Automobile wheel hub screw hole recognition method based on machine vision and shielding method and system

A technology of automobile wheel hub and machine vision, which is applied in the fields of product surface detection and manipulator control, which can solve the problems of slow placement of blocking balls, visual fatigue, low screw hole number and position recognition rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

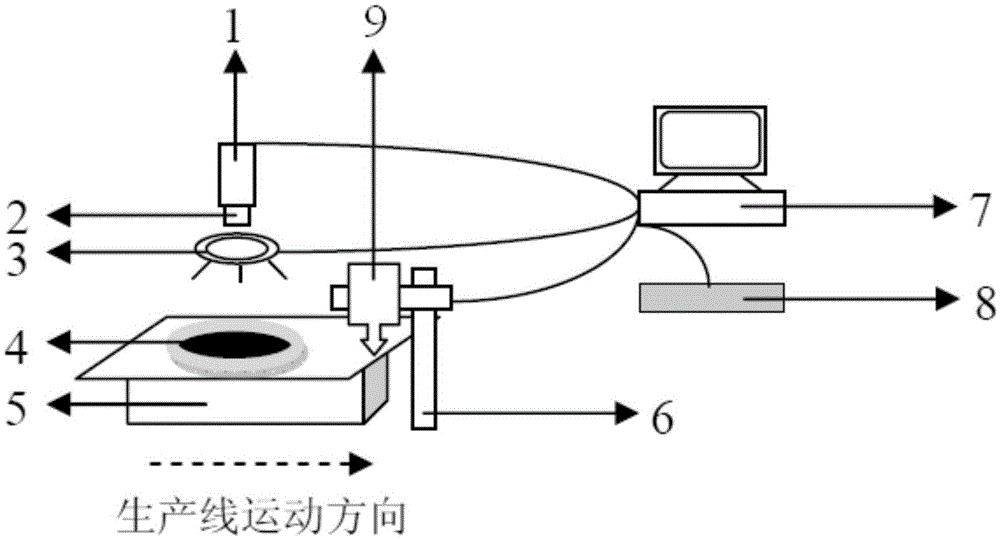

[0074] In order to describe the present invention more specifically, the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

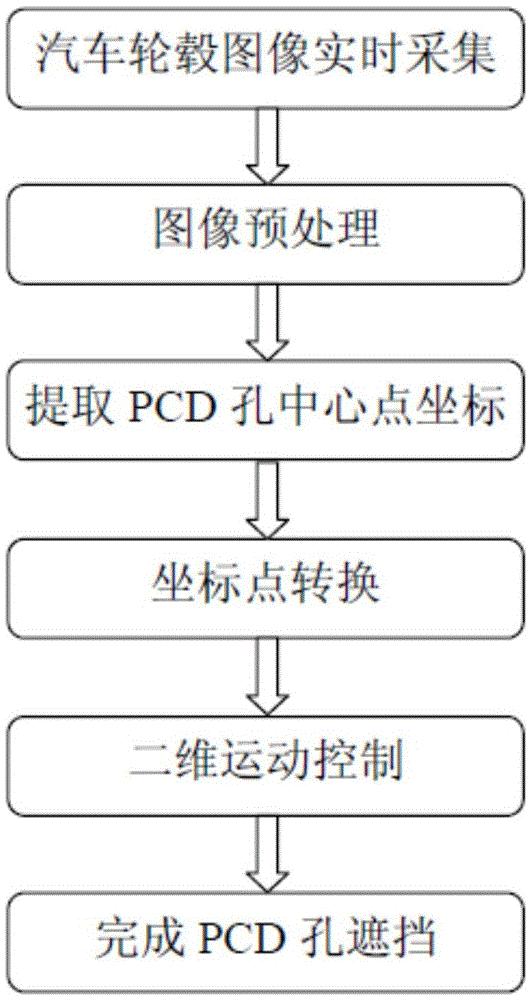

[0075] Such as figure 1 Shown, a kind of automobile hub screw hole (also claiming PCD hole) automatic covering method, comprises the steps:

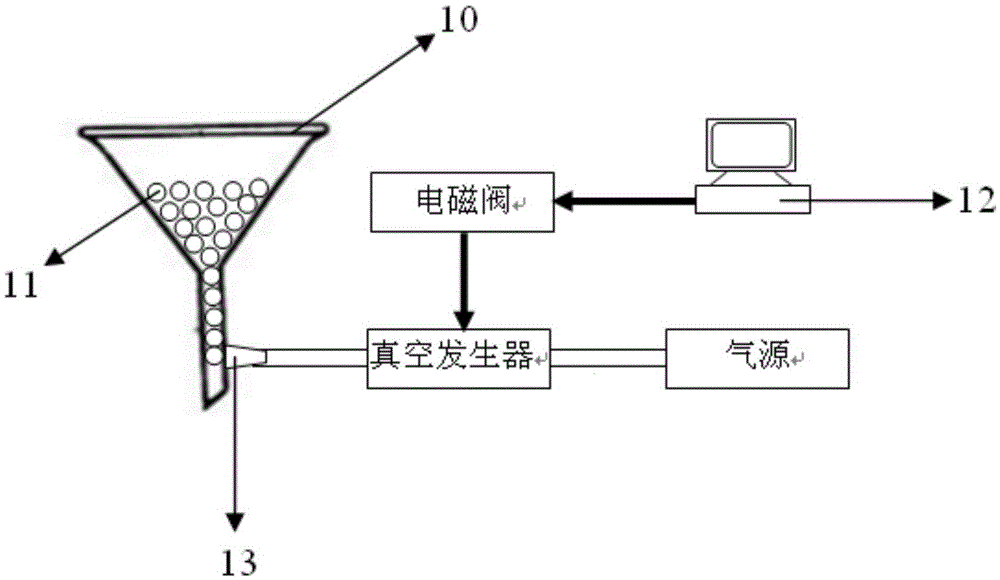

[0076] (1) Pre-collect the standard images of various types of wheel hubs on the automobile wheel hub spraying production line, and establish a sample library of all known types of wheel hub images; the coordinates of the center hole (center of the circle), the number of PCD holes and the PCD value of various standard wheel hub images (the diameter of the cross-sectional circle formed by connecting the centers of the bolt mounting holes), and store these data to establish a sample library of various types of wheel hub parameters. The construction of the hub image sample library is an optional step. Simultaneously ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com