Patents

Literature

43results about How to "The amount added is controllable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Microbial fermented composite antibiotic-free feed containing natural antibacterial components

ActiveCN108813098AReasonable nutritional structureLow costFood processingAnimal feeding stuffBiotechnologyAntibiotic Y

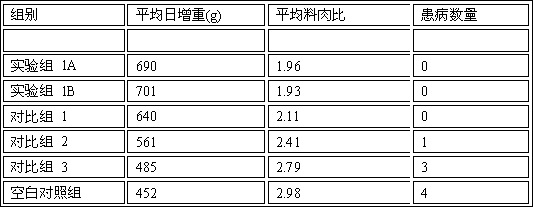

The present invention provides a microbial fermented composite antibiotic-free feed containing natural antibacterial components. The feed comprises a fermented product based on the united segmented fermentation of aerobic-anaerobic composite strains, composite natural antibacterial components, a non-plant source protein / polypeptide compound nutrient supplement agent, and an additive comprising atleast a soybean protein amino acid / polypeptide compound chelate. The composite strains comprises at least lactic acid bacteria, bacillus subtilis, yeast selected from candida utilis or saccharomyces cerevisiae, and enterococcus faecalis. The fermented product based on the united segmented fermentation is prepared by carrying out secondary fermentation on fermentation raw materials through the aerobic-anaerobic composite strains. The combination of the microbial fermented feed and the natural antibacterial components is beneficial to the balance of intestinal flora of animals, and can prevent the dysbacteriosis of digestive tracts, improve the immunity functions of animal organisms, reduce or replace the use of feed antibiotics, and significantly improve the digestion and absorption efficiency of the feed and the meat quality of animals.

Owner:JILIN QIAN KE LAI FEED TECH

Edible mix film and production process mainly with casting technique thereof

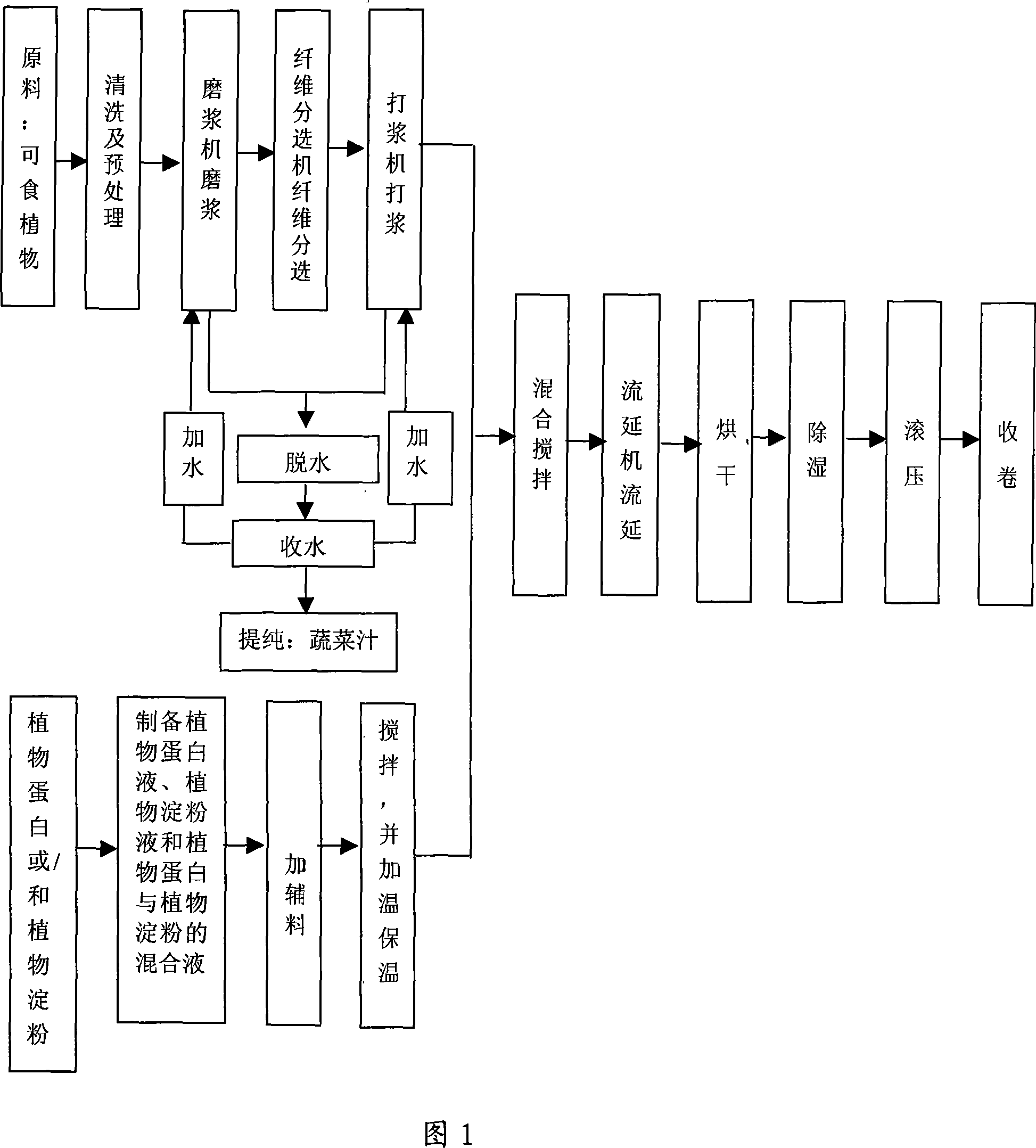

The invention discloses an edible mixed film and method for preparation, which is subject to tape casting process, and aims to provide the edible mixed film and method for preparation, which is made by edible plants and vegetable protein or / and starch and has various nutrition. According to weight percentage, the mixed film of the invention comprises 10-35 percent of edible plants, 80-50 percent of vegetable protein or / and vegetable starch, and 5-25 percent of auxiliary materials. The invention further provides a method for preparing mixed film using tape casting. Paper film of the invention is neither simple vegetable paper nor a simple protein film or a starch film, the nutrition is rich, and the invention integrates the advantages of physical and chemical properties of the vegetable paper and the protein film or the starch film. Further, the invention provides the method for preparation which is subject to the tape casting process and related technology, thereby overcoming the difficulties in the production process and technology. The mixed films are capable of being used as edible packaging of food, and also are capable of being used as food to eat directly.

Owner:TIANJIN UNIV OF COMMERCE

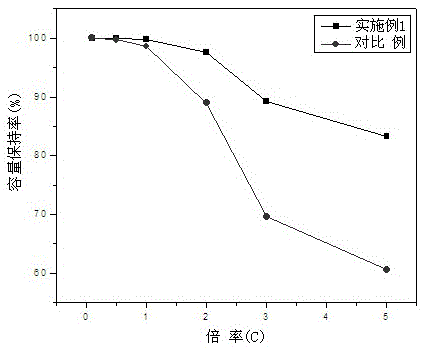

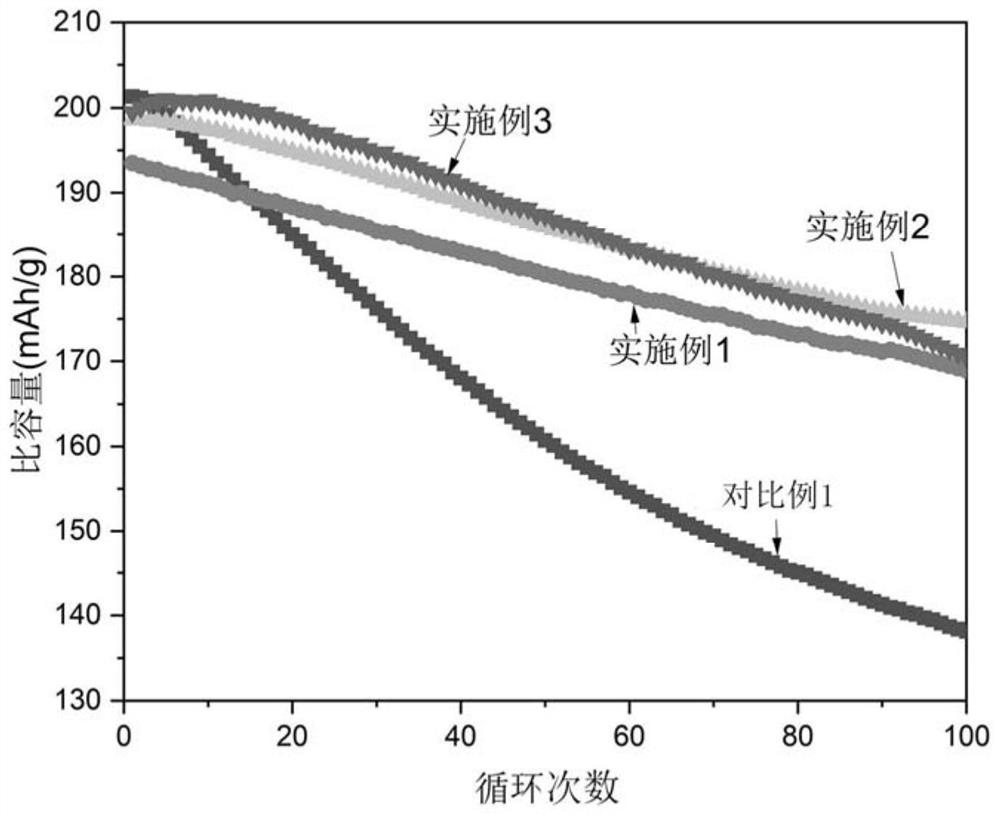

Modified natural graphite and preparation method and application thereof

InactiveCN105633370ASimple processEasy to controlCell electrodesSecondary cellsCruciblePhysical chemistry

The invention discloses modified natural graphite and a preparation method and an application thereof. The method comprises the following specific steps: firstly, mixing a graphite material with an intercalator evenly at the ratio, carrying out constant-temperature treatment on the mixed slurry at 90-200 DEG C for 1-16 hours to obtain an intercalated graphite material; adding an organic amine liquid to the intercalated graphite material, and stirring and mixing the organic amine liquid and the intercalated graphite material evenly; enclosing the obtained sample into a crucible, carrying out high-temperature thermal treatment in an inert gas atmosphere at 500-1500 DEG C for 0.5-14h, naturally cooling the sample and then taking out the sample to obtain the modified natural graphite material. The method is simple in process, mild in reaction condition, easy to control, relatively low in cost and beneficial to industrial implementation; and the obtained modified natural graphite is good in rate capability and cycle performance.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

