Preparation process of liquid edible salt

A preparation process and edible salt technology, which is applied in the field of liquid edible salt preparation process, can solve problems such as difficult to control the intake of salt, and achieve the effects of easy control of the amount of addition, convenient use, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

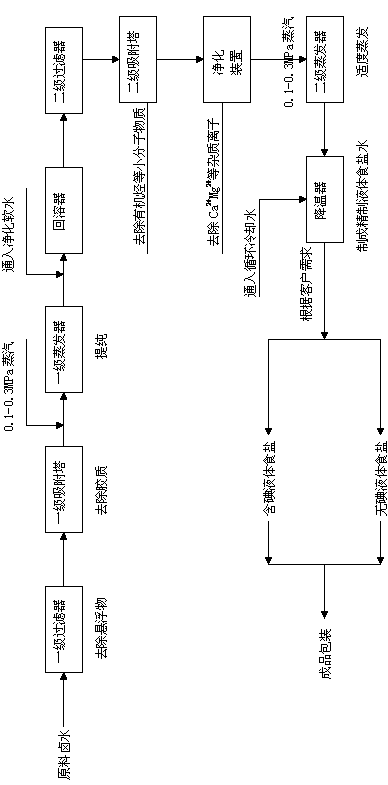

Method used

Image

Examples

Embodiment 1

[0020] Step 1: The raw brine is filtered through a primary filter until the content of suspended solids is 0.13%, and then is adsorbed through a primary adsorber until the content of colloidal substances is 0.25%;

[0021] The second step: the product obtained in the first step is evaporated at a vapor pressure of 0.1MPa through an evaporator to a brine purity of 96.7% and a concentration of 296.3g / L, and then redissolved with water through a re-dissolver and passed through a secondary filter. Grade filtration to 0.04% suspended solids;

[0022] The third step: the product obtained in the second step is subjected to secondary adsorption through the secondary adsorber until the content of small molecular substances such as organic hydrocarbons is 0.086%, and then the product after the secondary adsorption is purified to Ca 2+ Content: 0.34%, Mg 2+ Content: 0.12%;

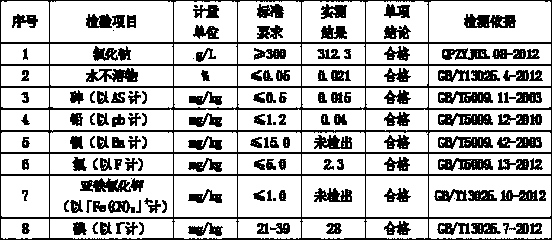

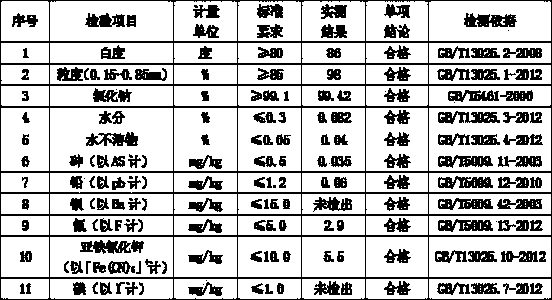

[0023] The fourth step: Evaporate the product obtained in the third step until the sodium chloride content is ≥ ...

Embodiment 2

[0030] The first step: the raw brine is filtered through a primary filter until the content of suspended solids is 0.10%, and then is adsorbed through a primary adsorber until the content of colloidal substances is 0.19%;

[0031] The second step: Evaporate the product obtained in the first step through the evaporator at a vapor pressure of 0.1-0.3MPa to a brine purity of 97.5% and a concentration of 295.9g / L, then add water to the reflux device and pass through the secondary filter Carry out secondary filtration until the suspended matter is 0.052%;

[0032] The third step: the product obtained in the second step is subjected to secondary adsorption through the secondary adsorber until the content of small molecular substances such as organic hydrocarbons is 0.063%, and then the product after the secondary adsorption is purified to Ca 2+ Content: 0.28%, Mg 2+ Content: 0.15%;

[0033] The fourth step: Evaporate the product obtained in the third step until the sodium chloride...

Embodiment 3

[0041] The first step: the raw brine is filtered through a primary filter until the content of suspended solids is 0.14%, and then is adsorbed through a primary adsorber until the content of colloidal substances is 0.11%;

[0042] The second step: Evaporate the product obtained in the first step through the evaporator under the steam pressure of 0.15MPa to a brine purity of 98.6% and a concentration of 298.3g / L, then add water to the re-dissolver and re-dissolve through the secondary filter Secondary filtration until the suspended matter is 0.067%;

[0043] The third step: the product obtained in the second step is subjected to secondary adsorption through the secondary adsorber until the content of small molecular substances such as organic hydrocarbons is 0.03%, and then the product after the secondary adsorption is purified to Ca 2+ Content: 0.21%, Mg 2+ Content: 0.17%;

[0044] The fourth step: Evaporate the product obtained in the third step until the sodium chloride co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com