System and method for preparing powdery active lime by modifying cement clinker production line

A technology for active lime and cement clinker, which is applied in the field of systems for producing powdery active lime, can solve the problems of incomplete cooling, affecting the performance and output of active lime, insufficient heating of active lime, etc. The effect of large production capacity and small transformation amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with drawings and embodiments.

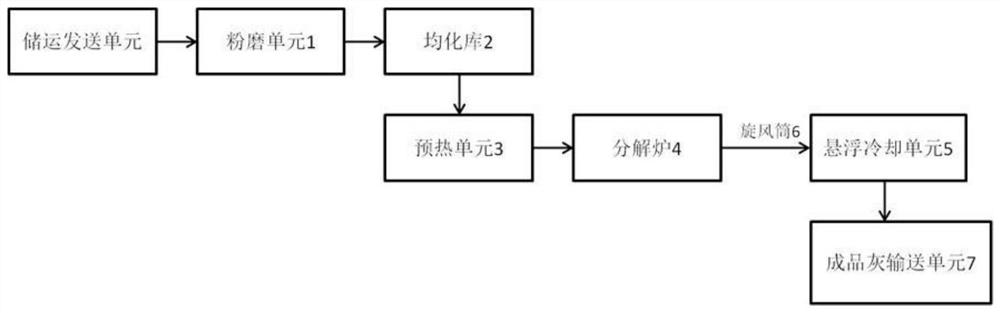

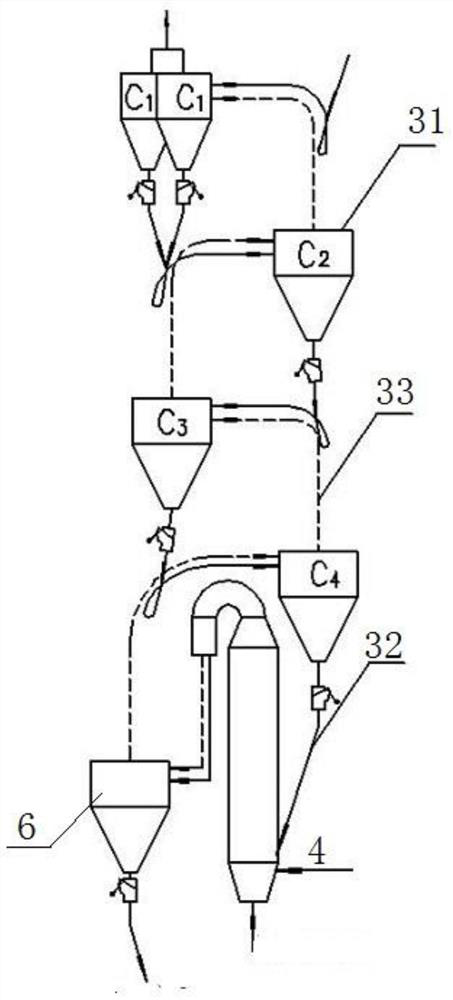

[0026] see Figure 1-6 A system for preparing powdered active lime by transforming a cement clinker production line, including a storage and delivery unit connected in sequence, a grinding unit 1 and a homogenization storehouse 2, a preheating unit 3, a calciner 4, a suspension cooling unit 5, and a cyclone Drum 6 and finished ash conveying unit 7.

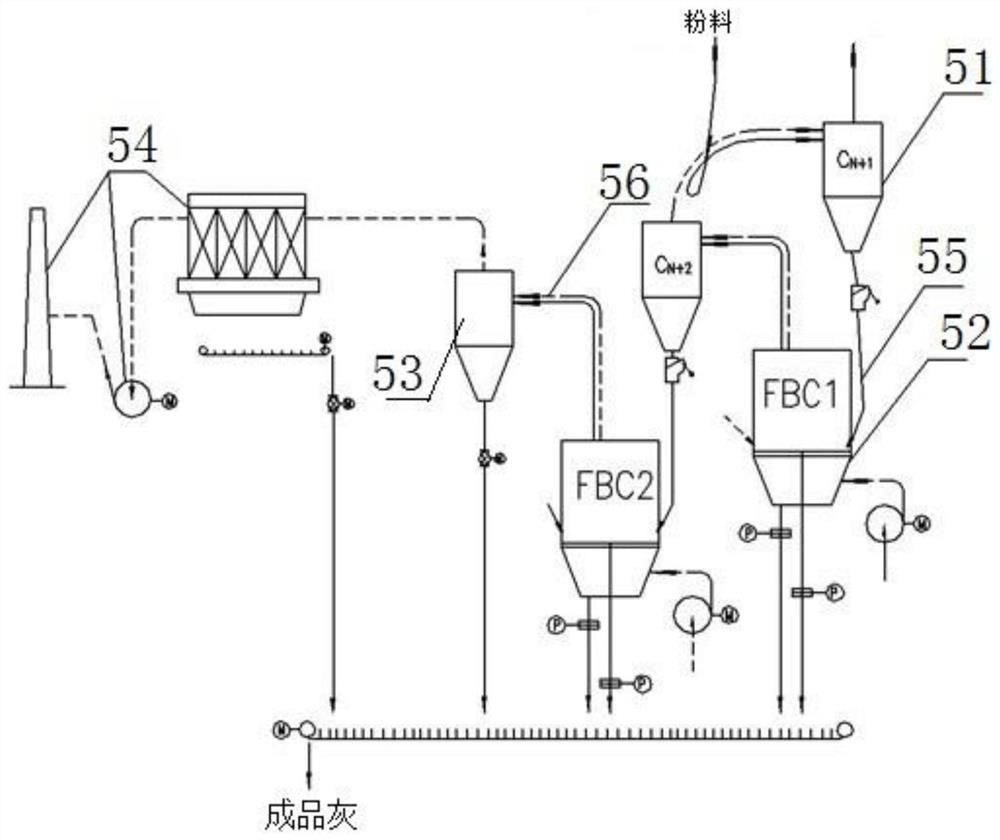

[0027] see figure 2 , the suspension cooling unit 5 includes a cyclone radiator 51, a fluidized bed cooler 52, a material collection cylinder 53 and a dust removal device 54; two groups of cyclone radiators 51 and two groups of fluidized bed coolers 52 are set in this embodiment, wherein The material powder of the calciner 4 enters the first cyclone radiator 51 under the action of the gas, disperses and is suspended in the air flow to cool under the action of the air flow, and then enters the first fluidized bed cooler 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com