Halide ion assisted copper sulfide micron flower-structure material as well as preparation method and application thereof

A technology of halide ions and copper sulfide, applied in the field of nanomaterials, can solve the problems of poor cycle stability of transition metal sulfides, large stability problems of transition metal sulfides, etc., and achieves improved cycle stability and rate performance, and low production costs. , the effect of structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

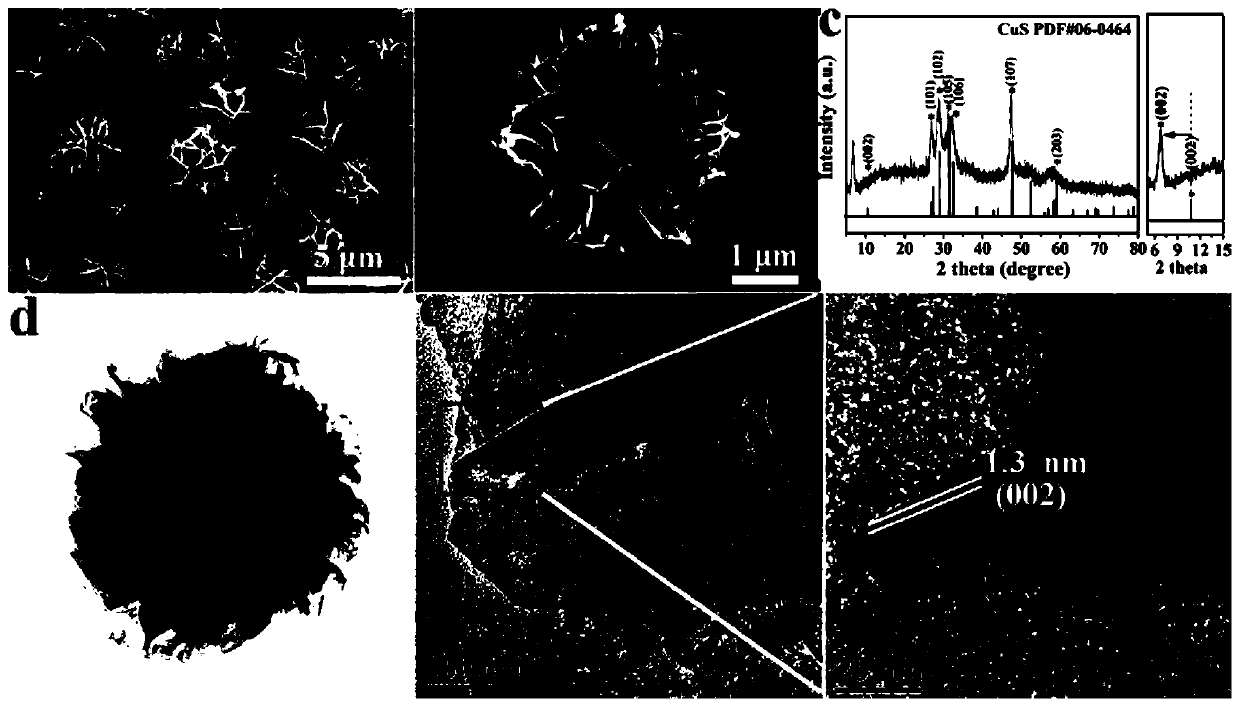

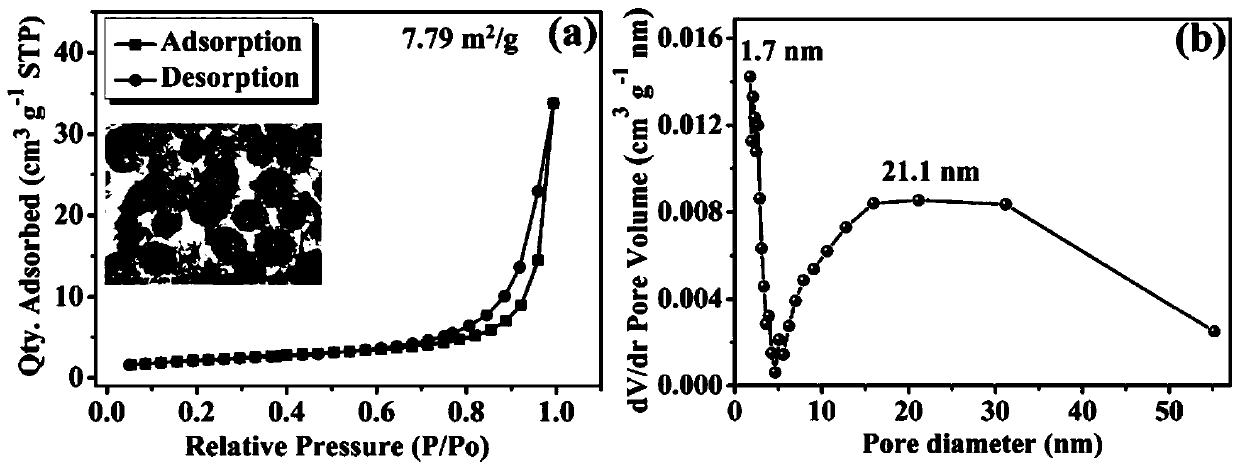

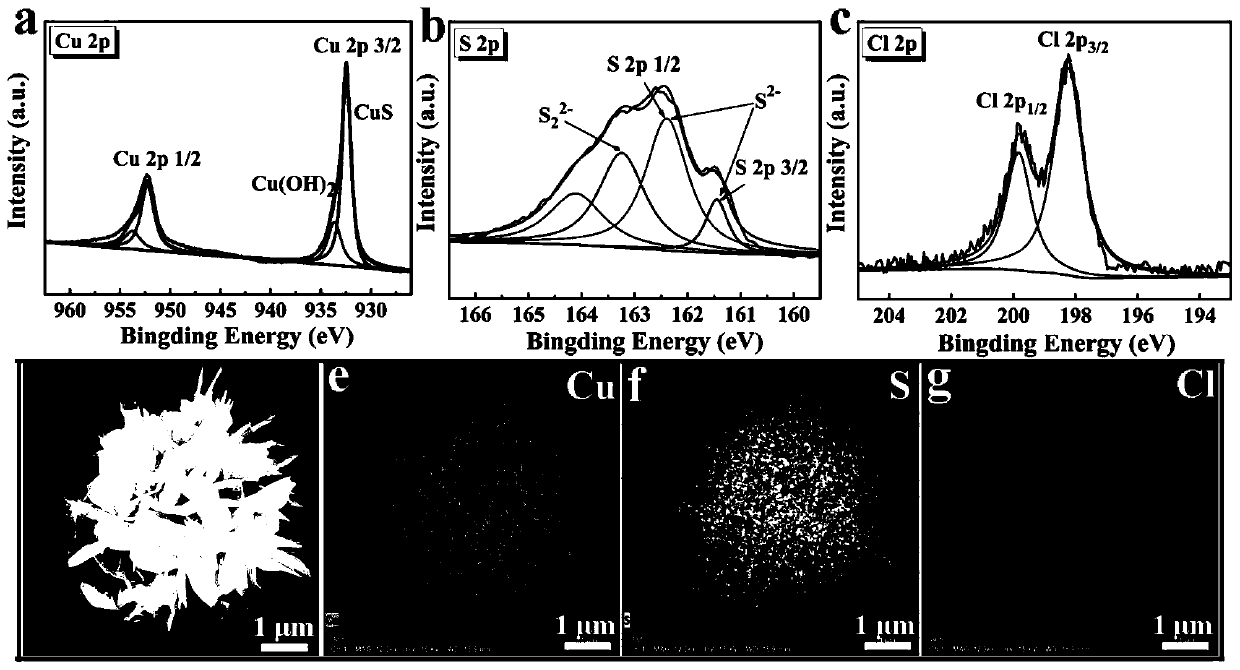

[0046] A preparation method of copper sulfide micron flower material assisted by chloride ions, comprising the following steps:

[0047] Dissolve copper nitrate in a mixed solution of 50ml double-distilled water and 20ml absolute ethanol, add thiourea and stir evenly, first magnetically stir for 5 minutes, then add sodium chloride to the mixed solution, and in the final mixed solution, copper nitrate, The concentrations of thiourea and sodium chloride are 0.1M, 0.2M, and 0.2M respectively. Stir the mixed solution for 30 minutes and then transfer it to a 100mL stainless steel polytetrafluoroethylene high-temperature reaction kettle for hydrothermal reaction at 120-140°C for 10- After 14 hours, take out the reactor and let it cool down to room temperature naturally. After that, collect the product by centrifugation, wash it several times with water and absolute ethanol respectively, and then put the product in a vacuum drying oven at 60 degrees to dry for 12 hours, and then you c...

Embodiment 2

[0055] A preparation method of copper sulfide micron flower material assisted by chloride ions, comprising the following steps:

