Preparation method of a multi-responsive polymer hollow microgel

A responsive polymer technology, applied in the field of materials, can solve the problems of complex preparation process and high energy consumption, and achieve the effects of low viscosity, fast heat transfer, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

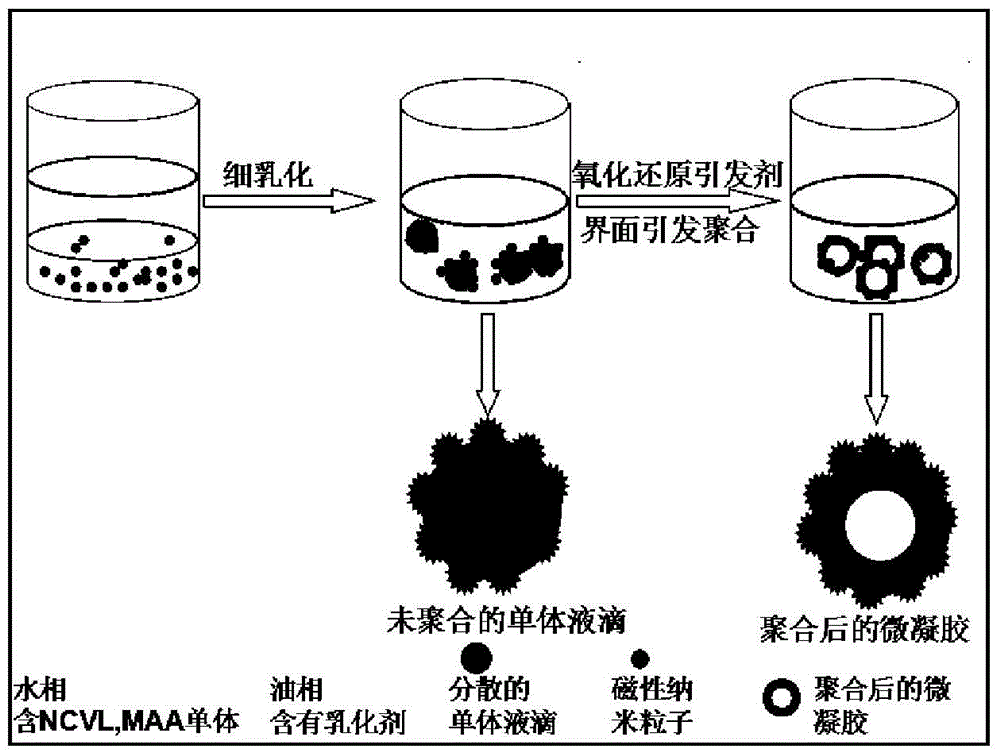

Method used

Image

Examples

Embodiment 1

[0044] Weigh 0.1g sodium chloride and 0.1g reducing initiator TEPA and dissolve in 8.0g deionized water, then add 0.2g crosslinking agent MBA and 1.5g monomer N-vinylcaprolactam (NVCL), and stir magnetically for 30min to make it fully mixed as the aqueous phase;

[0045] Weigh 45g of toluene and 2.4g of emulsifier SPAN-80, and magnetically stir for 15min to mix them evenly as the oil phase.

[0046] The oil phase was slowly added to the water phase and stirred magnetically for 15 minutes to form a pre-emulsion, and then homogeneously emulsified in an ice-water bath at a speed of 16,000 rpm for 5 minutes to obtain a stable inverse miniemulsion.

[0047] The inverse miniemulsion prepared above was added into a three-necked flask equipped with mechanical stirring, a thermometer and a reflux condensing device. After stirring nitrogen for 30 minutes, the water bath was heated to 50 ° C, and 0.2 g of oxidation initiator CHPO (dissolved in a small amount of toluene) was added to the...

