Modification method for realizing doping and coating of a high-nickel ternary positive electrode material by using pretreatment precursor

A technology of cathode materials and precursors, applied in the field of pretreatment of precursors to realize the modification of doped and coated high-nickel ternary cathode materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

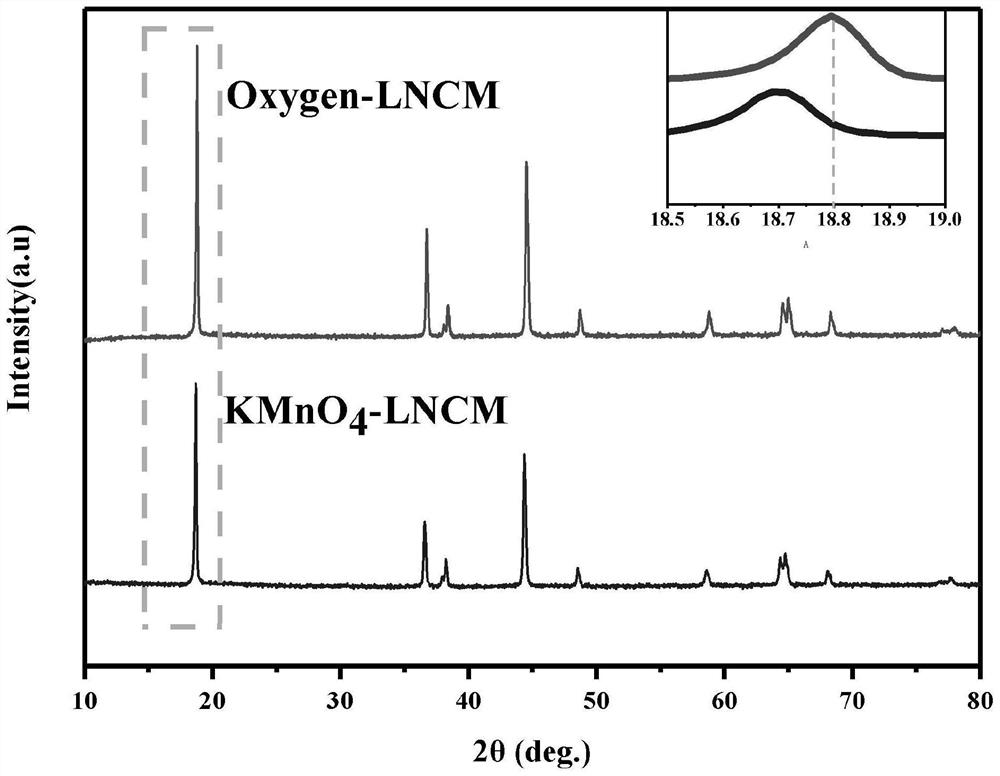

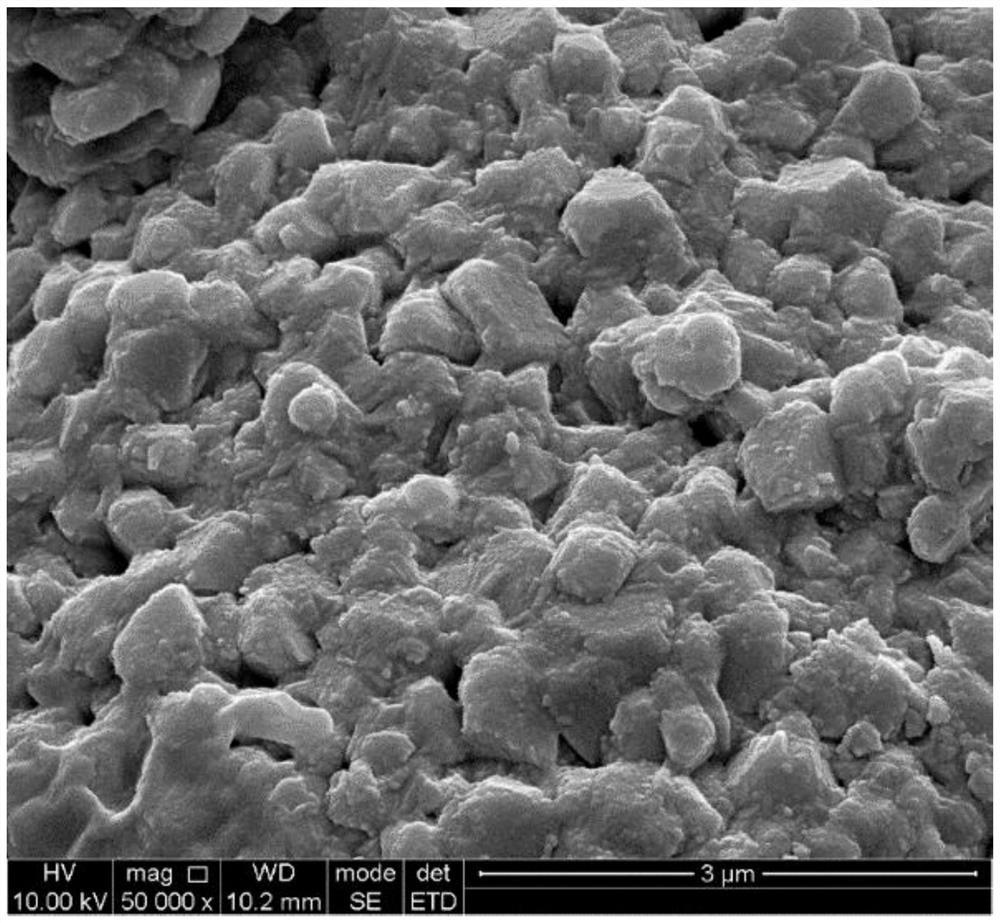

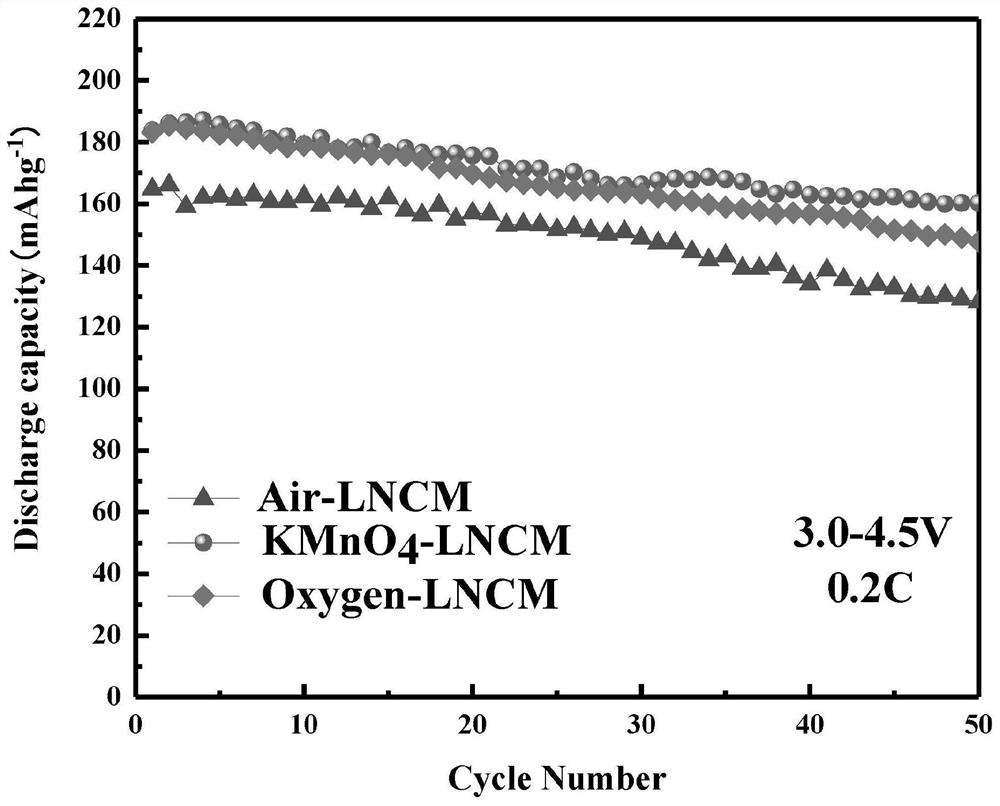

[0039] Example 1. A method for modifying a pretreated precursor to achieve doping and coating a high-nickel ternary positive electrode material, the method steps are as follows:

[0040] (1) Weigh 1g of the precursor and disperse it in 100mL of deionized water to obtain the precursor solution;

[0041] (2) Take 0.005g potassium permanganate and dissolve it in 10mL deionized water to obtain potassium permanganate solution;

[0042] (3) Add 7.5mL potassium permanganate solution to the precursor solution, continue stirring for 1h, then add the remaining 2.5mL potassium permanganate solution, continue stirring for 0.5h, the speed is 500rmp / min, and the temperature is 30°C ;

[0043] (4) After the reaction is completed, filter with deionized water for 5 times, and move the obtained pretreated precursor to a vacuum drying oven at 120°C for 12 hours;

[0044] (5) Combine the dried and pretreated precursor with LiOH·H 2 O was mixed and ground at a molar ratio of 1:1.05, kept at 48...

Embodiment 2

[0046] Example 2. A method for modifying a pretreated precursor to achieve doping and coating a high-nickel ternary positive electrode material, the method steps are as follows:

[0047] (1) Weigh 1g of the precursor and disperse it in 100mL of deionized water to obtain the precursor solution;

