Modified polytetrafluoroethylene (PTFE) and preparation method and application thereof

A polytetrafluoroethylene, modified technology, applied in the field of modified polytetrafluoroethylene and its preparation and application, can solve the problems of poor free flow, difficult storage and handling, high self-adhesiveness, etc., to achieve easy control and convenient storage , Improve the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

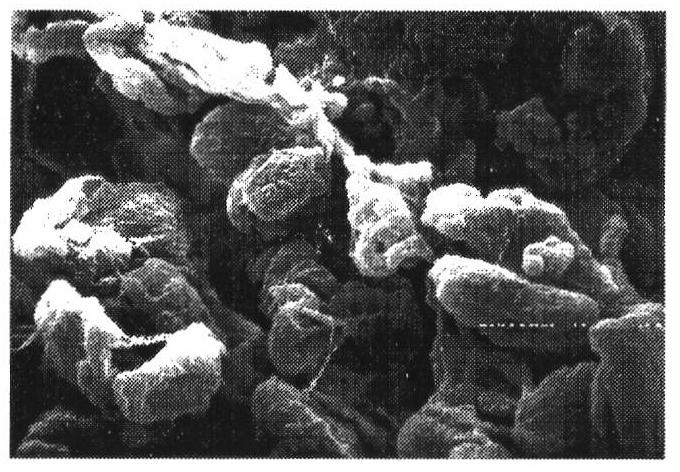

Image

Examples

Embodiment 1

[0028] Embodiment 1: the preparation method of modified polytetrafluoroethylene and its application:

[0029] In the preparation process of the modified polytetrafluoroethylene of the present invention, equipment such as a 15-liter reaction kettle, a magnetic stirrer, and a heating device are required. The set reaction conditions are: temperature 60° C., stirring speed 120 revolutions per minute.

[0030]Preparation of SAN and MMA copolymer: add 95 grams of silicone oil, 4 grams of chelating agent ethylenediaminetetraacetic acid i.e. EDTA and 1 gram of chain transfer agent hypophosphite sodium salt in the reaction kettle and mix as electrolyte mother liquor; Contains 0.25 g Fe 2+ / CHP (cumyl hydroperoxide) as the initiator, 18 grams of styrene and acrylonitrile mixed monomer and 60 ml of polytetrafluoroethylene emulsion are added to the reaction kettle, the temperature is raised to 60 ° C, and the polymerization reaction is stirred at this temperature After 8 hours, centrif...

Embodiment 2

[0032] Embodiment 2: the preparation method of modified polytetrafluoroethylene and its application:

[0033] The preparation of SAN copolymer: in reactor, add 95 grams of silicone oils, 4 grams of chelating agent ethylenediaminetetraacetic acid namely EDTA and 1 gram of chain transfer agent sodium dihydrate methyl sulfite (SFS) mix as electrolyte mother liquor; Then in the situation of stirring will contain 0.25 g Fe 2+ / CHP (cumene hydroperoxide) as the initiator, 18 grams of styrene and acrylonitrile mixed monomer and 55 ml of polytetrafluoroethylene emulsion are added to the reaction kettle, the temperature is raised to 65 ° C, and the polymerization reaction is stirred at this temperature 2 hours. Then raise the temperature to 95°C and stir the slurry with a stirring bar for 20 minutes, and then centrifugally filter the obtained powder. The powder is heated at 55°C for 30 minutes and then becomes a paste again. The solid content of the paste is It was 18%, and the powd...

Embodiment 3

[0035] Embodiment 3: the preparation method of modified polytetrafluoroethylene and its application:

[0036] The production process was the same as in Example 2, except that the initiator was changed to 1.5 g of ethylene propyl dicarbonate, and the product was washed with water, centrifugally dehydrated, and dried to obtain 143.6 g of modified polytetrafluoroethylene. The polytetrafluoroethylene content is 46.8%.

[0037] Use the above-mentioned anti-dripping agent 0.3%-5%, PBT95% and 4%-5% RDP in a twin-screw extruder for high-speed mixing and extruding to pelletize, and inject the pellets into a modified resin of 127x12x16mm (1 / 16) , Determination of flame retardant performance according to UL94 flame retardant classification requirements. The results show that in the modified mixed resin, the surface of the injection product is flat and smooth, and the flame retardancy level is V0 when burning, and there is no melt dripping phenomenon.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com