Ultraviolet radiation resistant composite insulator material added with nano particles and preparation method thereof

A composite insulator and nanoparticle technology is applied in the field of ultraviolet radiation-resistant composite insulator materials and preparation fields added with nanoparticles, and achieves the effects of simple production process operation, controllable addition amount, and small change in hydrophobicity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

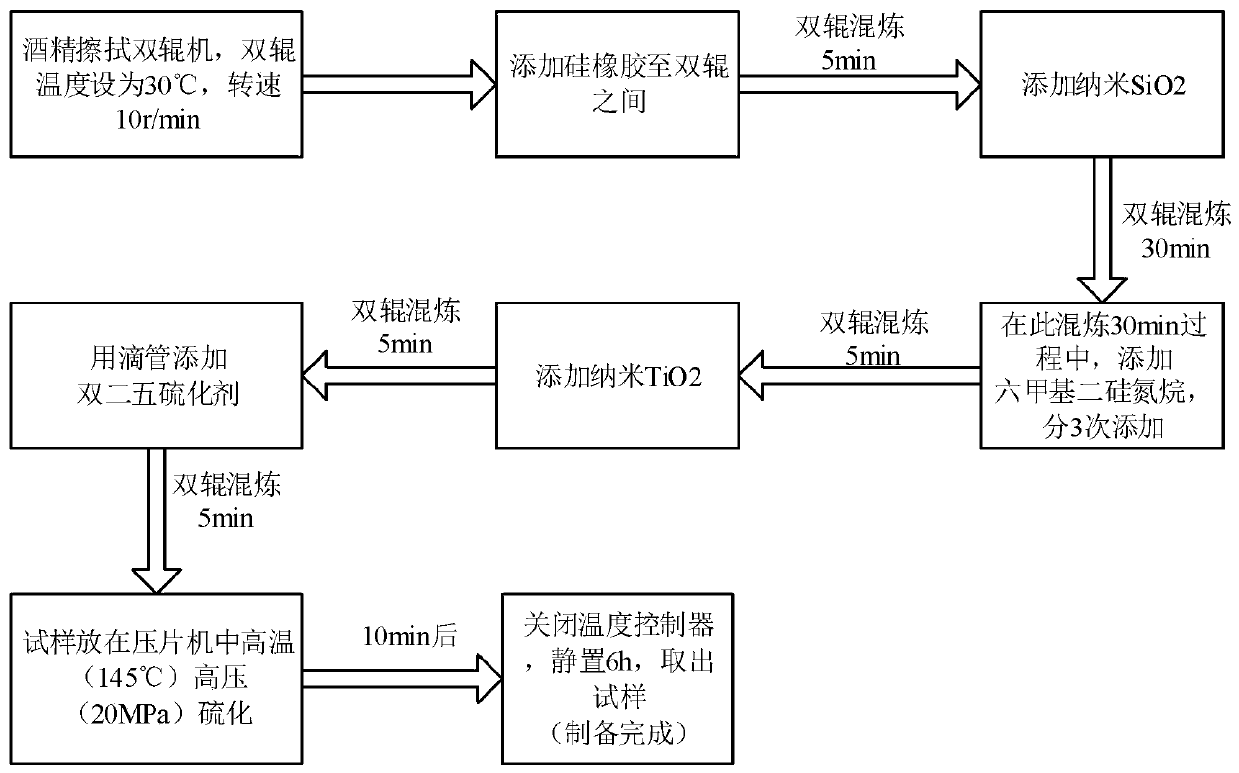

[0030] Such as figure 1 As shown, the preparation method of the ultraviolet radiation resistant composite insulator material adding nanoparticles of the present invention comprises the following steps:

[0031] 1) Select xg silicone rubber and 20x%g nano-SiO respectively 2 , 5x%g hexamethyldisilazane, 10x%g~40x%g nano TiO 2 , 1x% g bis-pentasulfurizing agent;

[0032] 2) Wipe the double-roller machine with alcohol, start the double-roller machine, set the roller speed to 10r / min, adjust the distance between the two wheels to 1.5mm, and set the roller temperature to 30°C; The double-roller machine is the model XL-KLYP1 double-roller machine from Xilong Electric Machinery Equipment Co., Ltd.

[0033] 3) After the roller temperature in step 2) reaches 30°C, place the silicone rubber in step 1) between the two rollers, and knead with the two rollers for 5 minutes;

[0034] 4) after the silicon rubber described in step 3) is uniform, get the nano-SiO described in step 1) 2 , e...

specific example 1

[0042] 1) Calculated according to the addition ratio: 10g of methyl silicone rubber, 2g of nano-SiO with a content ≥ 99% and an average particle size of 30nm 2 , 0.5g hexamethyldisilazane, 1g content ≥ 92%, average particle size 20nm, rutile nano-TiO 2 , 0.1g bis-pentasulfurizing agent;

[0043] 2) Wipe the double roller machine with alcohol, start the double roller machine, set the roller speed to 10r / min, adjust the distance between the two rollers to 1.5mm, and set the roller temperature to 30°C;

[0044] 3) After the roller temperature in step 2) reaches 30°C, place the measured methyl silicone rubber between the two rollers, and knead with the two rollers for 5 minutes;

[0045] 4) Nano-SiO with a content ≥ 99% and an average particle size of 30nm 2 , evenly added to the methyl silicone rubber between the rollers, and kneaded on two rollers for 30 minutes.

[0046] 5) Nano-SiO with content ≥ 99% and average particle size 30nm 2 After all the addition is complete, afte...

specific example 2

[0050] 1) Calculated according to the addition ratio: 10g of methyl vinyl silicone rubber, 2g of nano-SiO with a content ≥ 99% and an average particle size of 50nm 2 , 0.5g hexamethyldisilazane, 1g content ≥ 96%, average particle size 30nm, rutile nano-TiO 2 , 0.1g bis-pentasulfurizing agent;

[0051] 2) Wipe the double roller machine with alcohol, start the double roller machine, set the roller speed to 10r / min, adjust the distance between the two rollers to 1.5mm, and set the roller temperature to 30°C;

[0052] 3) After the roller temperature in step 2) reaches 30°C, place the measured methyl vinyl silicone rubber between the two rollers, and knead with the two rollers for 5 minutes;

[0053] 4) Nano-SiO with a content ≥ 99% and an average particle size of 50nm 2 , evenly added to the methyl vinyl silicone rubber between the rollers, and kneaded on two rollers for 30 minutes.

[0054] 5) Nano-SiO with content ≥ 99% and average particle size 50nm 2 After all the addition...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com