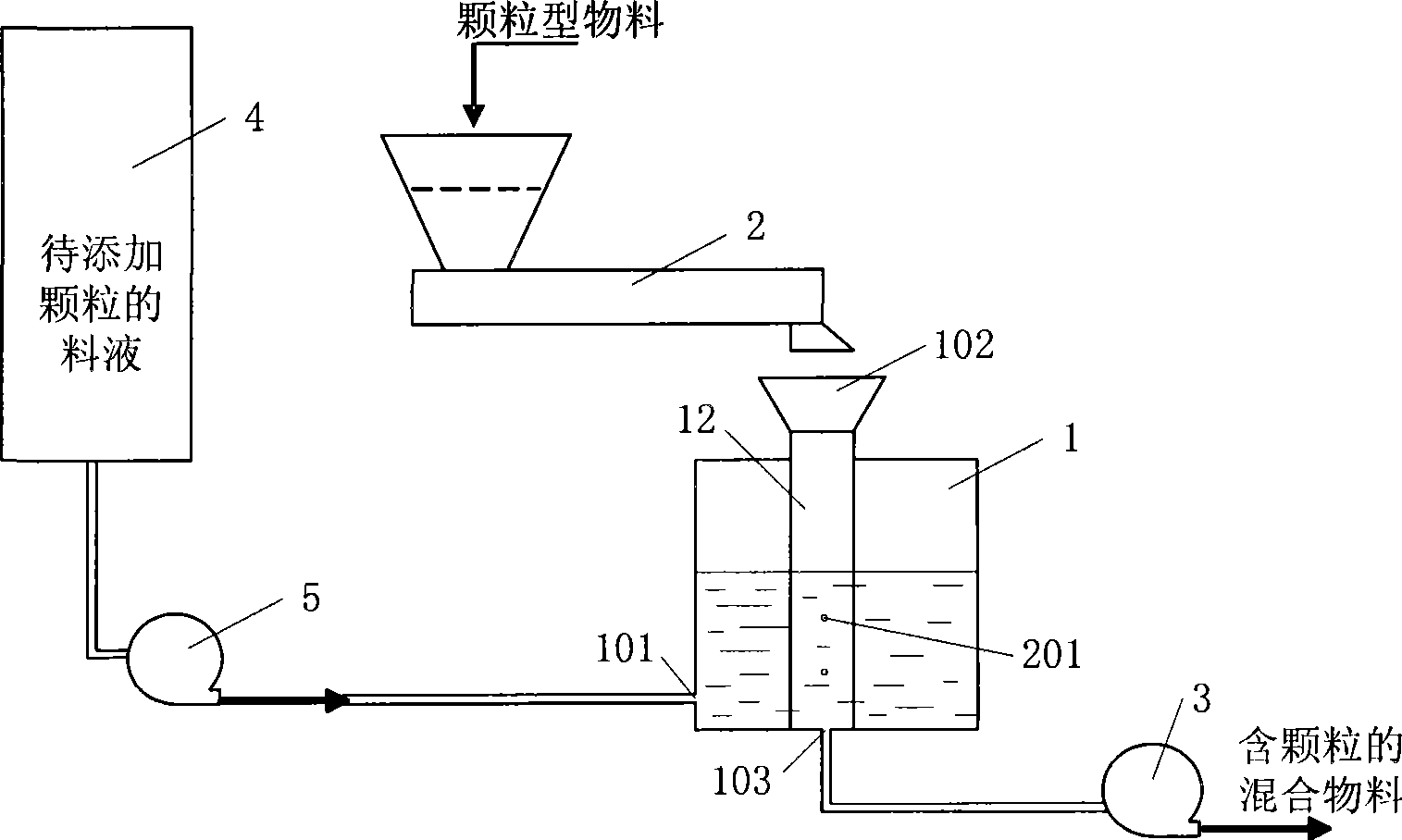

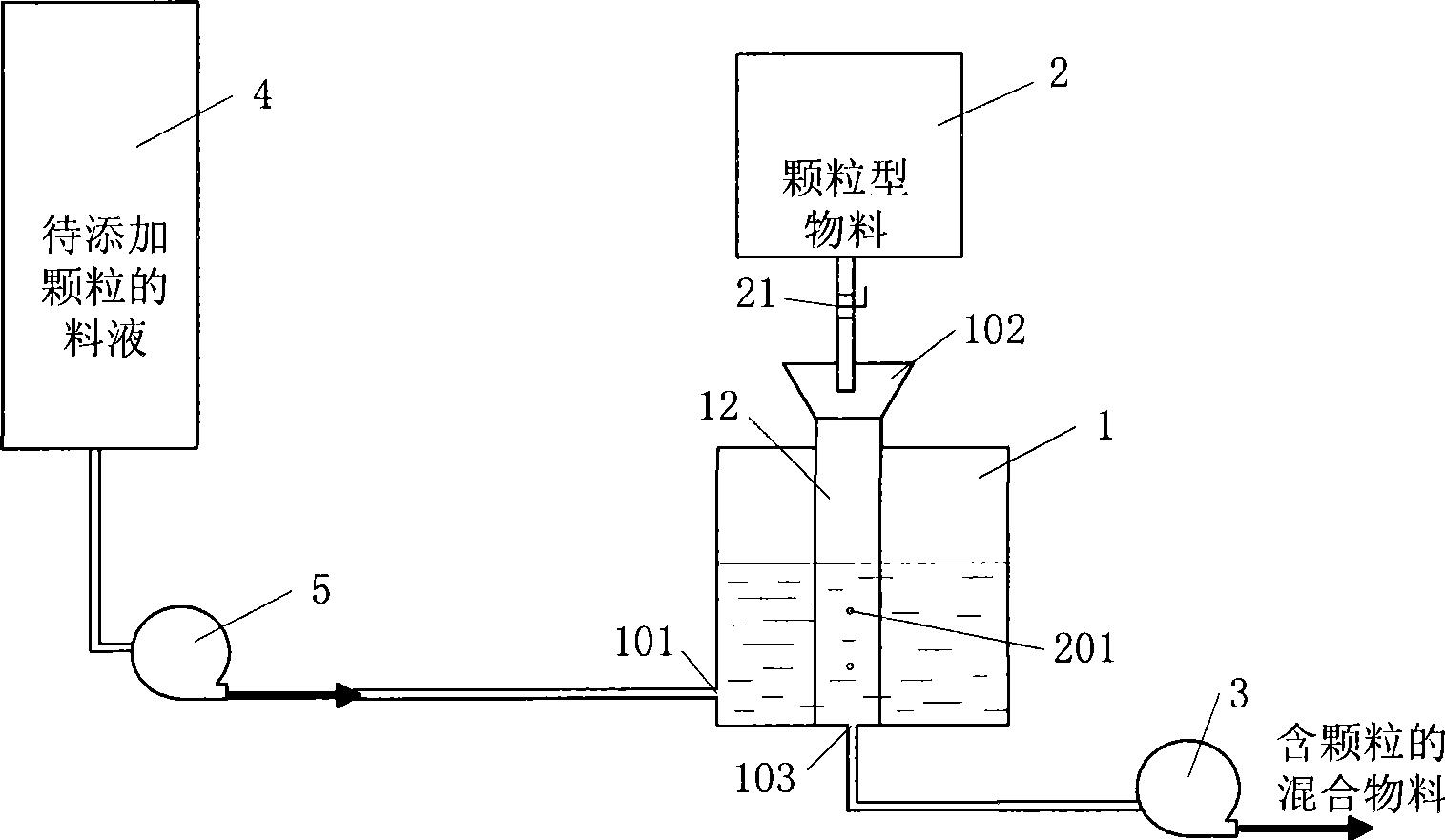

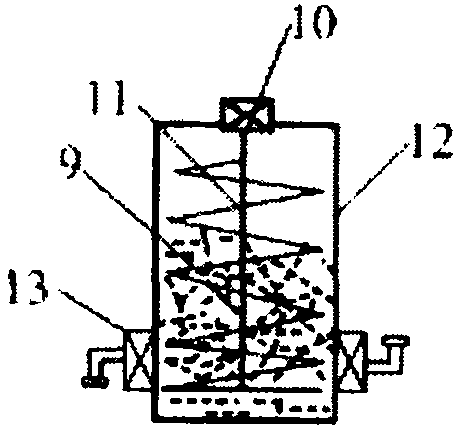

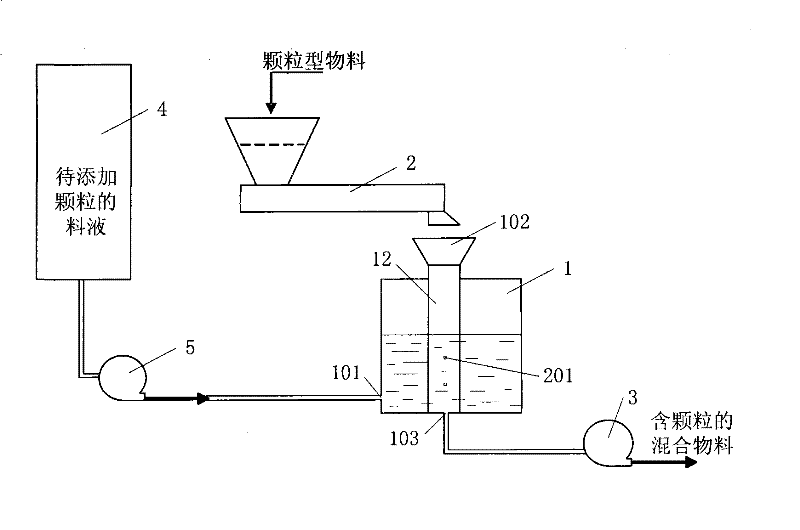

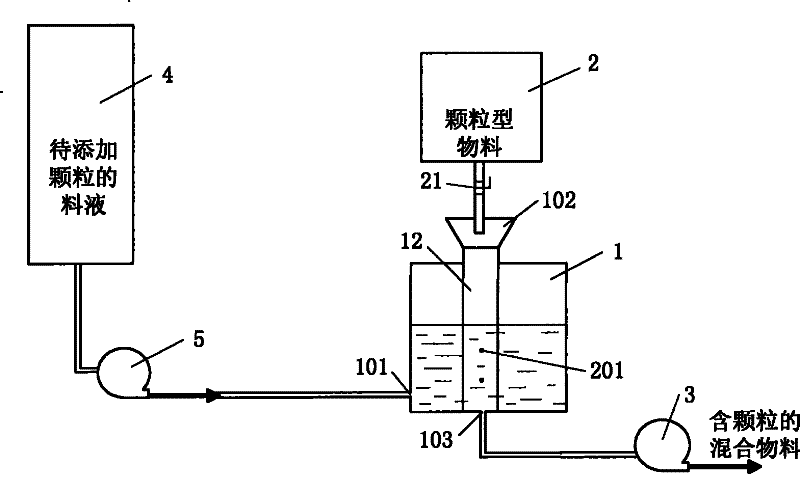

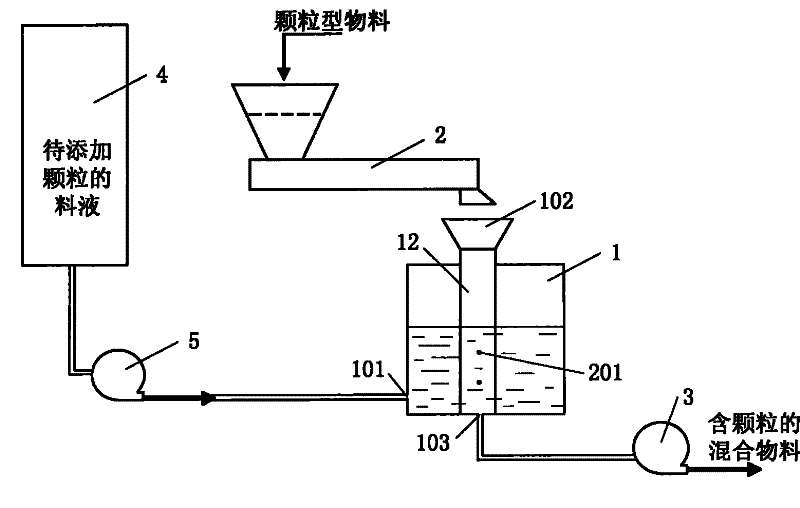

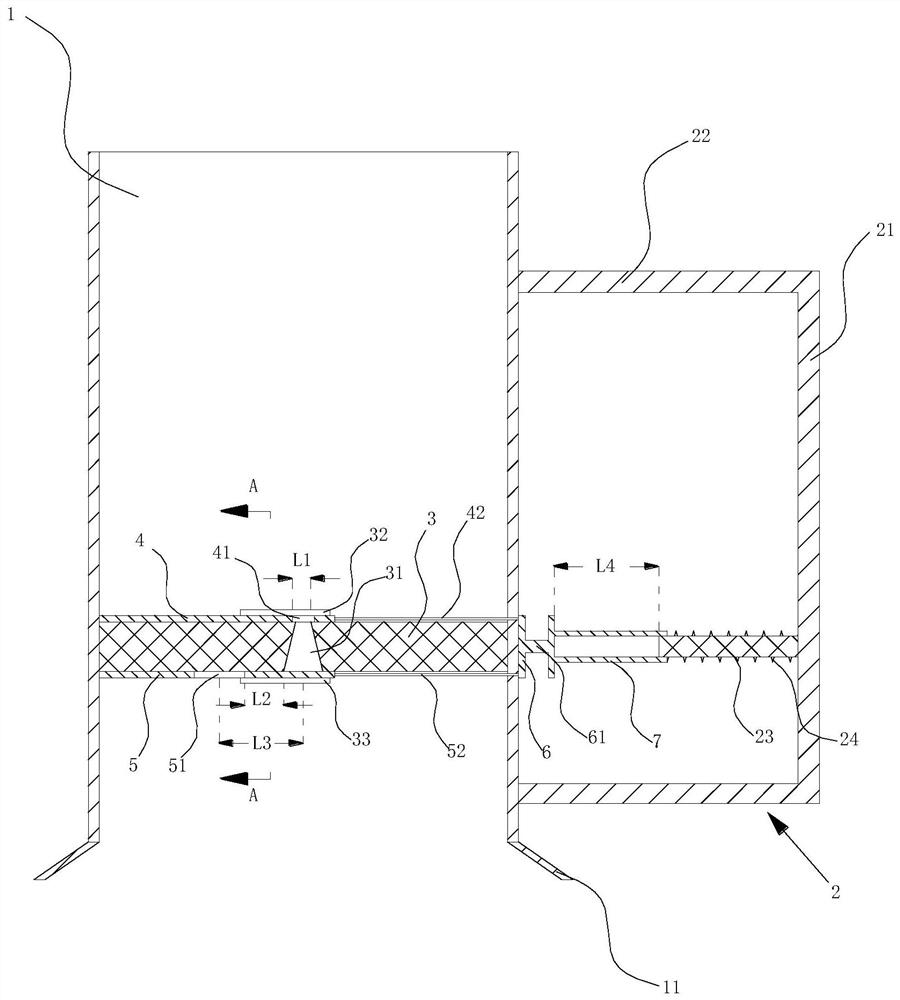

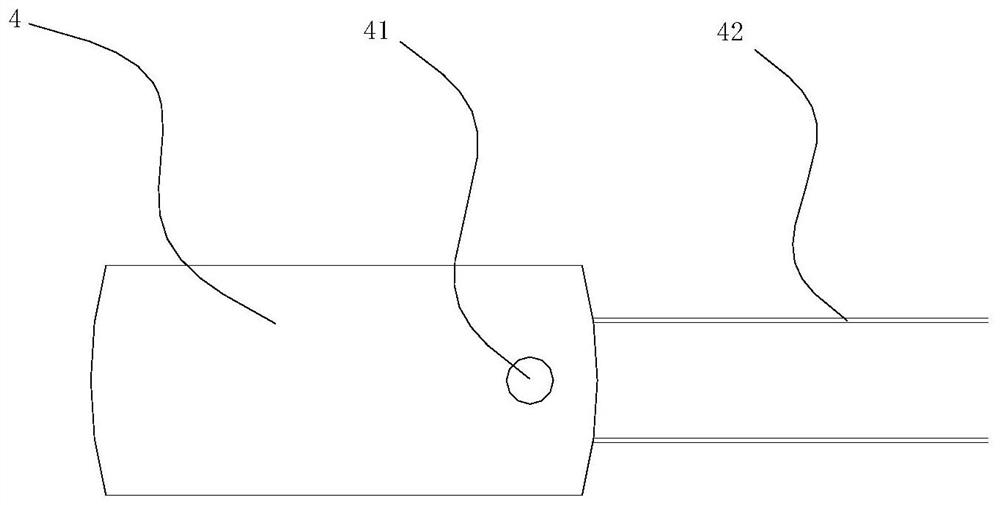

Granule-adding method and device for granule-containing liquid drink processing technique

ActiveCN101480266AReduce complexityIncrease the amount of controlMilk preparationPre-extraction tea treatmentLiquid stateEngineering

The invention provides a method and a device for adding granules in the process of inclusion granule liquid drink. The technical scheme of the device is mainly achieved as follows: a feeding pipe is arranged in a compensating groove, the wall of the feeding pipe is provided with holes, the bottom end of the feeding pipe contacts with the bottom surface of the compensating groove in a sealing way so as to enable feed liquid to be added with granules to enter into the feeding pipe from the holes on the wall of the feeding pipe after entering into the compensating groove, granular materials enter into the feeding pipe from the upper port of the feeding pipe, the feed liquid to be added with granules are mixed with the granular materials in the feeding pipe to form inclusion granule mixed materials which are led out of a mixed material outlet arranged on the bottom surface of the compensating groove corresponding to the bottom end surface of the feeding pipe from the compensating groove so that the granular materials are uniformly added into the feed liquid on line. The invention also provides a method for producing the inclusion granule liquid drink by the method and the device for adding granules.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

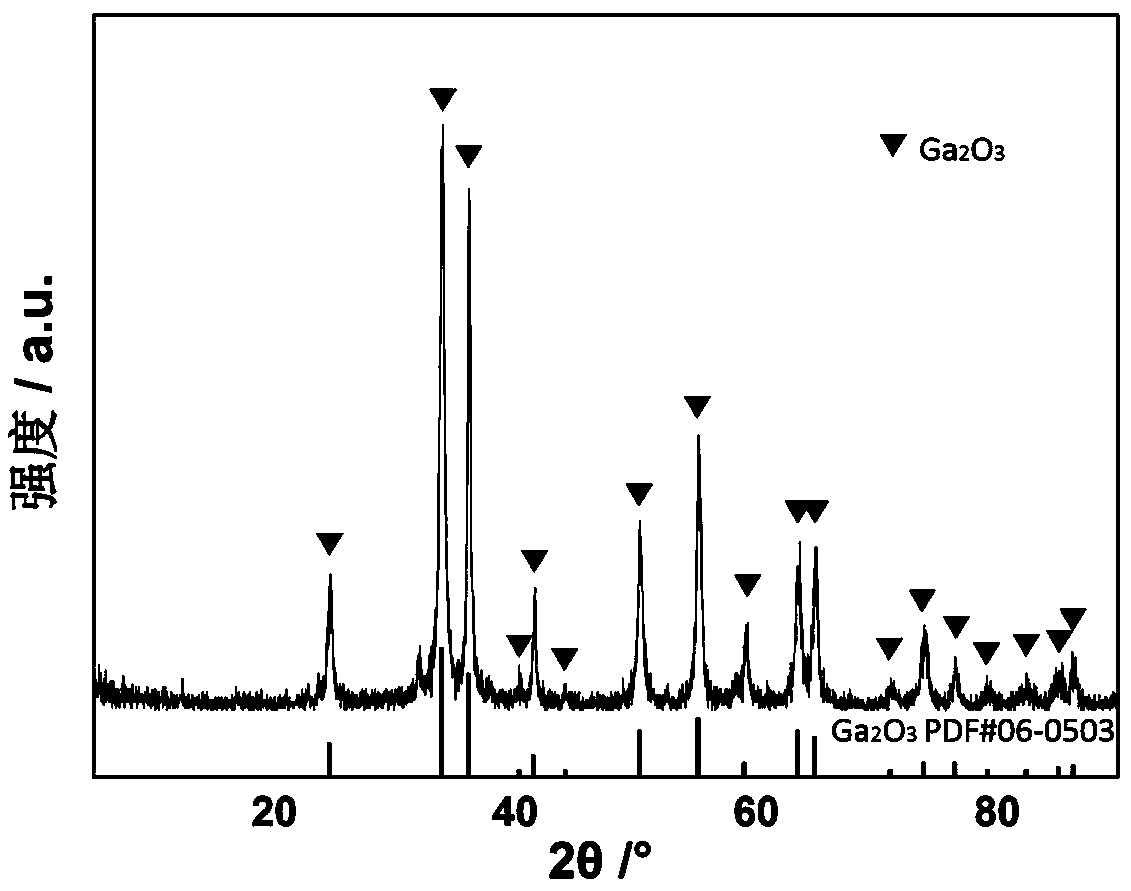

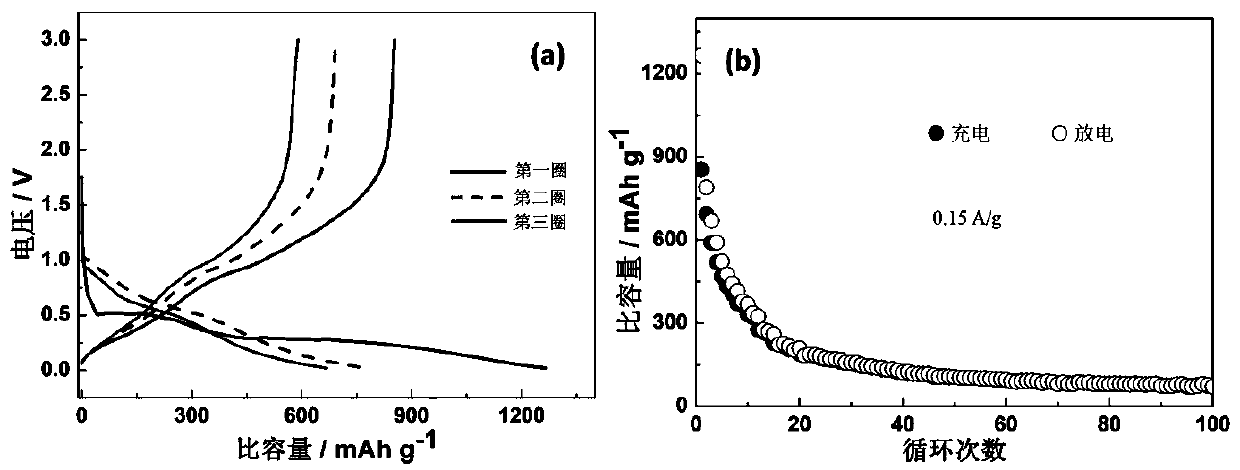

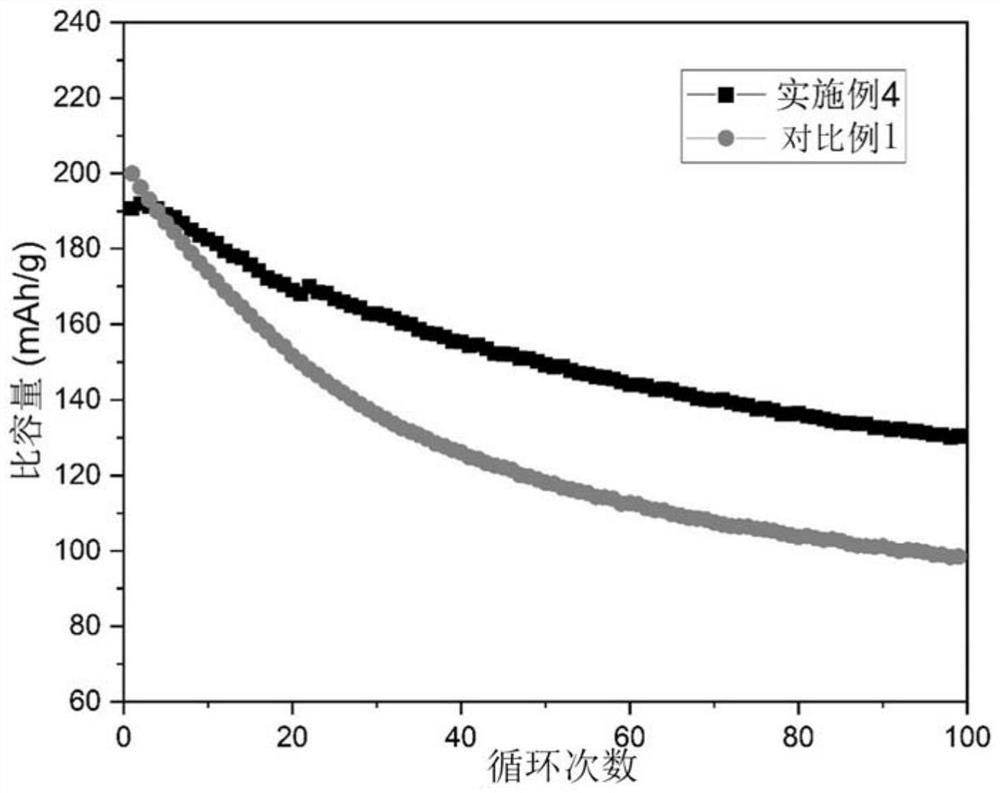

Stable compound lithium ion battery negative electrode material alpha-Ga2O3 and preparation method thereof

