a cuo-tio 2 Composite microtube, preparation method and application thereof

A technology of micron tubes and copper salts, applied in chemical instruments and methods, titanium compounds, chemical/physical processes, etc., can solve the problem of less research on hollow composite micro-nano materials, achieve stable structure of hollow composite micro-nano materials, and omit experiments steps, cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

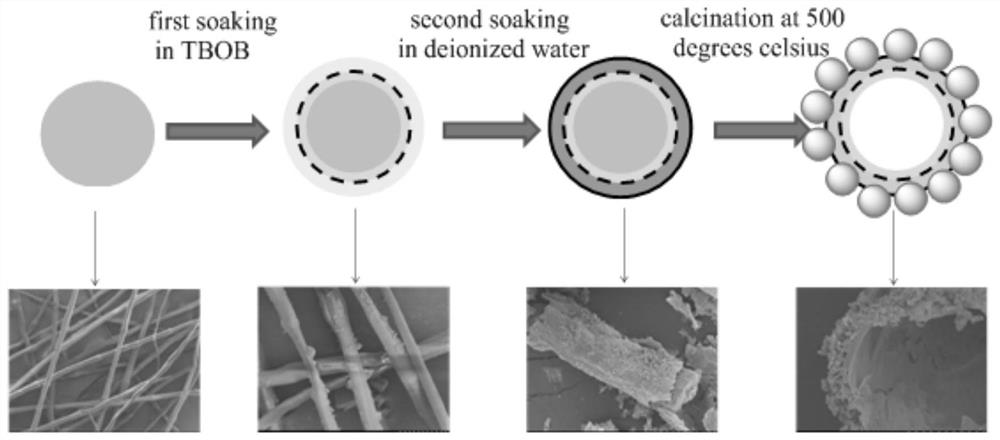

[0039] (2) In terms of preparation method, while utilizing the natural characteristics of biological templates, this method realizes the direct ingenious compounding of two materials on the biological template platform through two consecutive sol-gel impregnation methods, which not only overcomes the sol-gel The method is complicated to operate and needs to accurately control the shortcomings of various experimental parameters, and it also omits the tedious experimental steps in the composite material preparation process.

[0040] (3) In terms of material performance, since the sol-gel impregnation reaction occurs continuously on the surface of the biological template, it promotes the efficient combination of the two materials and the uniform distribution of the grains during the composite process, which contributes to the stability and stability of the composite material. A substantial boost in performance. The hollow composite micro-nano material prepared by the method has a...

