Quick crystallization method for realizing amorphous silicon nitride powder by taking silica powder as additive

A technology of silicon nitride powder and crystalline silicon nitride powder, which is applied in the field of preparation of ultrafine silicon nitride powder, can solve the problems of high cost and long process time of amorphous silicon nitride crystallization process, and achieve the promotion of phase transition Process, mass production of product purity, effect of shortening crystallization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

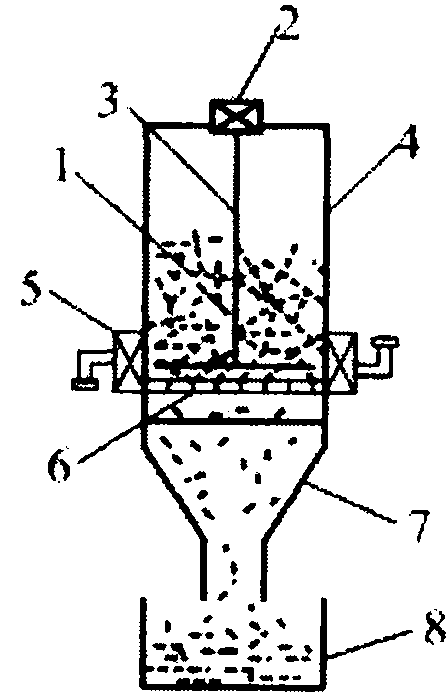

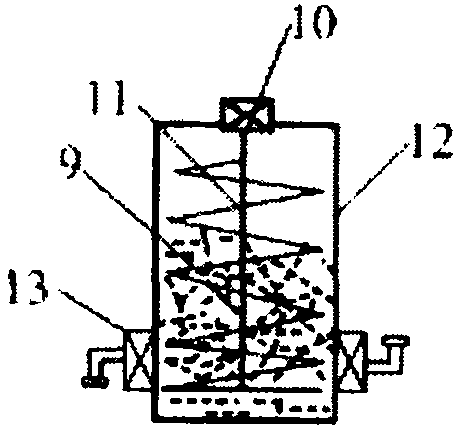

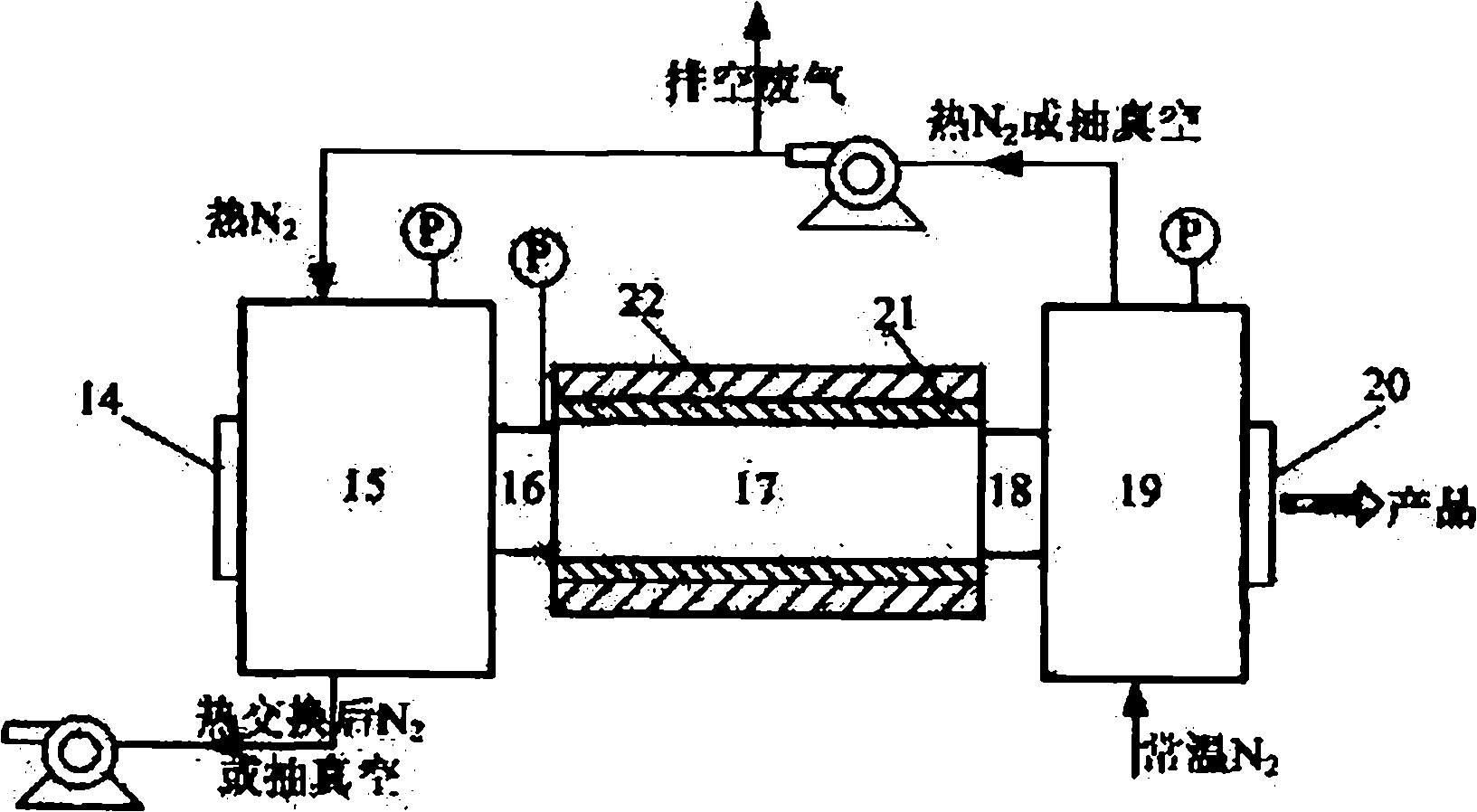

[0036] Amorphous silicon nitride powder with an average particle size of 0.2 μm and silicon powder with 10 μm are placed in a sieving device for sieving to remove large particles formed due to agglomeration and other reasons. Then, the two powders were put into the powder mixing device according to the mass ratio of silicon nitride powder: silicon powder=95:5 to fully mix, and then the mixed raw materials were put into a vacuum drying box and dried at 90°C for 8 hours. Put the dried raw material into the sieving device again for sieving, further remove the large-size agglomerated powder, and then put it into the crystallization heat treatment device, after ventilation, heat treatment in a nitrogen atmosphere at 1450°C for 30 minutes, and cool it out of the furnace to obtain super Fine silicon nitride powder. According to X-ray diffraction analysis, the content of α-phase silicon nitride in the product is more than 80%, the content of uncrystallized amorphous silicon nitride is ...

Embodiment 2

