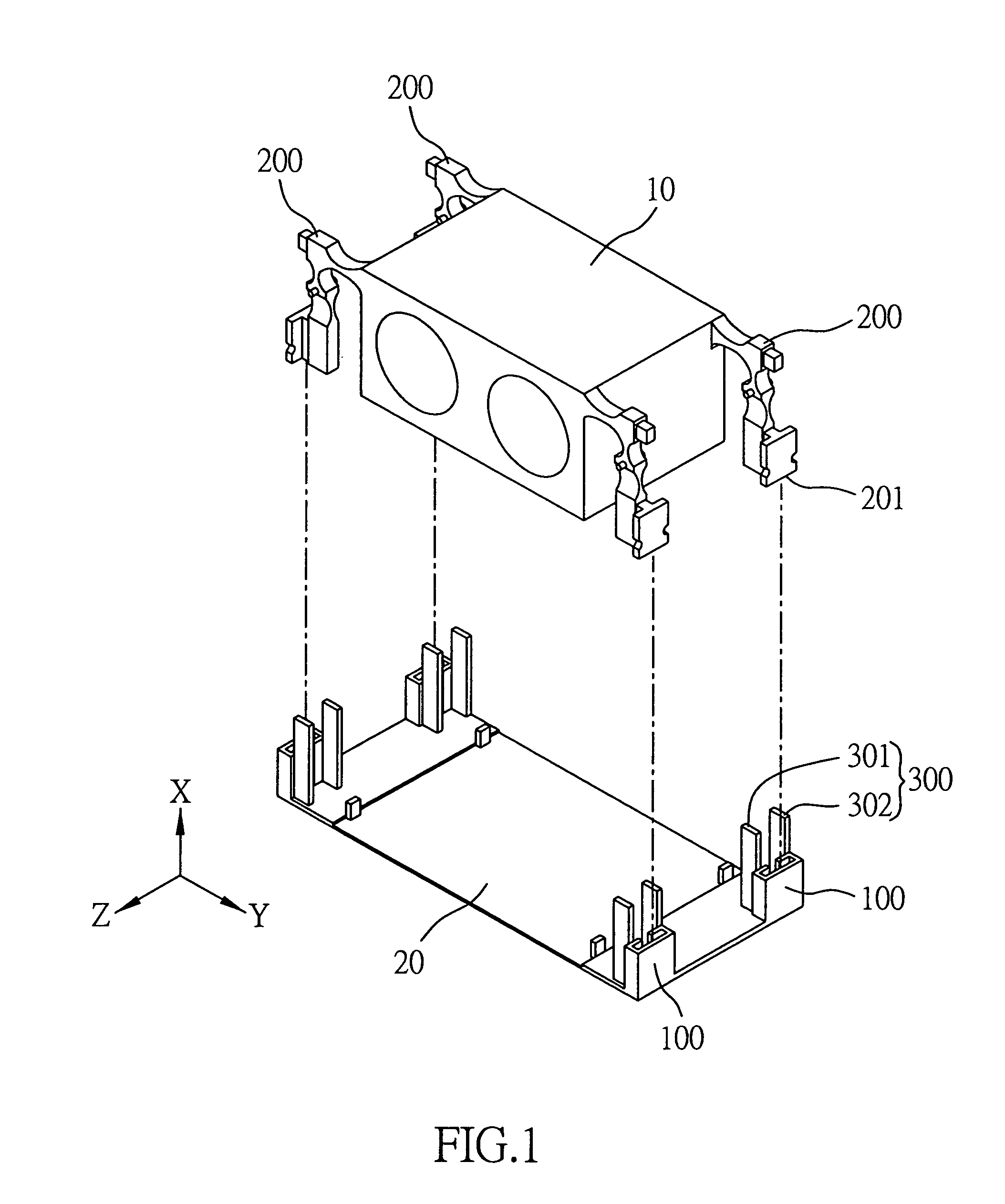

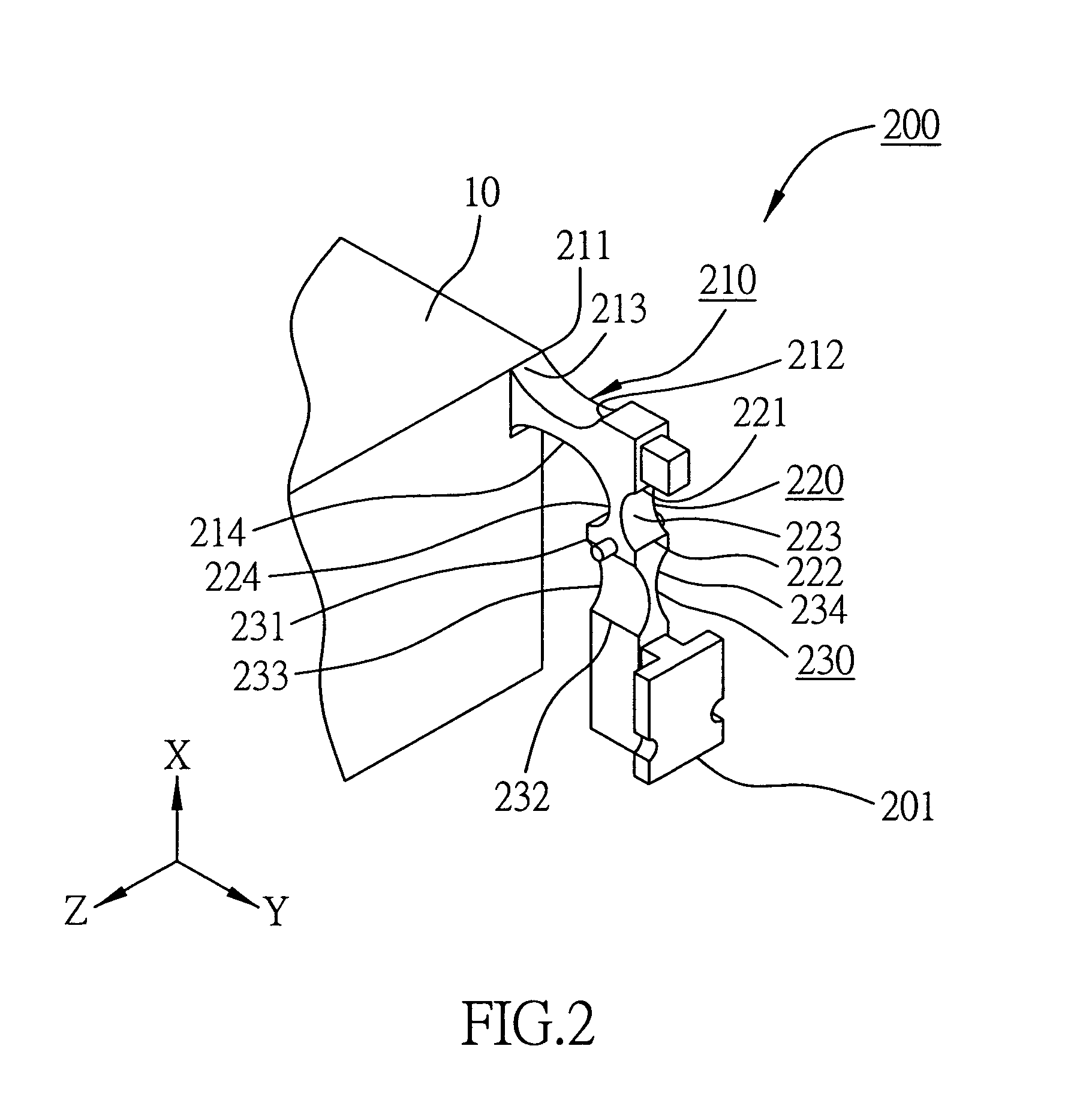

Three-dimensionally vibration-preventing buffering mechanism

A three-dimensionally vibration-preventing buffering mechanism is proposed, which is designed for use in conjunction with a dynamic module for the purpose of buffering the three dimensional vibrations of the dynamic module during operation, and which is characterized by the use of a group of specially-designed chained elastic members, each being composed of at least three integrally-linked flexure hinges whose axes of concavity are oriented respectively in parallel with the three axes of a three-dimensional rectangular coordinate system, so that the vibrations of the dynamic module in all three dimensional directions can be respectively buffered by these flexure hinges to provide a three-dimensional vibration-preventing buffering effect.

Owner:INVENTEC CORP

A stick-slip inertial linear actuator based on friction control of surface microstructure

ActiveCN109039150AIncrease one-way driving forceReduce displacement fluctuationPiezoelectric/electrostriction/magnetostriction machinesFlexure hingesLinear actuator

The invention relates to a sticky-slip inertial linear actuator based on friction control of surface microstructure, which relates to an actuator to solve the problems that the output displacement andoutput force of the existing piezoelectric inertial actuator are small and the displacement fluctuation of the actuator is large. The actuator comprises a flexure hinge amplifying mechanism, a piezoelectric stack actuator, a guide rail, a base, a mover and support balls. A magnify mechanism of that flexure hinge is fixed on the base, The piezoelectric stack actuator is installed on the flexure hinge amplifying mechanism, the piezoelectric stack actuator exerts a pretightening force through a pretightening connector screwed on the flexure hinge amplifying mechanism, a micro-structure is machined on the guide rail, and a friction material layer with self-lubricating characteristics in contact with the micro-structure is fixedly connected on the surface of the mover; Micro-structure can makethe forward friction large, reverse friction small, friction material layer with micro-structure, reduce the displacement of the actuator reverse backhaul displacement, improve the operation stability, and increase the unidirectional load capacity of the actuator. The present invention is used in the field of precision drive.

