Preparation method of high-performance CoSe/C-NS composite material, material and application

A composite material, C-NS technology, applied in the direction of active material electrodes, electrical components, electrochemical generators, etc., can solve the problem of inability to meet the energy density requirements of lithium-ion batteries, irregular material morphology and structure, and affect the negative electrode tap density and other issues, to achieve strong cycle stability, uniform distribution, and increase the effect of material yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

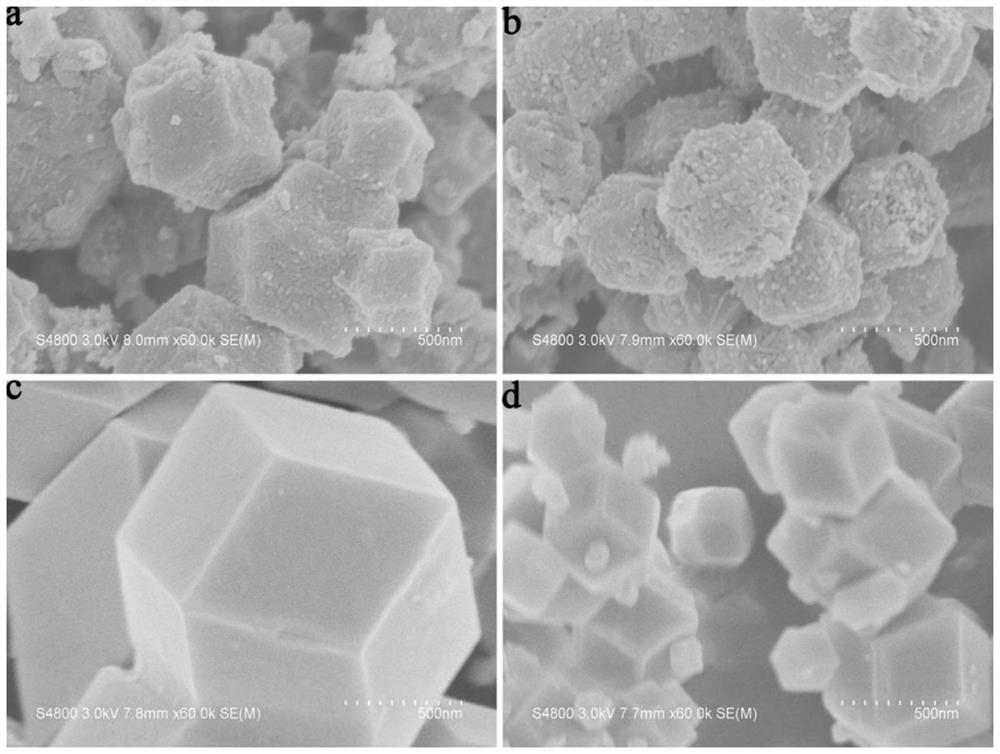

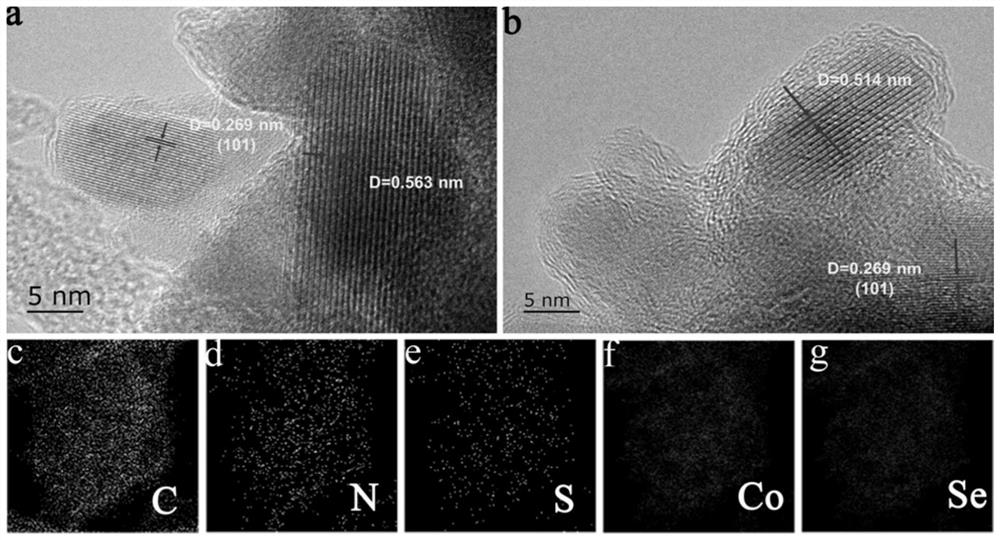

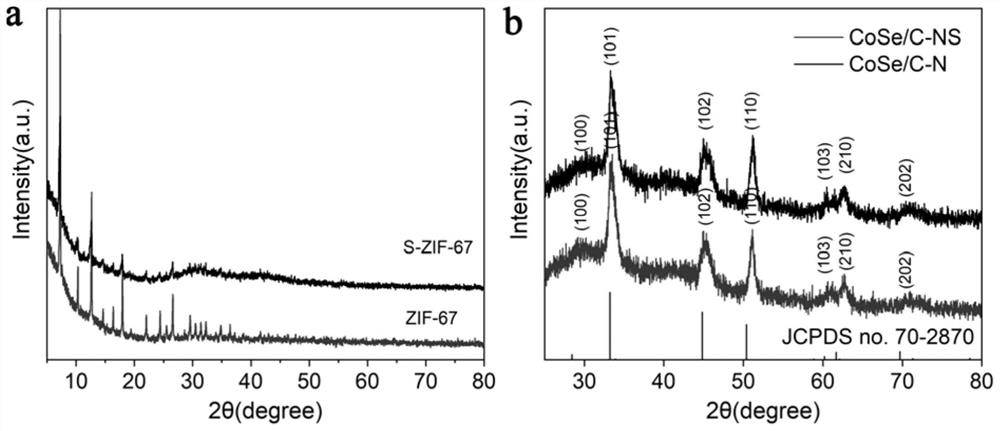

[0031] Example 1: The preparation method, material and application of a high-performance CoSe / C-NS composite material provided in this example, combined with the attached Figure 1-3 , including (1) the preparation process of S-doped ZIF-67 precursor (S-ZIF-67): fully dissolve 5mmol of Co(NO3)2·6H2O in 50ml of methanol to form A solution (magenta); Fully co-dissolve 20mmol of 2-methylimidazole and 15mmol of thiourea in 50ml of methanol to form solution B (colorless and transparent); under the strong stirring of a magnetic stirrer, use a rubber dropper to drop the solution A very slowly Add to solution B to form mixed solution C (dark purple); keep mixed solution C at room temperature under strong stirring of a magnetic stirrer for 24 hours, and then use methanol to dissolve the precipitate in mixed solution C repeatedly This process usually needs to be continued for more than 3 times, and then the purple precipitate after centrifugal washing is dried in a vacuum drying oven at...

Embodiment 2

[0036] Example 2: The preparation method, material and application of a high-performance CoSe / C-NS composite material provided in this example are basically the same as those in Example 1, except that:

[0037] S1: In the process of preparing ZIF-67, thiourea was added as a S source to make a S-ZIF-67 precursor doped with S; during the preparation of the S-ZIF-67 precursor, the Co(NO3 ) 2.6H2O, 2-methylimidazole, thiourea, and the ratio of the amount of methanol used are 5mmol: 20mmol: 15mmol: 50ml; the standing time is more than 24 hours; the drying is at 70°C for 24 hours Hour.

[0038] S2: After fully mixing the S-ZIF-67 precursor and selenium powder, annealing treatment was carried out under the protection of nitrogen to obtain CoSe / C-NS composite material. The mass ratio of S-ZIF-67 precursor to selenium powder is 1:0.8; the mixing time of S-ZIF-67 precursor and selenium powder is more than 10 minutes, and the annealing treatment conditions are: annealing treatment at a ...

Embodiment 3

[0039] Example 3: The preparation method, material and application of a high-performance CoSe / C-NS composite material provided in this example are basically the same as those in Example 1, except that:

[0040] S1: In the process of preparing ZIF-67, thiourea was added as a S source to make a S-ZIF-67 precursor doped with S; during the preparation of the S-ZIF-67 precursor, the Co(NO3 ) 2.6H2O, 2-methylimidazole, thiourea, and the ratio of the amount of methanol used are 5mmol: 20mmol: 15mmol: 150ml; the standing time is more than 24 hours; the drying is at 70°C for 24 hours Hour.

[0041] S2: After fully mixing the S-ZIF-67 precursor and selenium powder, annealing treatment was carried out under the protection of nitrogen to obtain CoSe / C-NS composite material. The mass ratio of S-ZIF-67 precursor to selenium powder is 1:0.8; the mixing time of S-ZIF-67 precursor and selenium powder is more than 10 minutes, and the annealing treatment conditions are: annealing treatment at a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com