Multi-ion doped battery-grade iron phosphate material and preparation method thereof

An ion doping, iron phosphate technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry and other directions, can solve the problem of not effectively improving doping uniformity, and achieve improved electrochemical performance and energy utilization efficiency, The effect of strong operability, excellent discharge capacity and cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

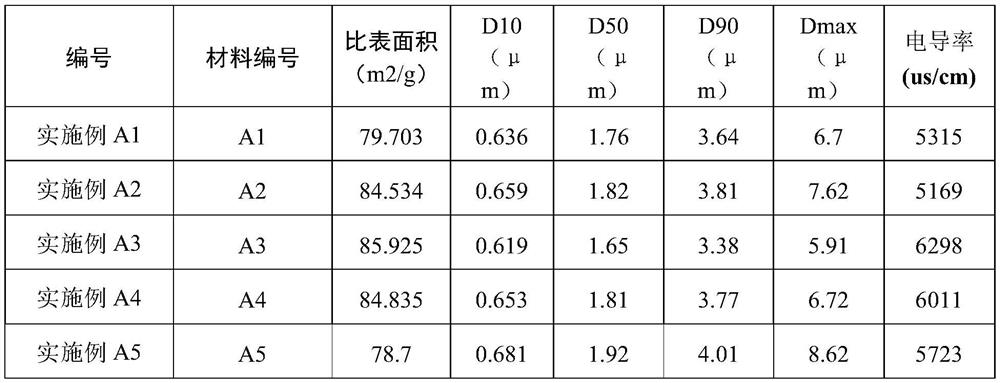

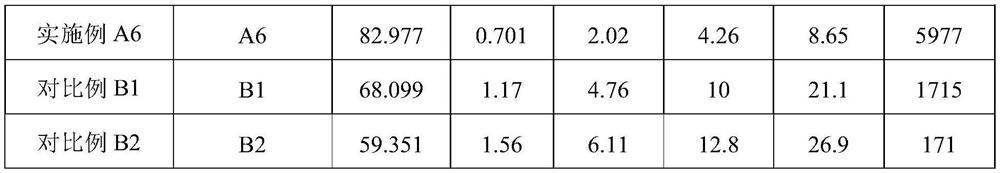

Examples

Embodiment A1

[0027] A method for preparing a multi-ion doped battery-grade iron phosphate material, comprising the following steps:

[0028] (1) add 1000L pure water in the reaction kettle, add 300kg technical grade ferrous sulfate heptahydrate, be warming up to the temperature of 60 ℃, add 2.5kg reduced iron powder, hydrolysis reaction 3 hours, adjust pH to 4.5~5.0, then Add 0.5kg ammonium fluoride and ammonium sulfide (mass ratio 1:1) mixture, add 0.05% mass fraction of cationic polyacrylamide 2L after 1 hour of reaction, stir well and filter; add 55% mass fraction of hydrogen to the filtrate dropwise 2 L of hydrofluoric acid, stirred and incubated at 60°C for 2 hours and filtered; 4 L of 85% phosphoric acid was added to the filtrate under stirring, and after stirring for 2 hours, let stand for 2 hours, and filtered to obtain a pure ferrous sulfate solution; It is 6kg metatitanic acid and 6kg ammonium metavanadate; add 180L hydrogen peroxide with a mass fraction of 27.5% in the above-men...

Embodiment A2

[0031] A method for preparing a multi-ion doped battery-grade iron phosphate material, comprising the following steps:

[0032](1) add 1000L pure water in the reaction kettle of , add 300kg technical grade ferrous sulfate heptahydrate, be warming up to temperature is 60 ℃, add 2.5kg reduced iron powder, hydrolysis reaction is 3 hours, pH is adjusted to 4.5~5.0, Then add 0.5kg of ammonium fluoride and ammonium sulfide (mass ratio 1:1) mixture, add 0.05% mass fraction of cationic polyacrylamide 2L after 1 hour of reaction, stir well and filter; add 55% mass fraction to the filtrate dropwise 2 L of hydrofluoric acid, stirred and incubated at 60°C for 2 hours and filtered; 4 L of 85% phosphoric acid was added to the filtrate under stirring, and after stirring for 2 hours, let stand for 2 hours, and filtered to obtain a pure ferrous sulfate solution; Add 9kg of metatitanic acid and 9kg of ammonium metavanadate; add 180L hydrogen peroxide with a mass fraction of 27.5% in the above-m...

Embodiment A3

[0035] A method for preparing a multi-ion doped battery-grade iron phosphate material, comprising the following steps:

[0036] (1) add 1000L pure water in the reaction kettle of , add 300kg technical grade ferrous sulfate heptahydrate, be warming up to temperature is 60 ℃, add 2.5kg reduced iron powder, hydrolysis reaction is 3 hours, pH is adjusted to 4.5~5.0, Then add 0.5kg of ammonium fluoride and ammonium sulfide (mass ratio 1:1) mixture, add 0.05% mass fraction of cationic polyacrylamide 2L after 1 hour of reaction, stir well and filter; add 55% mass fraction to the filtrate dropwise 2 L of hydrofluoric acid, stirred and incubated at 60°C for 2 hours and filtered; 4 L of 85% phosphoric acid was added to the filtrate under stirring, and after stirring for 2 hours, let stand for 2 hours, and filtered to obtain a pure ferrous sulfate solution; Add 9kg metatitanic acid and 12kg ammonium metavanadate; add 180L hydrogen peroxide with a mass fraction of 27.5% in the above-menti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com