Air spring vibration isolator based on piston type liquid viscous damping action

A kind of air spring, viscous damping technology, applied in the direction of spring/shock absorber, spring, shock absorber, etc., to achieve the effect of compact and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

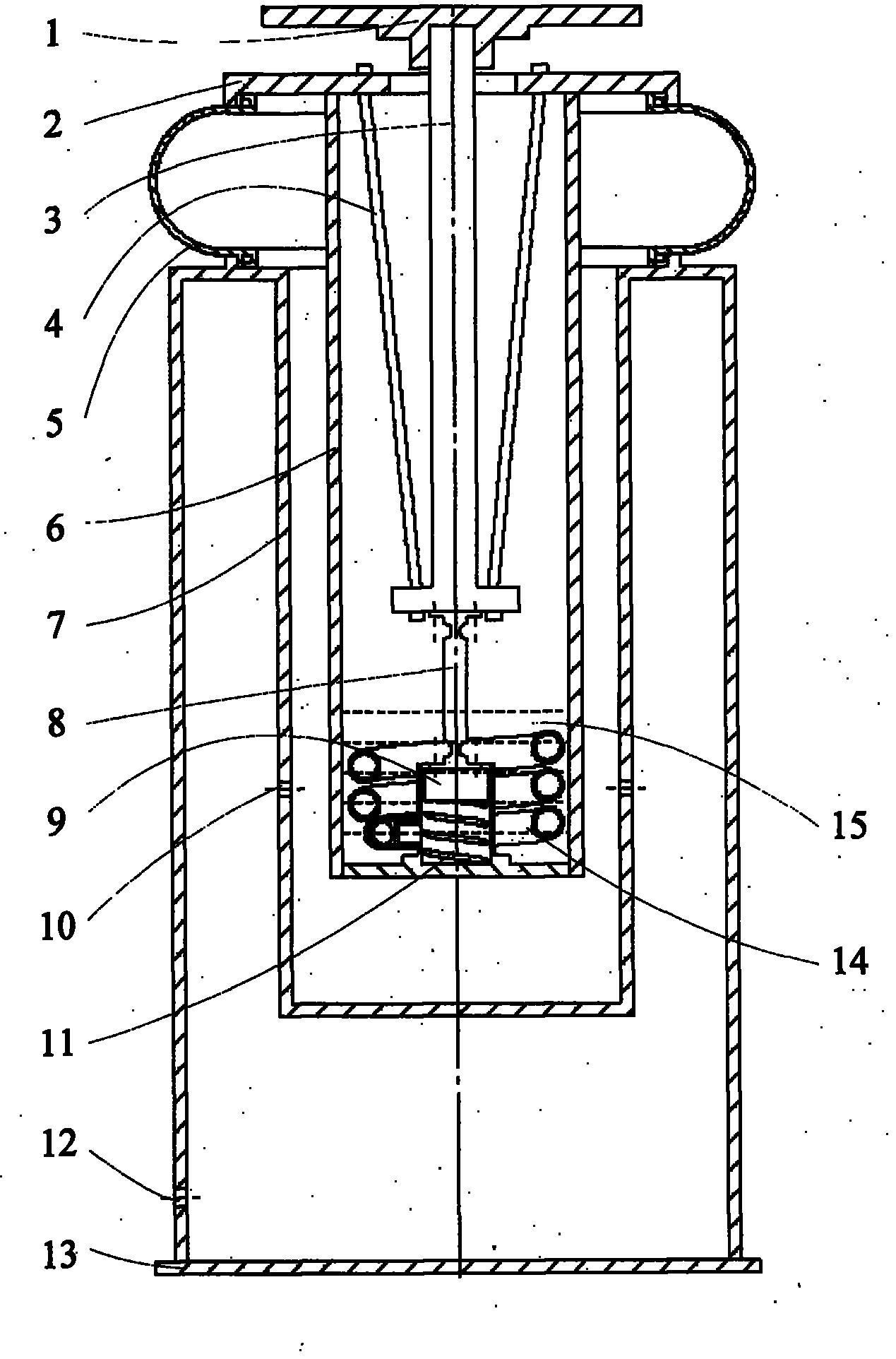

[0029] Specific embodiments of the present invention are described in detail below in conjunction with accompanying drawings, as figure 2 , image 3 and Figure 4 As shown, an embodiment of the air spring isolator of the present invention is shown.

[0030] The air spring vibration isolator is equipped with an inner cylinder 6 inside the outer cylinder 7, and the air spring airbag 5 is set outside the upper end of the inner cylinder 6. The outer cylinder 7 is sealed and connected with the lower end of the air spring airbag 5 through its upper end boss, and the inner cylinder 6 passes The annular cover plate 2 affixed to its upper end is sealingly connected with the upper end of the air spring air bag 5 , the air inlet 12 is arranged on the outer wall of the outer cylinder 7 , a group of throttle holes 10 arranged in a circle are arranged on the inner wall of the outer cylinder 7 , and at the lower end of the outer cylinder 7 The circular bottom plate 13 is sealed and fitted...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com