High-yield preparation method of functional monodisperse polyurea microspheres

A monodisperse and functional technology, applied in the field of preparing polymer monodisperse microspheres, can solve the problems of long polymerization time, cumbersome steps, low monomer content and microsphere yield, etc., and achieve short polymerization time and simple steps. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0006] Technical scheme of the present invention is as follows:

[0007] A method for preparing functional monodisperse polyurea microspheres with high yield, comprising the following steps:

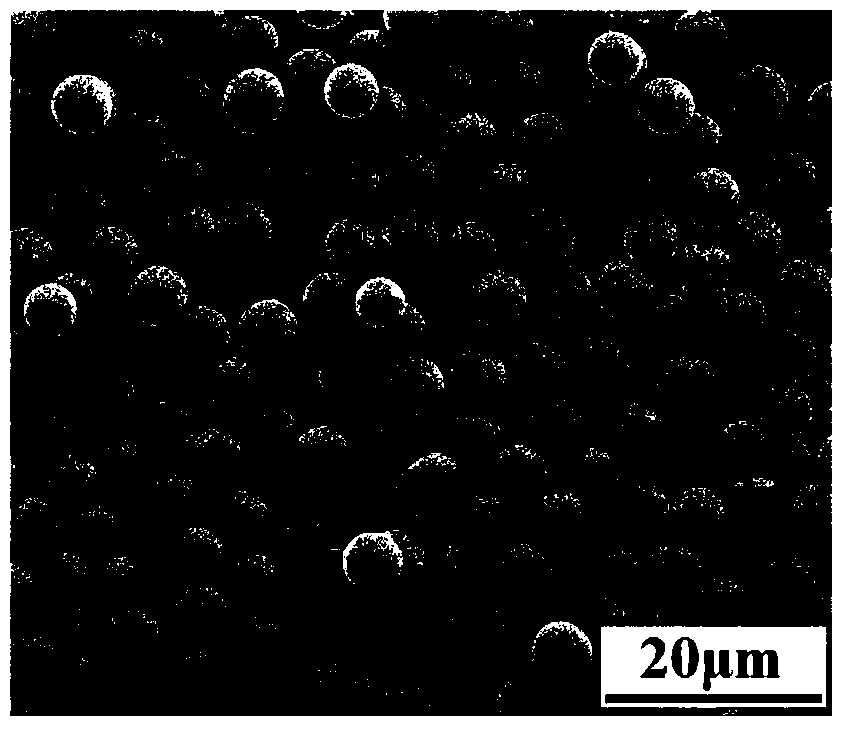

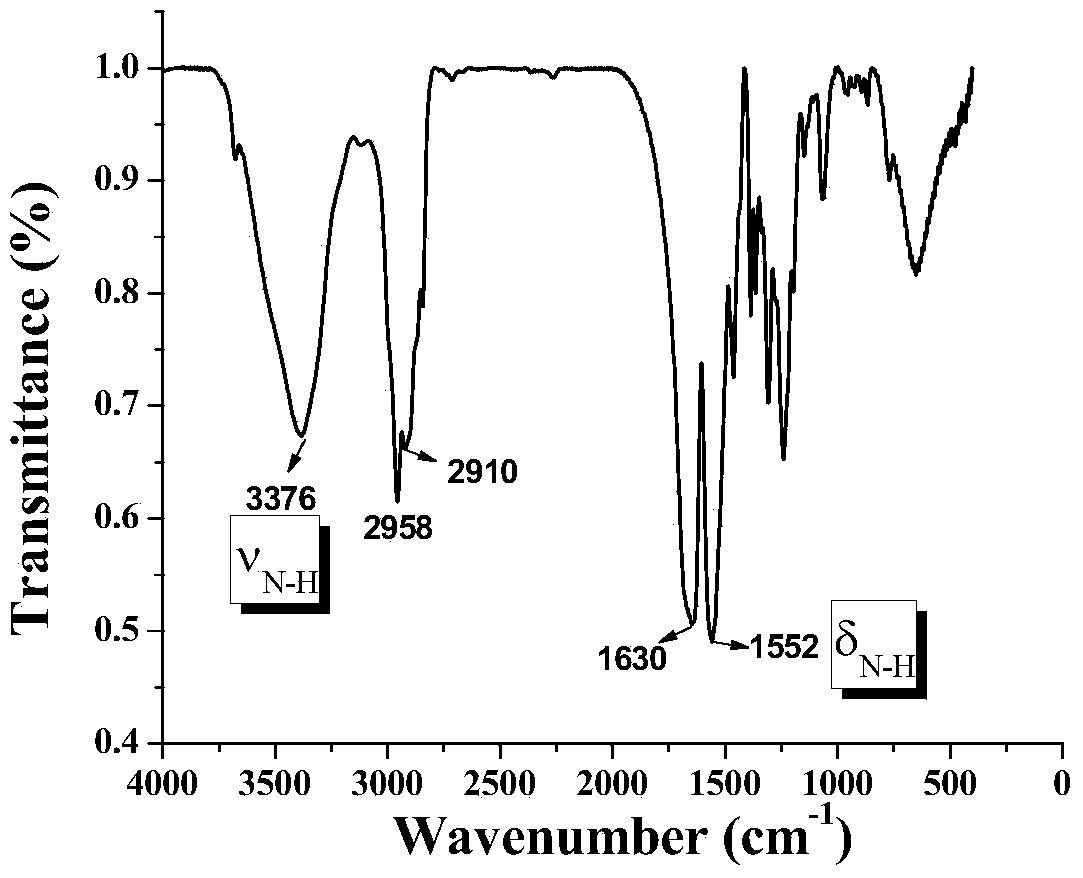

[0008] Add water / acetonitrile mass ratio to the reaction flask as a mixed solvent of 10 / 90 to 30 / 70 and account for 5 to 30% of the total mass of the system isophorone diisocyanate (IPDI) monomer, seal the reaction flask and shake it The monomer and solvent are mixed evenly, then the reaction bottle is placed in a constant temperature water bath with a temperature of 20-70°C, and the polymerization reaction is carried out under static or shaking conditions for 1-3.5 hours; then the polymerization system is centrifuged, washed and dried. That is, monodisperse polyurea microspheres are obtained.

[0009] Preferably according to the present invention, the mass ratio of water / acetonitrile in the mixed solvent is 15 / 85˜30 / 70. The most preferred mass ratio of water / acetonitrile is 20 / 80.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com