Preparation method of stratified-structure mineral reinforced rubber composite material

A technology of layered structure and reinforced rubber, which is applied in the preparation of layered structure mineral reinforced rubber composite materials and the field of layered structure mineral reinforced rubber composite materials, can solve the problem of uneven dispersion of fillers, pollution, easy to cause pollution, etc. problem, to achieve the effect of good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

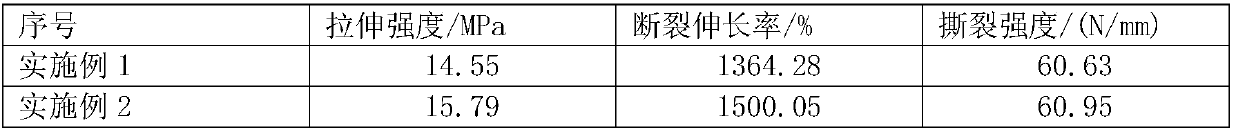

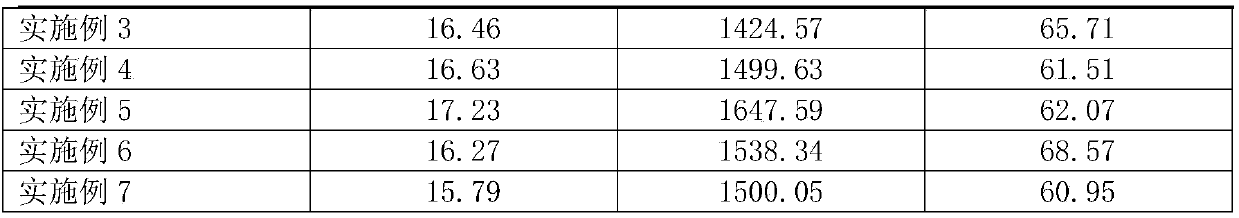

Examples

Embodiment 1

[0033] Nano organic modification of black talc mineral: Weigh 100g of black talc mineral with a particle size of D90 of 0.10mm and add it to a grinding tank, add 150g of grinding balls with a diameter of 10mm, 50ml of diluted hydrochloric acid with a mass percentage concentration of 10% and 50ml Water ethanol, set the ball mill speed to 1000rpm, after grinding for 2h, add 50g sodium dodecyl sulfonate, 1.0g silane coupling agent and aluminate coupling agent equal mass ratio to mix the organic modifier, Continue to grind under the same conditions for 2 hours, then suction filter, dry at 50°C, grind and pulverize, pass through a 250-mesh sieve, and mix to obtain organically modified nano-black talc mineral powder.

[0034] Preparation of organically modified nano-black talc mineral interspersed silicone rubber masterbatch: Add 100ml of liquid silicone rubber to the mixing tank, then add 20g of organically modified black talc mineral powder, 50ml of butyl acetate, and set the speed of...

Embodiment 2

[0040] Nano organic modification of mixed minerals with equal mass ratio of black talc and illite: Weigh 100g of mixed minerals with equal mass ratio of black talc and illite with a particle size D90 of 0.076mm and add it to the grinding jar, and add 200g of grinding balls with a diameter of 10mm , 75ml dilute sulfuric acid with a mass percentage concentration of 6% and 75ml absolute ethanol, set the ball mill speed to 500rpm, after grinding for 2.5h, add 60g sodium dodecylbenzene sulfonate and 10g titanate coupling agent into the ball mill Mix the organic modifier with the same mass ratio of cetyltrimethylammonium bromide, continue to grind under the same conditions for 2.5h, then suction filter, dry at 60℃, grind and crush, pass through a 250 mesh sieve, and mix to obtain Organically modified nano black talc and illite mixed mineral powder with equal mass ratio.

[0041] Preparation of organically modified nano black talc and illite mixed mineral interspersed nitrile rubber mas...

Embodiment 4

[0050] Nano-organic modification of kaolin minerals: Weigh 100g of kaolin minerals with a particle size D90 of 0.076mm and add them to a grinding tank, add 300g grinding balls with a diameter of 10mm, 50ml isopropanol and 50ml dilute sulfuric acid with a concentration of 3% by mass. Set the speed of the ball mill to 1200 rpm, and after grinding for 3 hours, add 100 g of dimethyl sulfoxide, 3 g of titanate coupling agent and silane coupling agent in an equal mass ratio, mix the organic modifier, and continue grinding under the same conditions After 3h, suction filtration, drying at 60°C, grinding and pulverizing, passing through a 250-mesh sieve, and mixing to obtain organically modified nano kaolin powder.

[0051] Preparation of organically modified nano-kaolin mineral interspersed chloroprene rubber masterbatch: Add 100ml of liquid chloroprene rubber to the mixing tank, then add 50g of organically modified kaolin, 75ml of butyl acetate, set the speed of the sand mill to 4000rpm,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com