Embodiment 1

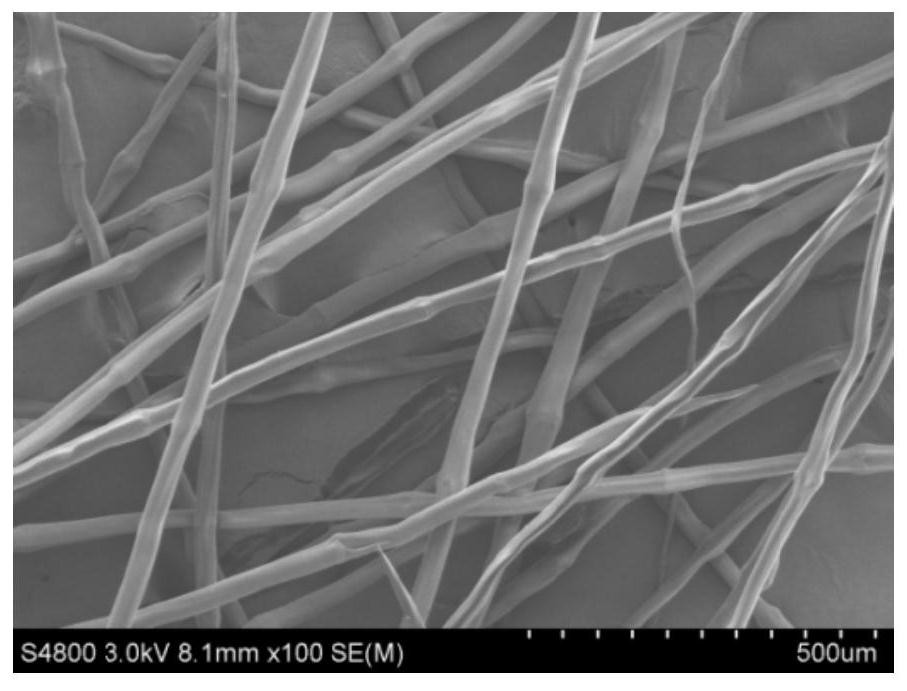

[0050] Use an electronic balance to weigh 1g of syringa fruit hair fiber and put it into 100mL of n-butyl titanate and soak for 2h; use tweezers to take out the intermediate product and transfer it to 100mL of copper sulfate solution with a concentration of 3mol / L and keep it for 3min for the second impregnation , the reacted fiber was dried at 60°C, and put into a muffle furnace for calcination at 500°C for 2h to remove the biological template, and CuO–TiO 2 micron tube.

[0051] Add 50 mg of prepared CuO–TiO to 50 mL of oxytetracycline solution with a concentration of 20 mg / L 2 As a photocatalyst, a 250W xenon lamp was selected as the light source, and the visible light catalytic degradation rate of oxytetracycline was 91% when the light distance was 10cm.

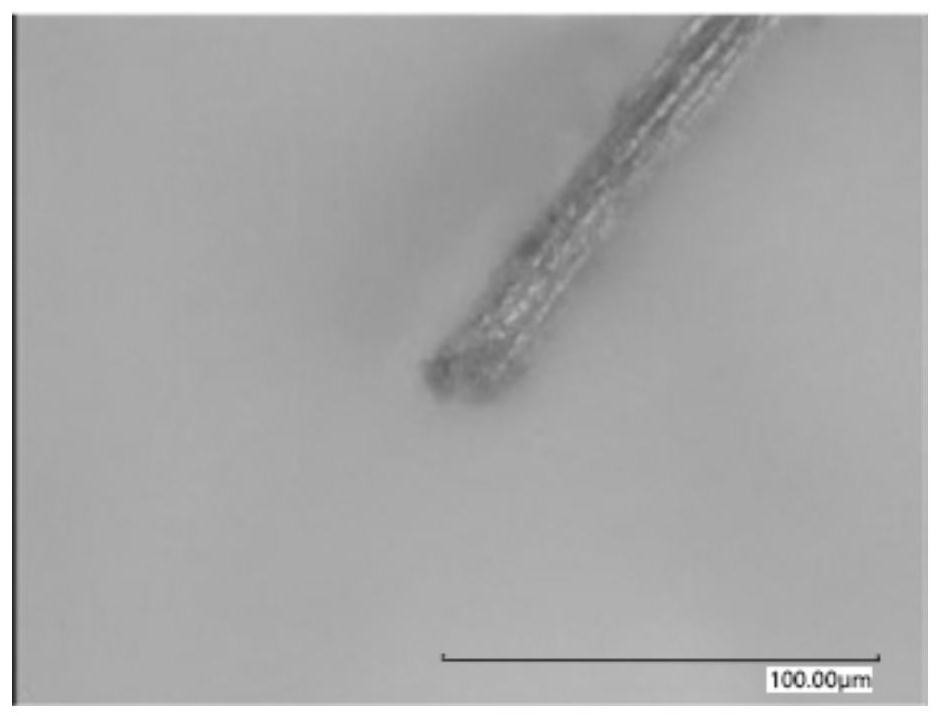

[0052] The electronic scanning photo of the sycamore fruit hair fiber used in embodiment 1 is shown in figure 2 , CuO–TiO 2 Ultra-depth-of-field micrographs of microtubes see image 3 , it can be seen that CuO-TiO ...

Embodiment 2

[0060] Wash the sycamore fiber with deionized water, and put the fiber into an oven at 60°C to dry. Use an electronic balance to weigh 1.5g of sycamore fruit hair fiber and put it into 100mL TiCl 4 Soak in water for 1.5h; take out the intermediate product and transfer it to 100mL of copper sulfate solution with a concentration of 4mol / L for 5min for the second impregnation; dry the reacted fiber at 70°C and put it in a muffle furnace for 500 Calcined at ℃ for 3h to remove the biological template to obtain CuO–TiO 2 micron tube.

[0061] Add 50 mg of prepared CuO–TiO to 50 mL of oxytetracycline solution with a concentration of 20 mg / L 2 As a photocatalyst, a 250W xenon lamp was selected as the light source, and the visible light catalytic degradation rate of oxytetracycline was 88% when the light distance was 10 cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com