ActiveCN107732221ALow preparation temperatureSintering conditions are simpleCell electrodesHexamethylenetetramineActive component

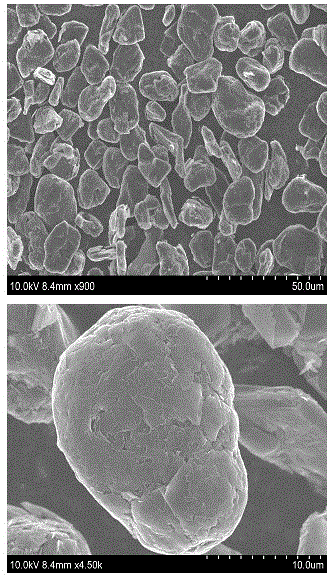

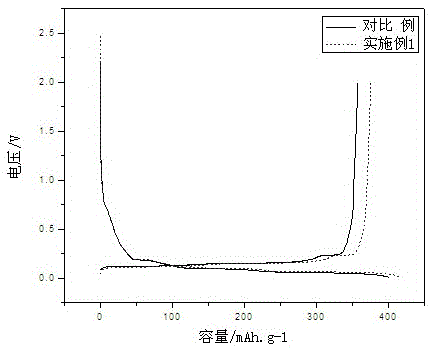

The invention provides a stable compound lithium ion battery negative electrode material, and the active component of the material comprises alpha-Ga2O3. Alpha-Ga2O3 is composed of a great amount of micrometer cubes, the length of cubes is 1-1.5 [mu]m, and the width and height are in a range of 200-800 nm. The preparation method comprises the following steps: adding gallium nitrate, hexamethylenetetramine, sodium sulfate, and citric acid into a container, adding deionized water, stirring until all components are dissolved; transferring the solution to a hydrothermal inner container, adding deionized water; fixing the inner container, carrying out hydrothermal reactions in a blowing drying oven to obtain a precursor; drying the precursor, and sintering the precursor in a tubular furnace toobtain alpha-Ga2O3. The alpha-Ga2O3 can be used to prepare a lithium ion battery negative electrode and has very good electrochemical characteristics and a wide application prospect.

Owner:CHINA THREE GORGES UNIV

Water-based environment-friendly colorful texture coating and preparation method thereof

ActiveCN104109443AEnvironmentally friendlyHydrophobicMulticolor effect coatingsWater basedSoftened water

The invention discloses a water-based environment-friendly colorful texture coating and a preparation method thereof to solve the problems that a product is poisonous and inflammable and pollutes the environment as the existing colorful coating contains organic solvent. The water-based environment-friendly colorful texture coating comprises the following components in parts by mass: 30-50 parts of emulsion, 20-40 parts of color particles, 0.5-1.5 parts of thickener, 0.4-0.8 part of dispersant, 0.2-0.4 part of wetting agent, 0.5-2 parts of propylene glycol, 0.2-0.5 part of defoaming agent, 1-3 parts of titanium dioxide, 3-5 parts of talcum powder, 1-5 parts of calcium carbonate, 0.1-0.3 part of neutralizer and 10-40 parts of softened water. Modified starch and pigment are used as raw materials to prepare color particles, the color particles and composite starch emulsion are used as raw materials to prepare the environment-friendly colorful particle coating, and the water-based environment-friendly colorful texture coating is environment-friendly, free of color bleeding, good in compatibility, good in repeatability and the like.

Owner:GANSU GLDARK NEW MATERIAL

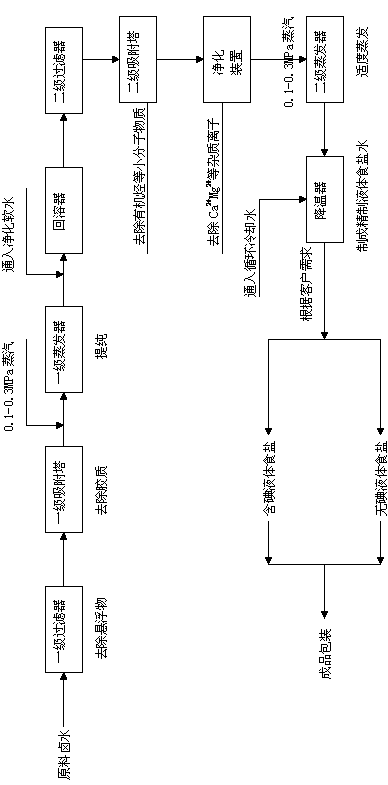

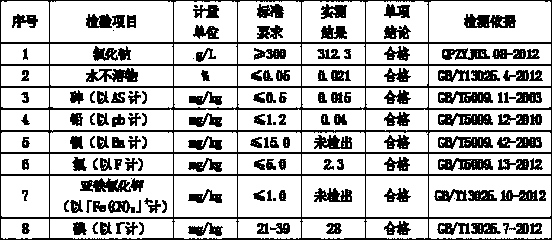

Preparation process of liquid edible salt

The invention belongs to the field of condiments and in particular relates to a preparation process of liquid edible salt. The liquid edible salt is obtained by carrying out first-level filtering, first-level adsorption, evaporation, redissolution, purification treatment, second-level filtering, second-level absorption and evaporation on a raw material of brine. The liquid edible salt produced by the preparation process is environmentally friendly, safe, convenient to use, free of pollution and any antitackiness agent and good in taste. Saline taste directly acts on the surface of cooked food during addition, the additive amount is easy to control, the addition is uniform, and the acceptable daily intake of the edible salt is easy to control.

Owner:中盐皓龙盐化有限责任公司

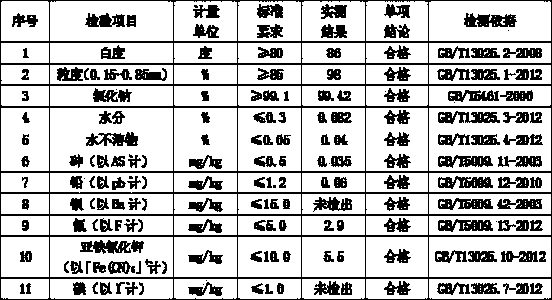

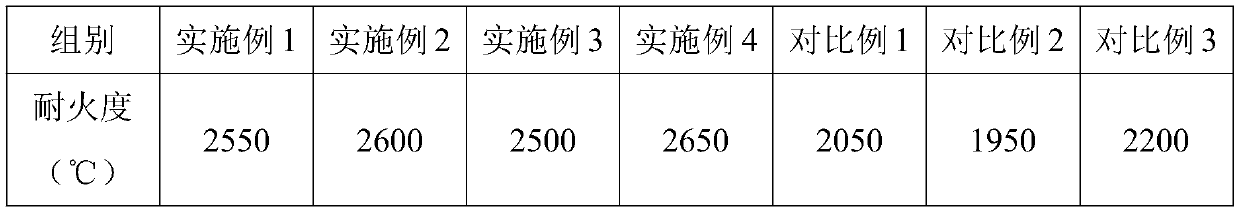

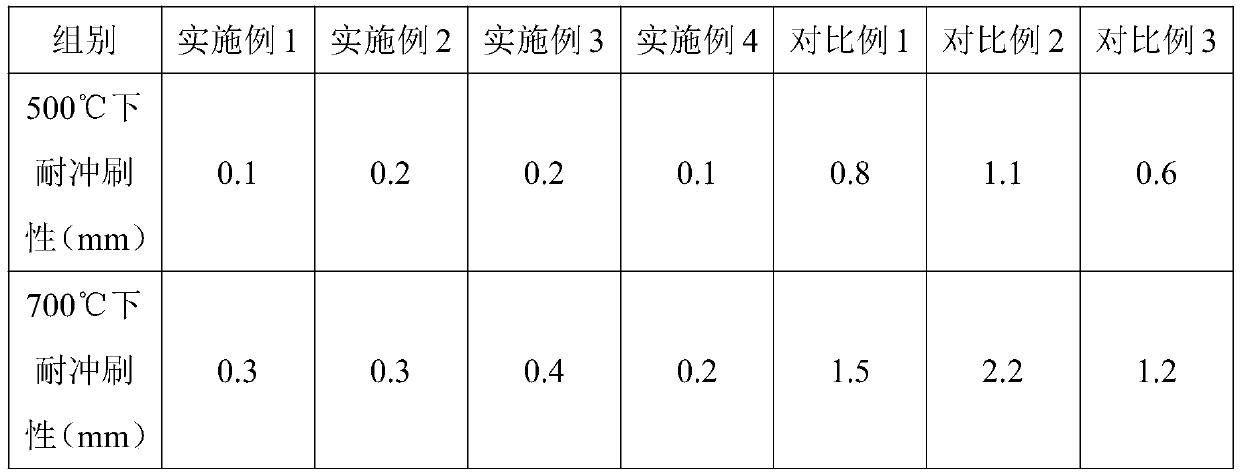

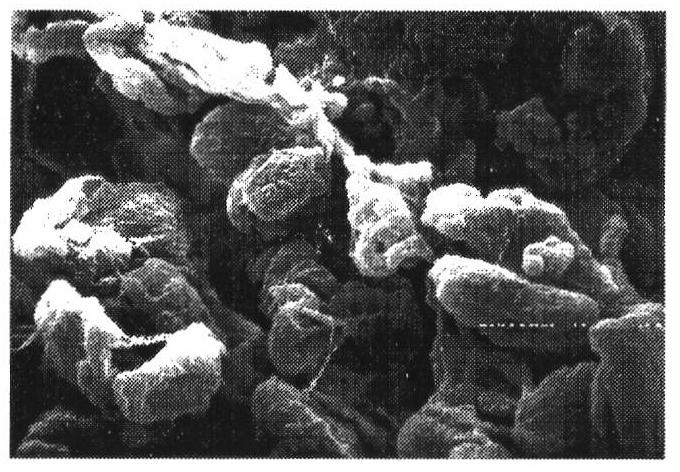

Preparation method for low-silicon, high-calcium and large-crystal fused magnesia

The invention discloses a preparation method for low-silicon, high-calcium and large-crystal fused magnesia. The preparation method comprises the following two steps: preparation of high-activity MgOand smelting with an electric arc furnace, i.e., during preparation of high-activity magnesium oxide powder, adding a sodium carbonate solution with a concentration of 3 to 8%, then adding high-puritygraphite powder into the prepared high-activity magnesium oxide powder as a reducing agent, carrying out balling with a device, after balling is completed, carrying out smelting with a fully-automatic electric arc furnace, carrying out cooling and crystallizing, and carrying out crushing and picking so as to obtain a finished product. According to the invention, through addition of the sodium carbonate solution, the point of melting is effectively reduced; the temperature of calcination is reduced; and energy is saved. Meanwhile, through a reaction between sodium carbonate with silicon dioxide impurities, sodium silicate and carbon dioxide can be generated; the silicon dioxide impurities in magnesite can be effectively removed; and the content of magnesium oxide is improved. The low-silicon, high-calcium and large-crystal fused magnesia provided by the invention reaches an MgO content of 99.90% or above, achieves a calcium-to-silicon ratio of 2.30 or above, has good high-temperature fire resistance and high-temperature scouring resistance, and can be used as a high-quality advanced refractory material to be applied in the industries of aerospace, electronics, steel and iron, metallurgy, etc.

Owner:LIAONING XINFAZHAN REFRACTORY MATERIAL GRP

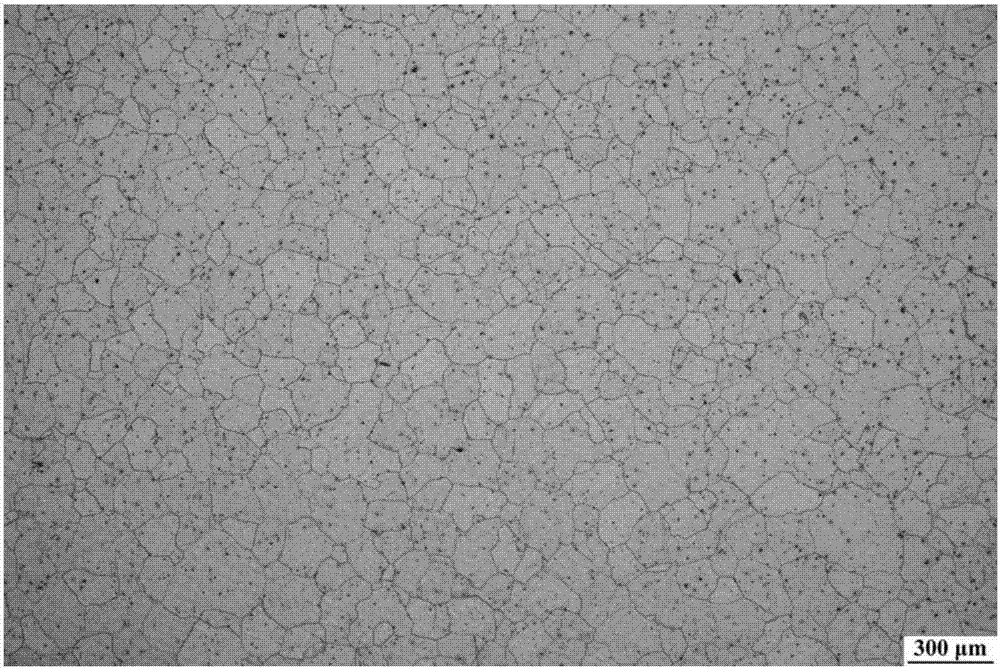

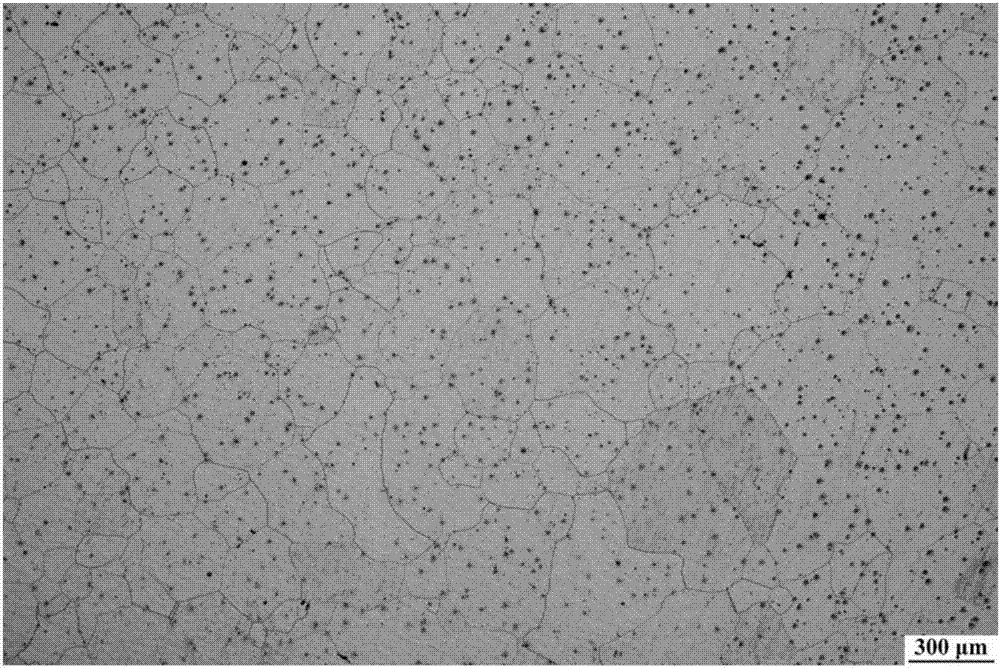

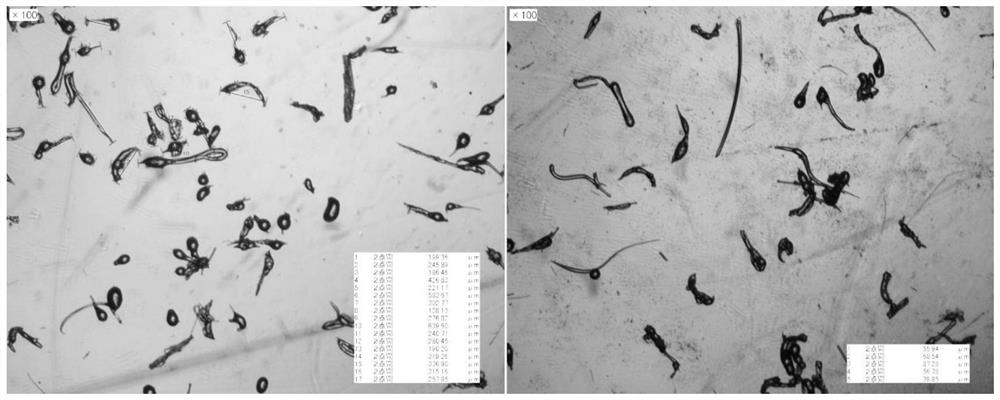

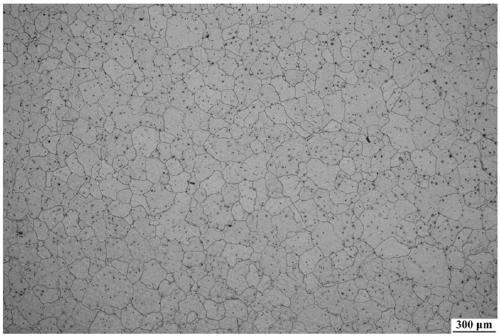

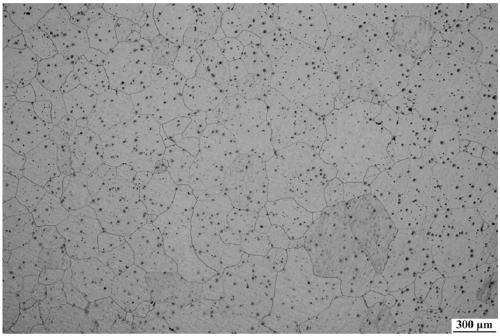

Vanadiferous magnesium intermediate alloy grain refiner and preparation method and application thereof

The invention discloses a vanadiferous magnesium intermediate alloy grain refiner and a preparation method and application thereof. The grain refiner comprises, by mass, 90-99% of magnesium and the balance vanadium compound which is composed of at least one of VC, VN, VC<x>N<1-x>, and in VC<x>N<1-x>, x is larger than 0 and less than 1. The invention further discloses the preparation method of the vanadiferous magnesium intermediate alloy grain refiner. According to the vanadiferous magnesium intermediate alloy grain refiner, the vanadium compound can be used as an effective heterogeneous nucleation core of magnesium alloy and prepared into magnesium intermediate alloy, the adding amount is easier to control, using is convenient, the yield is high, and limiting of the content of the magnesium alloy is avoided (the grain refiner can be added into both magnesium alloy containing Al and magnesium alloy free of Al); and after the grain refiner is added into the magnesium alloy, the grain of the magnesium alloy is effectively refined, magnesium and the magnesium alloy are strengthened, and the comprehensive mechanical property of the magnesium alloy is improved.