Owner:NINGBO UNIV

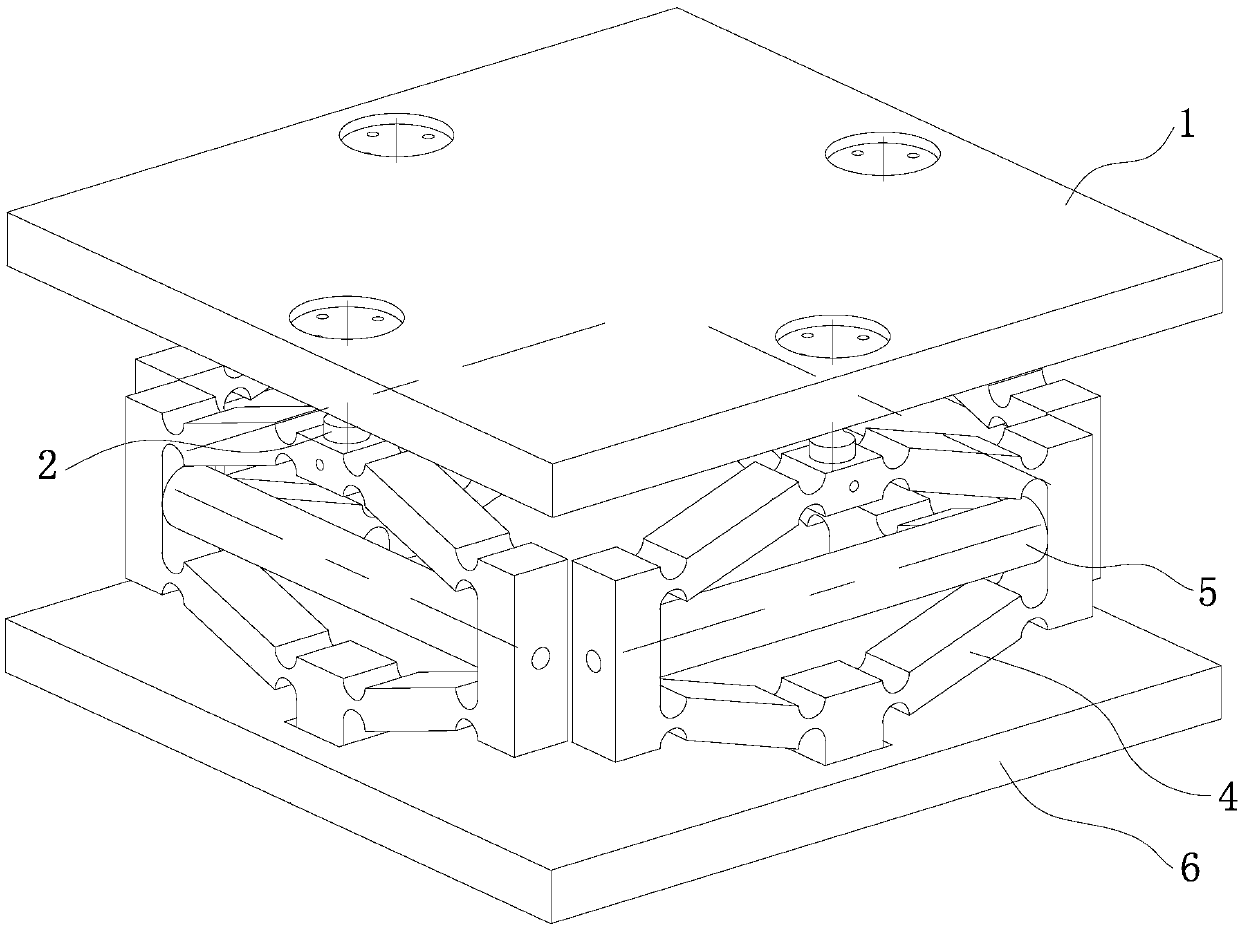

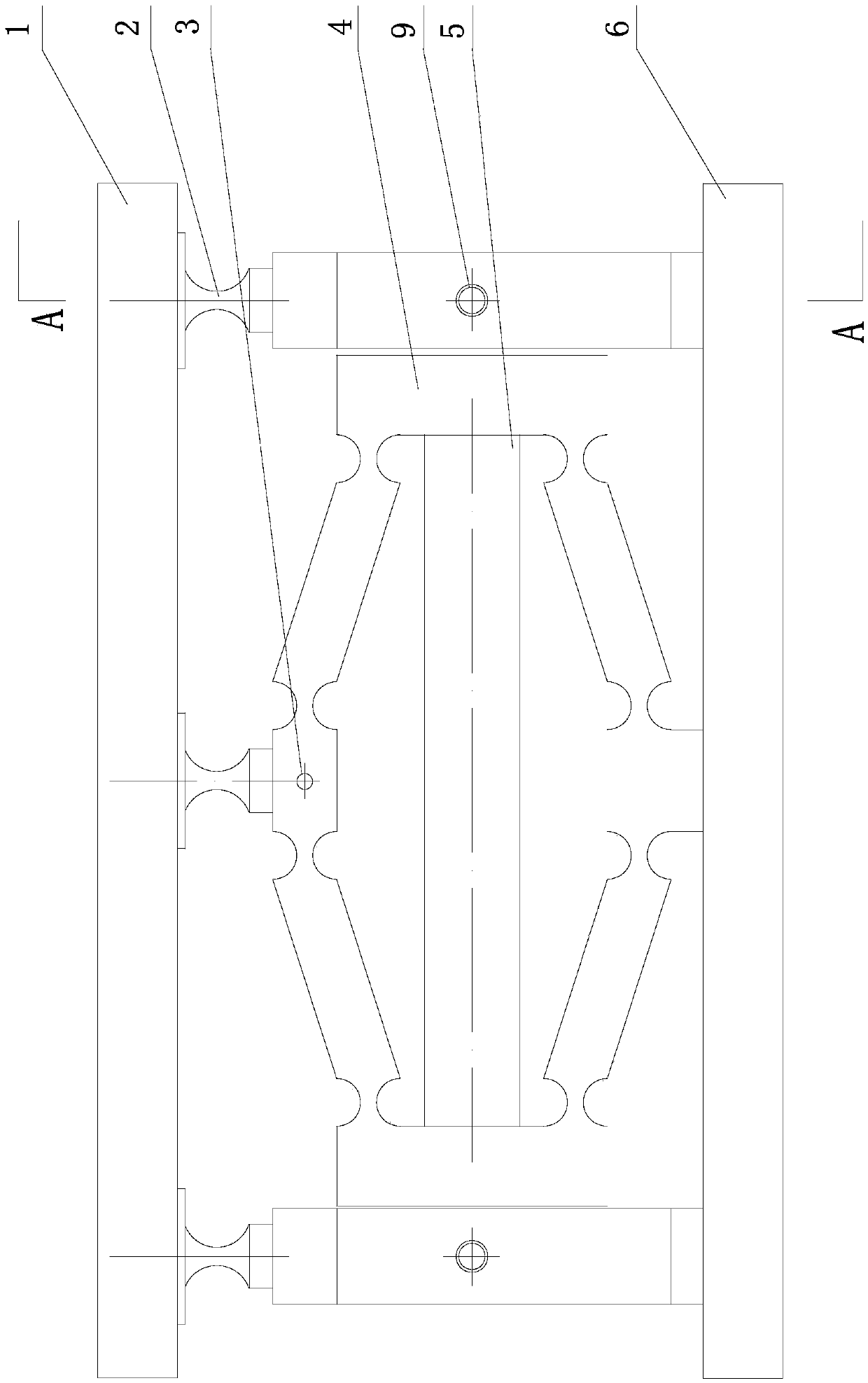

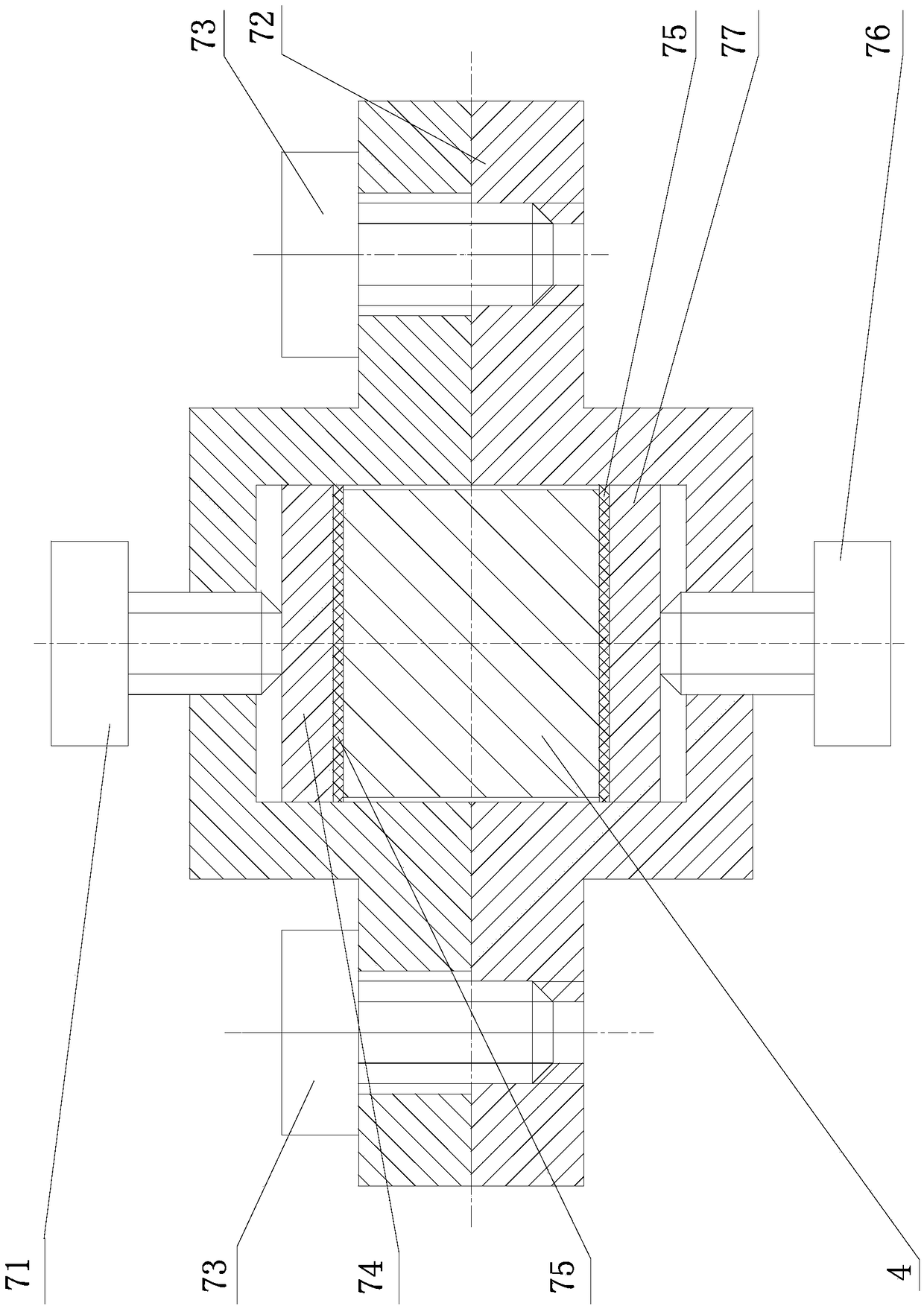

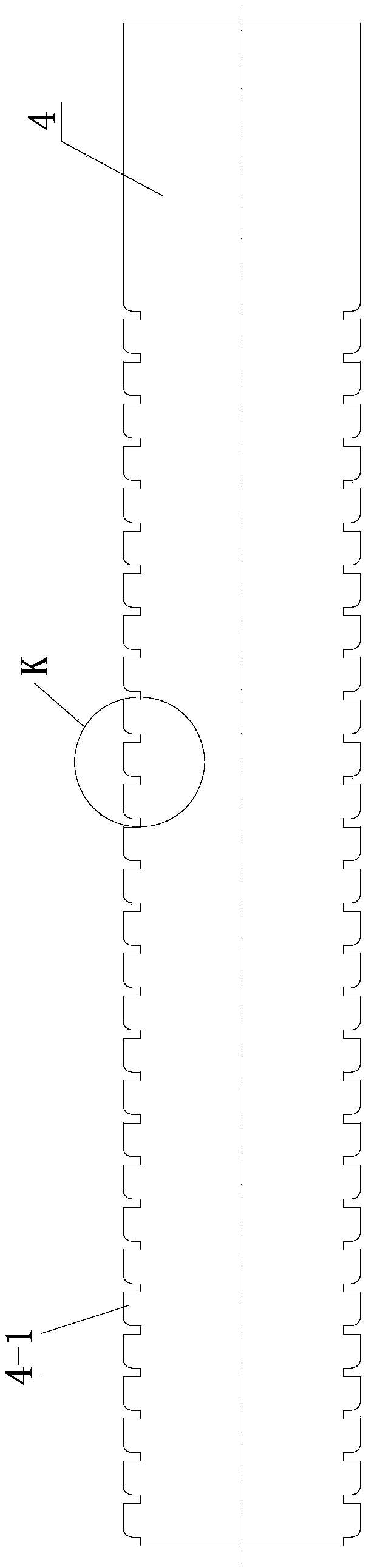

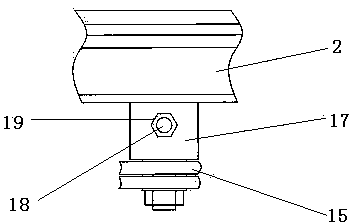

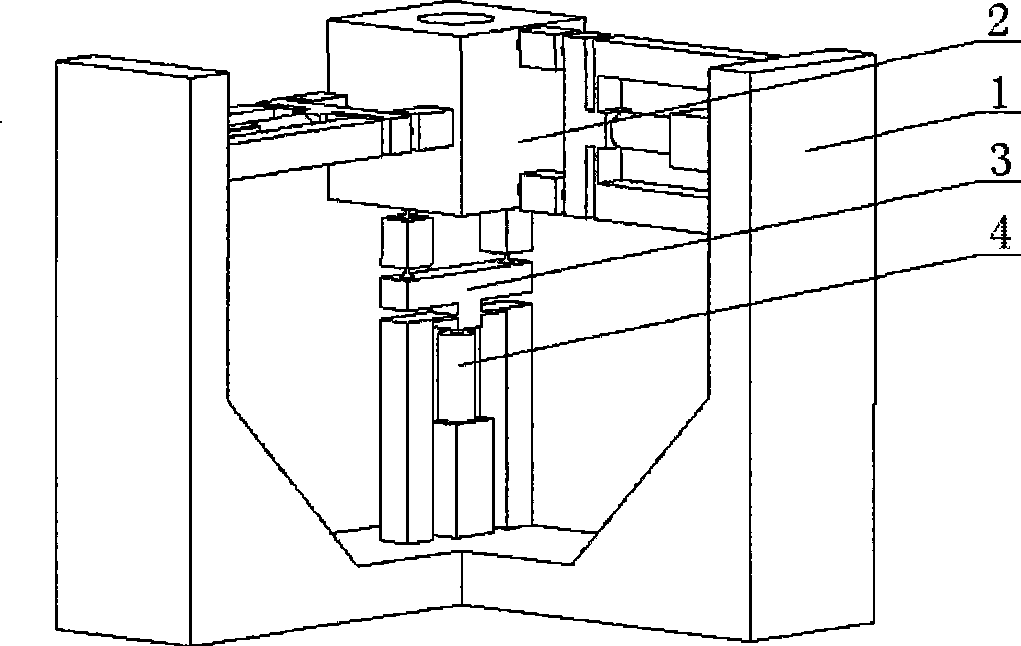

Six-freedom-degree modular pattern telescopic device and manufacturing technology thereof

ActiveCN104005335AMeet the cornerMeet the displacementBridge structural detailsSix degrees of freedomFlexure hinges

The invention belongs to the technical field of telescopic devices and discloses a six-freedom-degree modular pattern telescopic device and a manufacturing technology thereof. The telescopic device is mainly characterized in that side beam special-shaped steel, middle beam special-shaped steel, a displacement control box with a supporting horizontal beam, a side beam pressing support and a side beam pressure bearing support and a chain box provided with a transmission chain are included, a hanging frame, a middle beam pressing support and a middle beam pressure bearing support are arranged at the bottom of the middle beam special-shaped steel, the supporting horizontal beam is a solid cylinder or a hollow circular pipe body, the supporting horizontal beam is provided with a drum-shaped multi-direction flexure hinge, the contacting face of the side beam pressing support, the side beam pressure bearing support and the multi-direction flexure hinge is a concave spherical surface, the contacting face of the middle pressing support, the middle pressure bearing support and the supporting horizontal beam is a concave column face, the middle beam special-shaped steel is provided with a middle beam locating block, and a center shaft of a U-shaped locating shaft penetrates through the middle beam locating block. The telescopic device can achieve moving and rotating in a bridge-axis direction, in a direction perpendicular to the bridge-axis direction and in a vertical direction, and the requirements for beam body temperature changing, vehicle rolling, and rotating angles and displacement generated through wind power can be met.

