Evaporation and Concentration Method of Yeast Wastewater

A yeast wastewater, evaporation and concentration technology, applied in the direction of heating water/sewage treatment, etc., can solve the problem of high energy consumption and steam consumption, and achieve the effects of reducing wastewater treatment costs, reducing steam consumption, and preventing foaming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

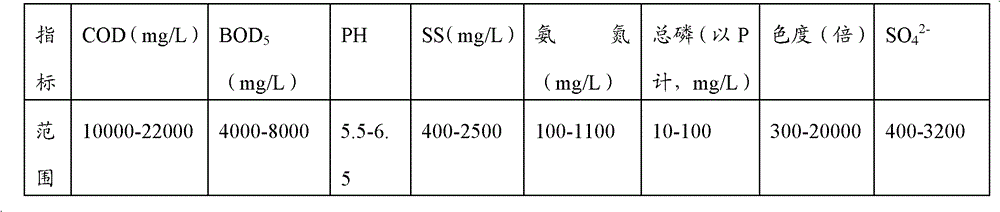

[0047] Beet honey was used as raw material to ferment Saccharomyces cerevisiae, and the yeast wastewater produced by the yeast during the yeast separation process was used as the evaporation and concentration object of this embodiment. The COD of the yeast wastewater is 5000mg / L, the solid content concentration in the wastewater is 4%±1% (W / W), and it is preheated to 60°C.

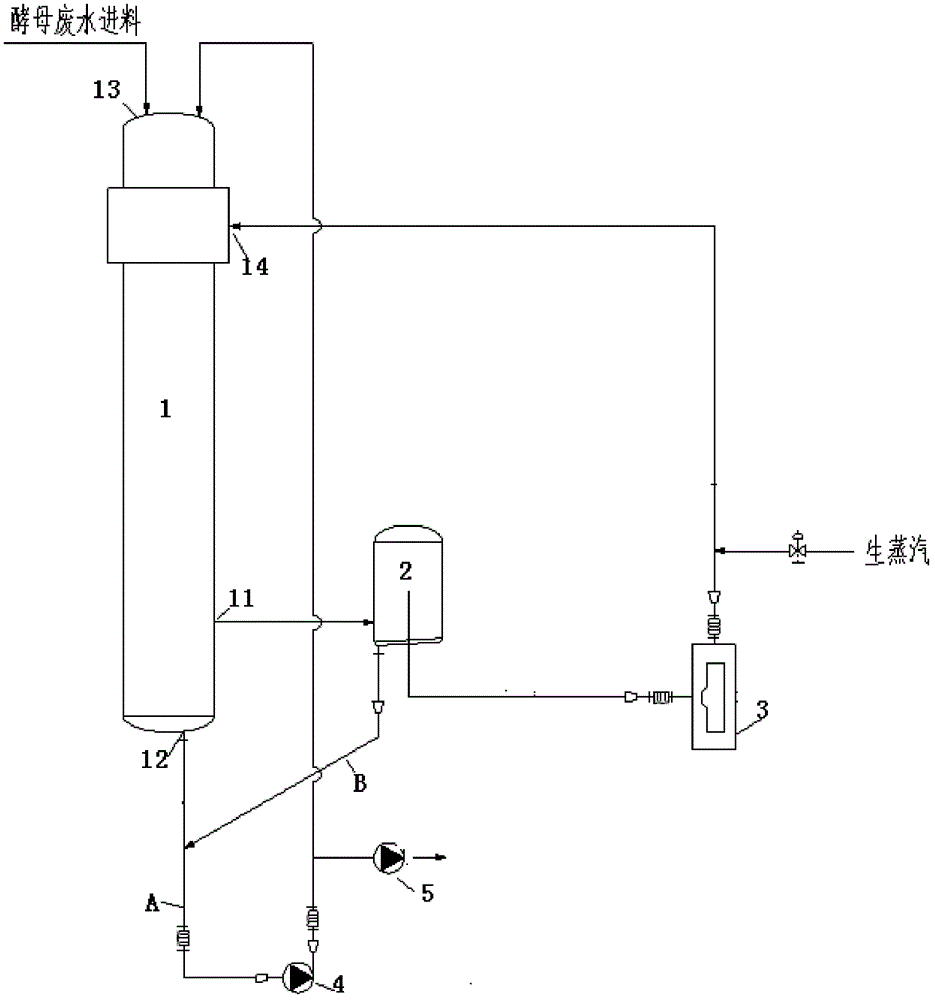

[0048] Yeast wastewater with 65m 3 The flow rate of / h enters the tubular heating tube of the heater 1 through the feed port 13 of the heater 1, and the material flows downward along the inner wall of the heating tube of the heater in a uniform film shape; at the same time, the raw steam at 115-125 ° C is passed through the inlet The gas port 14 enters the heater 1 and is evenly distributed on the outer wall of the tubular heating tube. The yeast wastewater in the heating tube exchanges heat with the raw steam on the outer wall of the heating tube to generate a two-phase material flow including gas phase a...

Embodiment 2

[0055] The process adopted in this example is basically the same as that in Example 1, except that the temperature of the compressed secondary steam is 85.5°C; the evaporation temperature of the yeast wastewater in the heater 1 is 78°C; the final solid concentration of the yeast wastewater is 10% (w / w). The MVR device using the process method of Example 2 can be continuously used for 17 days, and the scale thickness in the heater 1 is only about 5mm, and no crystallization occurs.

Embodiment 3

[0057] The process adopted in this example is basically the same as that in Example 1, except that the temperature of the compressed secondary steam is 85.5°C; the evaporation temperature of the yeast wastewater in the heater 1 is 78°C; the final solid concentration of the yeast wastewater is 12% (w / w). The MVR device using the process method of Example 3 can be continuously used for 16 days, and the scale thickness in the heater 1 is only about 5mm, and a small amount of crystallization is produced. Example 3 is compared with Example 1 to illustrate that the trend of material crystallization is enhanced while maintaining the output concentration while reducing the evaporation temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com