An electrical control cabinet for maintenance vehicles

A technology for electrical control cabinets and vehicles, applied in the field of control cabinets, can solve problems such as poor use effect and potential safety hazards, and achieve the effects of simple structure, accelerated heat dissipation, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

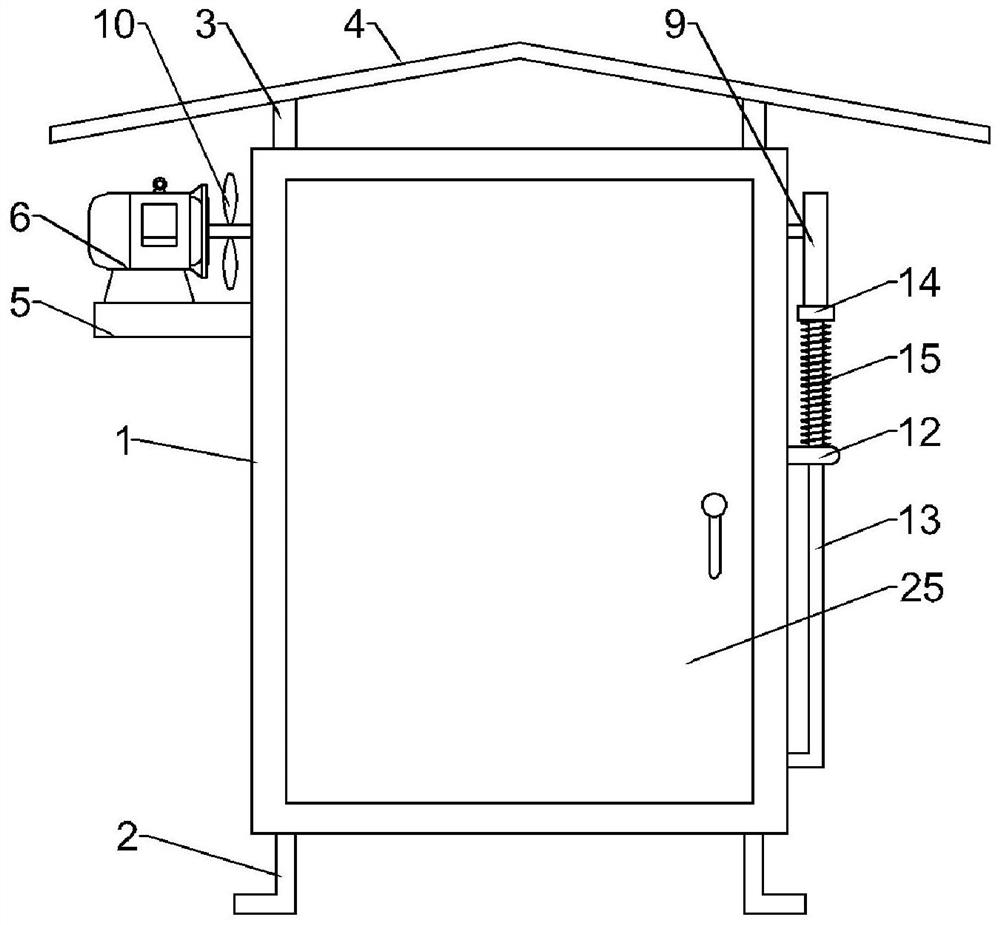

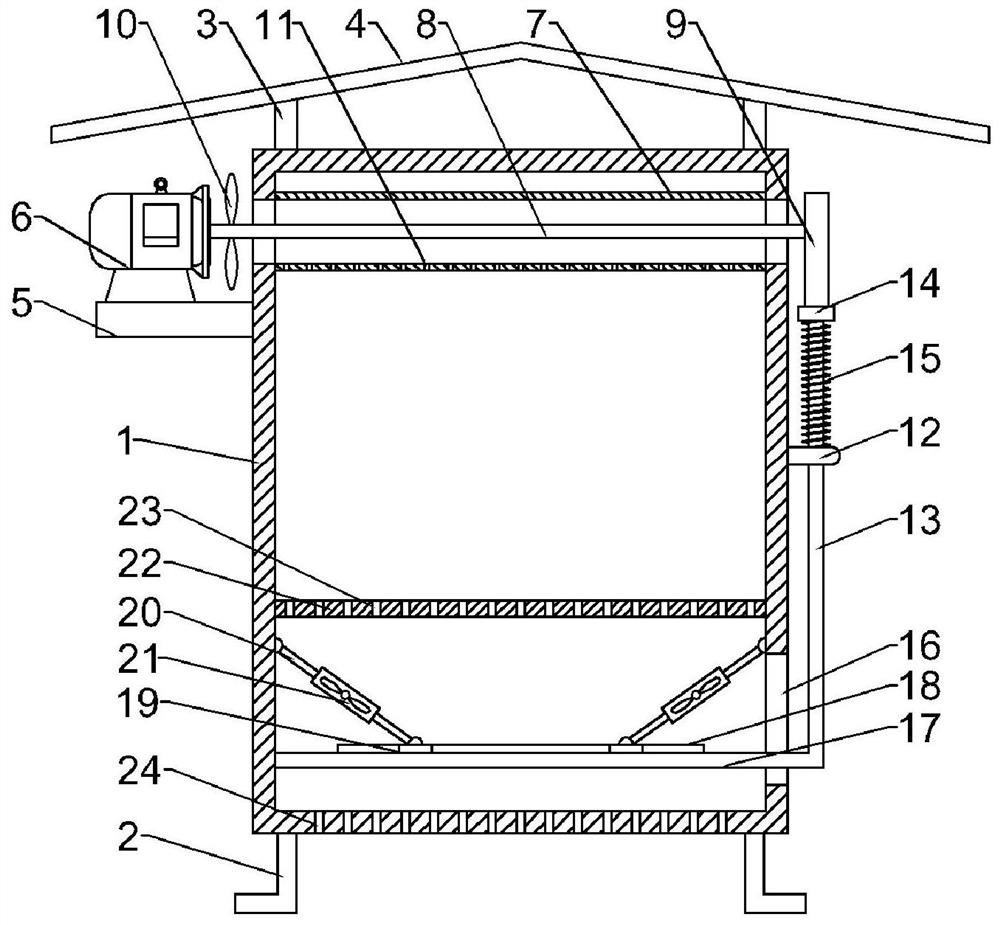

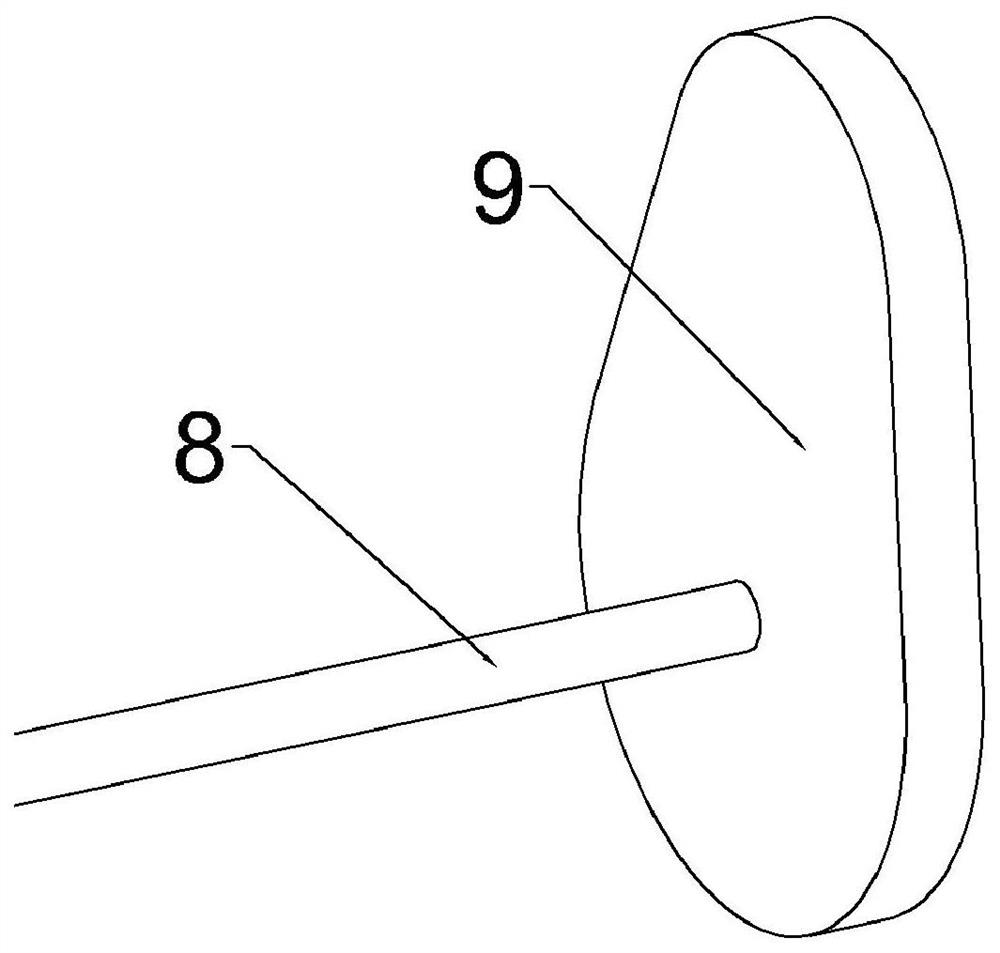

[0021] Example 1: Please refer to Figure 1-4 , an electrical control cabinet for maintenance vehicles, comprising a cabinet body 1, a fixed frame 5 fixedly connected to the upper left of the cabinet body 1, a motor 6 fixedly connected above the fixed frame 5, a horizontal pipe 7 fixedly connected to the top of the cabinet body 1, and a horizontal pipe 7 The left and right sides run through the cabinet body 1, the output end of the motor 6 is fixedly connected with a horizontal shaft 8, the horizontal shaft 8 runs through the horizontal pipe 7 and is connected with a cam 9, the cam 9 is located on the right side of the cabinet body 1, and the left end of the horizontal shaft 8 is fixed A spiral fan blade 10 is connected, and a number of cooling air holes 11 are provided at the bottom of the horizontal tube 7;

[0022] Turn on the motor 6 during use, the rotation of the motor 6 drives the horizontal shaft 8 to rotate, the rotation of the horizontal shaft 8 can drive the rotatio...

Embodiment 2

[0032] Embodiment 2: This embodiment is a further improvement of the previous embodiment: the heat dissipation fan 21 placed horizontally is fixed in the middle of the limit chute 18, and the heat dissipation is always upward during the up and down movement of the limit chute 18, effectively improving the heat dissipation efficiency .

[0033] The working principle of the present invention is: turn on the motor 6 when in use, the rotation of the motor 6 drives the horizontal shaft 8 to rotate, the rotation of the horizontal shaft 8 can drive the rotation of the cam 9, and at the same time drive the rotation of the spiral fan blade 10, and the rotation of the spiral fan blade 10 can drive the air flow After the horizontal pipe 7 moves to the right, based on the principle of jet flow, the flowing air will bring the airflow outside the cooling air hole 11 into the horizontal pipe 7 and blow it out to the right for heat dissipation. During the rotation of the cam 9, the longitudina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com