Owner:HEBEI BAOLI ENG EQUIP GRP CO LTD

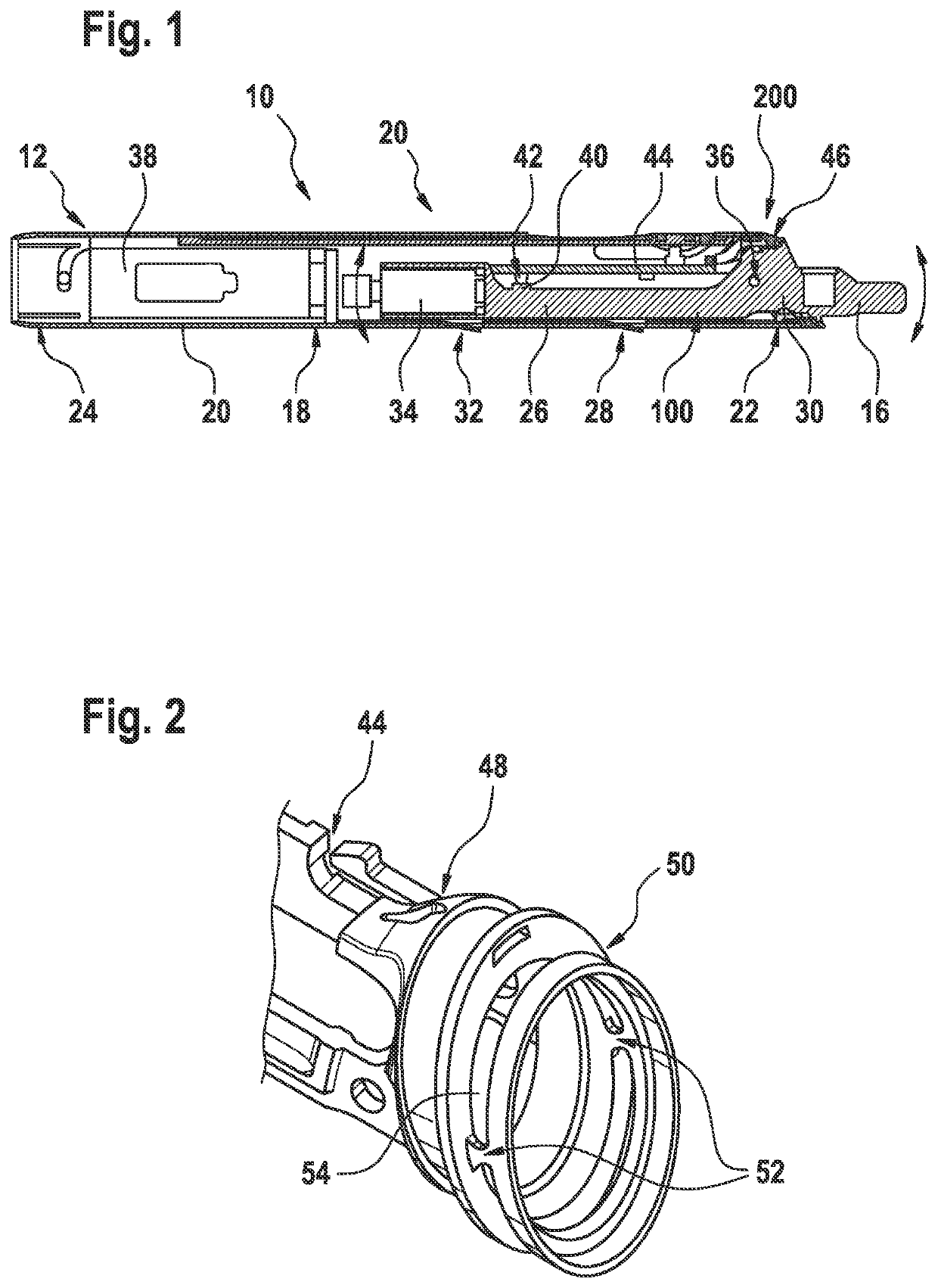

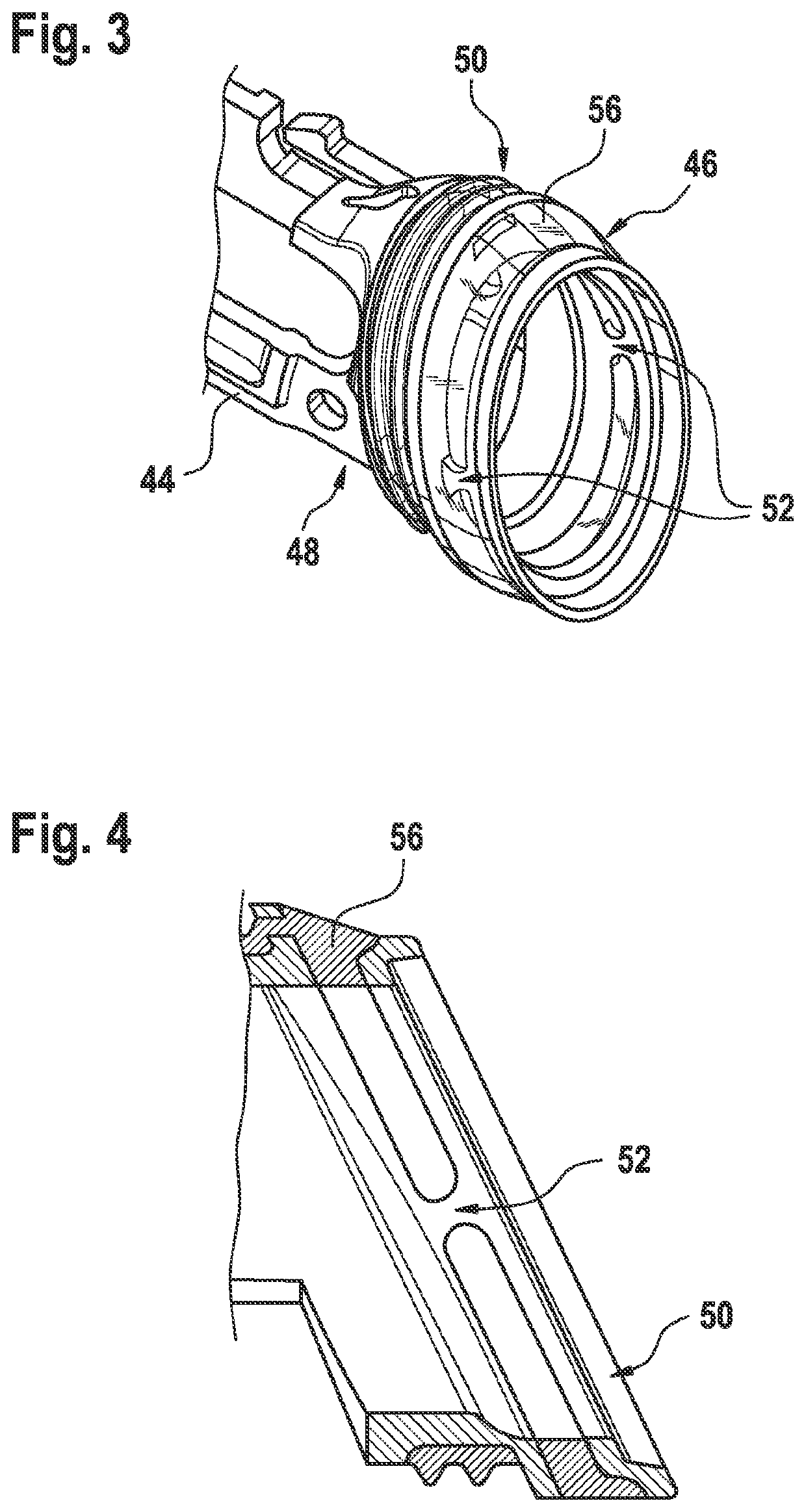

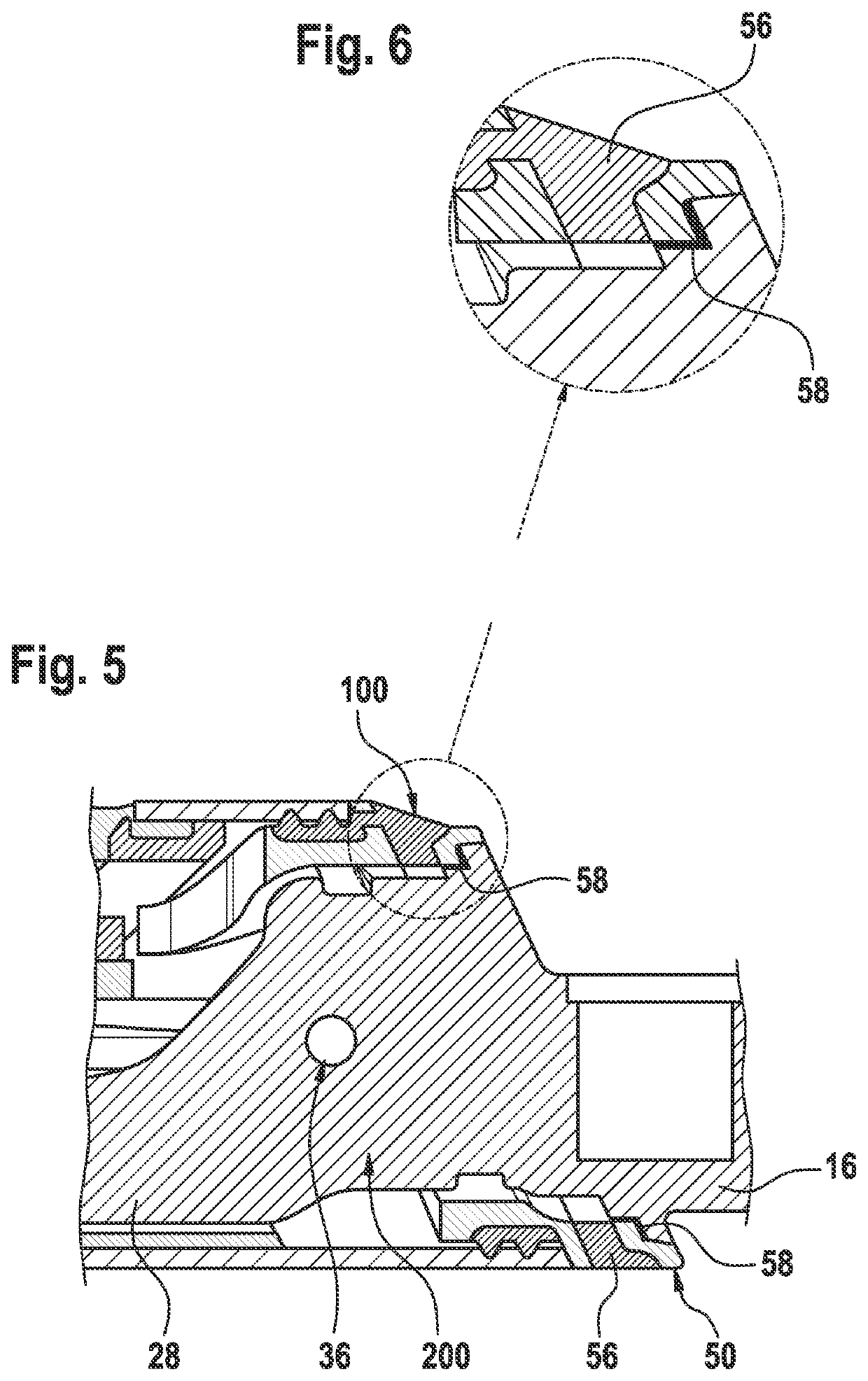

Unit for a handle of a personal-care implement and a personal-care implement

A unit for a handle of a personal-care implement is provided, the unit comprising a housing having a proximal end closest to a head being repeatably attachable to and detachable from the handle, and a light indication and sealing element, the light indication and sealing element comprising a ring structure and an elastic circular section, the ring structure being connected to the housing at the proximal end by two flexure hinges thereby creating a circular gap between the ring structure and the housing, the circular gap being filled with a transparent and / or translucent soft elastomeric material, the transparent and / or translucent soft elastomeric material forming the elastic circular section to seal the ring structure and the housing in a substantially water-tight manner.

