Edible mix film and production process mainly with casting technique thereof

A production method and mixed film technology, applied in food preparation, food science, application, etc., can solve the problems of high brittleness of plant protein film, poor smell and taste, complicated preparation process, etc., achieve rich nutrition, overcome mucous membrane, and good taste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: Preparation leek, soybean protein, cornstarch mixed film

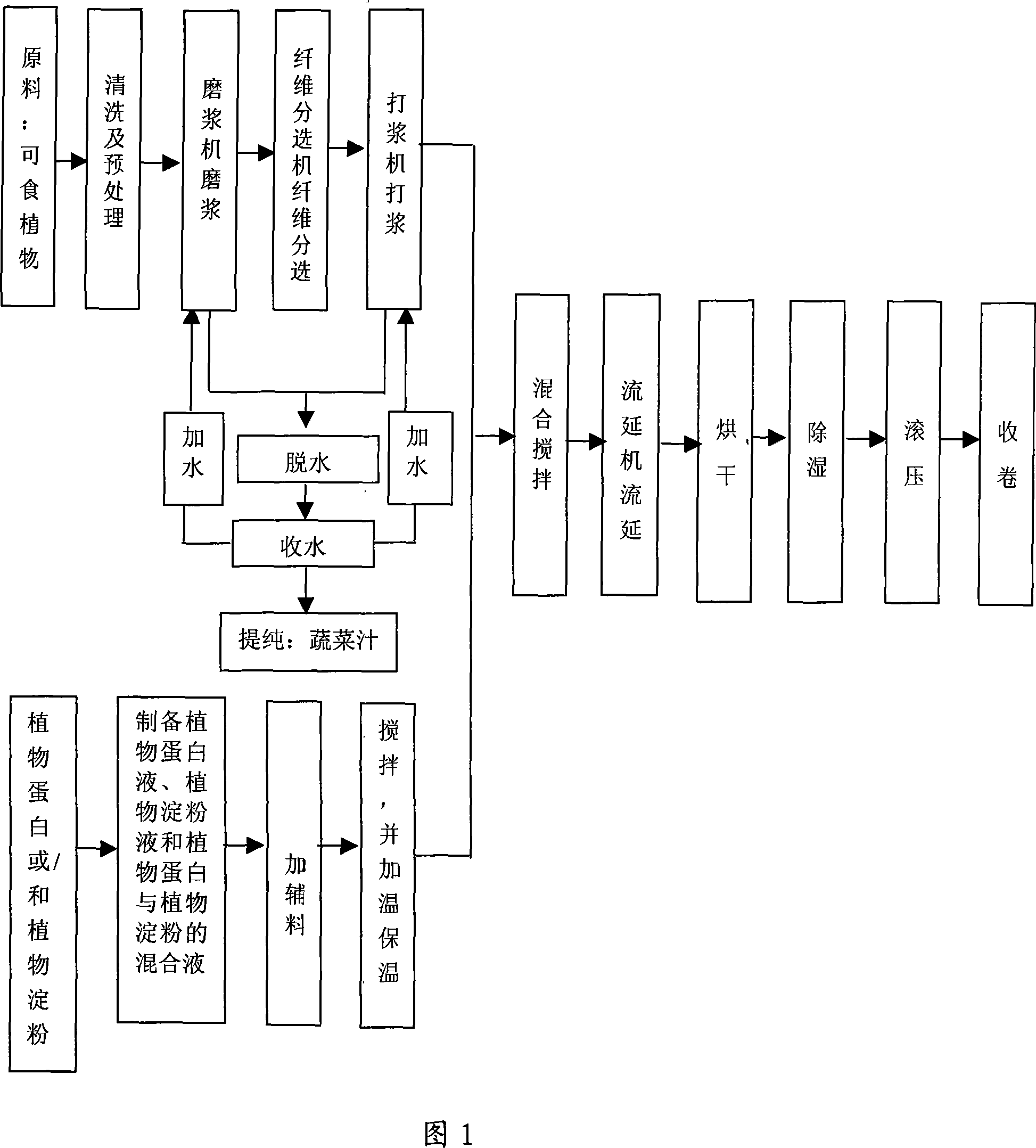

[0025] According to the above description and the production method in Fig. 1, mechanical pulping is adopted, that is, the leeks are cleaned and cut into small pieces with a length less than 5mm, and leek pulp with a moisture content of 80-90% is obtained through refining, beating, fiber sorting, etc. material. Wherein, the diameter of the fiber is less than 0.3mm. While preparing the leek slurry, prepare soybean protein and cornstarch mixed liquid, and take a certain amount of leek slurry, and its formula ratio is as follows:

[0026] 100g water, 20g soybean protein, 5g cornstarch, 5g food grade glycerin, 20g concentration is the food grade sodium polycarboxylate of 1ppm, 60g leek slurry.

[0027] Dissolve 20g of soybean protein powder and 5g of starch in 100g of water, heat to 80°C, stir for 40 minutes, add glycerin and sodium polycarboxylate, and stir for another 10 minutes to obtain a mixture...

Embodiment 2

[0029] Embodiment 2: Preparation of cabbage and soybean protein mixed film

[0030] According to the above description and the production method in Fig. 1, mechanical pulping is adopted, that is, the cabbage is cleaned and cut into small pieces with a length less than 5mm, and the cabbage pulp with a moisture content of 80-90% is obtained through refining, beating, fiber sorting, etc. material. Wherein, the diameter of the fiber is less than 0.3mm. While preparing the cabbage slurry, prepare soybean protein liquid, and take a certain amount of cabbage slurry, and its formula ratio is as follows:

[0031] 130g water, 20g soybean protein, 10g food grade glycerin, 30g concentration is the food grade sodium polycarboxylate of 1ppm, 60g cabbage slurry.

[0032] Dissolve 20g of soybean protein powder in 130g of water, heat to 80°C, stir for 40 minutes, add glycerin and sodium polycarboxylate, and stir for another 10 minutes to obtain soybean protein liquid, cool it down to 40°C, a...

Embodiment 3

[0034] Embodiment 3: preparation celery and soybean protein mixed film

[0035] According to above-mentioned description and the production method of Fig. 1, adopt mechanical method pulping, be about to celery cleaning, cutting length is less than 5mm fritter, obtains the celery pulp of water content rate 80-90% through refining, beating, fiber sorting etc. material. Wherein, the diameter of the fiber is less than 0.3mm. While preparing celery slurry, prepare soybean protein liquid, and get a certain amount of celery slurry, and its formula ratio is as follows:

[0036] 110g water, 20g soybean protein, 10g food grade glycerin, 20g food grade sodium polycarboxylate with a concentration of 1ppm, 60g celery slurry.

[0037] Dissolve 20g of soybean protein powder in 110g of water, heat to 80°C, stir for 40 minutes, add glycerin and sodium polycarboxylate, and stir for another 10 minutes to obtain soybean protein liquid, cool it down to 40°C, add celery slurry , and then stirred...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com