Owner:CHONGQING UNIV OF ARTS & SCI

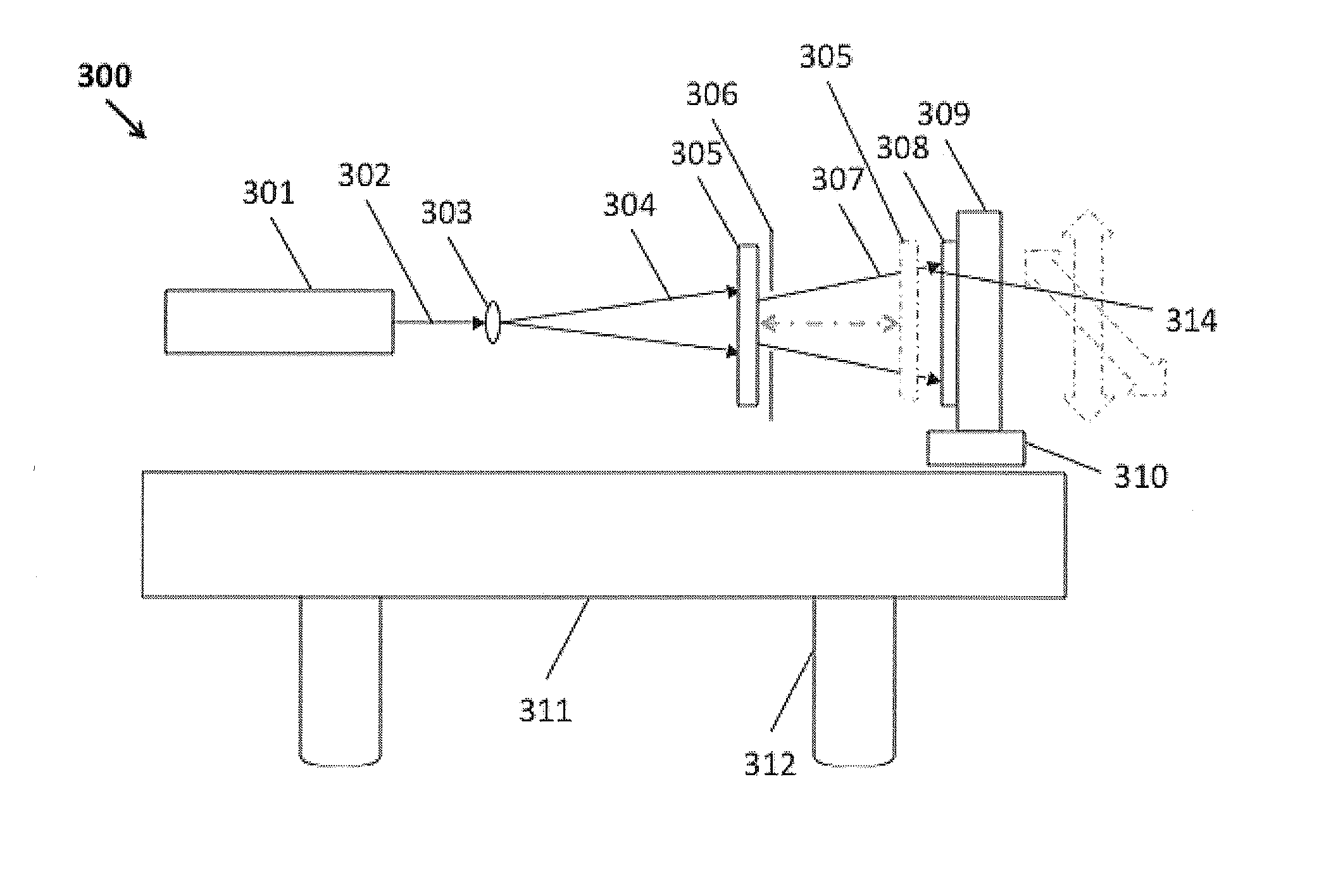

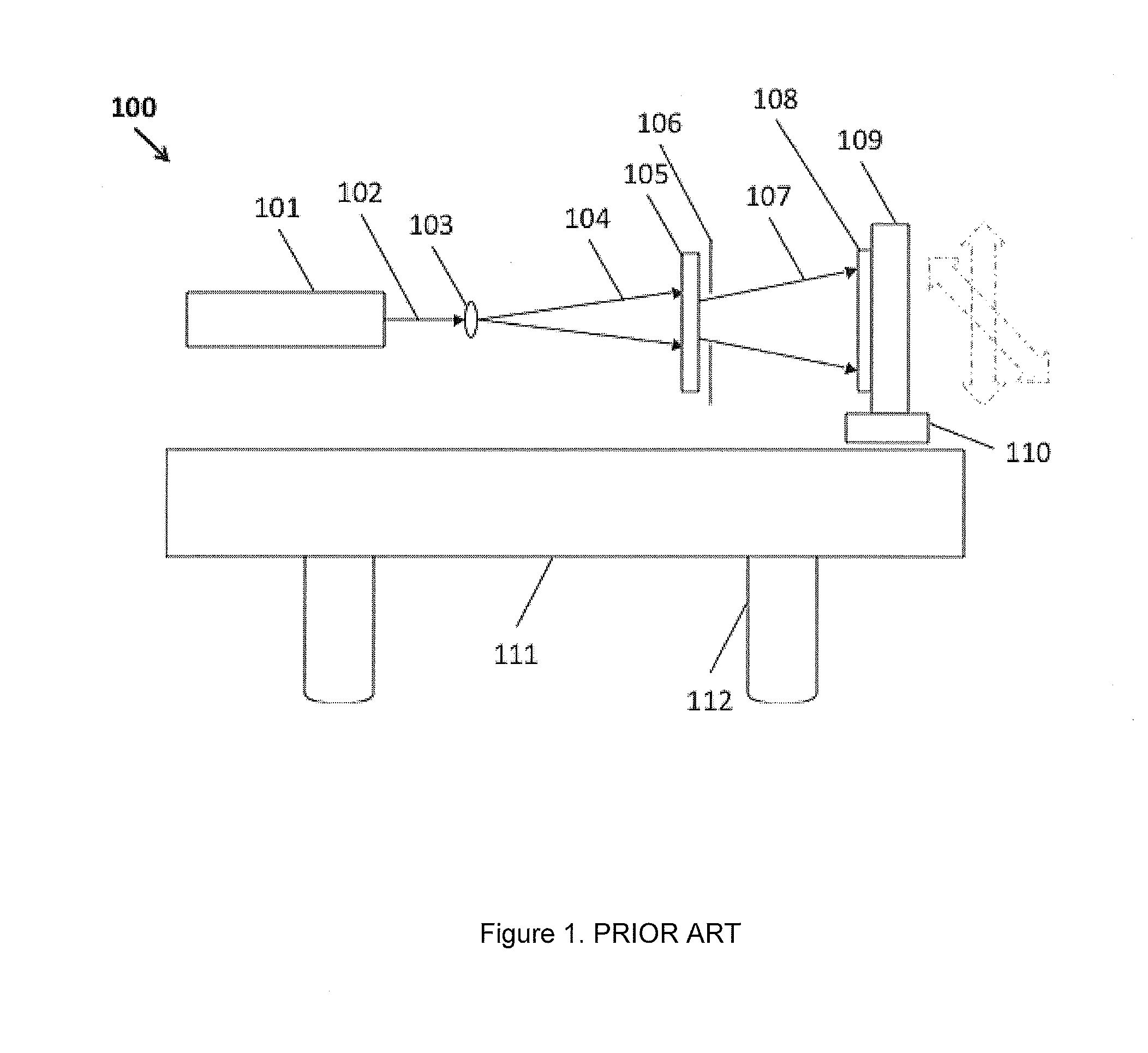

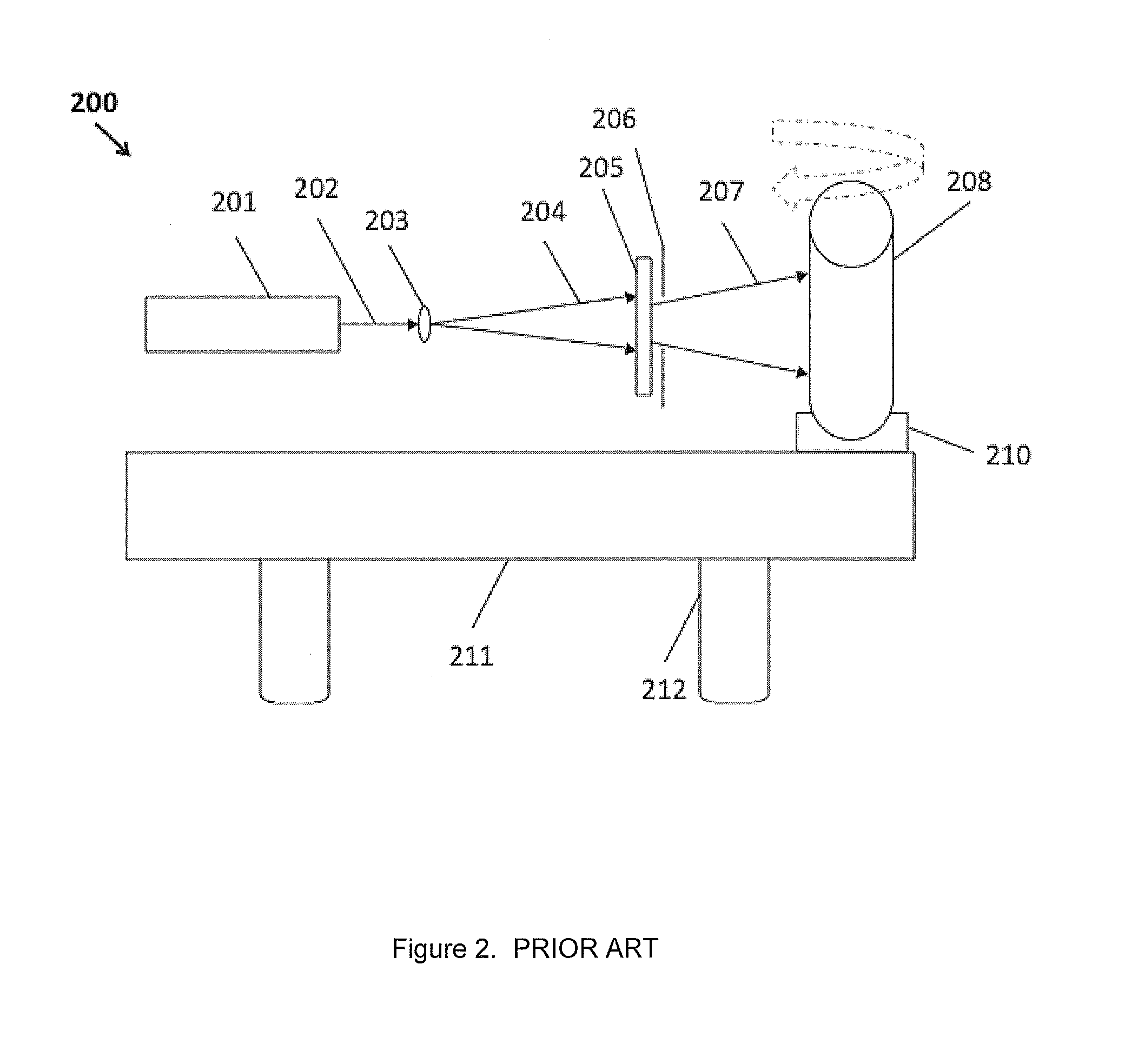

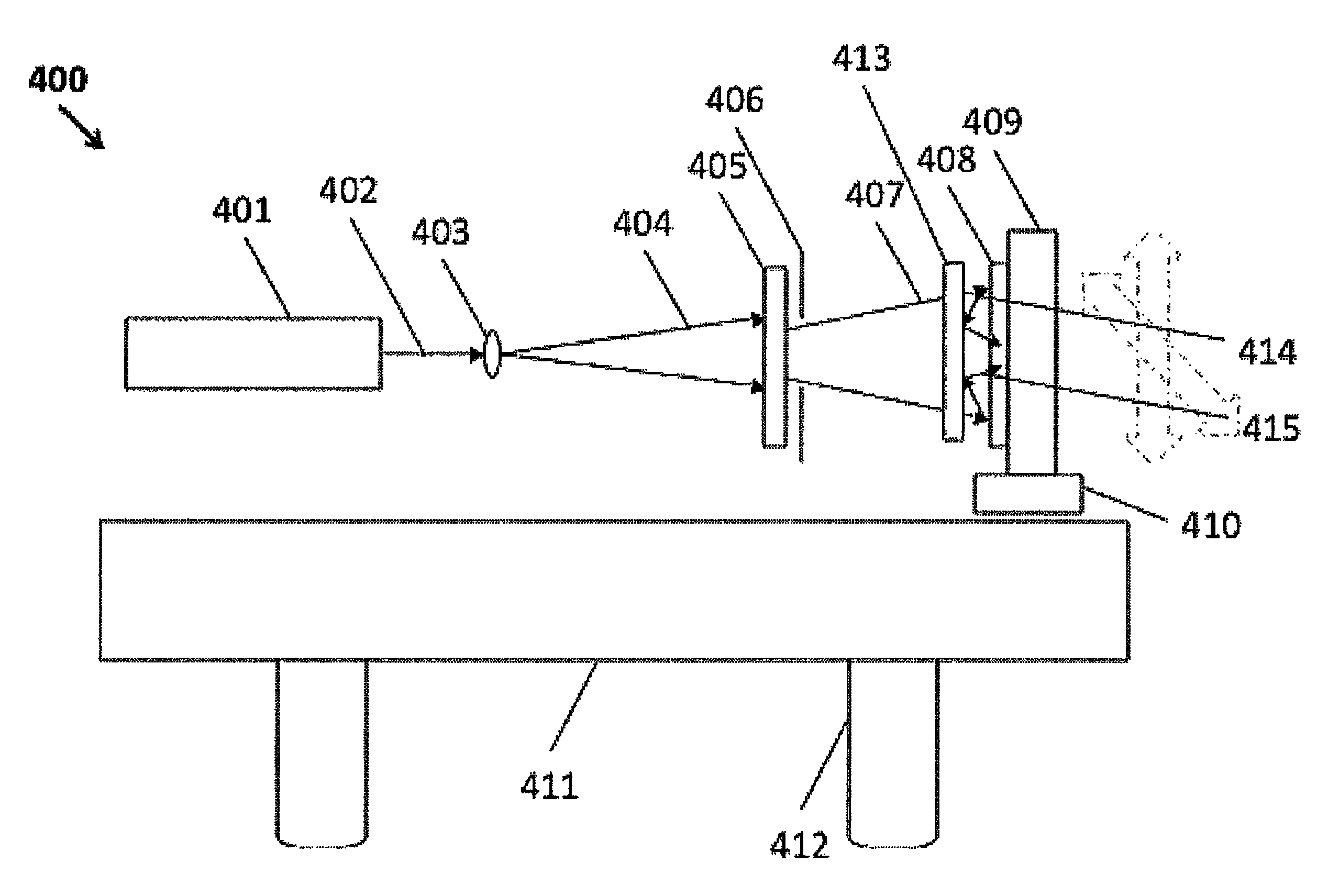

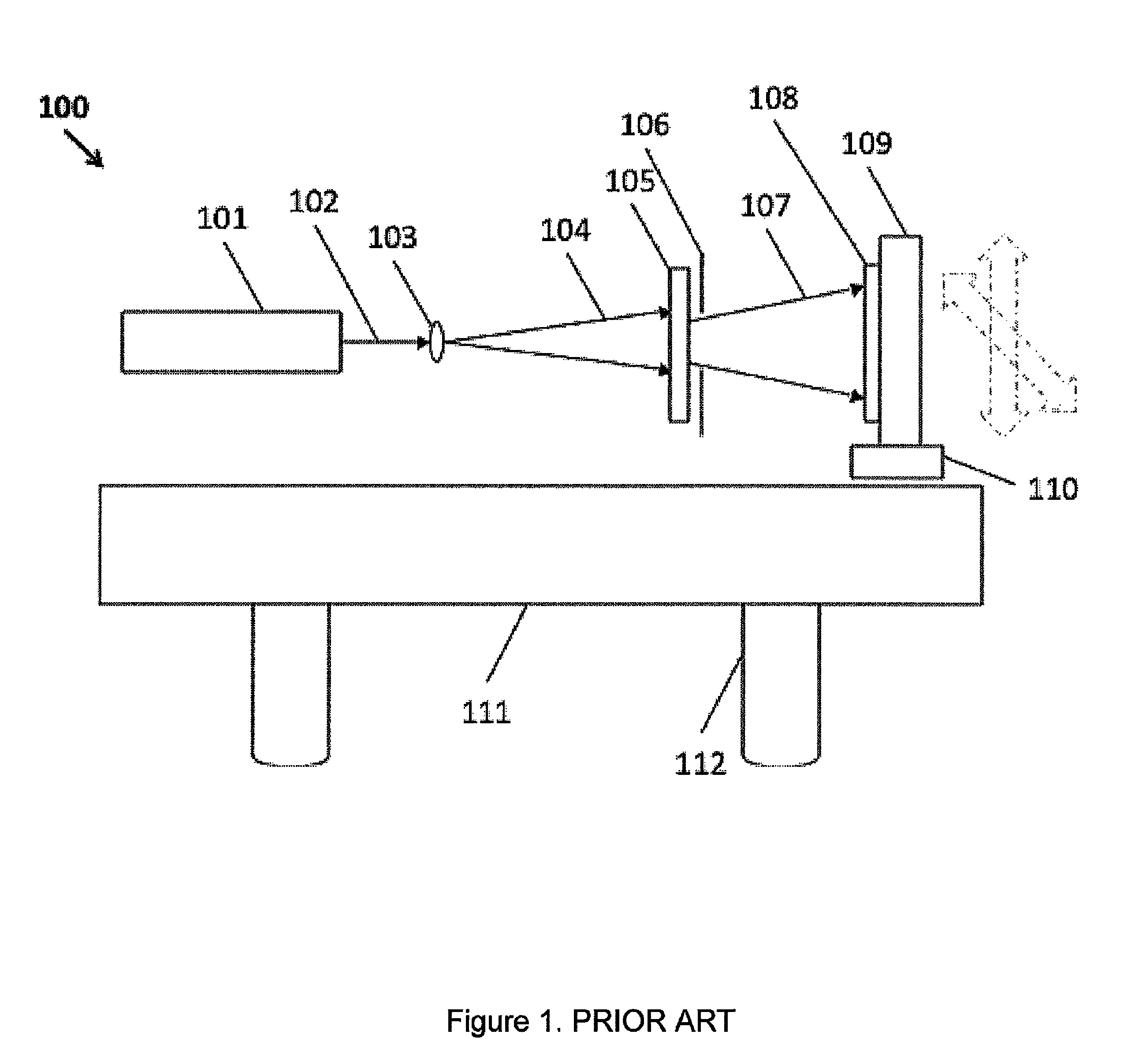

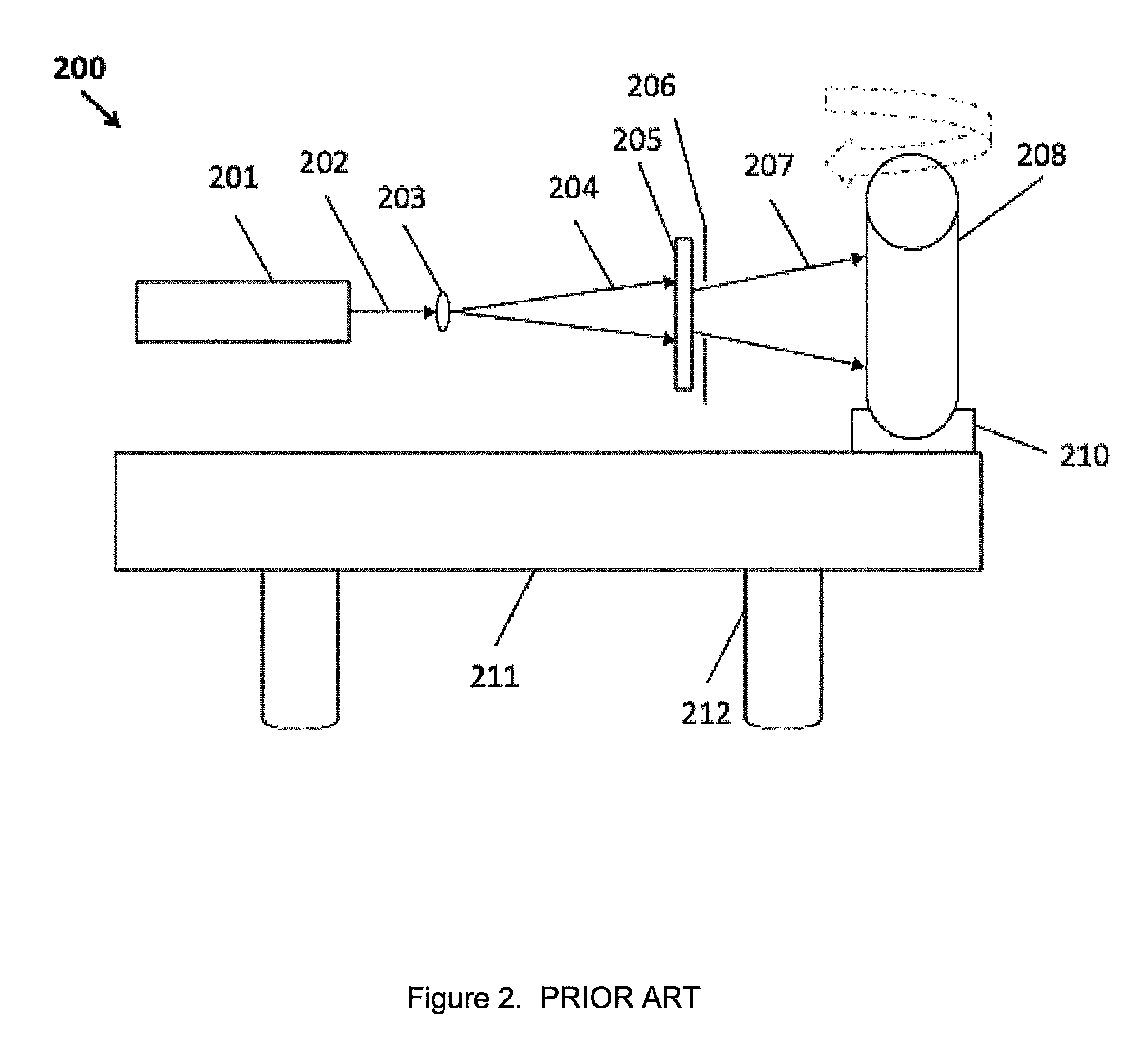

Composite Holographic Optical Diffuser Structure with High Frequency Overlay and Method of Fabrication Thereof

ActiveUS20150056561A1Reduce glareSharp imagePhotomechanical exposure apparatusMicrolithography exposure apparatusSurface reliefHead-up display

The optical diffuser mastering of the subject invention includes legacy microstructure surface relief patterns, along with smaller ones, overlaid on the larger ones. The characteristic features produced by the present invention will be found useful to eliminate visible structures in / on optical diffusers, such as those used in movie projection screens (utilizing either coherent (i.e., laser-generated) and non-coherent (e.g., lamp-generated) light), head-up displays (HUDs), laser projection viewing, etc., as the present invention produces much sharper images than those afforded by traditional holographic optical diffusers.

Owner:LUMINIT

Composite holographic optical diffuser structure with high frequency overlay and method of fabrication thereof

The optical diffuser mastering of the subject invention includes legacy microstructure surface relief patterns, along with smaller ones, overlaid on the larger ones. The characteristic features produced by the present invention will be found useful to eliminate visible structures in / on optical diffusers, such as those used in movie projection screens (utilizing either coherent (i.e., laser-generated) and non-coherent (e.g., lamp-generated) light), head-up displays (HUDs), laser projection viewing, etc., as the present invention produces much sharper images than those afforded by traditional holographic optical diffusers.

Owner:LUMINIT

Preparation method of low-silicon high-calcium macrocrystalline fused magnesite

The invention discloses a preparation method of a low-silicon high-calcium macrocrystalline fused magnesite. The preparation method comprises the following steps: putting magnesite with the MgO content of over 45% into a light roasting furnace for continuous calcinations for 4 h, uniformly adding an Na2CO3 solution during calcinations, and smashing a product after calcinations to obtain a high-activity MgO powder; adding the high-purity graphite powder into the high-activity MgO powder, putting the mixture into a full-automatic electric smelting electric-arc furnace for smelting for 5 to 8 h,and carrying out classification crushing after the smelting is ended so as to obtain the low-silicon high-calcium macrocrystalline fused magnesite. According to the preparation method, a sodium carbonate solution is added, so that the melting point is effectively reduced, the calcination temperature is reduced, and the energy is saved; moreover, sodium silicate and carbon dioxide can be generatedthrough the reaction of sodium carbonate and impurity silicon dioxide, and the silicon dioxide impurity inside the magnesite can be effectively removed, so that the content of magnesium oxide is improved; the content of MgO inside the product reaches 99.90% or more than 99.90%, the calcium-silicate ratio reaches 2.30 or more, the fused magnesite has high high-temperature fire resistance and high-temperature scouring resistance, and the fused magnesite can be applied to the industries such as spaceflight, electrons, steel, metallurgy and the like as a high-quality advanced refractory material.

