Synthetic method for hierarchical-pore ZSM-5 molecular sieve

A technology of ZSM-5 and synthesis method, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of high cost, heavy environmental pollution, and expensive carbon templates, and achieve high yield, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] Example 1 Sample 1 # preparation of

[0080] 0.10g of sodium metaaluminate was dissolved in 0.61 (25wt%) g of n-butylamine aqueous solution, and then 5.25g of silica sol (SiO 2 : 30.54wt%) was added dropwise into the solution obtained above, and continued to stir rapidly at room temperature for 2h until the mixture was uniform to obtain the initial gel mixture A. The molar ratio of each raw material in the initial gel mixture A is as follows: 50SiO 2 : 2.0NaAlO 2 : 3.9C 4 h 11 N: 427H 2 O. The initial gel mixture A was transferred to a PTFE-lined stainless steel reactor, and after dynamic crystallization at 160 °C for 5 h, it was cooled to room temperature to obtain precursor I.

[0081] Dissolve 0.62g of sodium metaaluminate and 0.40g of sodium hydroxide in 20g of deionized water, then gradually add 10.00g of white carbon black to the above-mentioned clear solution under rapid stirring (300rmp), and add 44.8g of Ionized water, continue to stir at room temperatu...

Embodiment 2

[0085] Example 2 Sample 2 # ~20 # preparation of

[0086] sample 2 # ~20 # The raw material type, raw material proportioning, crystallization condition are shown in Table 1, and batching process is the same as sample 1 in embodiment 1 # preparation.

[0087] Table 1 Molecular sieve synthesis ingredients and crystallization conditions

[0088]

[0089]

[0090] a : In the initial gel mixture A, the amount of silicon source added is SiO 2 The number of moles; the amount of aluminum source added in Al 2 o 3 The number of moles of template agent R is calculated by the number of moles of template agent R itself; the amount of water added is calculated by the number of moles of water itself.

[0091] b : In the initial gel mixture B, the addition amount of silicon source is SiO 2 The number of moles; the amount of aluminum source added in Al 2 o 3 The number of moles of the alkali source is calculated by the number of moles of the alkali source itself, if the alka...

Embodiment 3

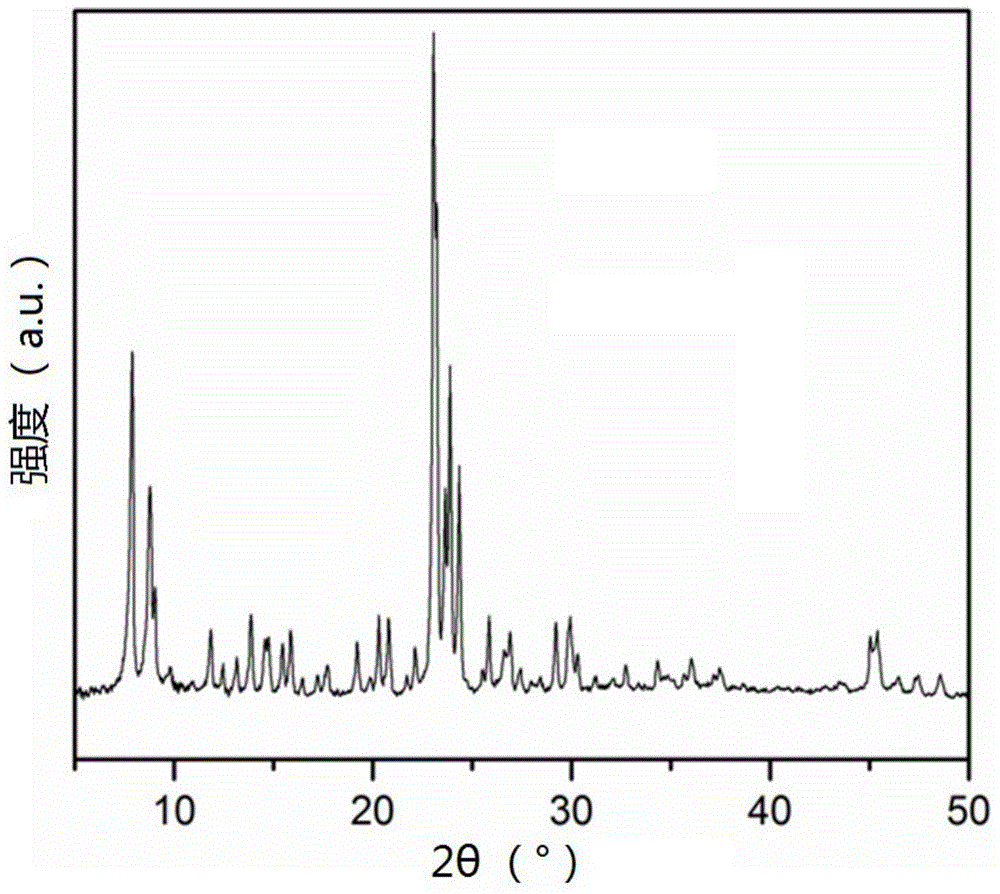

[0098] Example 3 Sample 1 # ~20 # and comparative sample 1 # ~3 # XRD analysis

[0099] Sample 1 was analyzed by X-ray diffraction method # ~20 # and comparative sample 1 # ~3 # phase analysis.

[0100] The result shows that the sample 1 prepared by embodiment 1 and 2 # ~20 # and comparative sample 1 # ~3 # Both are high-purity and high-crystallinity ZSM-5 molecular sieves, typical representatives such as figure 1 Medium sample 1 # The XRD spectrum. sample 2 # ~20 # and comparative sample 1 # ~3 # The XRD spectrum result and figure 1 Close, that is, the position and shape of the diffraction peaks are basically the same, and the relative peak intensity fluctuates within ±5% according to the change of synthesis conditions, indicating that sample 1 # ~20 # and comparative sample 1 # ~3 # It has the characteristics of ZSM-5 structure and no miscellaneous crystals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com