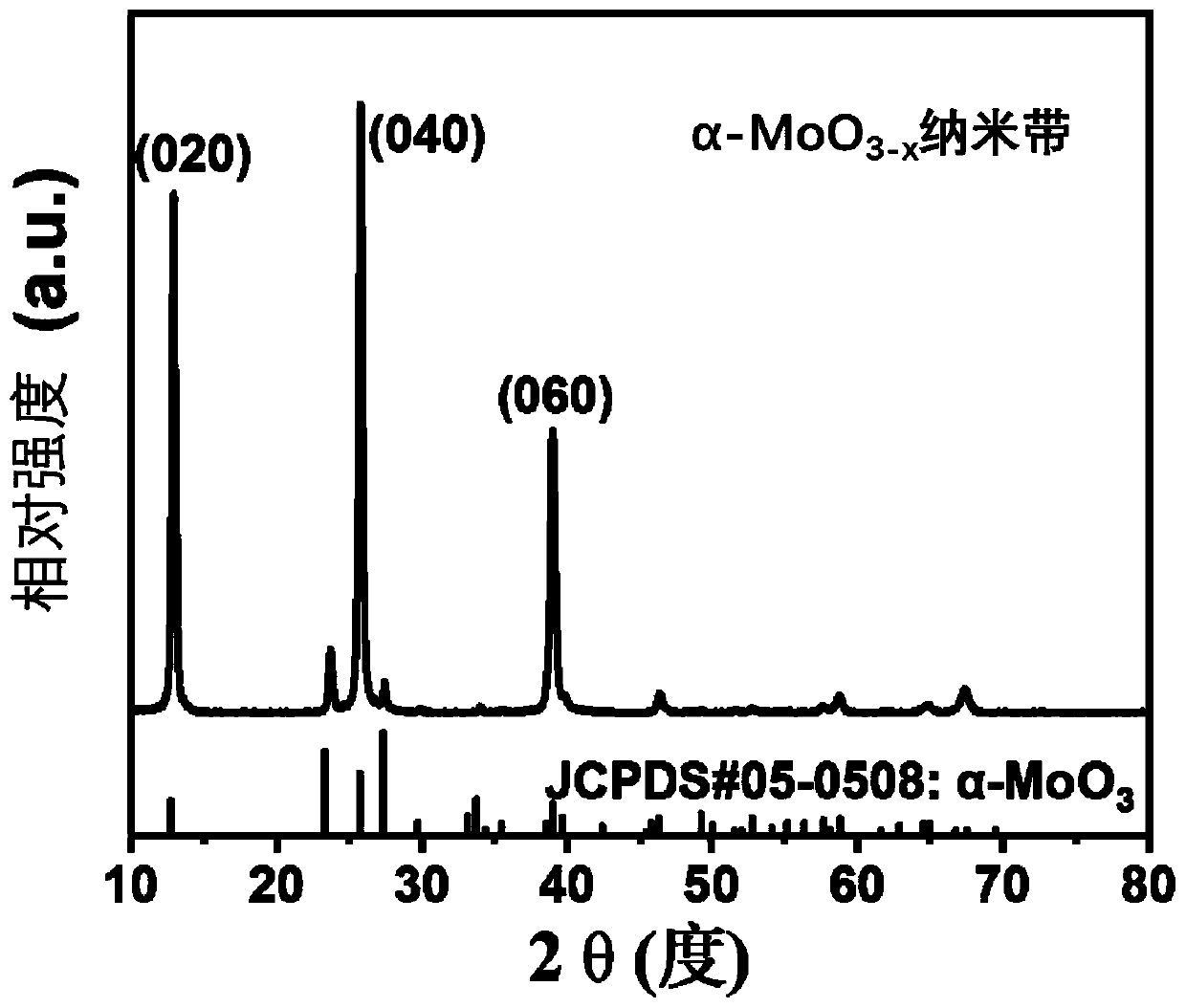

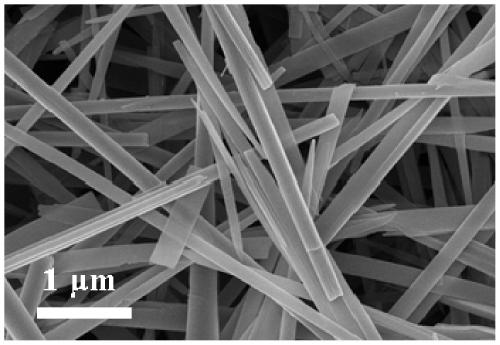

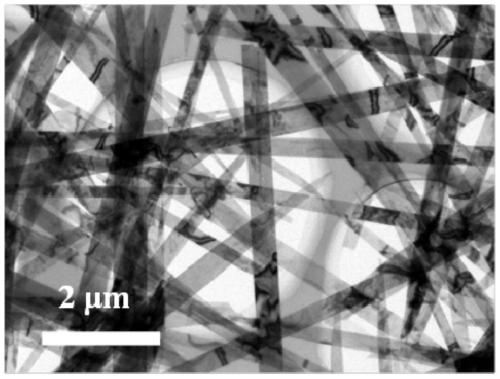

Alpha-MoO3-x nanobelt and preparation method thereof as well as electrode material and energy storage device

A -moo3-x, energy storage device technology, applied in the field of nanomaterials, can solve the problems of high price, small specific capacity of carbon materials, large resistance, etc., and achieve the effect of enhanced conductivity, increased capacity, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] This embodiment provides a kind of α-MoO 3-x The preparation method of nanobelt, comprises the following steps:

[0061] S1. Dissolve 0.5g of molybdenum powder in 10ml of hydrogen peroxide solution with a mass fraction of 30% in an ice bath, stir rapidly until uniform, and cool to obtain a yellow mixed solution;

[0062] S2. Add 10ml of absolute ethanol and 50ml of deionized water into the yellow mixed solution obtained in step S1, and stir for 1 hour to obtain a bright yellow mixed solution;

[0063] S3. Transfer the bright yellow mixed solution obtained in step S2 to a 100ml reactor for solvothermal reaction, the reaction temperature is 140°C, and the time is 18h;

[0064] S4. After the reaction kettle is naturally cooled to room temperature in step S3, open the reaction kettle, the upper layer is a blue solution, and the bottom sediment is a blue band-shaped product; the obtained sediment is alternately washed 5 times with absolute ethanol and deionized water , and...

Embodiment 2

[0066] This embodiment provides a kind of α-MoO 3-x The preparation method of nanobelt, comprises the following steps:

[0067] S1. Dissolve 0.3g of molybdenum powder in 10ml of hydrogen peroxide solution with a mass fraction of 25% under ice bath conditions, stir rapidly until uniform, and cool to obtain a yellow mixed solution;

