Multi-degree-of-freedom micromanipulator driven by multi-polarization mode piezoelectric actuator

A piezoelectric driver and micro-manipulation technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve the difficulty of miniaturization of micro-manipulators, rotational motion control Complicated, low motion precision and other problems, to achieve the effect of miniaturization, wide application range and high motion precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

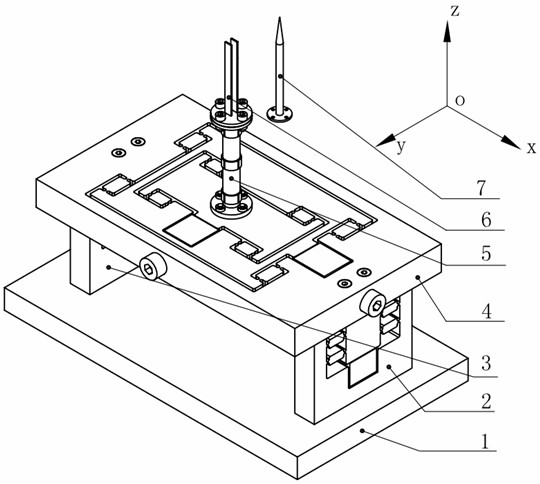

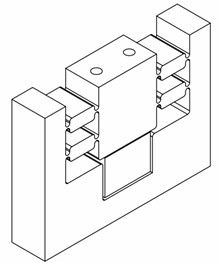

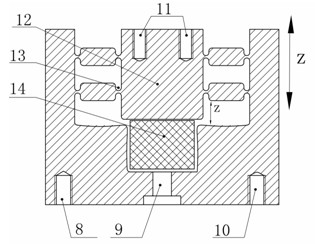

[0029] like figure 1As shown, the present invention includes a base 1, two Z-axis translation micro-motion mechanisms 2 and 3 with the same structure, a nested X-axis and Y-axis translation micro-motion mechanism 4, a Z-axis rotation micro-motion mechanism 5 and an end actuator mechanism, two Z-axis translation micro-motion mechanisms 2 and 3 with the same structure are symmetrically and vertically fixed on both sides of the base 1 through two sets of holes 8 and 10, 15 and 17, and the nested X-axis and Y-axis translation micro-motion mechanisms The two ends of the moving mechanism 4 are connected to the two Z-axis translation micro-moving mechanisms 2 and 3 respectively through two groups of holes 22 and 29, and the Z-axis rotating micro-moving mechanism 5 passes through a group of ring-shaped evenly distributed on the lower flange 33. The hole is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com