Glass fiber group and glass fiber reinforced resin-based composite material

A resin-based, glass fiber-reinforced technology, which is applied in the direction of synthetic cellulose/non-cellulose material pulp/paper, fiber raw material processing, glass manufacturing equipment, etc., can solve the problem of shortening fiber length, unstable production process factors, mixing There are problems such as deviation in the feeding amount of the extruder to achieve the effect of maintaining tensile strength and bending strength, keeping the working environment clean, and good tensile impact performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

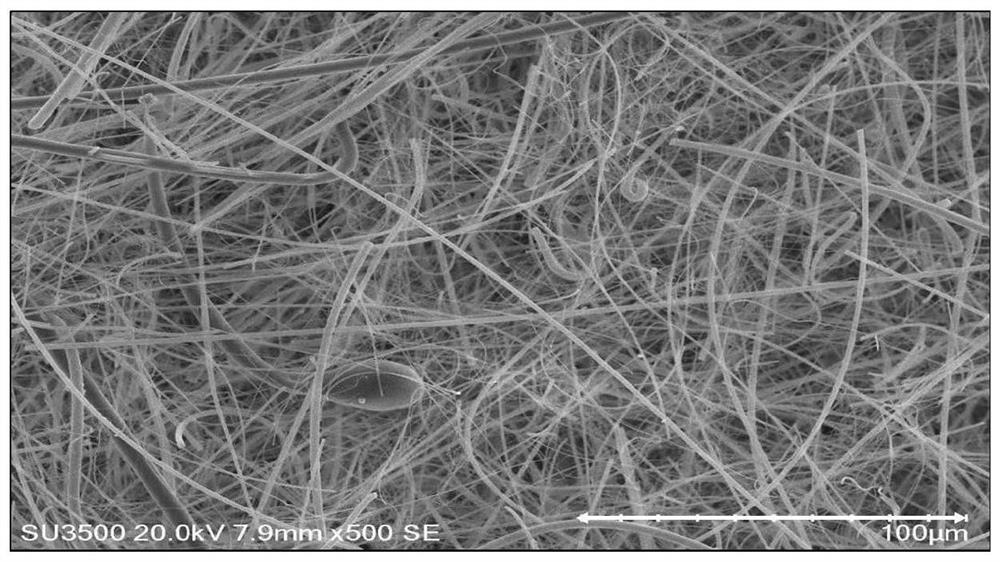

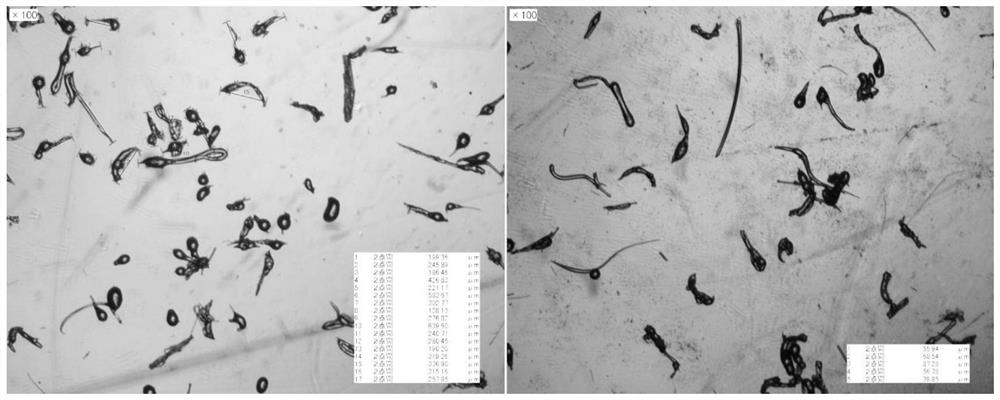

[0078] The glass fiber wool (average diameter 5um) was prepared by centrifugation. The glass fiber wool was firstly decomposed by a deionizer, and deionized water was added during the deionization. The mass ratio of glass fiber wool to deionized water was 1:10, and the deionization time was 5 minutes. Transport the decomposed glass fiber to the batching tank through a centrifugal pump, add deionized water to disperse the glass fiber more evenly in the water, suspend the glass fiber with a smaller quality in the deionized water, and sink the glass slag with a larger quality to the bottom , Remove glass slag, so just obtain the mixed slurry that glass fiber is dispersed in deionized water, the mixed slurry after deslagging is sent to the slurry storage tank, and the concentration of glass fiber in the mixed slurry is 2.8kg / L now.

