Polymer film, and preparation method and application thereof

A technology of polymer film and resin film, which is applied in the field of polymer film and its preparation, can solve the problems of poor heat sealing performance, complicated process and poor abrasion resistance of packaging materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

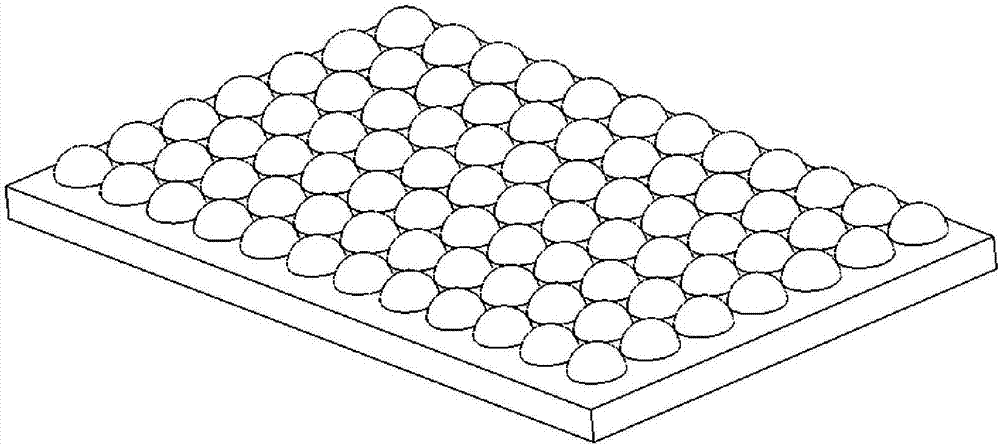

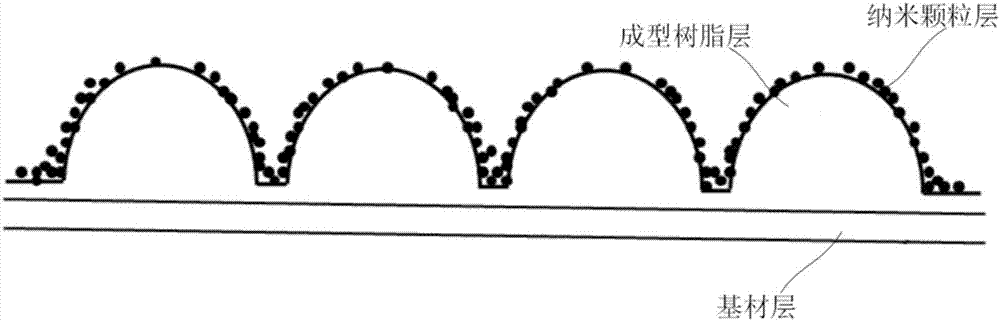

[0067] Use a laser engraving machine to engrave a spherical concave spherical array with a micron-scale convex spacing w=100 μm, a bottom surface diameter D=450 μm, a spherical height d=80 μm, and a honeycomb arrangement on a cylindrical steel roller to obtain an embossing roller .

[0068] The substrate is aluminum foil with a thickness of 16 μm; the molding resin is thermoplastic polyethylene film with a thickness of 60 μm, and the film raw material is Daqing Petrochemical 18D low-density polyethylene resin; the nanoparticles are fumed silica particles AEROSIL R812, with an average particle size of 7nm .

[0069] The polymer film was prepared as follows:

[0070] (1) After the base material and molding resin are compounded with polyurethane adhesive, they are cured in a drying room at 50°C for 24 hours to obtain a composite film; the embossing roller is heated to 120°C, and the obtained composite film is pressed at 5MPa Printing, get spherical body micron-scale projection ...

Embodiment 2

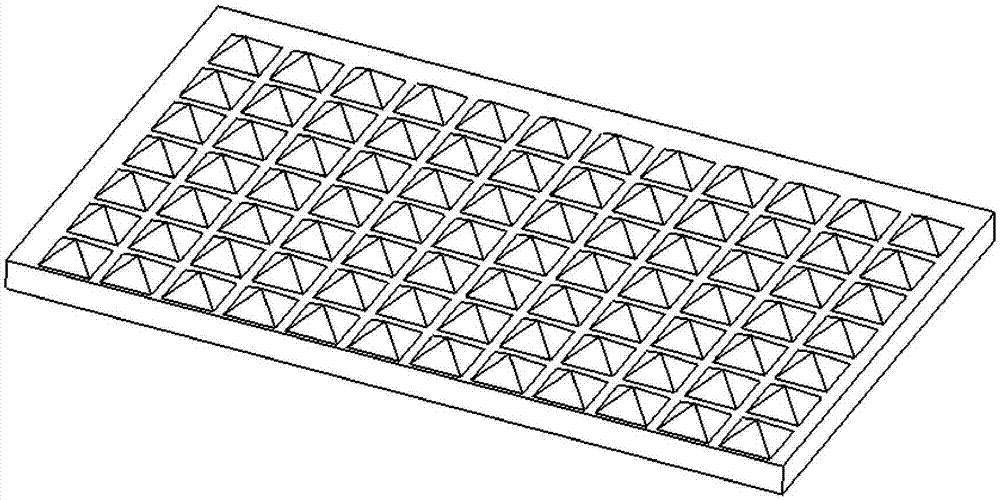

[0074] Use the mechanical scribing method to engrave a regular quadrangular pyramid on the cylindrical steel roller with a micron-scale convex spacing w=30μm, a bottom side length D=150μm, a cone height d=50μm, and a concave regular quadrangular pyramid structure arranged in a square. printing roller.

[0075] The substrate is aluminum foil with a thickness of 12 μm; the thermoplastic resin is polypropylene with a thickness of 70 μm; the nanoparticles are fumed silica particles AEROSIL R812S with an average particle size of 7 nm.

[0076] The polymer film was prepared as follows:

[0077] (1) Polypropylene is cast on the base material, and at the same time, the above-mentioned embossing roller is used to emboss the surface of the composite film cast, and the casting speed is controlled to make the total thickness of the polypropylene with micron-scale convex structure Be 70 μm, get the microstructure concave-convex film (see figure 2 );

[0078] (2) Disperse the fumed sili...

Embodiment 3

[0081] Use a photolithography machine to photoetch a spherical micro-scale convex micro-spherical lens array with a pitch w=10 μm, a bottom surface diameter D=50 μm, and a spherical height d=20 μm arranged in a honeycomb shape on a planar photoresist plate, and then use The LIGA technology replicates the structure on a metal nickel plate with a thickness of 80 microns, and pastes the metal nickel plate on a steel roller with double-sided adhesive to obtain an embossing roller.

[0082]The substrate is aluminum foil with a thickness of 16 μm; the thermoplastic resin is a polyethylene film with a thickness of 30 μm; the nanoparticles are fumed silica particles AEROSIL R812S with an average particle size of 7 nm.

[0083] The polymer film was prepared as follows:

[0084] (1) After the base material and molding resin are compounded with polyurethane adhesive, they are cured in a drying room at 50°C for 24 hours to obtain a composite film; the embossing roller is heated to 120°C a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com