Owner:LIAONING XINFAZHAN REFRACTORY MATERIAL GRP

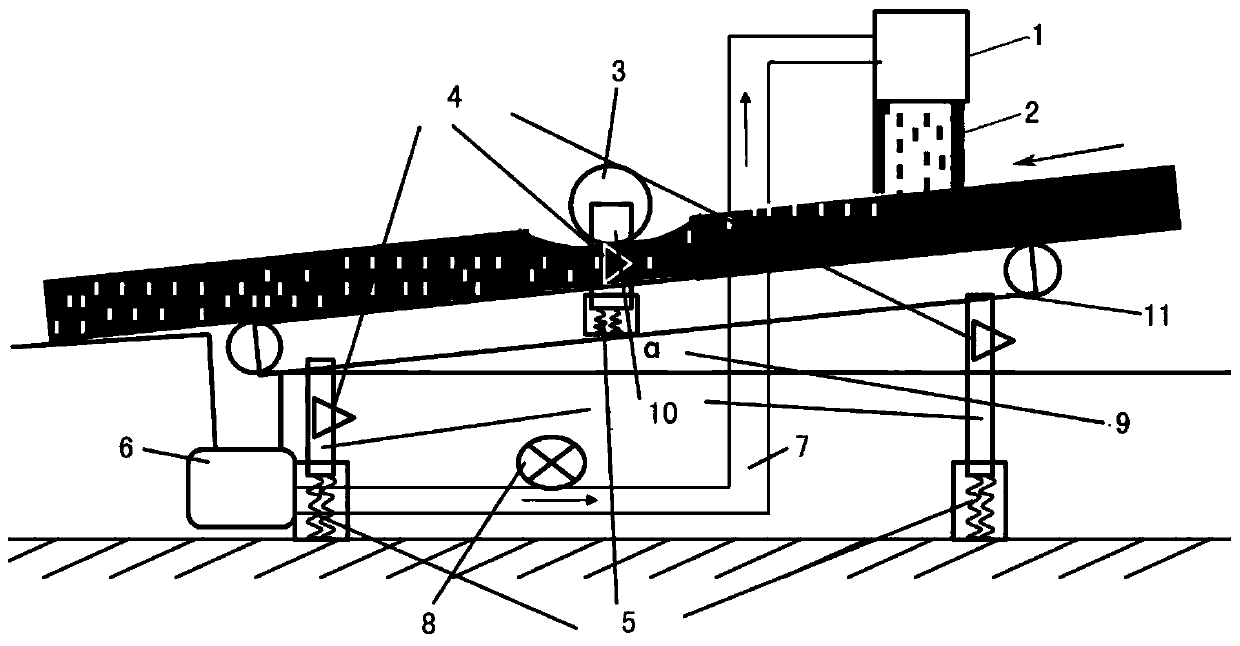

Efficient and low-pollution GMT powder scattering device and using method thereof

InactiveCN111376500AContaminated equipment area is smallThe amount added is controllableProcess engineeringChemistry

The invention provides an efficient and low-pollution GMT powder scattering device and a using method thereof. The powder scattering device comprises a powder scattering machine, a conveying belt, a bouncing roller, an elastic support, a vibration motor, a recycling bin and a circulating fan, in a dry-method GMT felt making process, additives can be directly added to a multi-layer felt net throughone-time powder scattering after net laying, the dispersion uniformity of powder in a net layer is kept through multiple vibration devices, sealed and circular treatment is carried out at all dust raising positions, the simplicity of later maintenance and cleaning is ensured, high efficiency, convenience and rapidness are achieved, and automation and productivity are improved.

Owner:浙江华江科技股份有限公司

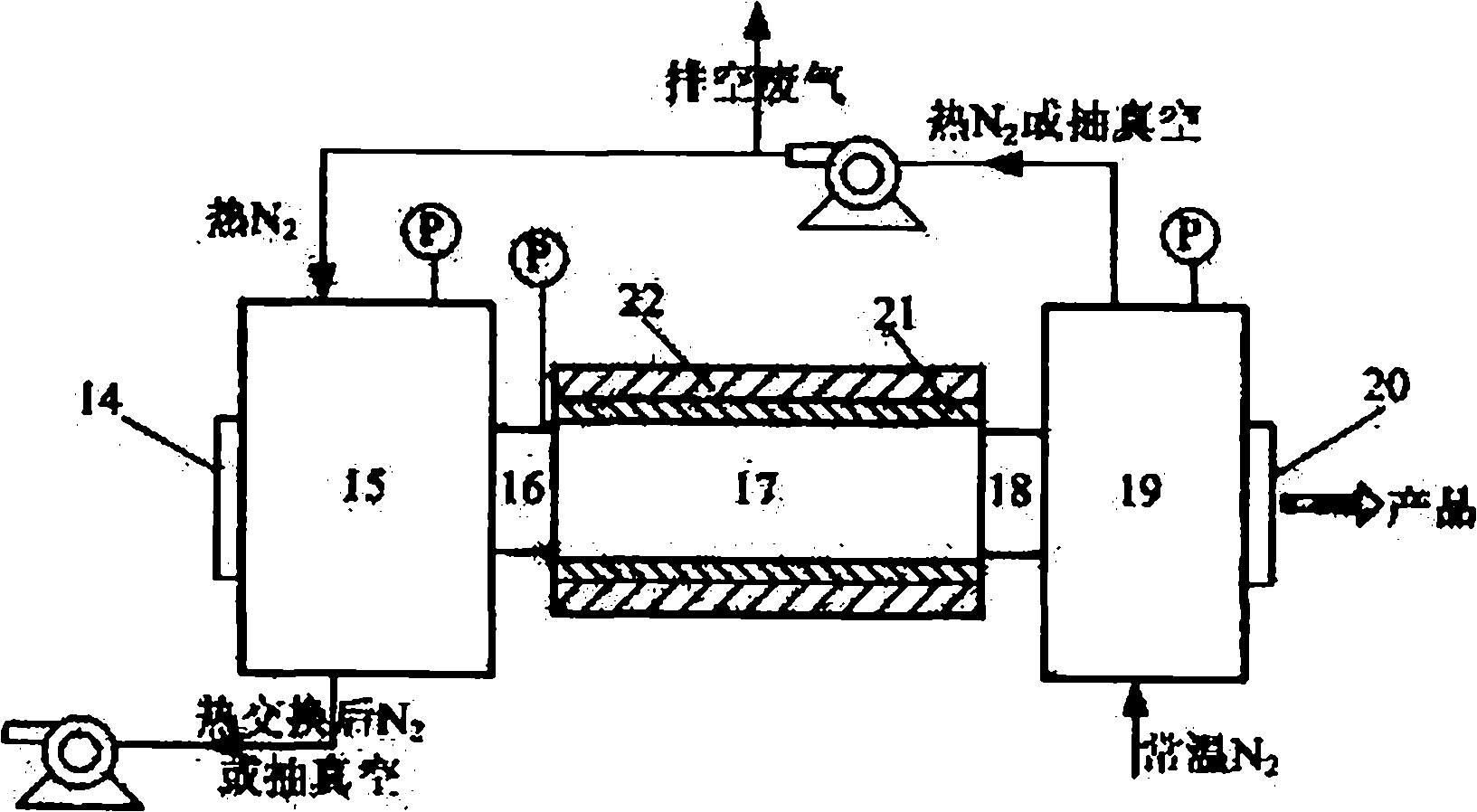

Quick crystallization method for realizing amorphous silicon nitride powder by taking silica powder as additive

ActiveCN102060544AFacilitate the phase transition processShorten crystallization timeSilica fumeNitrogen gas

The invention discloses a quick crystallization method for realizing amorphous silicon nitride powder by taking silica powder as additive, belonging to the technical field of preparation of ultrafine silicon nitride powder. The quick crystallization method is characterized in that the amorphous silicon nitride powder and silicon powder serving as the additive are fully mixed at the weight ratio of (98-50):(2-50); then the mixture is put into a high-temperature nitrogen furnace after being screened and dried for crystallizing the amorphous silicon nitride powder; the silicon powder is added to be subjected to combustion synthesis reaction together with nitrogen to generate alpha-phase silicon nitride while the crystallization time for the amorphous silicon nitride is effectively shortened; the final product is the alpha-phase silicon nitride powder, and the content of the silicon in the product is below 0.1%. The silicon powder serving as the crystallization can effectively accelerate the crystallization process of the amorphous silicon nitride powder, thus the nitriding of the nitrogen powder is completed while the crystallization time is greatly shortened. The method has the advantages of high production efficiency, simple equipment, quick energy conservation and high product purity, is convenient to operate, and is especially suitable for producing the high-quality silicon nitride powder with high alpha-phase content on batch by utilizing the amorphous silicon nitride powder.