Owner:THE GILLETTE CO

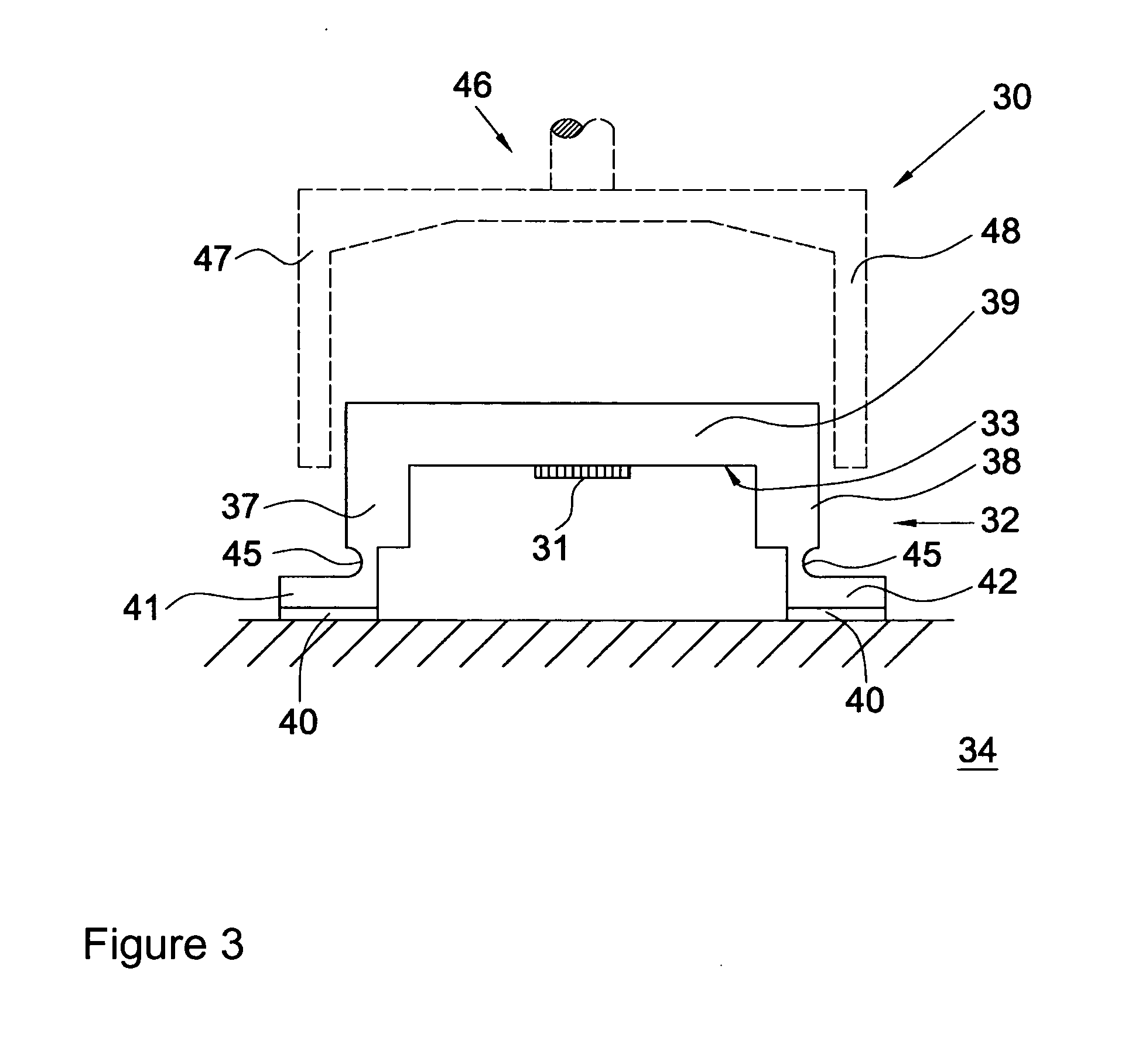

Strain sensor

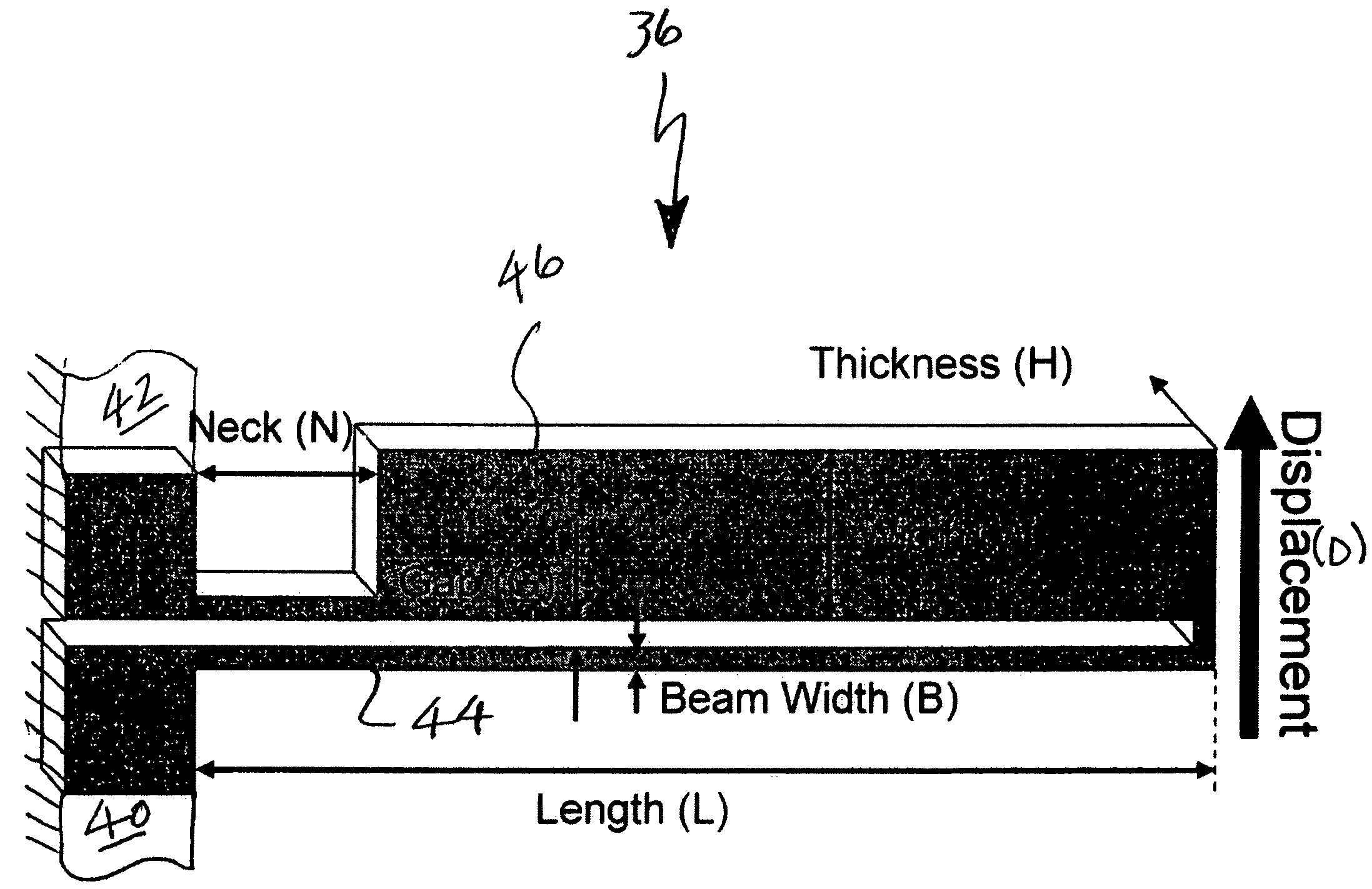

InactiveUS20120118070A1Strong and stable bending responseReliable and predictable bending responseWeighing apparatus using elastically-deformable membersForce measurementRelative displacementEngineering

The present invention defines a strain sensor for measuring strains induced on a component surface (34). The strain sensor comprises a strain gauge (31) and a support member (32), whereby the support member is attached to the component surface only at first and second attachment places. The support member comprises a beam portion (39) that is adapted to bend in response to a relative displacement of the first and second attachment places, and the strain gauge is integrated on a surface (33) of this beam portion. To ensure a strong and stable bending response of the beam portion, the attached support member comprises at least one flexure hinge (45).

Owner:AB SKF

Three-dimensionally vibration-preventing buffering mechanism

Owner:INVENTEC CORP

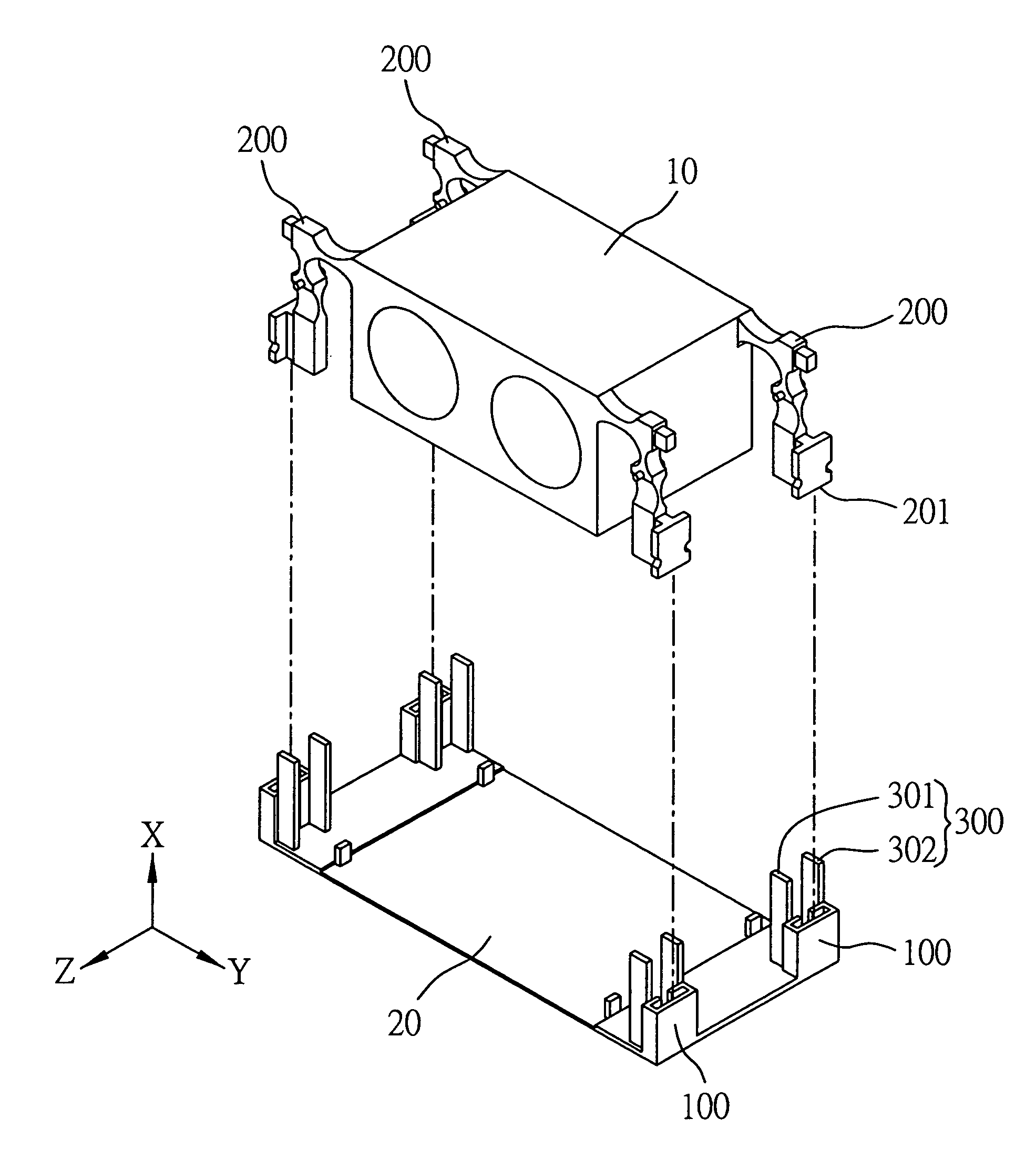

Lens positioning unit of optical system

According to example embodiments, a lens positioning unit includes a fixed structure, a monolithic flexure hinge structure, any one of upper and lower portions of which is provided with a lens mount on which a lens is mounted and the other portion of which is secured to the fixed structure, and an input unit rotatably coupled to the fixed structure, the input unit serving to convert rotational motion into vertical translational motion so as to transmit the vertical translational motion to the upper or lower portion of the monolithic flexure hinge structure provided with the lens mount.

Owner:SAMSUNG ELECTRONICS CO LTD

Lens Positioning Unit Of Optical System

According to example embodiments, a lens positioning unit includes a fixed structure, a monolithic flexure hinge structure, any one of upper and lower portions of which is provided with a lens mount on which a lens is mounted and the other portion of which is secured to the fixed structure, and an input unit rotatably coupled to the fixed structure, the input unit serving to convert rotational motion into vertical translational motion so as to transmit the vertical translational motion to the upper or lower portion of the monolithic flexure hinge structure provided with the lens mount.

