Spherical activated carbon with high compressive strength and its preparation method and use

A technology of spherical activated carbon and compressive strength, applied in the field of adsorption materials, can solve the problems of high energy consumption, difficulty in achieving the sphericity of spherical activated carbon, cracking rate adsorption performance, and inability to achieve optimal synergy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0093] The preparation of preparation example 1 spherical polymer matrix

[0094]Add 16 liters of water into a 50-liter polymerization kettle, heat to 50°C, add 8g of magnesium carbonate, 19g of gelatin and 0.13g of methylene blue under stirring, and add 2.7kg of methyl styrene, 0.9kg of The oil phase that dipentene and 18g benzoyl peroxide are mixed, add 1.0kg paraffin again, seal polymerization kettle, pass into clean compressed air in the polymerization kettle, keep the gas phase pressure in the kettle to be 0.02MPa. Then, stir quickly to adjust the liquid beads in the kettle to an appropriate particle size, raise the temperature to 80°C, keep warm for 10 hours, then raise the temperature to 110°C, keep warm for 18 hours, filter, wash, dry and sieve to obtain a white spherical polymer 1.95kg.

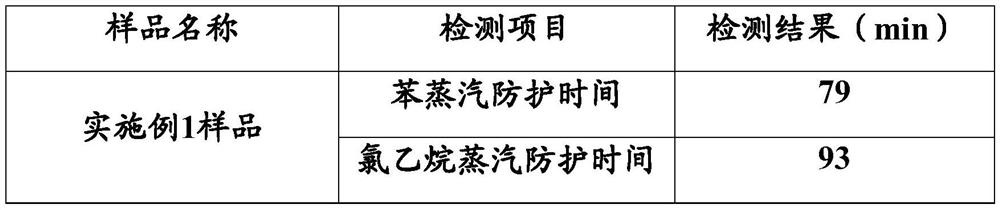

Embodiment 1

[0096] 1.1 Sulfonation

[0097] The spherical polymer (200g, median diameter is 0.5-3.0mm) that the mass ratio is 1:1 preparation example 1 obtains is mixed with concentrated sulfuric acid, then the mixture is added into the acid-resistant rotary tube furnace, under nitrogen atmosphere, with 5°C / min heating rate for the following heat treatment:

[0098] Heat to 200°C and stay for 60 minutes;

[0099] Carry out the following heat treatment at a heating rate of 4°C / min:

[0100] Heat to 300°C and stay for 120 minutes;

[0101] Heating to 310°C and staying for 120 minutes gave 224g of sulfonated product.

[0102] 1.2 carbonization

[0103] Under a mixed atmosphere of nitrogen and oxygen, the product obtained in step 1.1 sulfonated was subjected to the following heat treatment at a heating rate of 6°C / min:

[0104] Heat to 400°C and stay for 120 minutes;

[0105] Heat to 550°C and stay for 120 minutes;

[0106] It was then heated to 800°C and held for 100 minutes. The tem...

Embodiment 2

[0110] 2.1 Sulfonation

[0111] The spherical polymer (200g, median particle diameter is 0.5~3.0mm) that the mass ratio is 1:5 that preparation example 1 obtains is mixed with oleum, then the mixture is added into the acid-resistant rotary tube furnace, under nitrogen atmosphere, Carry out the following heat treatment at a heating rate of 4°C / min:

[0112] Heat to 210°C and stay for 120 minutes;

[0113] Carry out the following heat treatment at a heating rate of 5°C / min:

[0114] Heat to 280°C and stay for 120 minutes;

[0115] Heating to 300°C and staying for 240 minutes gave 218g of sulfonated product.

[0116] 2.2 Carbonization

[0117] Under a mixed atmosphere of nitrogen and oxygen, the product obtained in step 2.1 sulfonated was subjected to the following heat treatment at a heating rate of 5°C / min:

[0118] Heat to 400°C and stay for 120 minutes;

[0119] Heat to 550°C and stay for 120 minutes;

[0120] Then heat to 850°C and hold for 120 minutes. The temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com