Owner:UNIV OF SCI & TECH BEIJING

Method for adding fruit juice during foodstuff production process

InactiveCN101327028AAdd evenlyThe amount added is controllableMilk preparationFood preparationFruit juiceAlcohol

The invention provides a method for adding fruit juice in a food production process; the method comprises the following steps: antiseptic fruit juice is added into sterilized liquid food ingredients under an aseptic condition. The invention also provides a method for producing food with juice; the method comprises the following steps: the liquid food ingredients are sterilized; the antiseptic fruit juice is added into the sterilized liquid food ingredients. The method of the invention can reduce the nutrition loss of the juice in the food production process and keep the pure flavor of the fruit juice.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

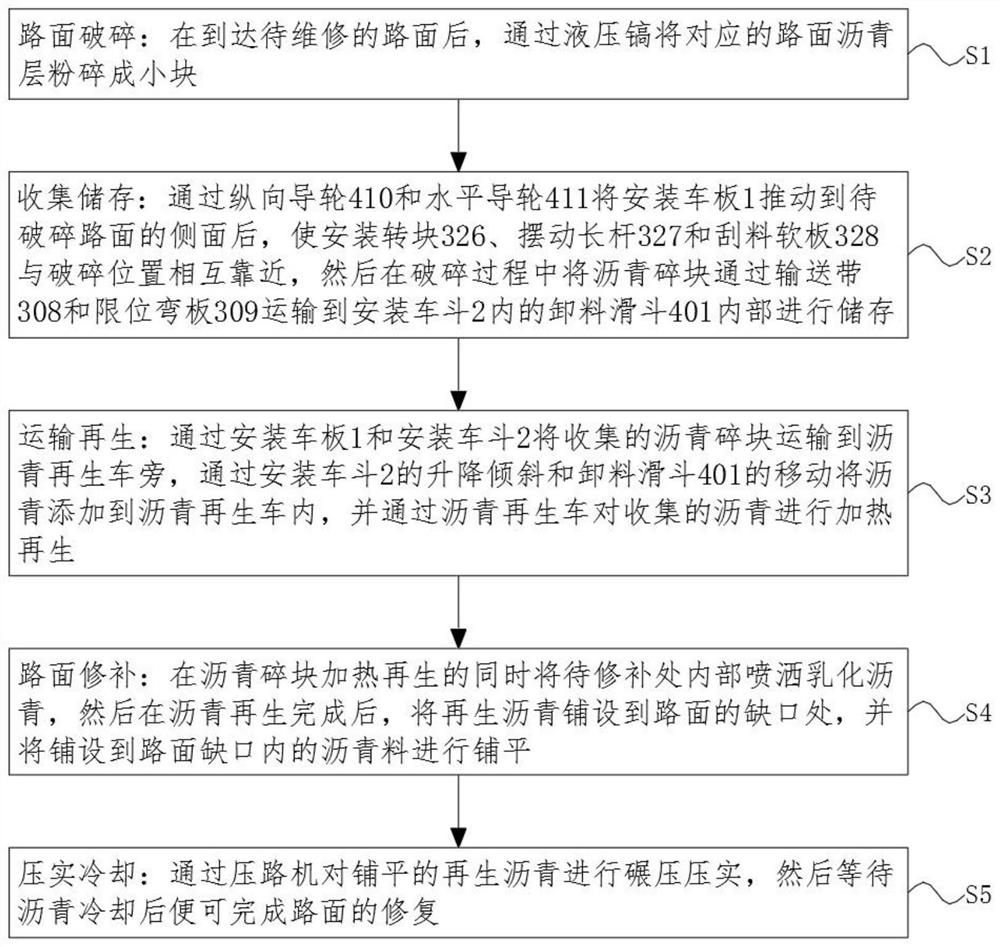

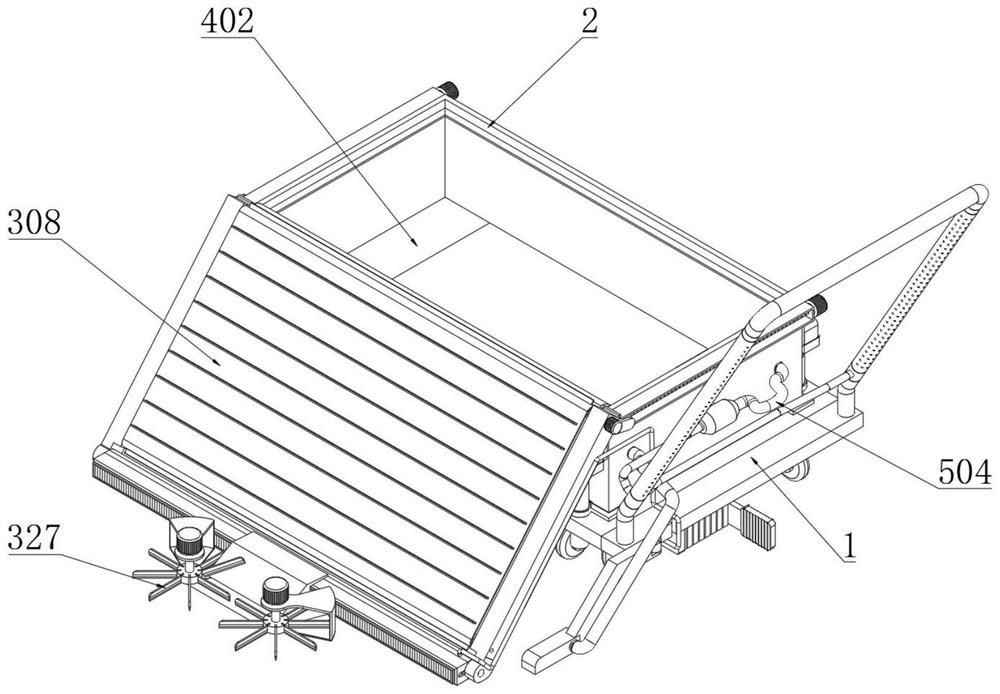

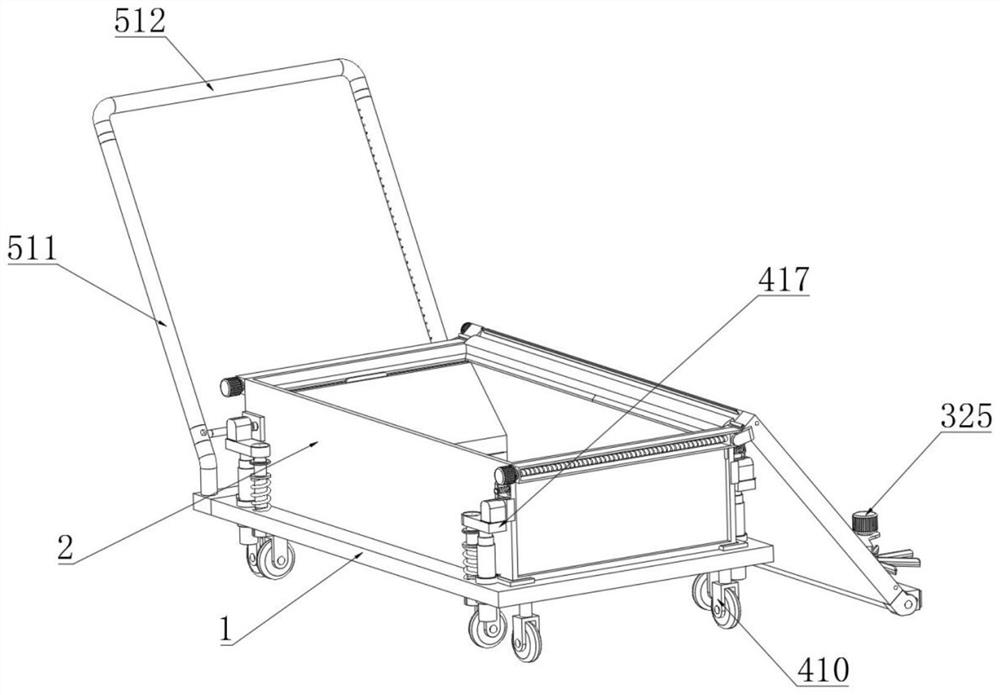

Environment-friendly road construction method

ActiveCN114134773AScientific and reasonable structureEasy to useIn situ pavingsDispersed particle filtrationArchitectural engineeringStructural engineering

The invention discloses an environment-friendly road construction method which comprises the following steps: S1, road surface crushing: after reaching a to-be-maintained road surface, crushing a corresponding road surface asphalt layer into small blocks through a hydraulic pickaxe, and S2, collecting and storing: pushing a mounting vehicle plate to the side surface of the to-be-crushed road surface through a longitudinal guide wheel and a horizontal guide wheel, and then carrying out road surface maintenance. According to the device, the labor intensity of road maintenance personnel is effectively reduced, meanwhile, when the collecting device is used, only one maintenance personnel needs to use a hydraulic pickaxe to damage the road surface, and the device is simple in structure, convenient to use and high in practicability. The asphalt fragments are collected by one cleaning person through the collecting device, so that simple preparation work can be completed, the personnel density in a single area is reduced, safety accidents caused by collision between instruments and personnel are reduced, and the use safety of the collecting device is effectively improved.

Owner:福建星原建设工程发展有限公司

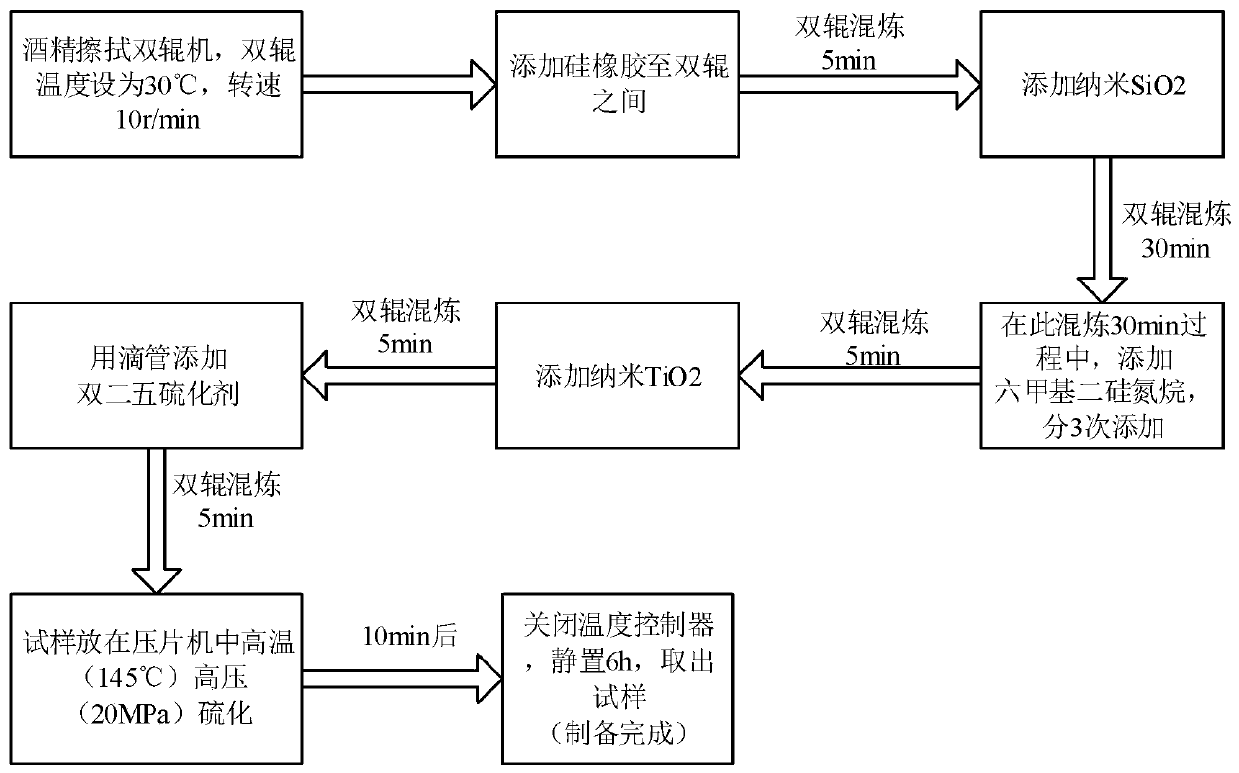

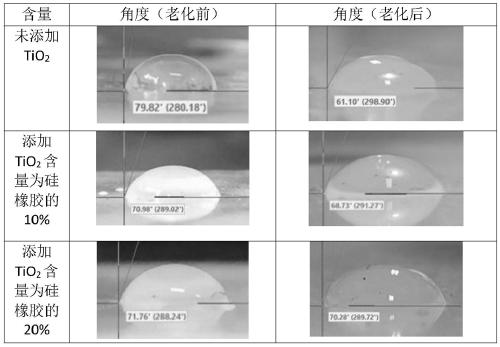

Ultraviolet radiation resistant composite insulator material added with nano particles and preparation method thereof

InactiveCN109762338ADoes not affect hydrophobicityThe amount added is controllableComposite insulatorsNano sio2

The invention relates to an ultraviolet radiation resistant composite insulator material added with nano particles and a preparation method thereof. According to the preparation method, silicon rubberis taken as a unit, and<x>g is taken, 20<x>% nano SiO2 is taken, 5<x>% of hexamethyldisilazane is taken, 10<x>%-40<x>% nano TiO2 is taken, and 1<x>% of 2,5-Dimethyl-2,5-di(tert-butylperoxy)hexane istaken; a twin-roller machine is started, and after the temperature reaches 30 EDG C, the silicone rubber is placed in the middle of two rollers for mixing; after homogenization, nano SiO2 is added into silicone rubber evenly, and then the mixture is mixed by two rollers; at the same time, the hexamethyldisilazane is added three times; after all the additives are added, twin-roller mixing is carried out, nano TiO2 is uniformly added, and after the additives are added, twin-roll mixing is carried out to obtain a mixed material; the 2,5-Dimethyl-2,5-di(tert-butylperoxy)hexane is uniformly droppedon the mixed material, twin-roller mixing is carried out, a sample is shoveled, the sample is rolled into a croissant shape, the sample is placed between the rollers for mixing again, the sample is taken down, and the sample is placed between two clean PET films; and the sample is vulcanized at high temperature by using a tablet press. The addition of the nano TiO2 does not affect the hydrophobicity of the composite insulator material.

Owner:国网西藏电力有限公司

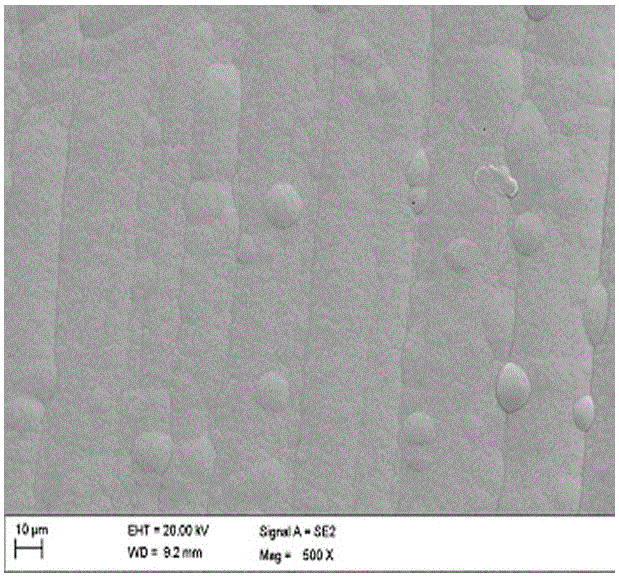

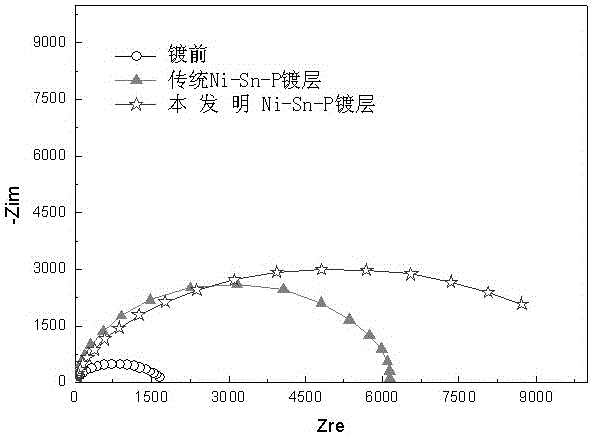

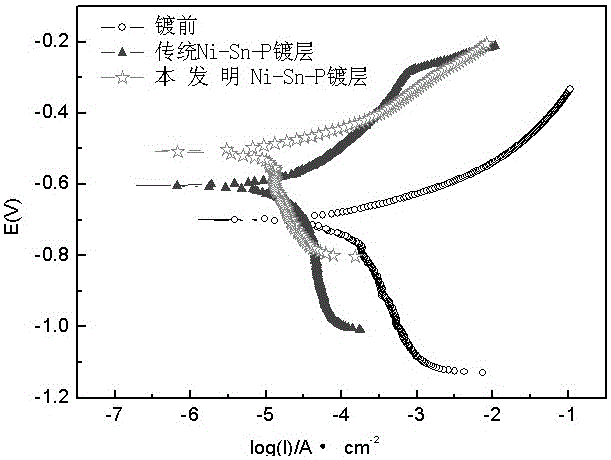

A kind of highly stable nickel-tin-phosphorus electroless plating solution

ActiveCN104561960BIncrease contentIncrease profitLiquid/solution decomposition chemical coatingAcetic acidSodium acetate

The invention discloses a high-stability nickel-tin-phosphorus chemical plating solution. Each liter of the plating solution comprises 20-45g of nickel chloride hexahydrate, 15-25g of sodium hypophosphite, (Sn(CH3SO3)2@SiO2) tin methanesulfonate microcapsules, 5-35g of sodium acetate, 6-35ml of acetic acid, 3-10g of a complexing agent, 4-15g of a stabilizer, 2-6g of a surfactant and the balance of water, wherein the pH value of the solution is 4.0-5.0. The high-stability nickel-tin-phosphorus chemical plating solution disclosed by the invention has the beneficial effects of high stability and gentle and controllable plating speed.