[0056] Dissolve copper nitrate in a mixed solution of 50ml double-distilled water and 20ml absolute ethanol, add thiourea and stir evenly, first magnetically stir for 5 minutes, then add sodium chloride to the mixed solution, and in the final mixed solution, copper nitrate, The concentrations of thiourea and sodium chloride are 0.2M, 0.4M, and 0.2M respectively. Stir the mixed solution for 30 minutes and then transfer it to a 100mL stainless steel polytetrafluoroethylene high-temperature reactor, and conduct a hydrothermal reaction at 120-140°C for 10- After 14 hours, take out the reactor and let it cool down to room temperature naturally. After that, the product is collected by centrifugation, washed several times with water and absolute ethanol respectively, and then put the product in a vacuum drying oven at 60°C for 12 hours to obtain chloride io...

Embodiment 3

[0058] A preparation method of copper sulfide micron flower material assisted by chloride ions, comprising the following steps:

[0059] Dissolve copper nitrate in a mixed solution of 50ml double-distilled water and 20ml absolute ethanol, add thiourea and stir evenly, first magnetically stir for 5 minutes, then add sodium chloride to the mixed solution, and in the final mixed solution, copper nitrate, The concentrations of thiourea and sodium chloride were 0.1M, 0.2M and 0.3M, respectively. Stir the mixed solution for 30 minutes, then transfer it to a 100mL stainless steel polytetrafluoroethylene high-temperature reactor, and conduct a hydrothermal reaction at 120-140°C for 10-14 hours, take out the reactor and cool it to room temperature naturally, after that, collect the product by centrifugation, and then water and anhydrous ethanol for several times, and then put the product into a vacuum drying oven at 60°C for 12 hours to obtain the copper sulfide micron flower material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| lattice spacing | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com