Super-hydrophobic film with singular microstructure, and preparation method thereof

A microstructure and super-hydrophobic technology, applied in the direction of microstructure technology, microstructure devices, manufacturing microstructure devices, etc., can solve the problems of high cost and complicated process, and achieve the effect of low cost, simple process and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] refer to Figure 1 to Figure 8 , a method for preparing a superhydrophobic film with a singular microstructure of the present invention, comprising the following steps:

[0039] (1) Preparation and processing of the metal through-hole template: the required circular through-hole microarray pattern structure is processed on the 304 stainless steel with a thickness of 30-50 μm by exposure etching process, and the diameter of the through-hole of the metal template is 50-80 μm. The spacing between the microholes is 50-80μm, and the surface of the metal through-hole template is modified by perfluorosilane to reduce its surface energy;

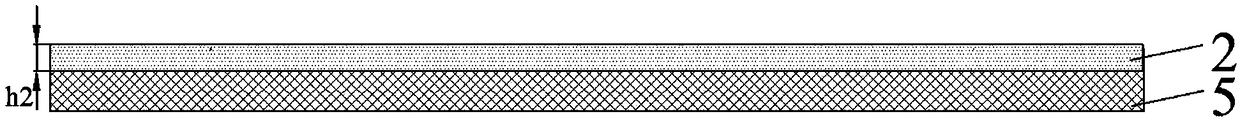

[0040] (2) Selection of upper and lower electrodes and polymer materials: the upper and lower electrodes are made of flat plates with excellent conductivity, ITO glass or highly doped conductive silicon wafers can be used, and the polymer is made of thermosetting polymer polydimethylsiloxane ( PDMS);

[0041] (3) Polymer preforming: Spin-co...

Embodiment 1

[0046] A method for preparing a superhydrophobic film with a singular microstructure based on electric field induction of the present invention, comprising:

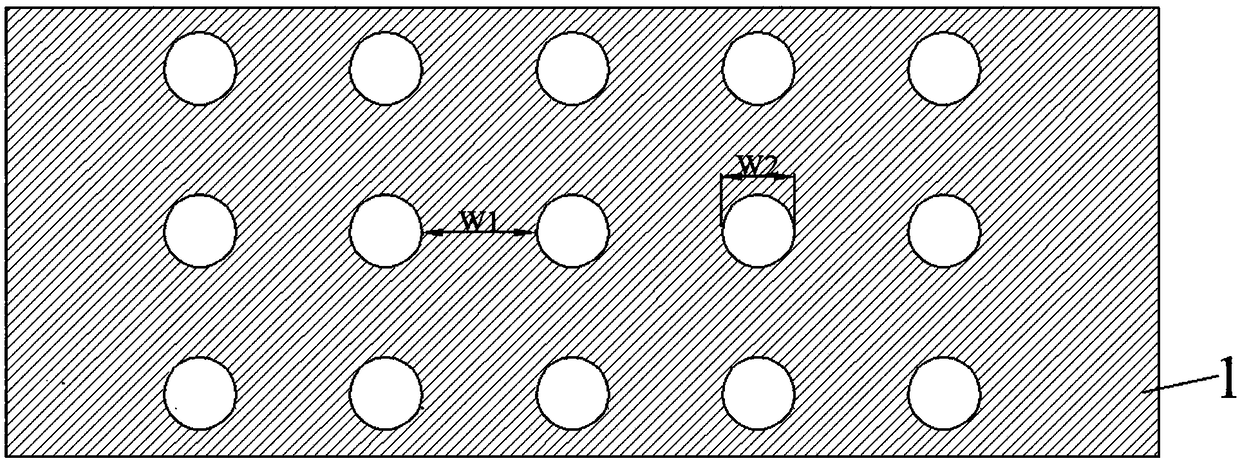

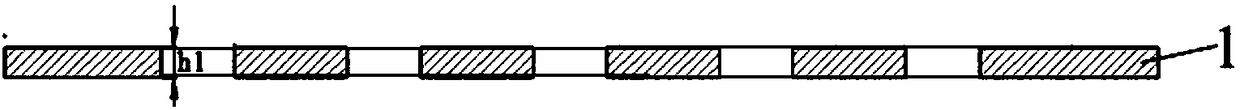

[0047] (1) Preparation and processing of metal through-hole template: refer to figure 1 and figure 2 , the metal via hole template 1 adopts the exposure etching process to prepare a microstructure array with through holes on the surface, the thickness h1 of the metal via hole template is 30 μm, the through hole W2 of the microstructure array is 50 μm, and the spacing W1 between the microholes is 50 μm , the surface of the through-metal template is modified by heptadecafluorodecyltriethoxysilane, that is, a self-assembled monomolecular fluorine-silicon film layer is formed on the surface of the through-metal template, so that the treated through-metal template 1 The surface has an extremely low surface energy, which prevents the polymer from sticking to the surface during the final detachment process.

[0048] (2) Select...

Embodiment 2

[0054] A method for preparing a superhydrophobic film with a singular microstructure based on electric field induction of the present invention, comprising:

[0055] (1) Preparation and processing of metal through-hole template: refer to figure 1 and figure 2 , the metal through-hole template 1 adopts the exposure etching process to prepare a microstructure array with through holes on the surface, the thickness h1 of the metal through-hole template is 40 μm, the through hole W2 of the microstructure array is 60 μm, and the spacing W1 between the microholes is 70 μm , the surface of the through-metal template is modified by perfluorosilane, that is, a self-assembled monomolecular fluorine-silicon film layer is formed on the surface of the through-metal template, so that the surface of the through-metal template 1 after treatment has an extremely low surface area. Yes, it prevents the polymer from sticking to its surface during final release.

[0056] (2) Selection of upper a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com