Embodiment 2

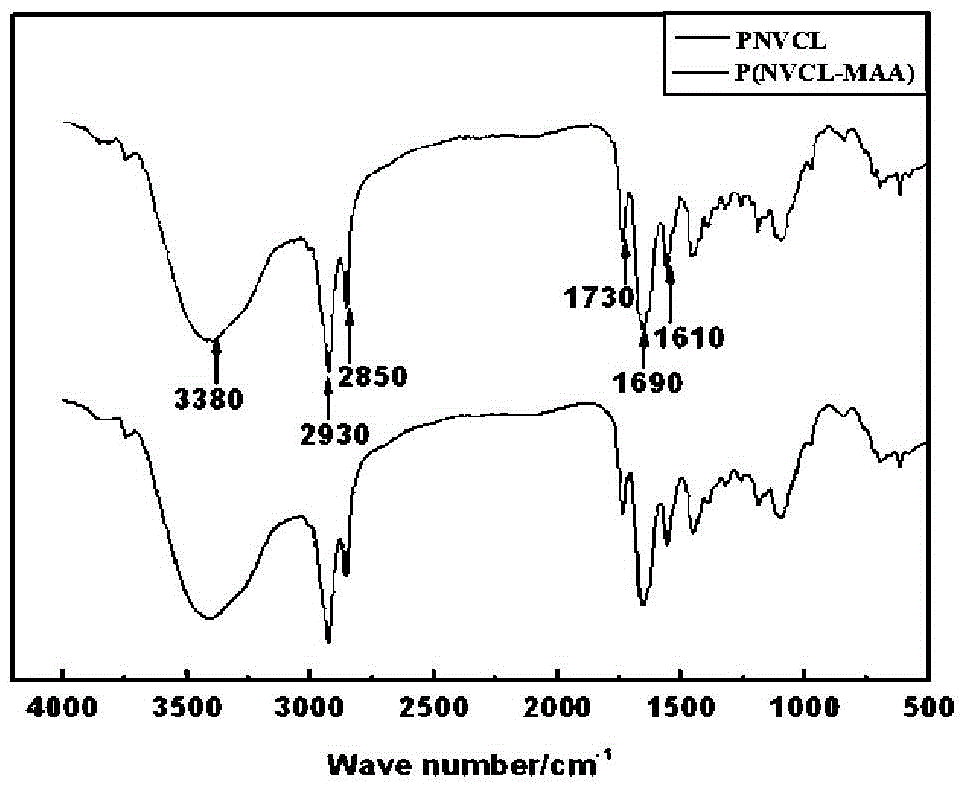

[0049] Weigh 1.5g of monomeric N-vinyl caprolactam (NVCL) and 0.5g of monomeric methacrylic acid (MAA) and mix them thoroughly. The above-mentioned mixed monomers, 0.1g of sodium chloride and 0.1g of reducing initiator TEPA are dissolved in 8.0 Add 0.2 g of cross-linking agent MBA to 1 g of deionized water, stir magnetically for 30 minutes to fully mix it as the water phase; weigh 45 g of toluene and 2.4 g of emulsifier SPAN-80, stir magnetically for 15 minutes to mix evenly as the oil phase.

[0050] The oil phase was slowly added to the water phase and stirred magnetically for 15 minutes to form a pre-emulsion, and then homogeneously emulsified in an ice-water bath at a speed of 16,000 rpm for 5 minutes to obtain a stable inverse miniemulsion.

[0051] The inverse miniemulsion prepared above was added into a three-necked flask equipped with mechanical stirring, a thermometer and a reflux condensing device. After stirring nitrogen for 30 minutes, the water bath was heated to ...

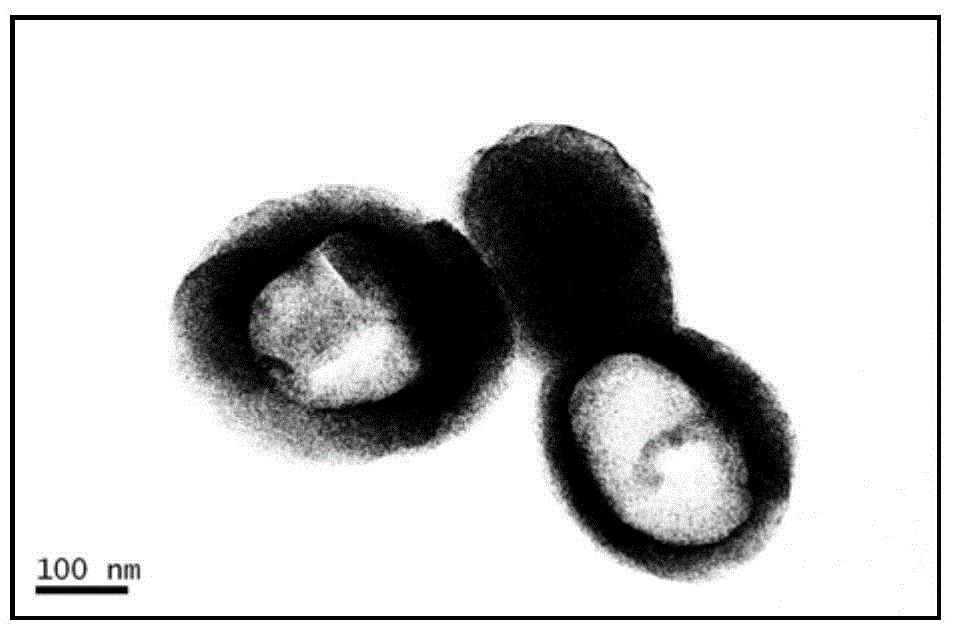

Embodiment 3

[0054] Take by weighing 1.5g monomer N-vinyl caprolactam (NVCL) and 0.5g monomer methacrylic acid (MAA) and fully mix, mix above-mentioned mixed monomer, 0.1g sodium chloride, 0.1g reducing initiator TEPA, and 0.3 g Hydrophilic Fe 3 o 4 Dissolve magnetic nanoparticles in 8.0g deionized water, then add 0.2g cross-linking agent MBA, stir magnetically for 30min to make it fully mixed as the water phase;

[0055] Weigh 45g of toluene and 2.4g of emulsifier SPAN-80, and magnetically stir for 15min to mix them evenly as the oil phase.

[0056] The oil phase was slowly added to the water phase and stirred magnetically for 15 minutes to form a pre-emulsion, and then homogeneously emulsified in an ice-water bath at a speed of 16,000 rpm for 5 minutes to obtain a stable inverse miniemulsion.

[0057] The miniemulsion prepared above was added into a three-necked flask equipped with mechanical stirring, a thermometer and a reflux condensation device. After stirring nitrogen for 30 minu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com