Three-dimensional FBG (fiber bragg grating) acceleration sensor based on flexure hinges

A three-dimensional acceleration, flexible hinge technology, applied in multi-dimensional acceleration measurement, acceleration measurement using inertial force, etc., can solve the problems of fiber grating easy to produce chirp, low sensitivity, etc., to achieve long-term reliability, high sensitivity, simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

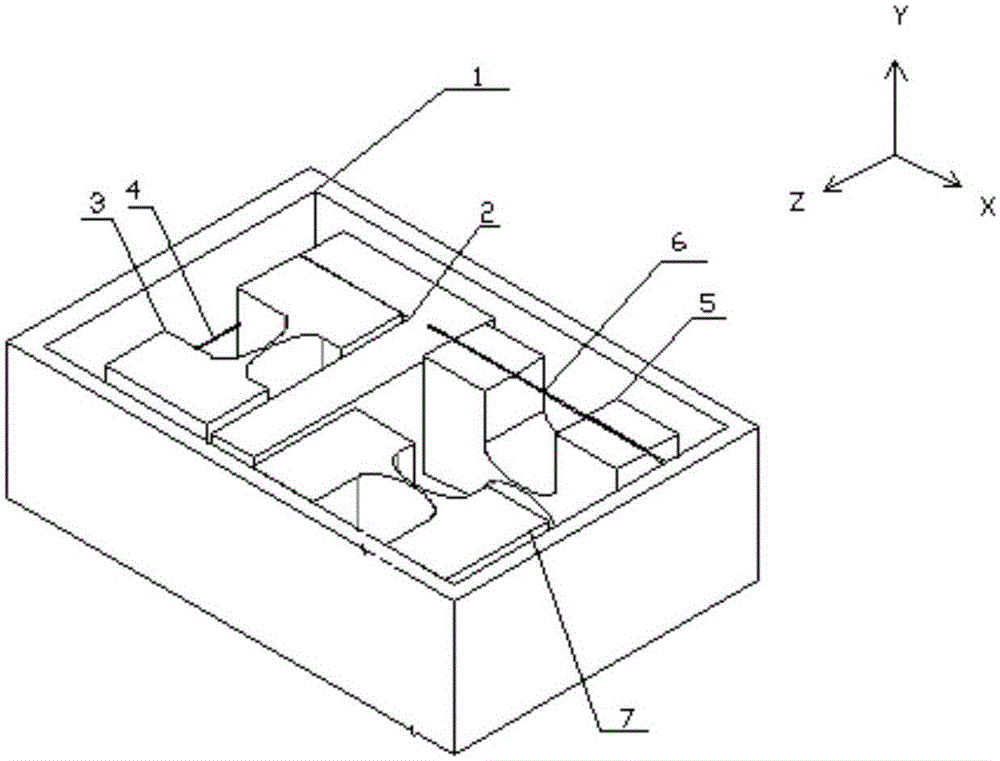

[0034] exist figure 1 Among them, the fiber Bragg grating three-dimensional acceleration sensor based on the flexible hinge of this embodiment consists of a housing 1, an L-shaped base 2, a flexible hinge 3 in the X direction, a fiber grating in the X direction 4, a flexible hinge in the Y direction 5, a fiber Bragg grating in the Y direction 6, Z-direction flexible hinge 7, Z-direction fiber grating.

[0035] The housing 1 of this embodiment is a hollow cubic shape, and the L-shaped base 2 is integrated with the housing 1 and is made of 304 stainless steel. The X-direction flexible hinge 3 and the Z-direction flexible hinge 7 are fixed on the long arm of the L-shaped base 2 by screws, and the Y-direction flexible hinge 5 is fixed on the short arm of the L-shaped base 2 .

[0036] The X-direction flexible hinge 3 , the Y-direction flexible hinge 5 and the Z-direction flexible hinge 7 are all single-axis flexible hinges. One end of each uniaxial flexible hinge is a fixed end,...

