Efficient and low-pollution GMT powder scattering device and using method thereof

A dusting device and low-polluting technology, which is applied in the field of high-efficiency and low-pollution GMT dusting devices, can solve the problems of low odor, reducing the effect of additives, and affecting the dispersibility of powder materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

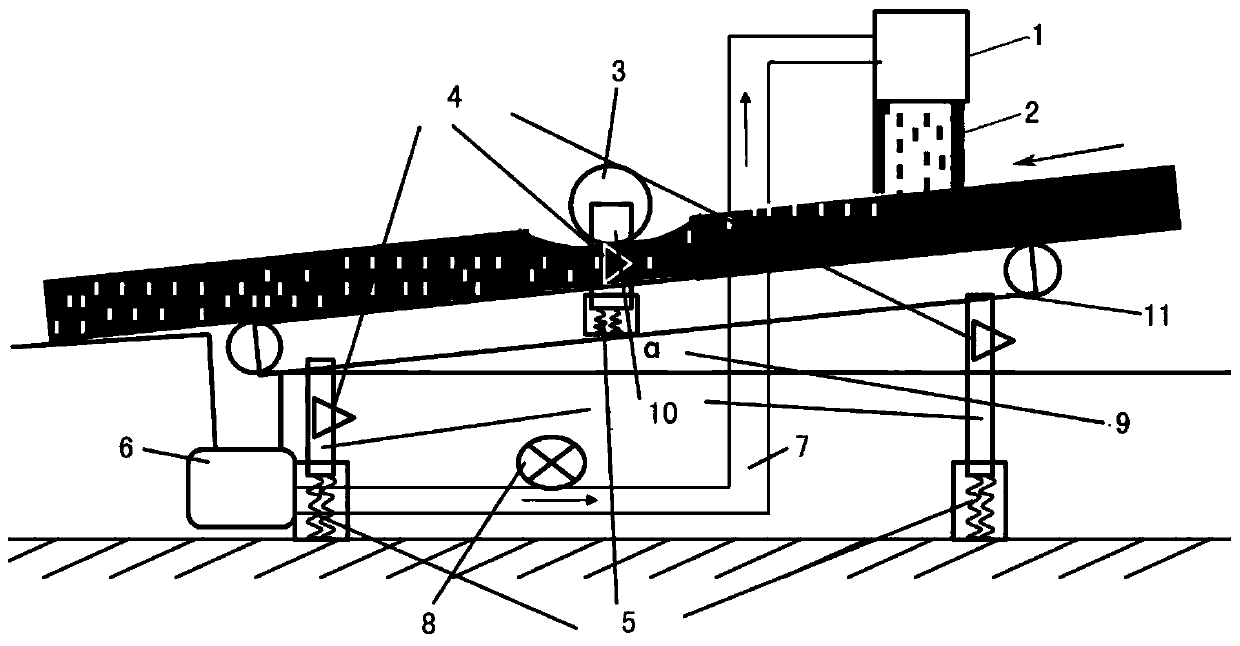

[0032] Embodiments of the present invention are described in further detail below in conjunction with accompanying drawings:

[0033] This embodiment is a high-efficiency and low-pollution GMT powder spreading device. The powder spreading device includes a powder spreader 1, a conveyor belt 11, a bouncing stick 3, an elastic support 10, a vibration motor 4, a recovery cabin 6, and a circulation fan 8;

[0034] The plane of the conveyor belt 11 and the ground plane form an angle a 9, that is, the conveyor belt 11 is placed at an angle a 9, and the angle a 9 is 0-70°. In this embodiment, the angle a 9 is preferably 30°, and the angle a 9 can be adjusted according to production needs. , as long as it does not exceed 70°.

[0035] A powder spreader 1 is arranged above the conveyor belt 11, and the powder spreader 1 is erected at the front end of the felt net of the powder spreader; a lifting baffle 2 is set under the powder spreader 1, and the lifting baffle can be automatically r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com