Preparation method of high-performance CoSe/C-NS composite material, material and application

A composite material, C-NS technology, applied in the direction of active material electrodes, electrical components, electrochemical generators, etc., can solve the problem of inability to meet the energy density requirements of lithium-ion batteries, irregular material morphology and structure, and affect the negative electrode tap density problems such as high energy density, uniform distribution, and increased material yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

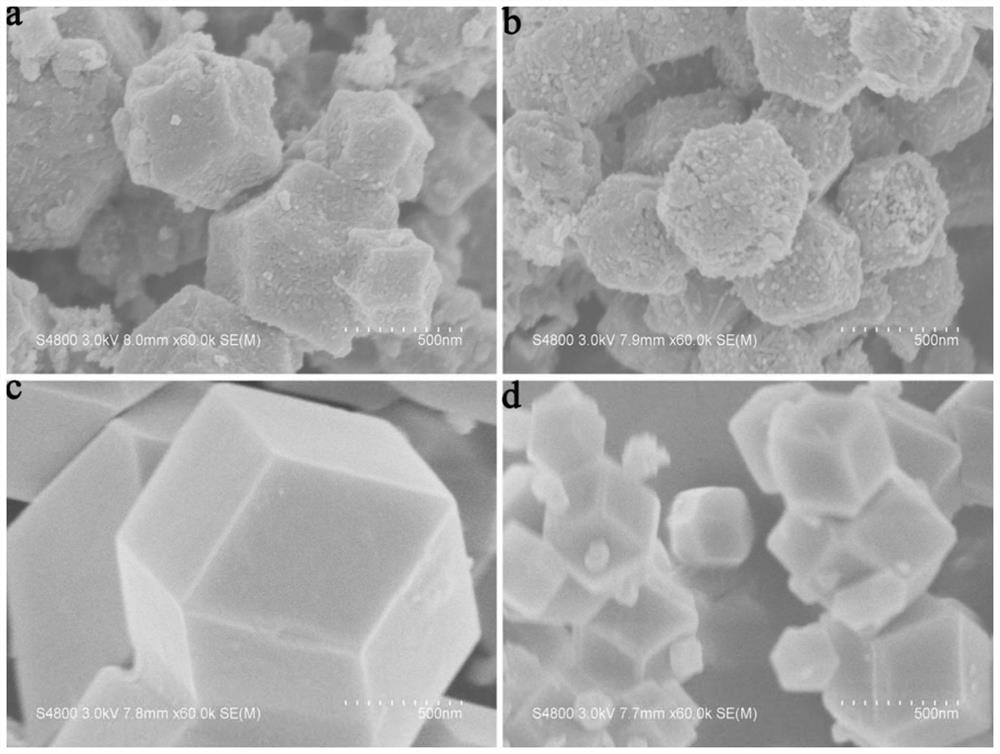

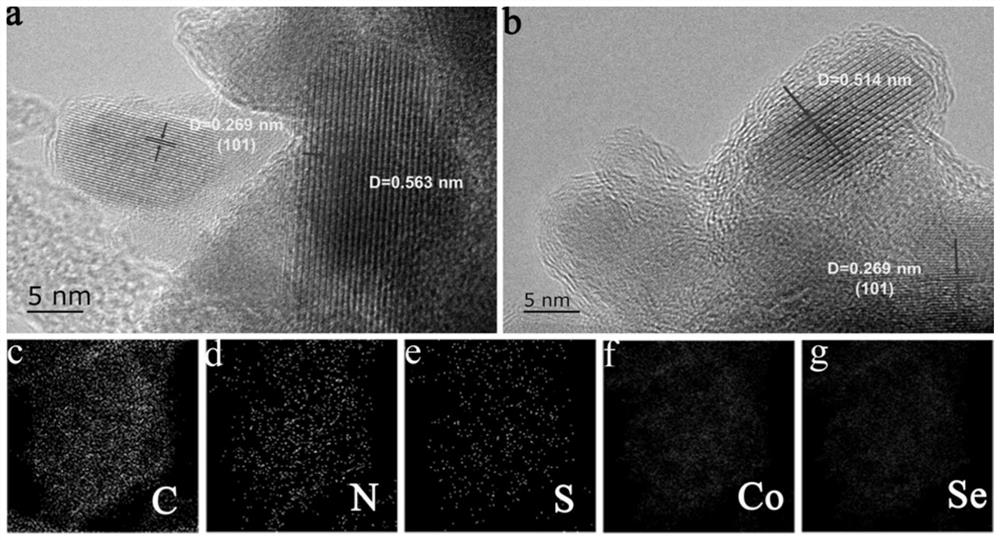

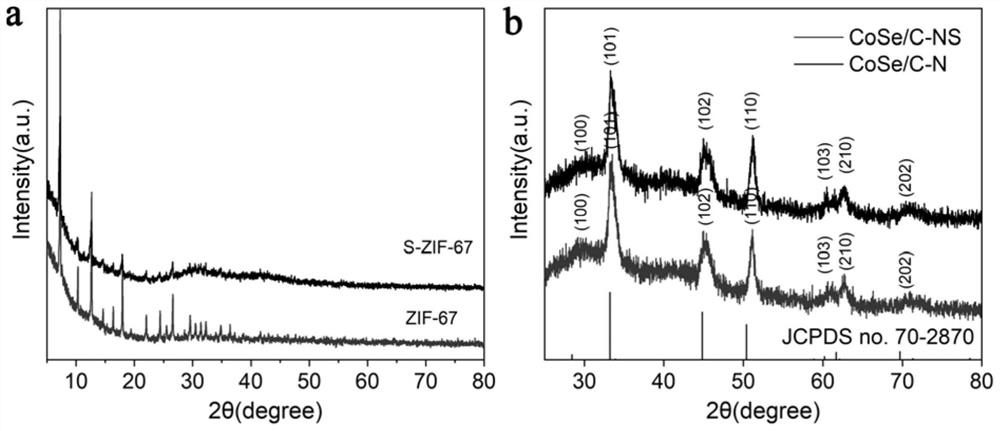

[0024] Example 1: The preparation method, material and application of a high-performance CoSe / C-NS composite material provided in this example, combined with the attached Figure 1-3 , including (1) the preparation process of S-doped ZIF-67 precursor (S-ZIF-67): fully dissolve 5mmol of Co(NO3)2·6H2O in 50ml of methanol to form A solution (magenta); Fully co-dissolve 20mmol of 2-methylimidazole and 15mmol of thiourea in 50ml of methanol to form solution B (colorless and transparent); under the strong stirring of a magnetic stirrer, use a rubber dropper to drop the solution A very slowly Add to solution B to form mixed solution C (dark purple); keep mixed solution C at room temperature under strong stirring of a magnetic stirrer for 24 hours, and then use methanol to dissolve the precipitate in mixed solution C repeatedly This process usually needs to be continued for more than 3 times, and then the purple precipitate after centrifugal washing is dried in a vacuum drying oven at...

Embodiment 2

[0029] Example 2: The preparation method, material and application of a high-performance CoSe / C-NS composite material provided in this example are basically the same as those in Example 1, except that:

[0030] S1: In the process of preparing ZIF-67, thiourea was added as a S source to make a S-ZIF-67 precursor doped with S; during the preparation of the S-ZIF-67 precursor, the Co(NO3 ) 2.6H2O, 2-methylimidazole, thiourea, and the ratio of the amount of methanol used are 5mmol: 20mmol: 15mmol: 50ml; the standing time is more than 24 hours; the drying is at 70°C for 24 hours Hour.

[0031] S2: After fully mixing the S-ZIF-67 precursor and selenium powder, annealing treatment was carried out under the protection of nitrogen to obtain CoSe / C-NS composite material. The mass ratio of S-ZIF-67 precursor to selenium powder is 1:0.8; the mixing time of S-ZIF-67 precursor and selenium powder is more than 10 minutes, and the annealing treatment conditions are: annealing treatment at a ...

Embodiment 3

[0032] Example 3: The preparation method, material and application of a high-performance CoSe / C-NS composite material provided in this example are basically the same as those in Example 1, except that:

[0033] S1: In the process of preparing ZIF-67, thiourea was added as a S source to make a S-ZIF-67 precursor doped with S; during the preparation of the S-ZIF-67 precursor, the Co(NO3 ) 2.6H2O, 2-methylimidazole, thiourea, and the ratio of the amount of methanol used are 5mmol: 20mmol: 15mmol: 150ml; the standing time is more than 24 hours; the drying is at 70°C for 24 hours Hour.

[0034] S2: After fully mixing the S-ZIF-67 precursor and selenium powder, annealing treatment was carried out under the protection of nitrogen to obtain CoSe / C-NS composite material. The mass ratio of S-ZIF-67 precursor to selenium powder is 1:0.8; the mixing time of S-ZIF-67 precursor and selenium powder is more than 10 minutes, and the annealing treatment conditions are: annealing treatment at a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com