Inertial linear piezoelectric motor

A piezoelectric motor and linear technology, applied to electrical components, piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, etc., can solve the problems of low motor efficiency and high efficiency, and achieve improved efficiency, The effect of low noise and low matching circuit requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

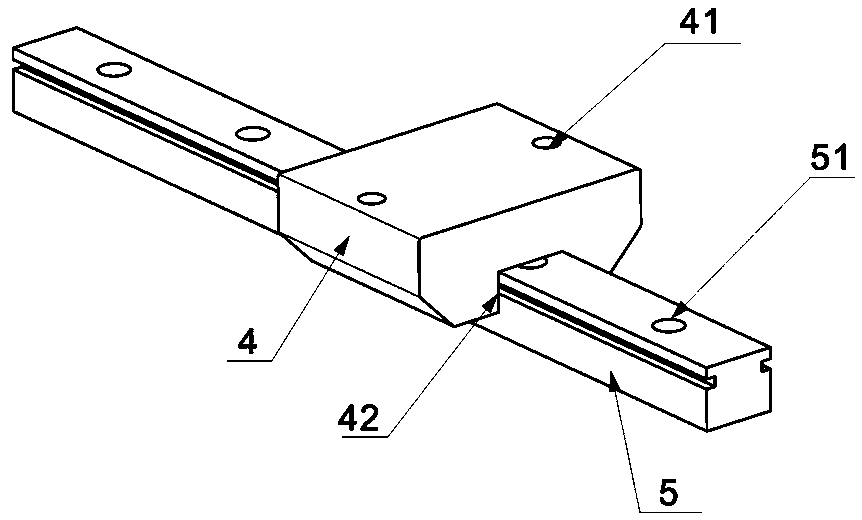

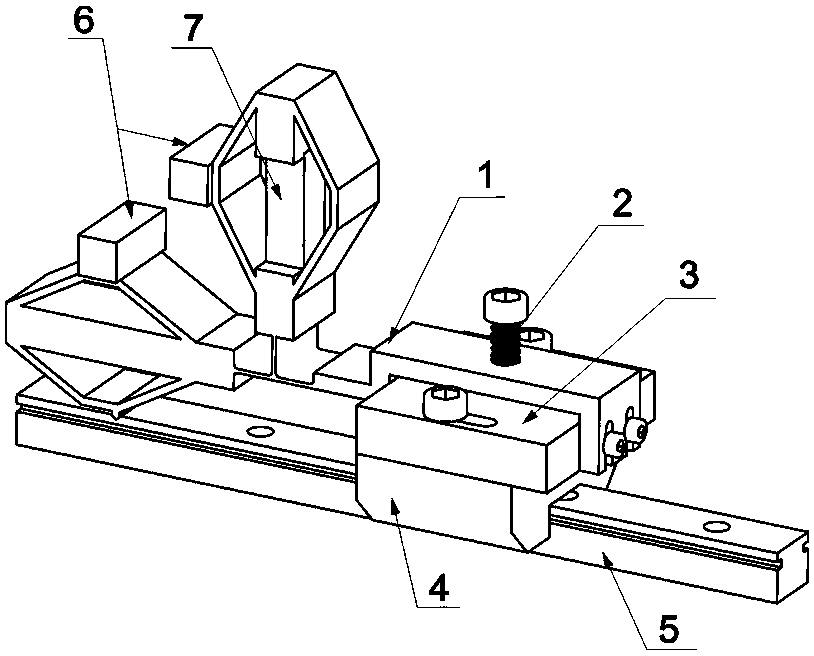

[0032] see figure 1 , an inertial linear piezoelectric motor includes a bottom plate 1, a slider 4, a slide rail 5, two mass blocks 6 and a piezoelectric stack 7. The piezoelectric stack 7 is formed by stacking several piezoelectric sheets, and the material of the piezoelectric sheets is Piezoelectric Ceramics.

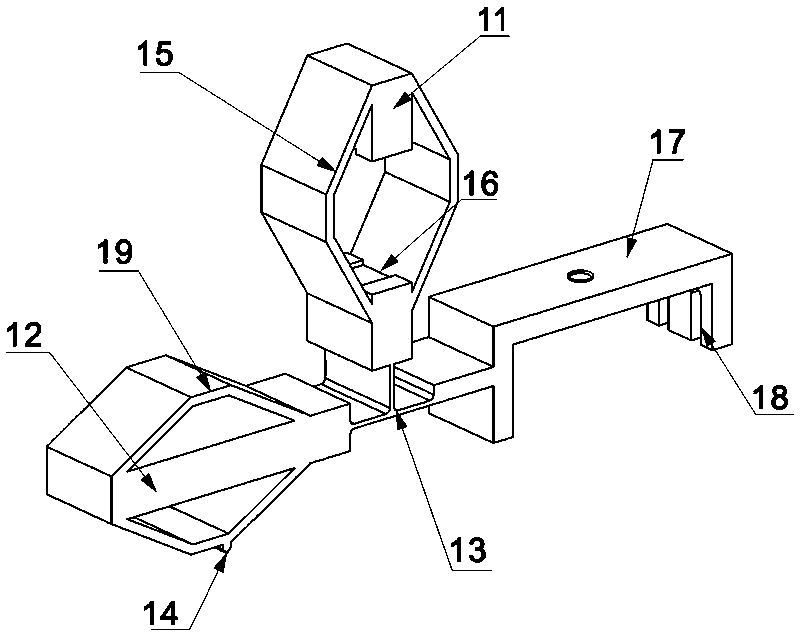

[0033] see figure 1 and figure 2 , the bottom plate 1 is a strip-shaped plate, one end is connected to the slider 4, and the other end is respectively connected to the vertical structural member 11 and the horizontal structural member 12 through a flexible hinge 13, and the flexible hinge 13 is a T-shaped thin plate structure. The vertical structural member 11 and the horizontal structural member 12 are hollow diamond-shaped structural members with the same structure. A mass block 6 is installed on the outer middle part of the vertical structural member 11 adjacent to the horizontal structural member 12, and another mass block 6 is installed on the outer middle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com