Joint heat regenerative system

A heat recovery system and heat exchanger technology, applied in preheating, feed water heaters, lighting and heating equipment, etc., can solve problems such as heat loss, low-temperature condensation of equipment, black smoke from fuel, etc., to alleviate equipment blockage, Achieve the effect of drying output and increasing the temperature of feed water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

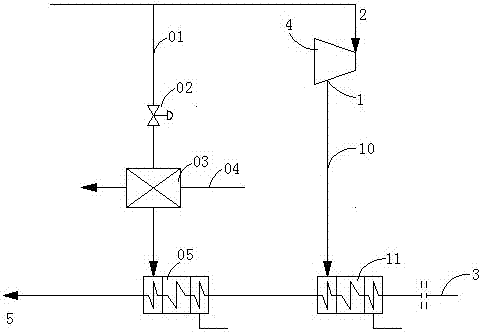

[0051] figure 1 It is a schematic diagram of the system of the specific embodiment 1 of the present invention. In this embodiment, on the basis of the conventional final steam extraction port 1, the conventional final steam extraction 10, the conventional final feed water heater 11, and the main steam pipeline 2, additional An additional pipeline 01, a steam side regulating valve 02 on the additional pipeline, a heat exchanger 03, and an additional adjustable rear feedwater heater 05 are provided.

[0052] The additional adjustable post-final feedwater heater 05 is connected to the heat exchanger 03 and the main steam pipeline 2 through the additional pipeline 01, and the steam side regulating valve 02 is set in the additional pipeline 01 between the main steam pipeline 2 and the heat exchanger 03 superior. The steam side regulating valve 02 is used to regulate the main steam in the additional pipeline 01, and the feedwater temperature at the outlet of the additional adjustab...

Embodiment 2

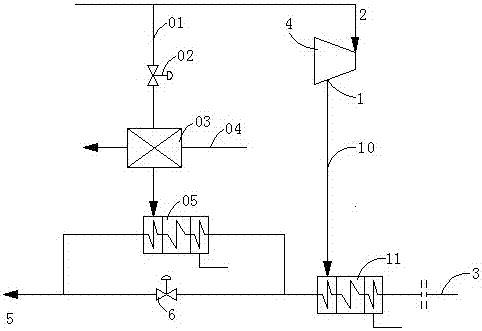

[0057] figure 2 It is a schematic diagram of the system of the specific embodiment 2 of the present invention. In this embodiment, on the basis of the conventional final steam extraction port 1, the conventional final steam extraction 10, the conventional final feed water heater 11, and the main steam pipeline 2, an additional An additional pipeline 01, a steam side regulating valve 02 on the additional pipeline, a heat exchanger 03, an additional adjustable rear feedwater heater 05, and a water side regulating valve 6 are provided.

[0058] The main difference between this embodiment and Embodiment 1 is that a water-side regulating valve 6 is added, which is connected in parallel with the additional adjustable final feedwater heater 05. Therefore, the additional adjustable rear final feedwater heater 05 can be designed as a part capacity feedwater heaters, reducing heater costs.

[0059] The only difference between the usage method of the system of this embodiment and that ...

Embodiment 3

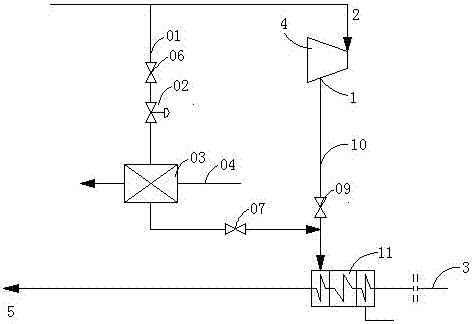

[0061] image 3 It is a schematic diagram of the system of the specific embodiment 3 of the present invention. This embodiment adds additional Pipeline 01, steam side regulating valve 02 on the additional pipeline, heat exchanger inlet isolating valve 06, heat exchanger outlet isolating valve 07, heat exchanger 03.

[0062] The main difference between this embodiment and Embodiment 1 is that no additional adjustable rear feedwater heater 05 is added. The steam pipeline passing through the heat exchanger is directly sent to the original conventional final stage feed water heater 11 . Its advantage is that it saves an additional adjustable post-final feedwater heater 05, which reduces investment, and it can completely recover the steam heat that would have been wasted through the bypass system in the start-up stage of the unit, just like Example 1. On the other hand, the original conventional final stage feed water heater 11 can also be used to supplement and heat the feed wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com