Modified natural graphite and preparation method and application thereof

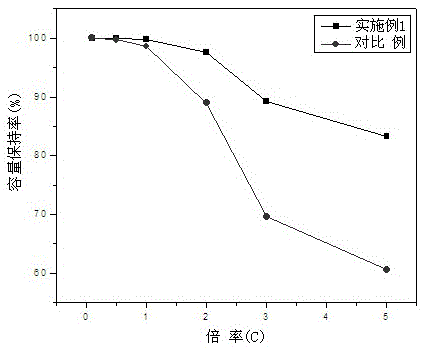

A natural graphite, modified technology, applied in the direction of electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of poor rate performance, uneven carbon coating on the surface of modified graphite, insufficient doping, etc., to achieve It is beneficial to insert and extract, improve graphite interlayer corrosion, and improve cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

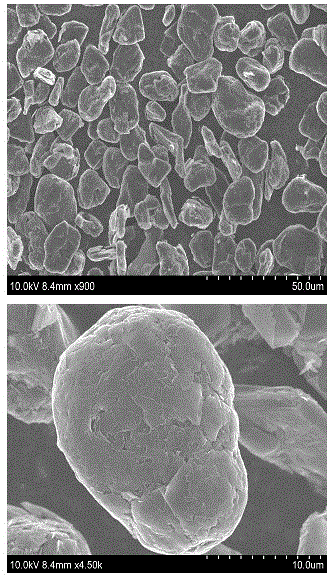

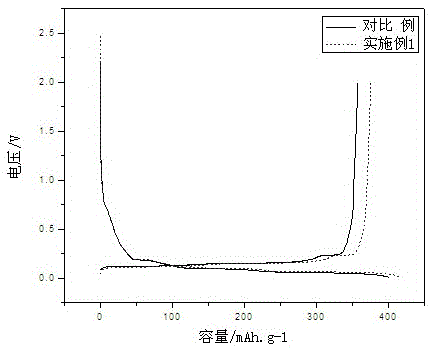

[0030] The modified natural graphite raw material prepared in this example, the specific method is to intercalate the natural graphite with concentrated phosphoric acid for 6 hours at 180°C, and then coat it with diethylamine. The coating of diethylamine The amount is about 20%.

[0031] The specific preparation process is as follows: get 60g natural graphite (particle size D 50 =16.9μm), add 30g of concentrated phosphoric acid with a concentration of 85.11%, stir, mix evenly, treat at a constant temperature in a blast drying oven at 180°C for 6h, take it out after natural cooling; add 12g of diethylamine to the obtained sample, stir , mix evenly, then put the sample into the quartz porcelain boat, push the quartz porcelain boat into the tube furnace, under N 2 Under the atmosphere, the temperature was raised to 900°C at a rate of 10°C / min, treated at a constant temperature for 10 hours, cooled naturally to room temperature, and then taken out to obtain a modified natural gra...

Embodiment 2

[0037] Take 60g natural graphite (particle size D 50 = 16.9μm), add 15g of concentrated sulfuric acid with a concentration of 98wt%, stir, mix evenly, treat at a constant temperature in a blast drying oven at 200°C for 2h, take it out after natural cooling; add 20g of formamide to the obtained sample, stir, Mix well, then put the sample into the quartz porcelain boat, push the quartz porcelain boat into the tube furnace, 2 Under the atmosphere, the temperature was raised to 1500°C at a rate of 5°C / min, treated at a constant temperature for 1 hour, cooled naturally to room temperature, and then taken out to obtain a modified natural graphite sample. The preparation of the button cell was the same as in Example 1, and the electrochemical performance test results are listed in Table 1.

Embodiment 3

[0039] Take 60g natural graphite (particle size D 50 =16.9μm), add 25g of concentrated hydrochloric acid with a concentration of 37.5wt%, stir, mix evenly, and then treat it at a constant temperature in a blast drying oven at 90°C for 16h, take it out after natural cooling, put the sample into a quartz porcelain boat, Push the quartz porcelain boat into the tube furnace, at N 2 Under the atmosphere, the temperature was raised to 500°C at a rate of 15°C / min, treated at a constant temperature for 14 hours, cooled naturally to room temperature, and then taken out to obtain a modified natural graphite material. The preparation of the button cell was the same as in Example 1, and the electrochemical performance test results are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com