[0068] S2. Add 5ml of absolute ethanol and 50ml into the yellow mixed solution obtained in step S1, and stir for 1 hour to obtain a bright yellow mixed solution;

[0069] S3. Transfer the bright yellow solution obtained in step S2 to a 100ml reactor for solvothermal reaction, the reaction temperature is 170°C, and the time is 10h;

[0070] S4. After the reaction kettle is naturally cooled to room temperature in step S3, open the reaction kettle, the upper layer is a blue solution, and the bottom sediment is a blue band-shaped product; the obtained sediment is alternately washed 5 times with absolute ethanol and deionized water , and dried at 80°C ...

Embodiment 3

[0072] This embodiment provides a kind of α-MoO 3-x The preparation method of nanobelt, comprises the following steps:

[0073] S1. Dissolve 0.6g of molybdenum powder in 10ml of hydrogen peroxide solution with a mass fraction of 40% under ice bath conditions, stir rapidly until uniform, and cool to obtain a yellow mixed solution;

[0074] S2. Add 10ml of absolute ethanol and 50ml of deionized water into the yellow solution obtained in step S1, and magnetically stir for 3 hours to obtain a bright yellow mixed solution;

[0075] S3. Transfer the bright yellow solution obtained in step S2 to a 100ml reactor for solvothermal reaction, the reaction temperature is 140°C, and the time is 24h;

[0076] S4. After the reaction kettle is naturally cooled to room temperature in step S3, open the reaction kettle, the upper layer is a blue solution, and the bottom sediment is a blue band-shaped product; the obtained sediment is alternately washed 5 times with absolute ethanol and deionized...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com