A kind of highly stable nickel-tin-phosphorus electroless plating solution

An electroless plating solution, high stability technology, applied in liquid electroless plating, metal material coating process, coating and other directions, can solve the problem of unstable nickel tin phosphorus electroless plating solution, difficult to control the amount of addition, and utilization of tin salts. low problems, to achieve the effect of good popularization and application value, simple implementation, improved corrosion resistance and compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

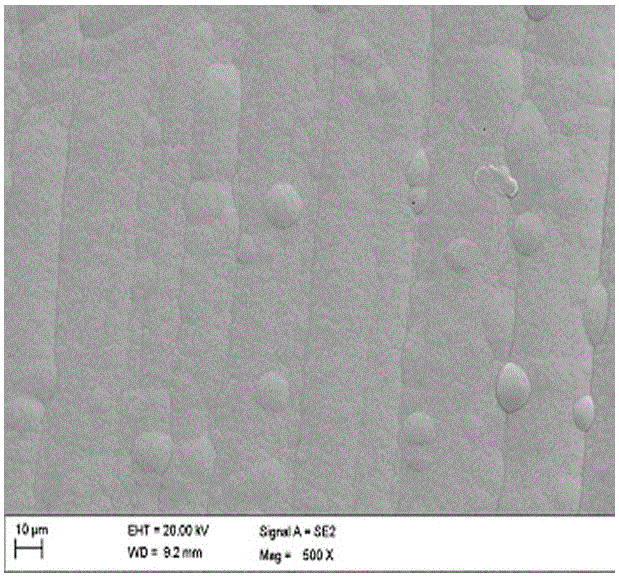

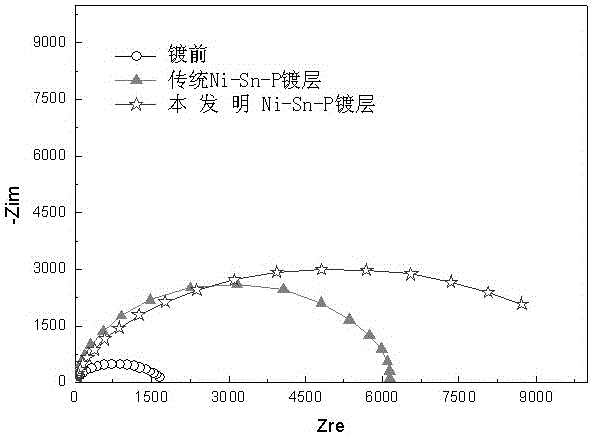

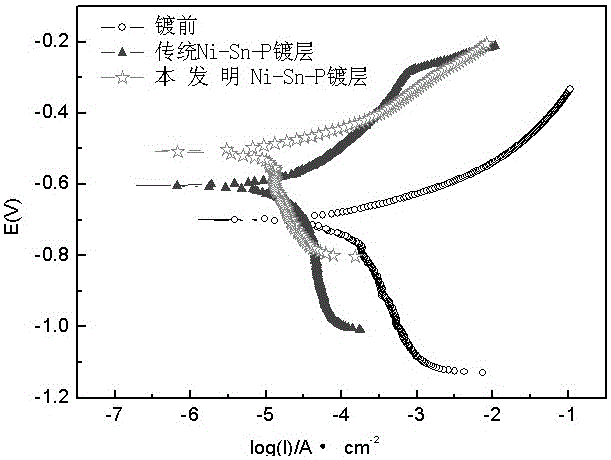

Image

Examples

Embodiment 1

[0019] Prepare a kind of highly stable nickel-tin-phosphorus electroless plating solution according to the following formula, containing in every liter of solution:

[0020] NiCl 2 ·6H 2 O 25g

[0021] NaH 2 PO 2 ·H 2 O 20g

[0022] Sn(CH 3 SO 3 ) 2 @SiO 2 15g

[0023] CH 3 COONa 8g

[0024] CH 3 COOH 10ml

[0025] Complexing agent 3.5g

[0026] Stabilizer 4g

[0027] Surfactant 2g

[0028] The remainder is water;

[0029] The complexing agent is prepared according to the following ratio: 35% glycine, 20% citric acid, 45% lactic acid, and the stabilizer is a mixture of ethoxy-a-naphtholsulfonic acid (ENSA), thiourea, and sodium thiosulfate. Among them, ethoxy-a-naphtholsulfonic acid (ENSA) accounts for 45%, thiourea accounts for 35%, sodium thiosulfate accounts for 20%, and the surfactant is n-octyl sodium sulfate. After preparing the solutions in turn, use dilute Sulfuric acid and potassium bicarbonate solution adjust the pH to 4.7, and the plating tempera...

Embodiment 2

[0038] Prepare a kind of highly stable nickel-tin-phosphorus electroless plating solution according to the following formula, containing in every liter of solution:

[0039] NiCl 2 ·6H 2 O 25g

[0040] NaH 2 PO 2 ·H 2 O 20g

[0041] Sn(CH3 SO 3 ) 2 @SiO 2 6.5g

[0042] CH 3 COONa 7g

[0043] CH 3 COOH 10ml

[0044] Complexing agent 4g

[0045] Stabilizer 4g

[0046] Surfactant 2.5g

[0047] The remainder is water;

[0048] The complexing agent is prepared according to the following ratio: 60% glycine, 40% adipic acid, and the stabilizer is a mixture of ethoxy-a-naphthol sulfonic acid (ENSA), thiourea, and sodium thiosulfate, of which ethoxy Base-a-naphtholsulfonic acid (ENSA) accounts for 45%, thiourea accounts for 35%, sodium thiosulfate accounts for 20%, and the surfactant is n-octyl sodium sulfate. After preparing the solution in turn, use dilute sulfuric acid and carbonic acid to The potassium hydrogen solution adjusts the pH to 4.0, and the plating temp...

Embodiment 3

[0057] Prepare a kind of highly stable nickel-tin-phosphorus electroless plating solution according to the following formula, containing in every liter of solution:

[0058] NiCl 2 ·6H 2 O 35g

[0059] NaH 2 PO 2 ·H 2 O 25g

[0060] Sn(CH 3 SO 3 ) 2 @SiO 2 20g

[0061] CH 3 COONa 15g

[0062] CH 3 COOH 20ml

[0063] Complexing agent 5g

[0064] Stabilizer 8g

[0065] Surfactant 3.5g

[0066] The remainder is water;

[0067] The complexing agent is prepared according to the following ratio: 30% citric acid, 40% propionic acid, 30% adipic acid, and the stabilizer is ethoxy-a-naphtholsulfonic acid (ENSA), thiourea, and thiosulfuric acid Sodium mixture, of which ethoxy-a-naphthol sulfonic acid (ENSA) accounts for 40%, thiourea accounts for 30%, sodium thiosulfate accounts for 30%, and the surfactant is n-octyl sodium sulfate. After the solution is prepared in turn , adjust the pH to 4.8 with dilute sulfuric acid and potassium bicarbonate solution, and the plati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com