Owner:SAMSUNG ELECTRONICS CO LTD

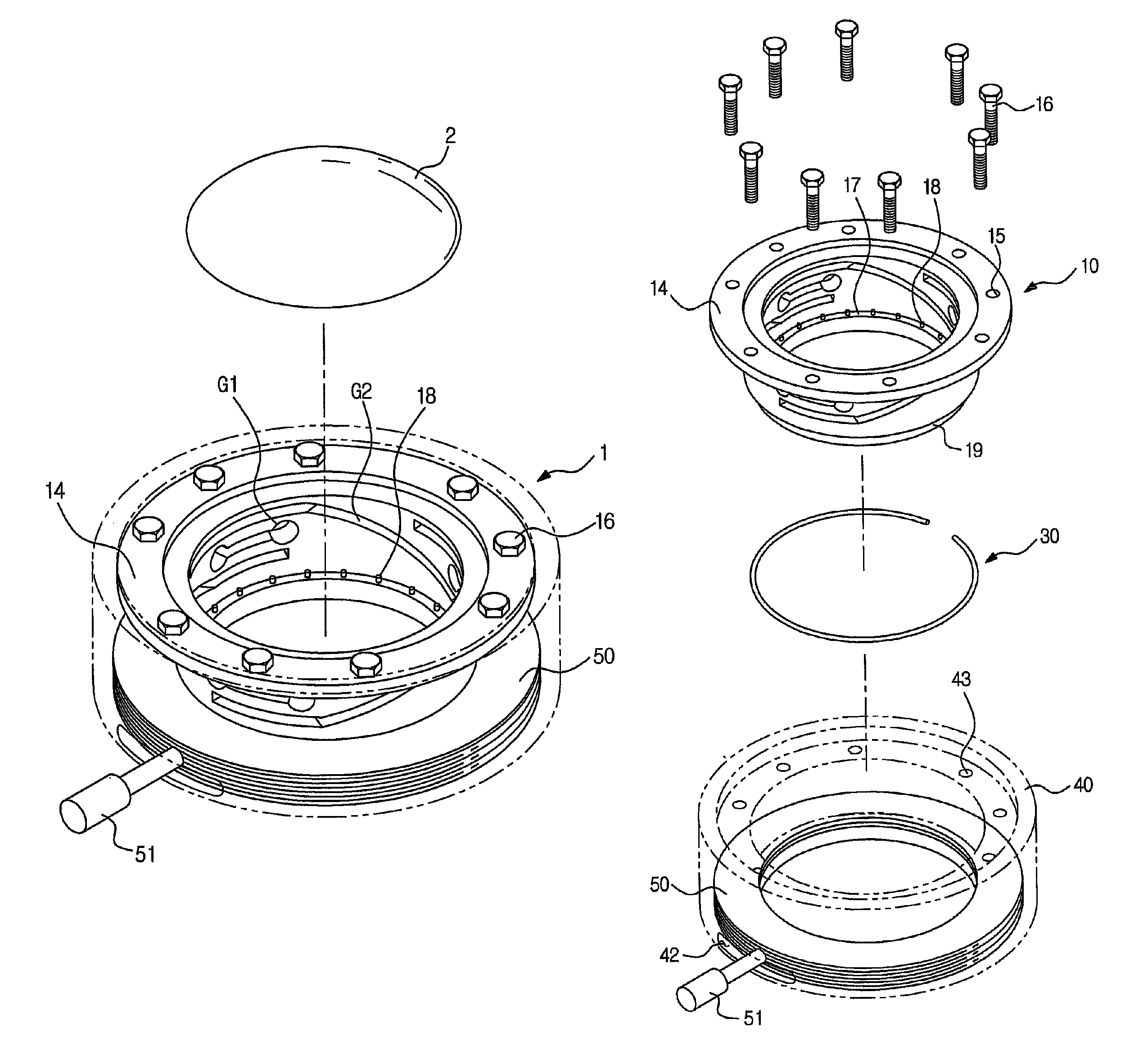

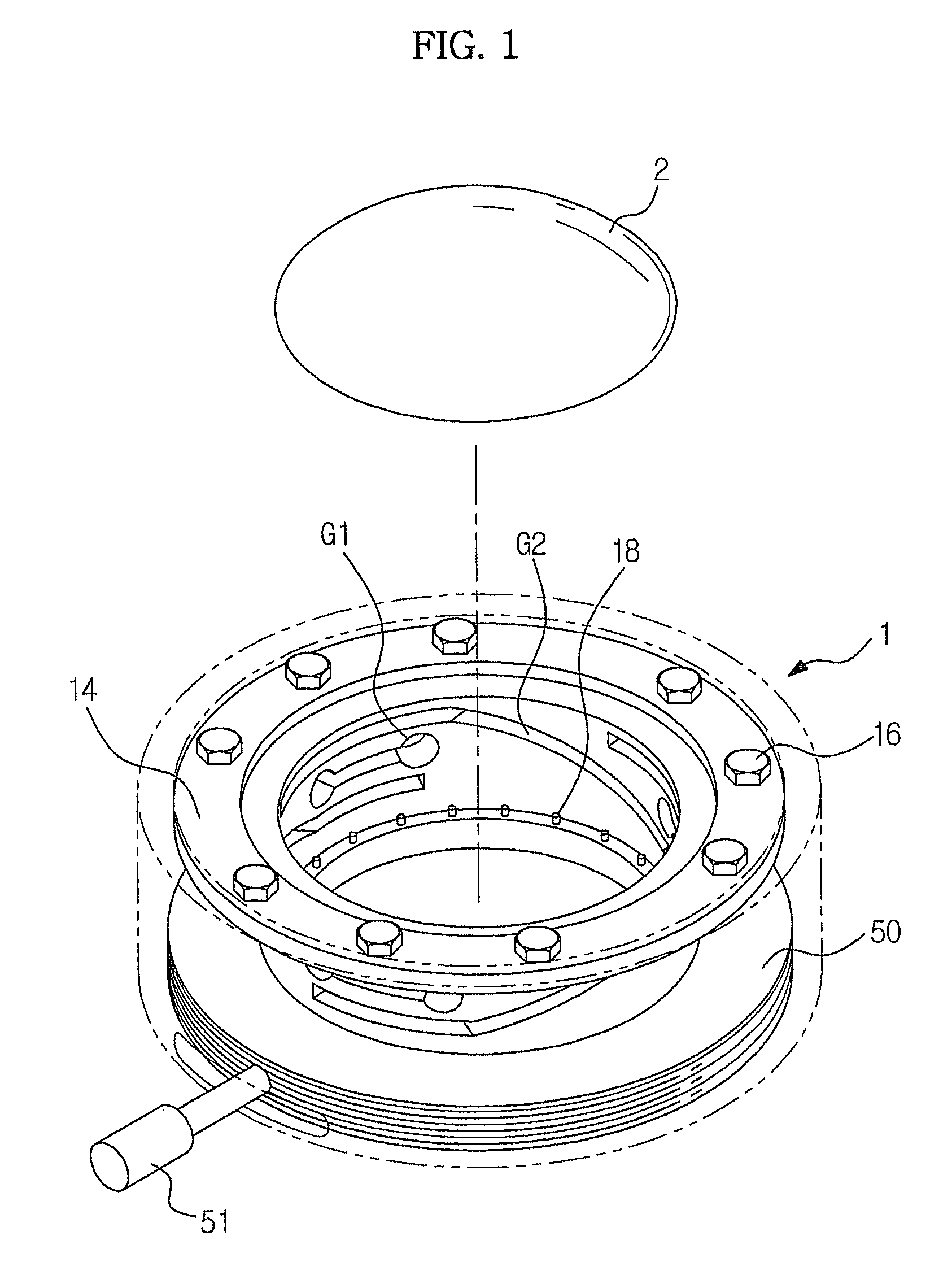

Capacitive torque sensor without limit in flexure hinge

Provided herein is a capacitive torque sensor, which can completely offset forces / torques in all axial directions, except for force / torque in a direction of a central axis, by measuring variations in capacitances of four sensing cells arrayed at angular intervals of 90 degrees on the basis of a center of the sensor and can offer a sensing value for the torque in a central axis direction.