[0048] (2) Weigh 0.01g potassium permanganate and dissolve it in 10mL deionized water to obtain potassium permanganate solution;

[0049] (3) Add 7.5mL potassium permanganate solution to the precursor solution, continue stirring for 1 hour, then add the remaining 2.5mL potassium permanganate solution, continue stirring for 1 hour, the rotation speed is 500rmp / min, and the temperature is 30°C;

[0050] (4) After the reaction is completed, filter with deionized water for 5 times, and move the obtained pretreated precursor to a vacuum drying oven at 120°C for 12 hours;

[0051] (5) Combine the dried and pretreated precursor with LiOH·H 2 O was mixed and ground at a molar ratio of 1:1.0...

Embodiment 3

[0053] Example 3. A method for modifying a pretreated precursor to achieve doping and coating a high-nickel ternary positive electrode material, the method steps are as follows:

[0054] (1) Weigh 1g of the precursor and disperse it in 100mL of deionized water to obtain the precursor solution;

[0055] (2) Weigh 0.015g potassium permanganate and dissolve it in 10mL deionized water to obtain potassium permanganate solution;

[0056] (3) Add 7.5mL potassium permanganate solution to the precursor solution, continue stirring for 1.5h, then add the remaining 2.5mL potassium permanganate solution, continue stirring for 0.5h, the speed is 500rmp / min, the temperature is 30 ℃;

[0057] (4) After the reaction is completed, filter with deionized water for 5 times, and move the obtained pretreated precursor to a vacuum drying oven at 120°C for 12 hours;

[0058] (5) Combine the dried and pretreated precursor with LiOH·H 2 O was mixed and ground at a molar ratio of 1:1.05, kept at 480°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com