Grain refinement and preparation method of Fe-Ni-SiO2 alloy coating

A fe-ni-sio2, alloy coating technology, applied in metal material coating process, coating, etc., can solve problems such as cracking of deposited layers, achieve low cost, improve comprehensive mechanical properties, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

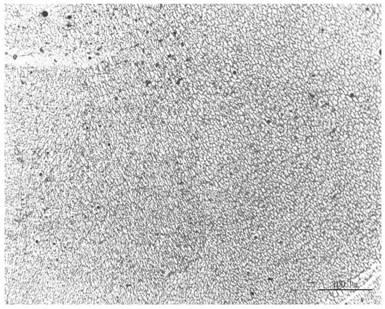

Embodiment 1

[0026] A Fe-Ni-SiO2 alloy coating grain refinement and a preparation method thereof, mainly comprising the following steps:

[0027] Substrate pretreatment:

[0028] The material of the substrate is No. 45 steel, and the size is 100mm×100mm×10mm. The QF-6050 manual sandblasting machine is used to blast the substrate, and the abrasive is emery.

[0029] Composite powder preparation:

[0030] Select suitable Fe, Ni and SiO2 powders with appropriate particle size, and use ball milling process to mix them evenly. The particle size range of the powder is 150-300 mesh, and the chemical composition is: Invar alloy powder+SiO2 is 2wt%.

[0031] Preparation of bulk materials by laser multilayer superposition deposition technology:

[0032] The single-layer overlapping deposition path is "S" type. After the single-layer deposition is completed, the laser cladding head moves up and the coordinates return to the initial position. The single-layer overlapping deposition process is repea...