Owner:江苏矽智半导体科技有限公司

Water-based environmental protection colorful texture paint and preparation method thereof

Owner:GANSU GLDARK NEW MATERIAL

Method for adding lutein ester during food manufacture

InactiveCN101336742AReduce high temperature oxidationReduce denaturationMilk preparationFood preparationLiquid stateFood processing

The present invention relates to a method for adding lutein esters into foods, belonging to food processing field. The method comprises the steps of adding sterile lutein esters into sterilized food base material of liquid state under aseptic condition. The present invention also relates to a method for producing a food added with lutein esters, which comprises the steps that bactericidal processing is performed for food base material of liquid state, and sterile lutein esters preparation is added into sterilized food base material of liquid state. In the present invention, the loss of lutein esters in food processing can be reduced, the loss of health function of lutein esters caused by oxidation can be prevented, and the amount of addition of lutein esters can be decreased.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

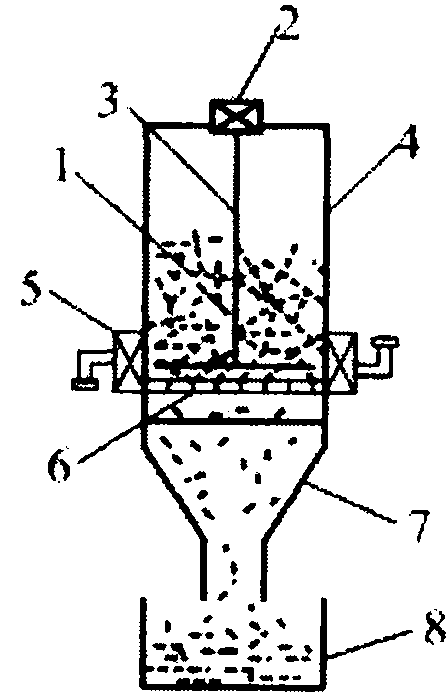

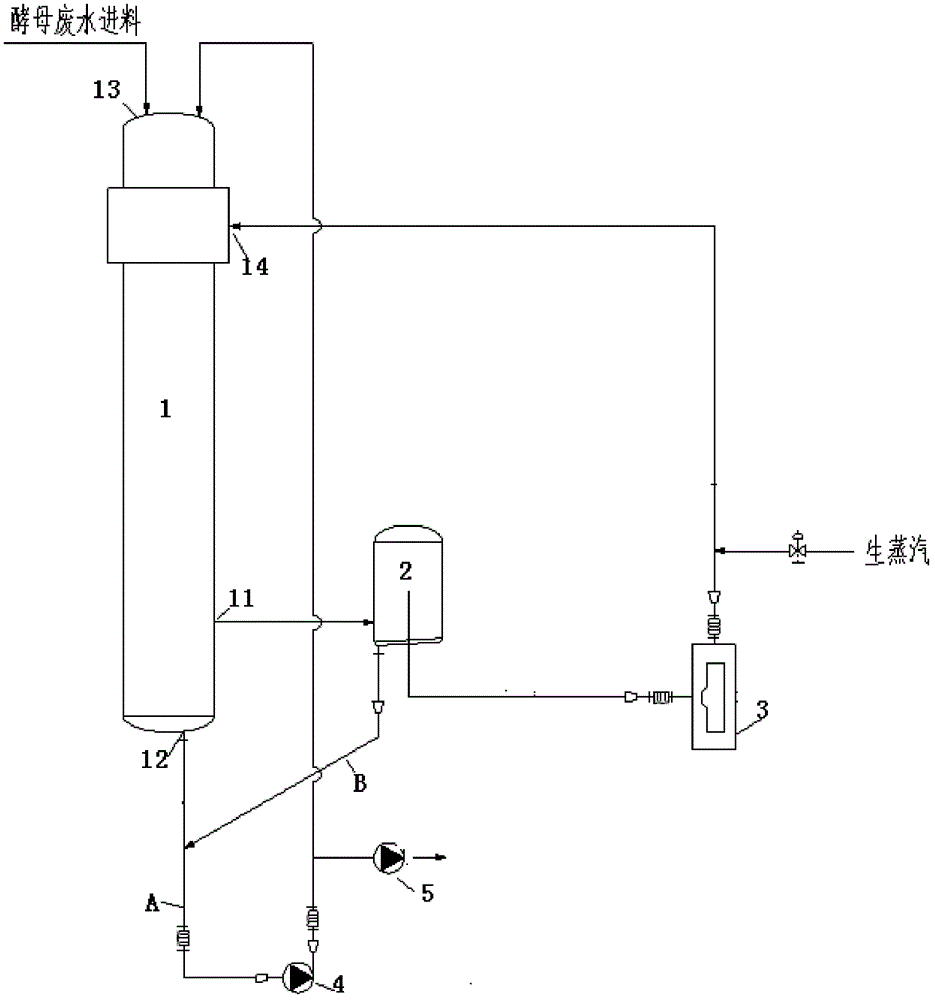

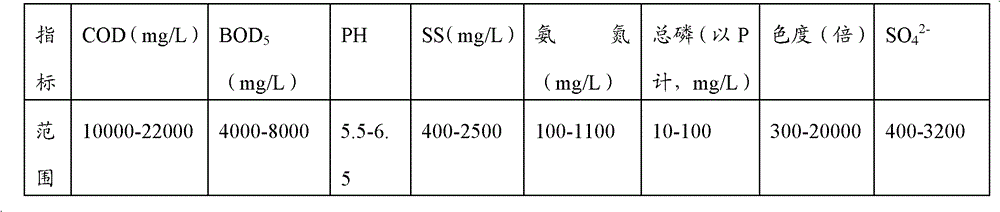

Evaporation and Concentration Method of Yeast Wastewater

ActiveCN103373747BReduce processing costsReduce consumptionWater/sewage treatment by heatingDouble phaseGas phase

The invention provides an evaporation concentration method of yeast wastewater. The method comprises the following steps: (1) an evaporation process, namely introducing the yeast wastewater into a heater (1) for heat treatment, and heating the wastewater to 78-82 DEG C to carry out evaporation to obtain a double-phase material flow comprising a gas phase and a liquid phase; (2) a separation process, namely separating the double-phase material flow in a separator (2); (3) steam compression circulation process, namely separating the compressed secondary steam obtained by treating the secondary steam using a steam compressor (3), wherein the compressed secondary steam is recycled to the heater (1) to be reused as a supplemental heat source; (4) a mother solution re-evaporation process, namely again carrying out the evaporation process in the heater (1) by recycling the mother solution separated from the separator (2) into the heater (1) until the solid content concentration in the yeast wastewater is 10-14% (W / W). By adopting the method provided by the invention, steam consumption is reduced, and the wastewater treatment cost is reduced.

Owner:ANGELYEAST CO LTD

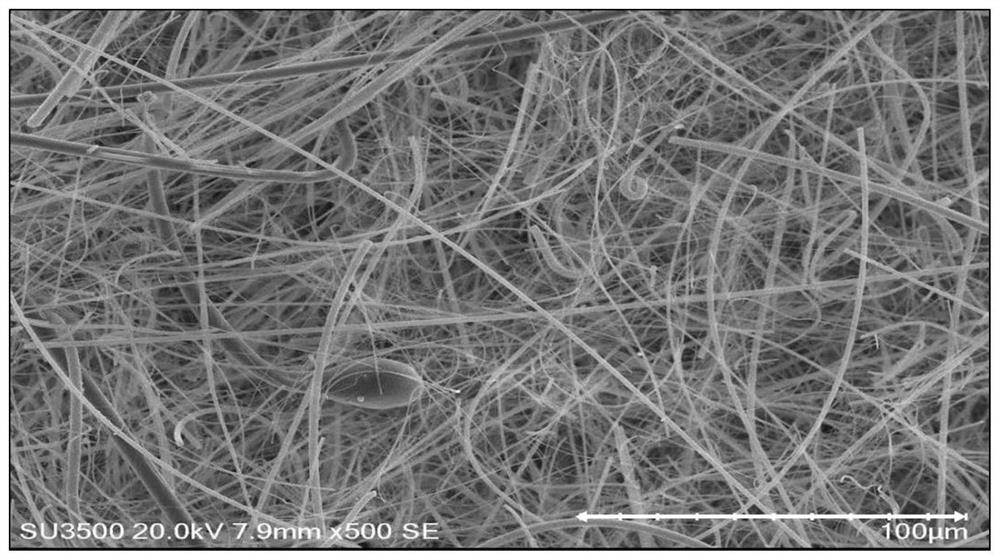

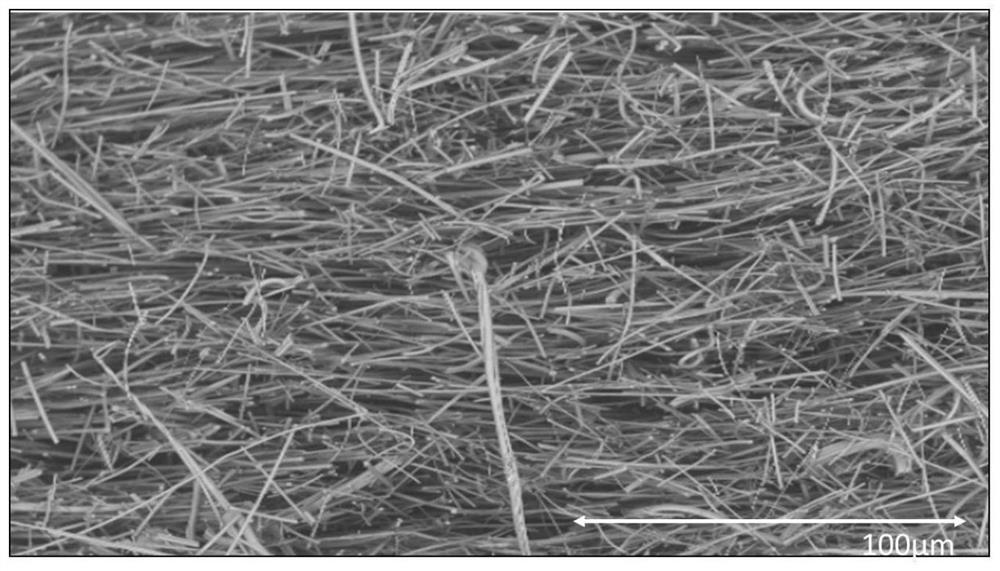

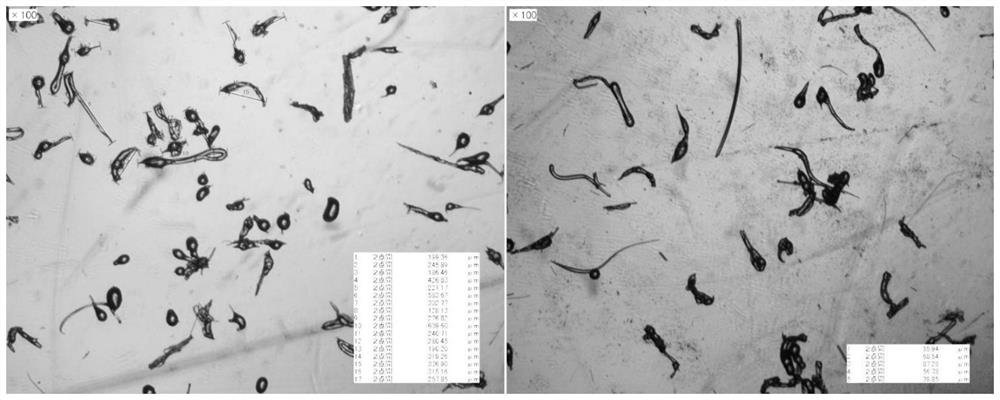

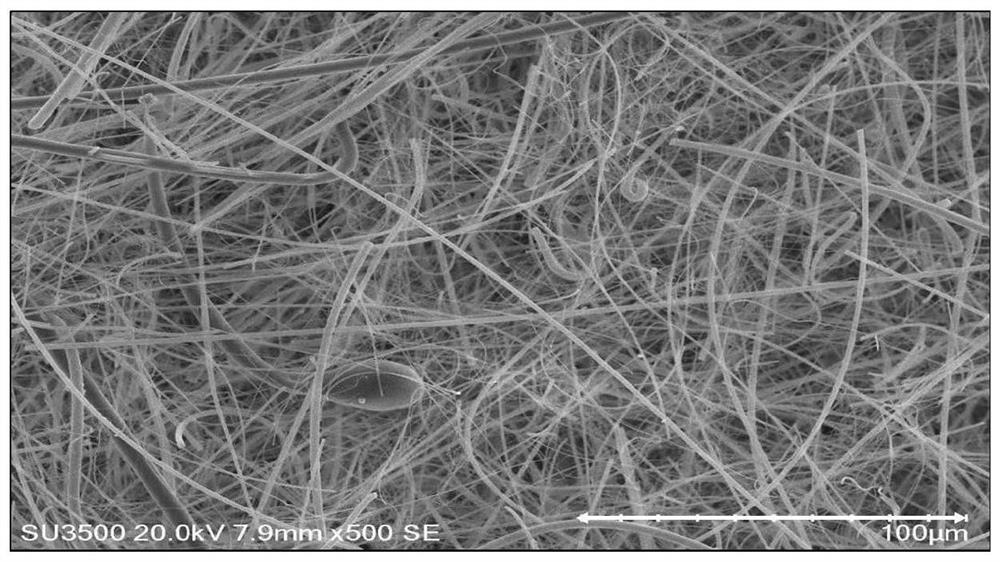

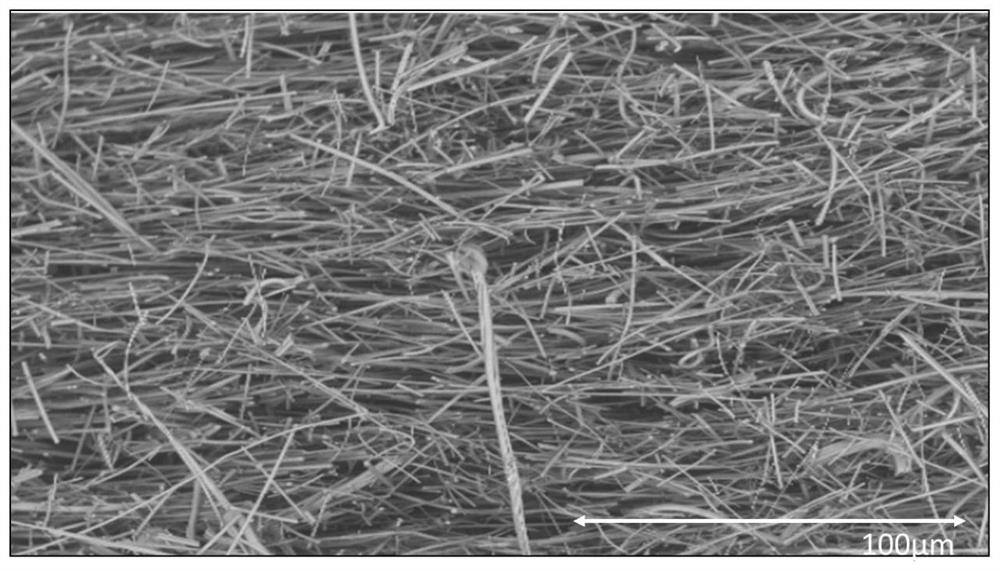

Glass fiber group and manufacturing method thereof, and glass fiber reinforced resin-based composite material and manufacturing method thereof

ActiveCN112759250AGuaranteed contentStable tensile strengthGlass making apparatusGlass fiberResin-Based Composite

The invention discloses a glass fiber group and a manufacturing method thereof, and a glass fiber reinforced resin-based composite material and a manufacturing method thereof. The manufacturing method of the glass fiber group is characterized by comprising the following steps: producing glass fibers by using a centrifugal method, and carrying out a wet-process molding or dry-process molding process on the glass fibers to obtain the glass fiber group with a predetermined shape. According to the invention, since the glass fibers are manufactured by adopting a centrifugal method, glass residues and powdery glass can be obviously reduced through a wet molding process, and the non-fibrosis phenomenon in the composite material is reduced, so that the added glass material can achieve the effect of enhancing the resin performance. The retention length of the glass fibers in the glass fiber reinforced resin-based composite material is larger, the content of the glass fibers is stable and controllable, and the glass fibers are uniformly dispersed. The mechanical strength and the performance of the glass fiber reinforced resin-based composite material are improved, and the glass fiber reinforced resin-based composite material is more stable.