Embodiment 2

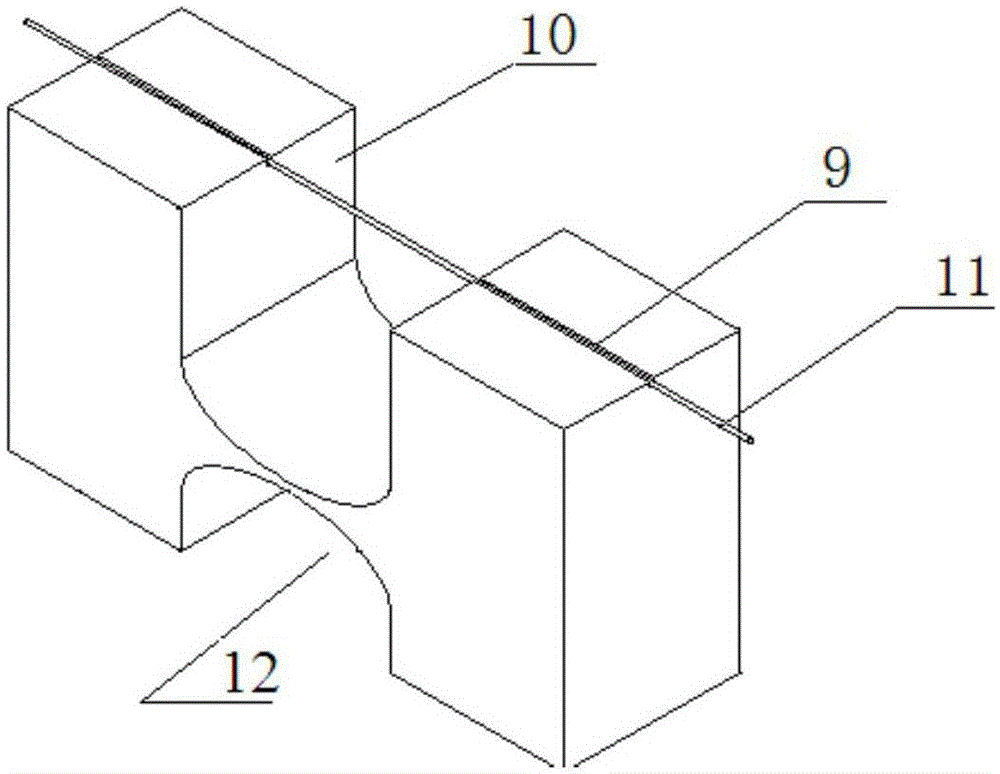

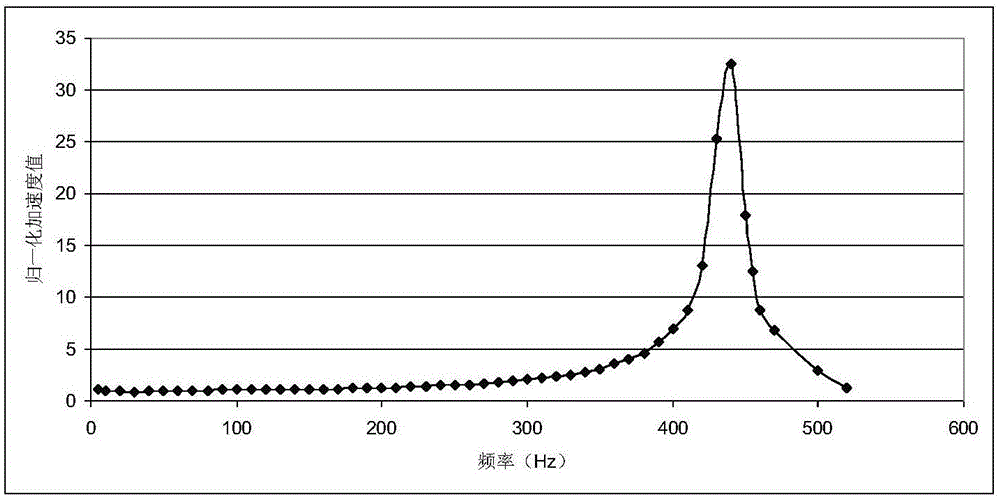

[0053] In this embodiment, the height of the rectangular cutout of the upper groove 10 of the flexible hinge is 7 mm, the height of the rectangular cutout of the lower groove 12 is 3 mm, the thickness t of the thin wall is 1 mm, and the thickness h of the thick wall is 17 mm. Other dimensions of the flexible hinge are the same as Example 1 is the same. The other components and the connection relationship of the components are the same as in Embodiment 1. Experimental results show that the resonance frequency of the sensor is 790Hz, and the wavelength sensitivity is 24pm / g.

Embodiment 3

[0055] In this embodiment, the thickness t of the thin wall of the flexible hinge is 0.3 mm, the thickness h of the thick wall is 16.3 mm, and other dimensions of the flexible hinge are the same as those in Embodiment 1. The other components and the connection relationship of the components are the same as in Embodiment 1. Experimental results show that the resonance frequency of the sensor is 290Hz, and the wavelength sensitivity is 162pm / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Center wavelength | aaaaa | aaaaa |

| Thin wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com