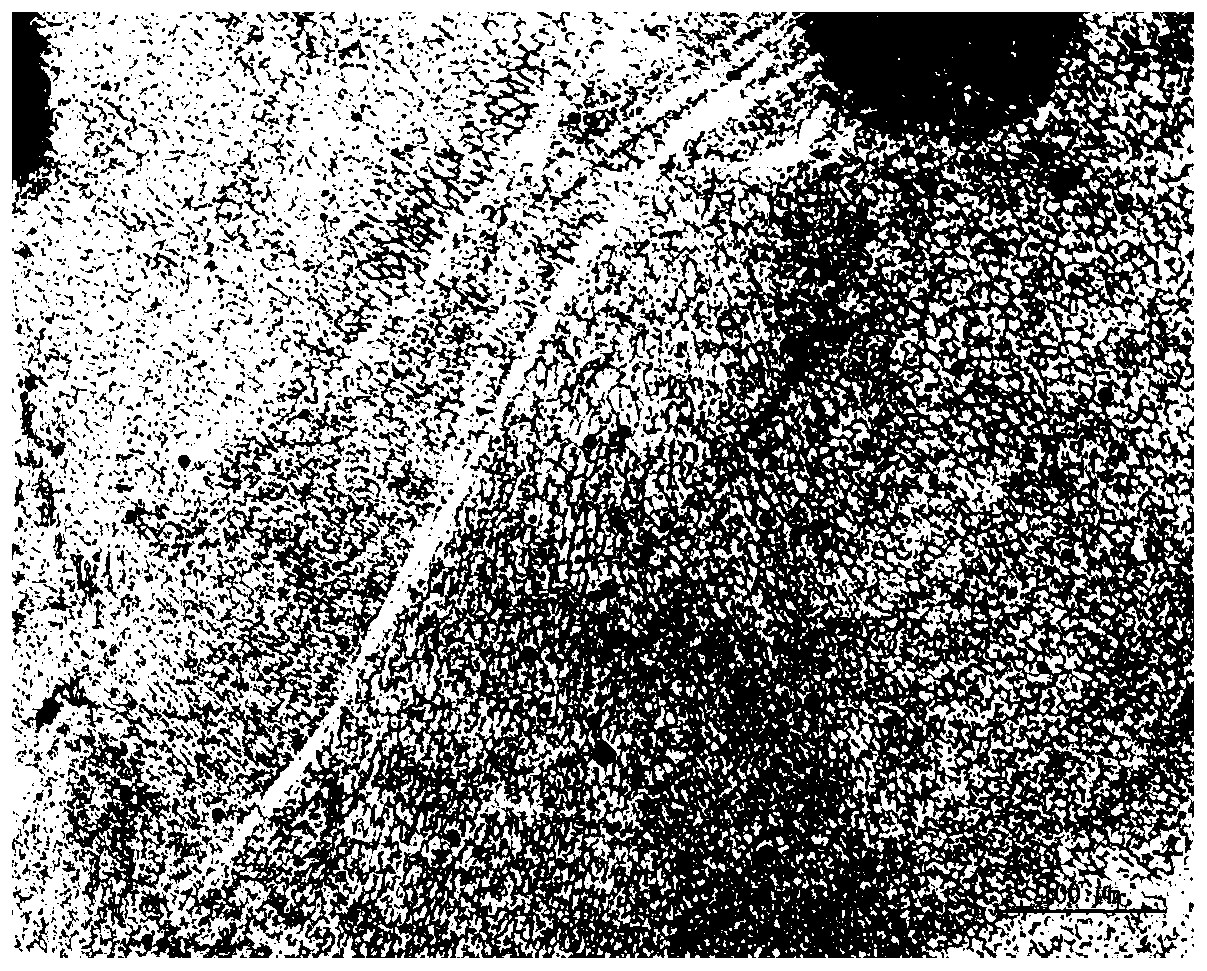

Embodiment 2

[0035] A Fe-Ni-SiO2 alloy coating grain refinement and a preparation method thereof, mainly comprising the following steps:

[0036] Substrate pretreatment:

[0037] The material of the substrate is No. 45 steel, and the size is 100mm×100mm×10mm. The QF-6050 manual sandblasting machine is used to blast the substrate, and the abrasive is emery.

[0038] Composite powder preparation:

[0039] Select suitable Fe, Ni and SiO2 powders with appropriate particle size, and use ball milling process to mix them evenly. The particle size range of the powder is 150-300 mesh, and the chemical composition is: Invar alloy powder+SiO2 is 4wt%.

[0040] Preparation of bulk materials by laser multilayer superposition deposition technology:

[0041] The single-layer overlapping deposition path is "S" type. After the single-layer deposition is completed, the laser cladding head moves up and the coordinates return to the initial position, repeating the single-layer overlapping deposition proces...

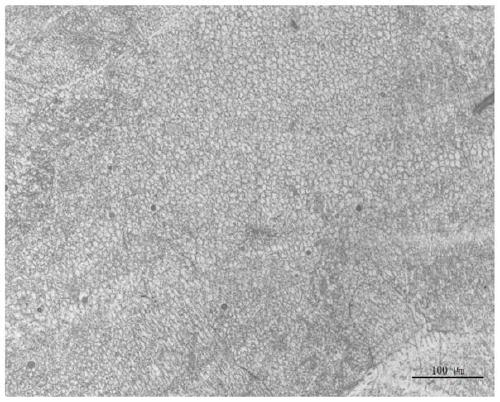

Embodiment 3

[0044] A Fe-Ni-SiO2 alloy coating grain refinement and a preparation method thereof, mainly comprising the following steps:

[0045] Substrate pretreatment:

[0046] The material of the substrate is No. 45 steel, and the size is 100mm×100mm×10mm. The QF-6050 manual sandblasting machine is used to blast the substrate, and the abrasive is emery.

[0047] Composite powder preparation:

[0048] Select suitable Fe, Ni and SiO2 powders with appropriate particle size, and use ball milling process to mix them evenly. The particle size range of the powder is 150-300 mesh, and the chemical composition is: Invar alloy powder + SiO2 is 6 wt%.

[0049] Preparation of bulk materials by laser multilayer superposition deposition technology:

[0050] The single-layer overlapping deposition path is "S" type. After the single-layer deposition is completed, the laser cladding head moves up and the coordinates return to the initial position, repeating the single-layer overlapping deposition pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com