Owner:袁飞 +1

Glass fiber group and glass fiber reinforced resin-based composite material

ActiveCN112759794AGuaranteed contentStable tensile strengthGlass making apparatusSynthetic cellulose/non-cellulose material pulp/paperGlass fiberResin-Based Composite

The invention discloses a glass fiber group and a glass fiber reinforced resin-based composite material. The glass fiber group is characterized in that the glass fiber group comprises a plurality of glass fibers or modified glass fibers with the diameter of 1-7 microns. According to the invention, since the glass fibers are manufactured by adopting a centrifugal method, glass residues and powdery glass can be obviously reduced through a wet molding process, and the non-fibrosis phenomenon in the composite material is reduced, so that the added glass material can achieve the effect of enhancing the resin performance. The retention length of the glass fibers in the glass fiber reinforced resin-based composite material is larger, the content of the glass fibers is stable and controllable, and the glass fibers are uniformly dispersed. The mechanical strength and the performance of the glass fiber reinforced resin-based composite material are improved, and the glass fiber reinforced resin-based composite material is more stable.

Owner:袁飞 +1

Modified polytetrafluoroethylene (PTFE) and preparation method and application thereof

Owner:SHANGHAI ENTROPY CHEM

Vanadium-containing magnesium master alloy grain refiner and its preparation method and application

The vanadium-containing magnesium master alloy grain refiner of the present invention and its preparation method and application, in terms of mass fraction, the refiner includes 90-99% of magnesium, the rest is a compound of vanadium, the compound is VC, VN, at least one of VCxN1‑x, where 0<x<1 in the VCxN1‑x. The invention also discloses several preparation methods of the vanadium-containing magnesium master alloy grain refiner. The vanadium-containing magnesium master alloy grain refiner of the present invention, the vanadium compound can be used as an effective heterogeneous nucleation core of the magnesium alloy, and can be prepared into a magnesium master alloy, the addition amount is easier to control, the use is convenient, and the yield is high. It is not limited by the composition of magnesium alloys (it can be added to magnesium alloys containing Al or not containing Al). After being added to magnesium alloys, it can effectively refine the grains of magnesium alloys, strengthen magnesium and magnesium alloys, and improve the comprehensive performance of magnesium alloys. mechanical properties.

Owner:CHONGQING UNIV OF ARTS & SCI

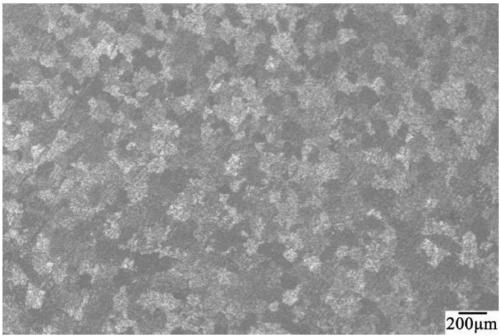

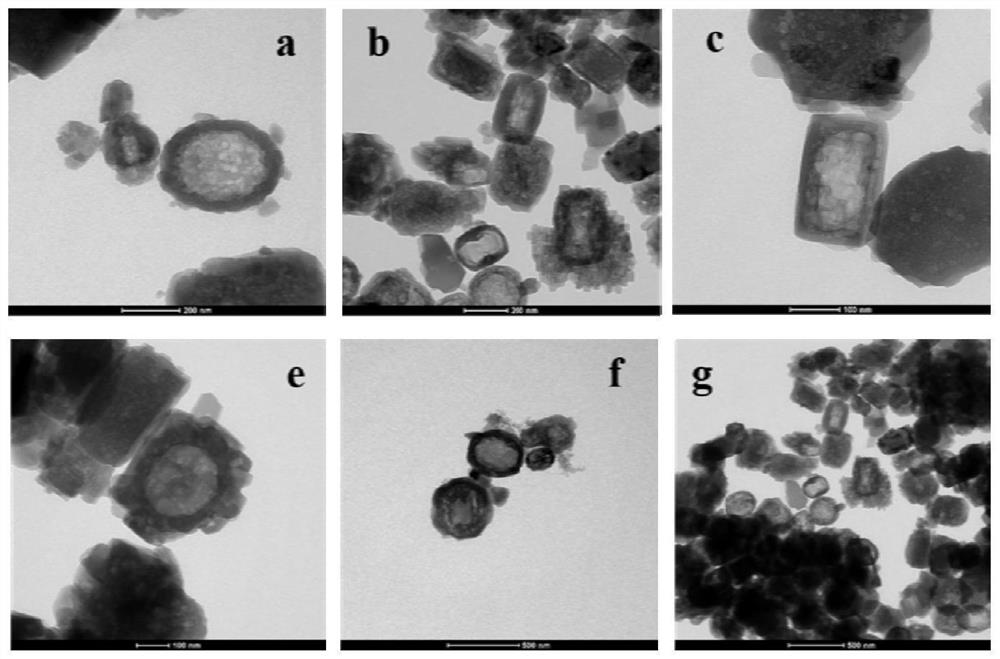

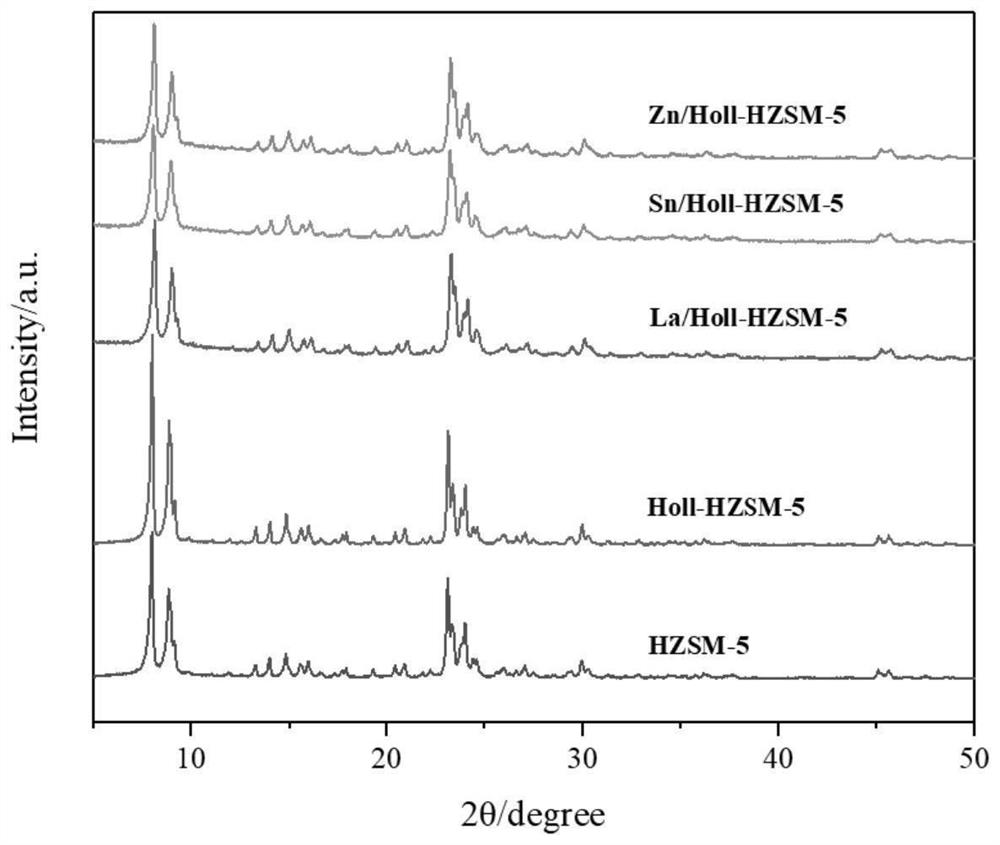

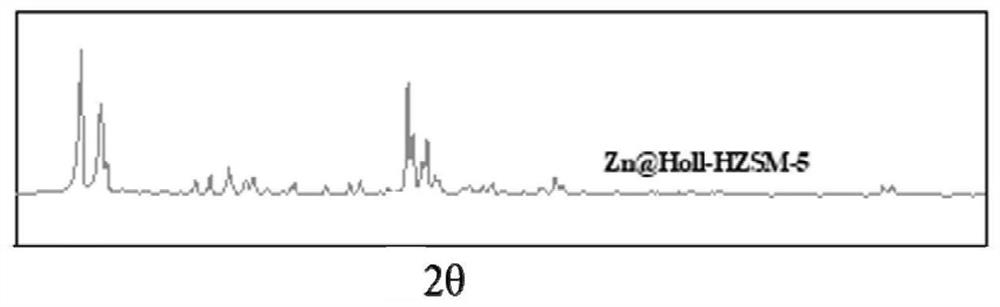

Metal-modified hollow HZSM-5 catalyst for aromatization of glycerin and preparation method of metal-modified hollow HZSM-5 catalyst

PendingCN113649059AHigh activityThe load is easy to controlMolecular sieve catalystsLiquid hydrocarbon mixture productionMolecular sievePtru catalyst

The invention discloses a metal modified hollow HZSM-5 catalyst for glycerol aromatization and a preparation method, and belongs to the technical field of fine chemicals, the catalyst is HZSM-5 molecular sieve hollow particles, and metal is loaded on the surface of a molecular sieve skeleton or embedded in the molecular sieve skeleton. The metal modified hollow HZSM-5 molecular sieve catalyst retains the skeleton and pore structure of the HZSM-5 molecular sieve, the hollow structure widens the internal space and the overall specific surface area, carbon deposition on the catalyst can be effectively inhibited, and the service life of the catalyst in a glycerin aromatization reaction is obviously prolonged.

Owner:SOUTHEAST UNIV

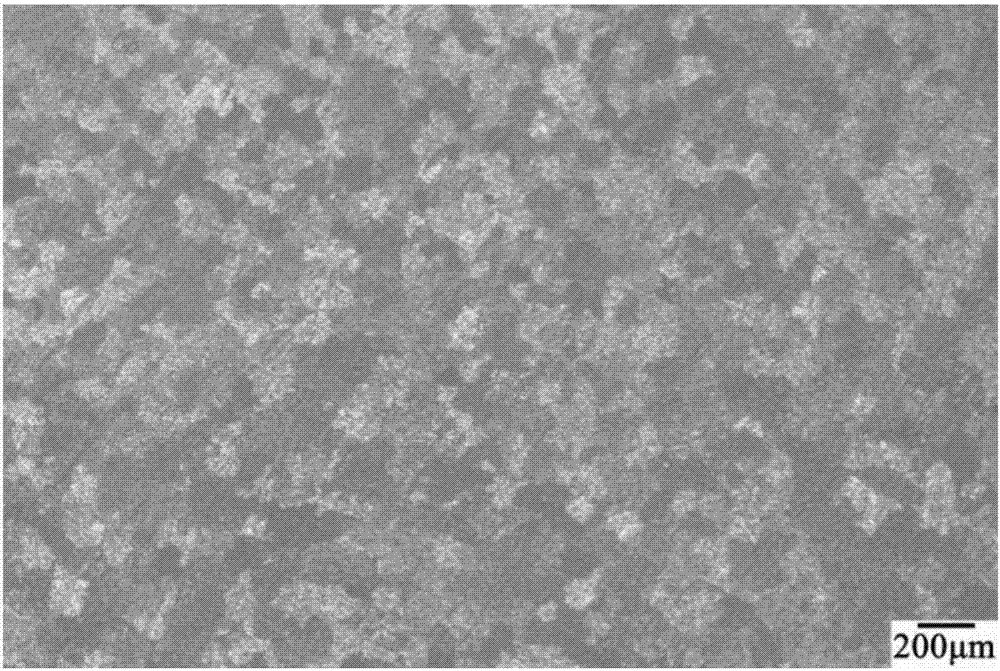

Grain refinement and preparation method of Fe-Ni-SiO2 alloy coating

InactiveCN111041476AThe amount added is controllableEasy to useMetallic material coating processesCrazingLaser light

The invention relates to a grain refinement and preparation method of a Fe-Ni-SiO2 alloy coating. The Fe-Ni-based alloy wear-resistant coating is prepared from Fe powder, Ni powder and SiO2 powder through a laser metal direct deposition technology and specifically comprises steps of screening out element powder with proper particle size, uniformly mixing in proportion, ball-milling, drying at constant temperature, conveying the ground powder to a surface of a substrate, and melting and depositing the mixed powder on the surface of the substrate by using a laser light source under the protection of argon. The method is advantaged in that by controlling the number of heterogeneous nucleation cores in the solidification process, microstructure morphology control over the Fe-Ni-based alloy coating in the laser metal direct deposition process is simply and effectively achieved, the obtained coating is free of hot cracks and has good combination with a substrate.

Owner:EAST CHINA JIAOTONG UNIVERSITY

Granule-adding method and device for granule-containing liquid drink processing technique

ActiveCN101480266BReduce complexityIncrease the amount of controlMilk preparationPre-extraction tea treatmentLiquid stateEngineering

The invention provides a method and a device for adding granules in the process of inclusion granule liquid drink. The technical scheme of the device is mainly achieved as follows: a feeding pipe is arranged in a compensating groove, the wall of the feeding pipe is provided with holes, the bottom end of the feeding pipe contacts with the bottom surface of the compensating groove in a sealing way so as to enable feed liquid to be added with granules to enter into the feeding pipe from the holes on the wall of the feeding pipe after entering into the compensating groove, granular materials enter into the feeding pipe from the upper port of the feeding pipe, the feed liquid to be added with granules are mixed with the granular materials in the feeding pipe to form inclusion granule mixed materials which are led out of a mixed material outlet arranged on the bottom surface of the compensating groove corresponding to the bottom end surface of the feeding pipe from the compensating groove so that the granular materials are uniformly added into the feed liquid on line. The invention also provides a method for producing the inclusion granule liquid drink by the method and the device for adding granules.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

Quantitative salt pot

Owner:李天勇

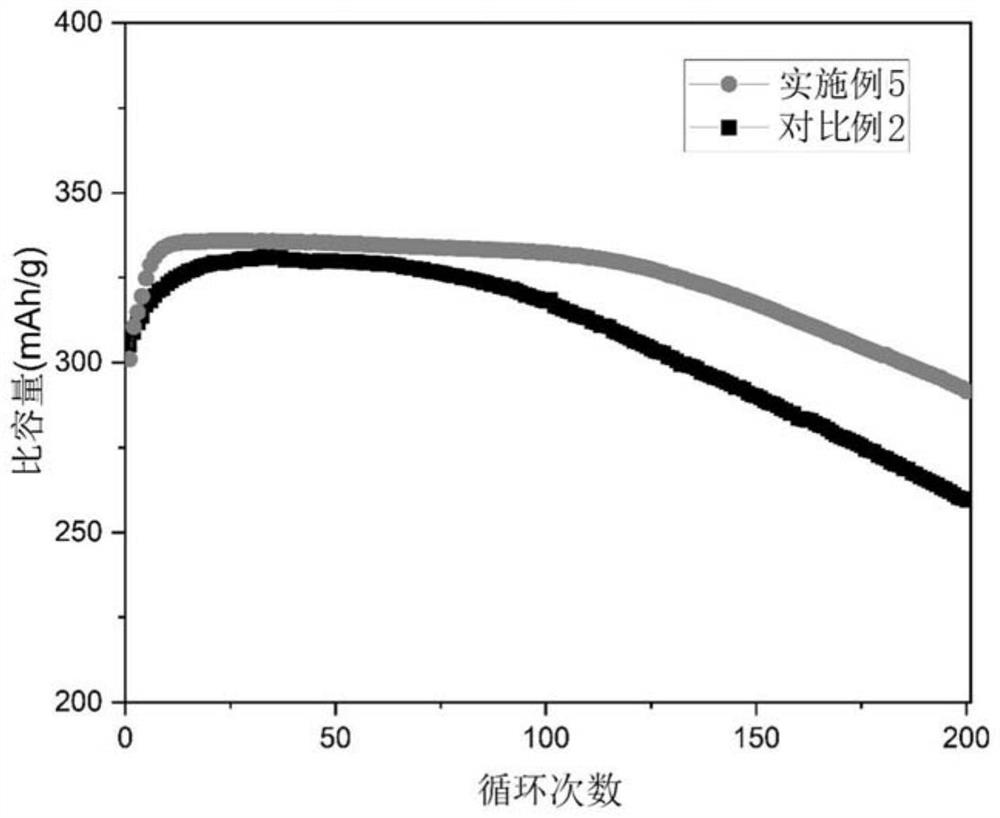

Additive of lithium ion battery, electrode plate and lithium battery

PendingCN114843605AImprove structural stabilityReduce interface side reactionsSecondary cellsPhosphoric Acid EstersCarboxyl radical

The invention belongs to the technical field of lithium ion batteries, and discloses an additive for stabilizing the electrochemical performance of an electrode material of a lithium ion battery, an electrode plate containing the additive and the lithium ion battery. The additive is used in electrode slurry of a positive plate and / or a negative plate, and is a compound with the following structural formula: R1 is selected from phosphate ester, metal salt of phosphate ester, sulfate ester and metal salt of sulfate ester; r2, R3, R4, R5 and R6 are independently selected from alkyl, hydroxyl, carboxyl, phosphate, metal salt of phosphate, phosphite, metal salt of phosphite, pyrophosphate, metal salt of pyrophosphate, sulfate, metal salt of sulfate, sulfonic acid group, metal salt of sulfonic acid, sulfinic acid group and metal salt of sulfinic acid. The additive can improve the high-voltage electrochemical stability of a positive electrode material, prolong the cycle life of a negative electrode material, improve the rate capability of the negative electrode material, and obtain a lithium battery with high cut-off voltage, high energy density and long cycle life.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com