[0038] Amorphous silicon nitride powder with an average particle size of 0.2 μm and silicon powder with 10 μm are placed in a sieving device for sieving to remove large particles formed due to agglomeration and other reasons. Then, the two powders were put into the powder mixing device according to the mass ratio of silicon nitride powder: silicon powder=70:30 to fully mix, and then the mixed raw materials were put into a vacuum drying box and dried at 90°C for 8 hours. Put the dried raw material into the sieving device again for sieving, further remove the large-size agglomerated powder, and then put it into the crystallization heat treatment device, after ventilation, heat treatment at 1450℃ in a nitrogen atmosphere for 20 minutes, and cool it out of the furnace to obtain a super Fine silicon nitride powder. According to X-ray diffraction analysis, the content of α-phase silicon nitride in the product is more than 90%, the content of uncrystallized amorphous silicon nitride i...

Embodiment 3

[0040] Amorphous silicon nitride powder with an average particle size of 0.2 μm and silicon powder with 10 μm are placed in a sieving device for sieving to remove large particles formed due to agglomeration and other reasons. Then put the two powders into the powder mixing device according to the mass ratio of silicon nitride powder: silicon powder=50:50 to fully mix, then put the mixed raw materials into a vacuum drying oven and dry them at 90°C for 8 hours. The dried raw materials are put into the sieving device again for sieving to further remove the large-size agglomerated powder, and then put into the crystallization heat treatment device, after ventilation, heat treatment in a nitrogen atmosphere at 1500°C for 15 minutes, and cool down after being discharged from the furnace to obtain super Fine silicon nitride powder. According to X-ray diffraction analysis, the α-phase silicon nitride content of the product is more than 75%, the β-phase silicon nitride content is less t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com