[0079] The mixed slurry in the slurry storage tank is dehydrated and rapidly formed by a vacuum pump to obtain a density of 100kg / m 3 The glass fiber...

Embodiment 2

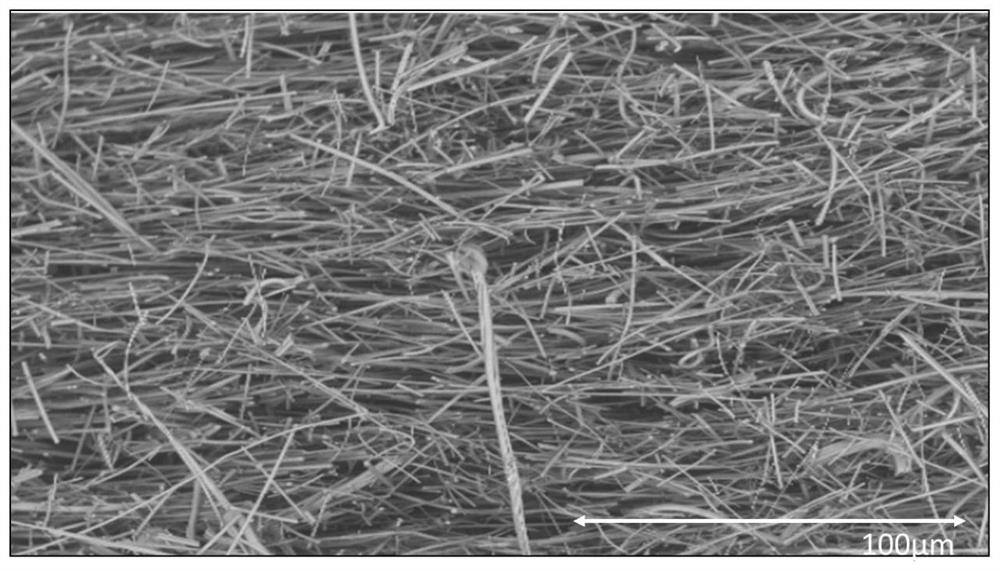

[0083] Glass fiber wool (average diameter 3.5um) is prepared by centrifugation. First, the glass fiber wool is decomposed by a de-fibrillator, and deionized water is added during de-ionization. The mass ratio of glass fiber wool and deionized water is 1:12, and the de-ionization time is 10 minutes. . Transport the deflated glass fiber to the batching tank through a centrifugal pump, add deionized water to obtain a mixed slurry of glass fiber dispersed in deionized water, add deionized water to make the glass fiber dispersed in water more uniformly, and reduce the quality of glass fiber Suspended in deionized water, the larger glass slag sinks to the bottom, and the glass slag is removed, so that the mixed slurry of glass fibers dispersed in deionized water is obtained, and the mixed slurry after deslagging is sent to the slurry storage tank, at this time The concentration of glass fiber in the mixed slurry is 3kg / L.

[0084] The mixed slurry is dehydrated and rapidly formed b...

Embodiment 3

[0088] The glass fiber wool (average diameter 4um) was prepared by centrifugation. Firstly, the glass fiber wool was disintegrated by a disintegrator, and deionized water was added during the disintegration. The mass ratio of glass fiber wool to deionized water was 1:15, and the disintegration time was 17 minutes. Transport the deflated glass fiber to the batching tank through a centrifugal pump, add deionized water to obtain a mixed slurry of glass fiber dispersed in deionized water, add deionized water to make the glass fiber dispersed in water more uniformly, and reduce the quality of glass fiber Suspended in deionized water, the larger glass slag sinks to the bottom, and the glass slag is removed, so that the mixed slurry of glass fibers dispersed in deionized water is obtained, and the mixed slurry after deslagging is sent to the slurry storage tank, at this time The concentration of glass fiber in the mixed slurry is 3.4kg / L.

[0089] The mixed slurry is dehydrated and r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com