Owner:RES & BUSINESS FOUND SUNGKYUNKWAN UNIV

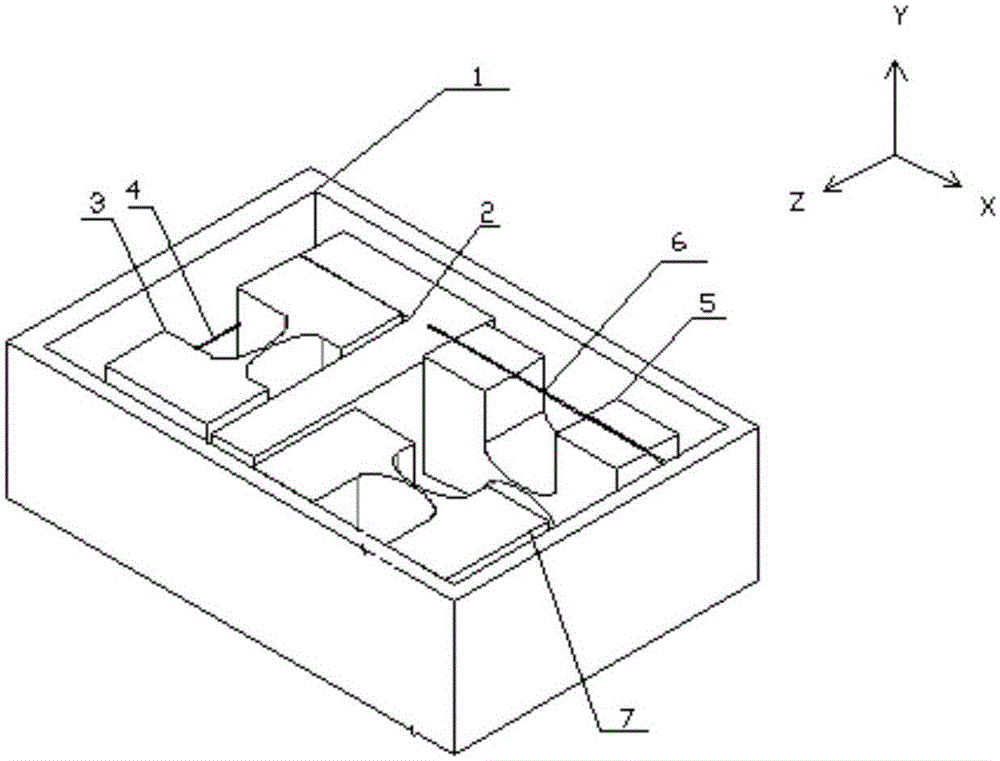

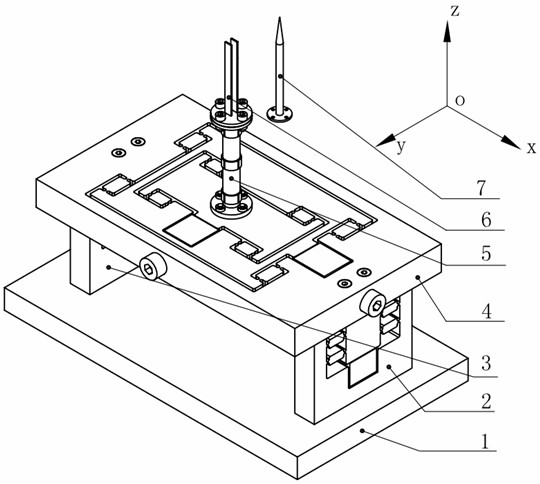

Micro-nano working platform of three-dimensional mobile orthogonal structure

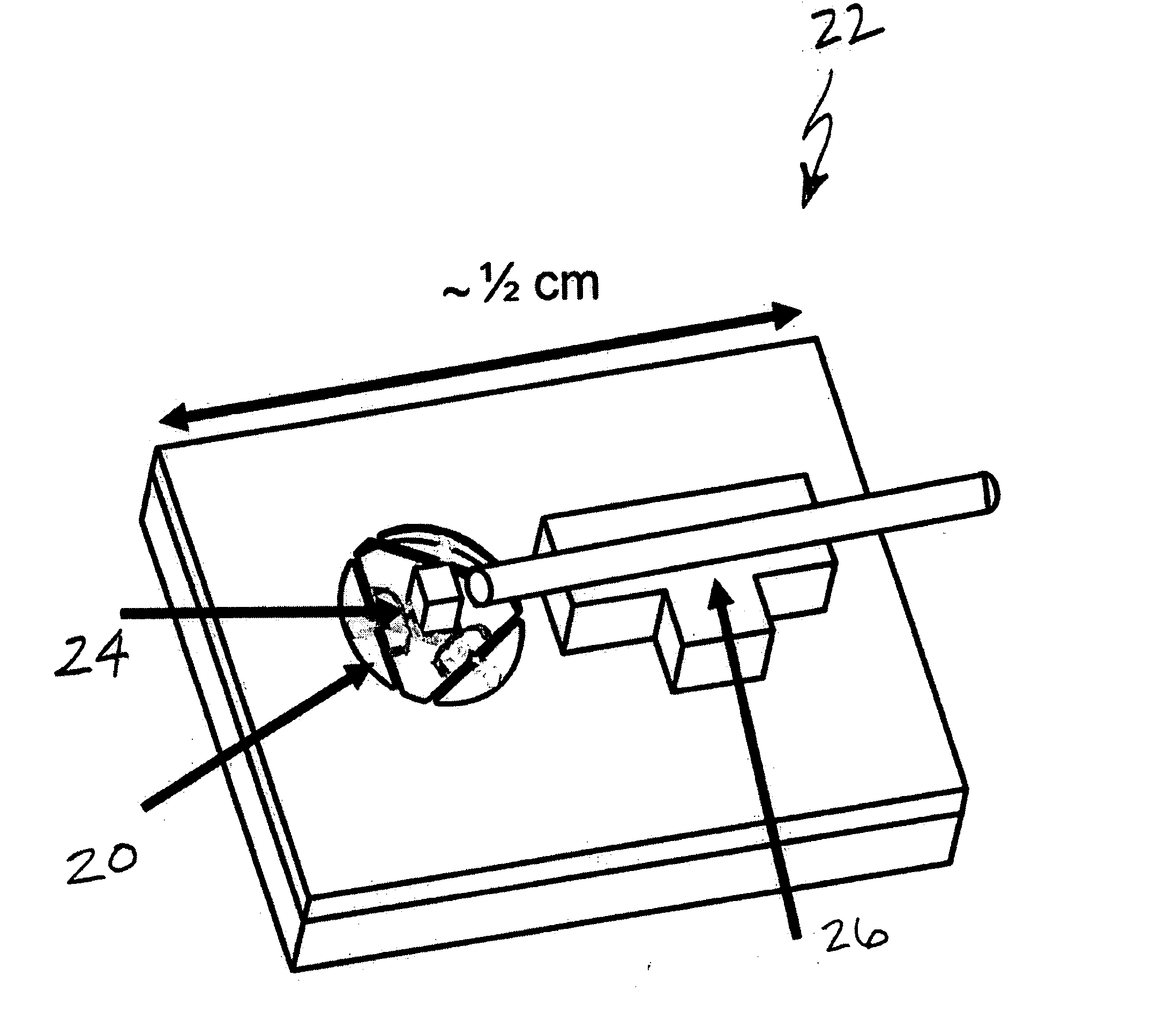

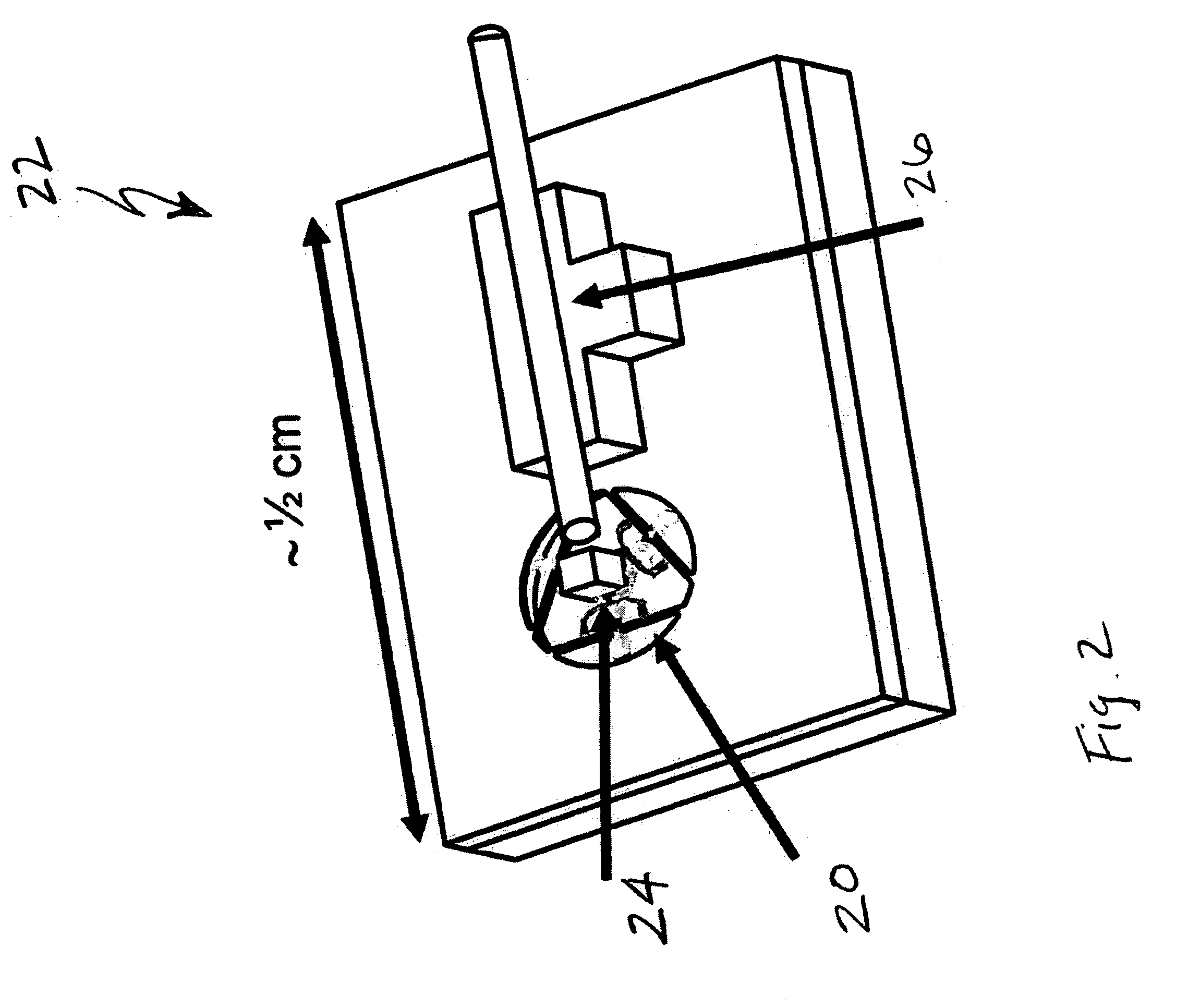

The invention relates to a micro-nano working platform of three-dimensional mobile orthogonal structure, belonging to the robotics field and comprising bases, a workbench, three P-4S branched chains and piezoelectric actuators. The bases are connected with the workbench via the three P-4S branched chains formed by flexure hinges; the three branched chains are arranged along three orthogonal direction respectively, and planes formed by pillar axes of each group are orthogonal. Each base corresponding to each branched chain thereon is processed with a parallel plate elasticity sliding joint directly and is provided with a piezoelectric actuator respectively, the movement along the three directions of X, Y and Z can be realized in a manner that the three P-4S branched chains drive the workbench. The invention can realize the three-dimensional movement of zero friction, zero clearance, zero lubrication and zero hysteresis, can be widely applied in the fields of optical fiber connecting, nanometer imprinting, life and genetic engineering, micro-assembling and the like.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com