Vanadium-containing magnesium master alloy grain refiner and its preparation method and application

A grain refiner and master alloy technology is applied in the field of vanadium-containing magnesium master alloy grain refiner and its preparation, and achieves the effects of high yield, convenient use and easy control of addition amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

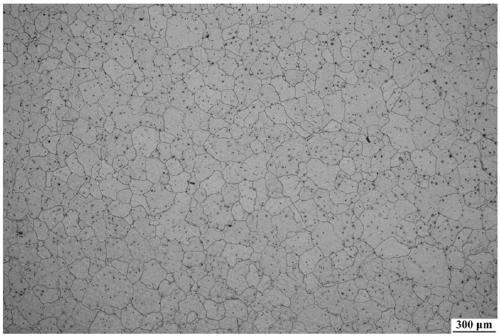

[0034] Weigh 360g of pure magnesium powder and 40g of VC powder as raw materials, and mix the above two powders by ball milling. The ball milling medium is alcohol, and the ratio of ball to material is 10:1. Grinding on the type ball mill for 12 hours, using intermittent ball milling mode, that is, ball milling for 3 hours, pausing for 20 minutes, after the ball milled mixed powder is vacuum dried, the mixed powder is placed in a graphite mold with a diameter of 70mm, and the pressure is 40MPa in a vacuum hot pressing furnace , the hot pressing temperature is 550° C., the heat preservation time is 60 min, and the 90wt.% Mg-10wt.% VC master alloy sintered block is obtained by hot pressing.

[0035] Sinter the above-mentioned intermediate alloy block, remove the surface scale to a suitable size, and preheat it at 400°C for 2 hours. In the extruder, the extrusion temperature is 400°C, and the extrusion ratio is 89:1 to obtain a diameter of 9mm. 90wt.% Mg-10wt.% VC master alloy gr...

Embodiment 2

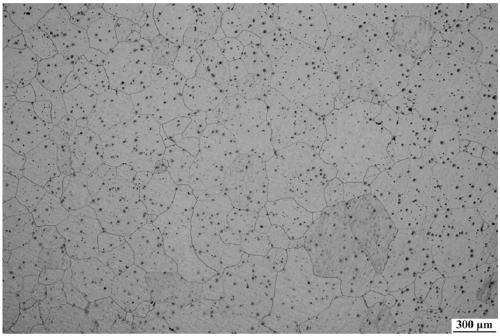

[0037] Take by weighing raw material pure magnesium powder 396g, VC powder 4g, above-mentioned two kinds of powder ball mills are mixed, and ball milling medium is acetone, is 8:1 according to ball-to-material ratio, is placed in agate jar, feeds argon protection after vacuumizing, in The planetary ball mill was milled for 6 hours, and the intermittent ball milling mode was adopted, that is, the ball milled for 3 hours and paused for 15 minutes. After the ball-milled mixed powder is dried in vacuum, the mixed powder is placed in a graphite mold with a diameter of 70 mm. In a vacuum hot-pressing furnace, the pressure is 30 MPa, the hot-pressing temperature is 450 ° C, and the temperature is kept for 30 minutes. 99wt.% Mg- 1wt.% VC master alloy sintered block.

[0038] Sinter the 99wt.%Mg-1wt.%VC master alloy block, car off the surface scale to a suitable size, preheat at 350°C for 1h, and in the extruder, the extrusion temperature is 350°C, and the extrusion ratio is 89:1 to o...

Embodiment 3

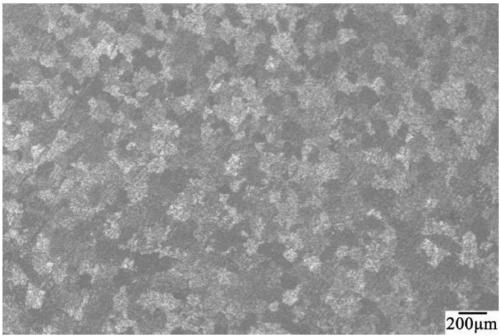

[0040]Weigh 360g of pure Mg powder and 40g of VN powder as raw materials, mix the above two powders by ball milling, the ball milling medium is alcohol, and the ratio of ball to material is 8:1. The ball mill was milled on the type ball mill for 6 hours, and the intermittent ball mill mode was adopted, that is, the ball mill was milled for 3 hours, and the pause was 15 minutes. After the ball-milled mixed powder is dried in vacuum, the mixed powder is placed in a graphite mold with a diameter of 70mm, and placed in a vacuum hot-pressing furnace with a pressure of 40MPa, a hot-pressing temperature of 450°C, and a heat preservation time of 30min to obtain 90wt.% Mg by hot-pressing - 10wt.% VN master alloy sintered block.

[0041] Sinter the 90wt.%Mg-10wt.%VN master alloy block, car off the surface scale to a suitable size, preheat it at 350°C for 1h, and put it in the extrusion machine, the extrusion temperature is 350°C, and the extrusion ratio is 89:1, to obtain Φ9mm Mg-10wt....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com