Artificial graphite composite negative electrode material for lithium ion battery as well as preparation method and application of artificial graphite composite negative electrode material

A lithium-ion battery, artificial graphite technology, applied in battery electrodes, graphite, negative electrodes and other directions, can solve the problems of not significantly improving the overall performance of artificial graphite negative electrode materials, artificial graphite separation, low rate, etc., to achieve high capacity, phase Good capacitance and good rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

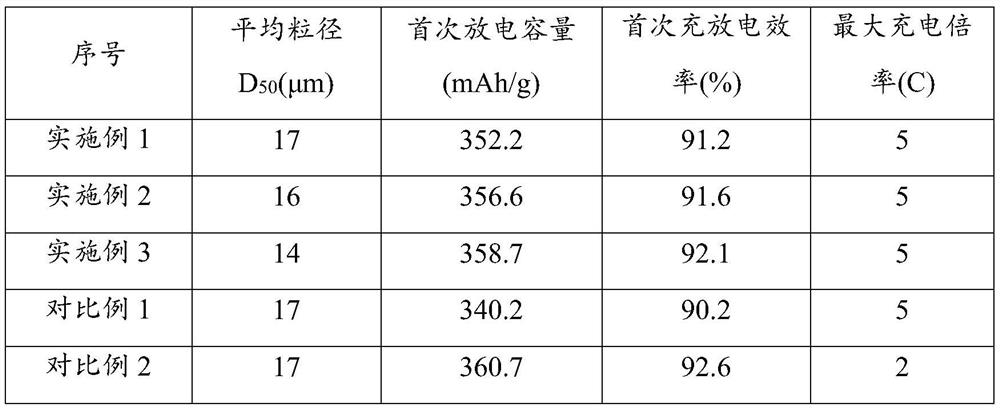

Examples

Embodiment 1

[0050] (a) coke the oil-based needle coke (D 50 is 10mm) calcined at a high temperature of 850 ° C for 6 hours, cooled to obtain shallow calcined coke; then crushed in an impact pulverizer, shaped and sieved to obtain an average particle size D 50 5μm coke powder.

[0051] (b) the coke powder obtained in step (a) and pitch (softening point of 150° C., residual carbon value of 56%) are uniformly mixed at a weight ratio of 100:25 and then put into the granulation reaction kettle, and put into the granulation reaction kettle. 2 Heating to 550°C under protection, the stirring speed in the kettle is 30r / min, and the heating and heating program is: use a heating rate of 1.5°C / min to raise the temperature to 300°C, and keep the temperature constant for 30 minutes; The temperature was increased to 550°C at a heating rate of 3.0°C / min, and the temperature was maintained for 6 hours. Then, it was cooled to room temperature and sieved to obtain secondary particles with an average parti...

Embodiment 2

[0054] (a) coke the oil-based needle coke (D 50 15mm) calcined at a high temperature of 950°C for 6 hours, cooled to obtain shallow calcined coke; then crushed in an impact pulverizer, shaped and sieved to obtain coke powder with an average particle size D50 of 5μm.

[0055] (b) the coke powder obtained in step (a) and pitch (softening point of 180° C., residual carbon value of 60%) are uniformly mixed in a weight ratio of 100:20 and then put into the granulation reaction kettle, and placed in a N 2 Heating to 600°C under protection, the stirring speed in the kettle is 35r / min, and the heating and heating program is: use a heating rate of 1.5°C / min to raise the temperature to 300°C, and keep the temperature constant for 30 minutes; 0.8°C / min. The temperature was raised to 600°C at a heating rate of 3.0°C / min, and the temperature was maintained for 4 hours. Then, it was cooled to room temperature and sieved to obtain secondary particles with an average particle diameter D50 of...

Embodiment 3

[0058] (a) coke the oil-based needle coke (D 50 is 20mm) calcined at a high temperature of 1050 ° C for 6 hours, cooled to obtain shallow calcined coke; then crushed in an impact pulverizer, shaped and sieved to obtain an average particle size D 50 5μm coke powder.

[0059] (b) the coke powder obtained in step (a) and pitch (softening point of 220° C., carbon residue value of 62%) are uniformly mixed at a weight ratio of 100:15 and then put into the granulation reaction kettle, and then put into the granulation reactor. 2 Heating to 650°C under protection, the stirring speed in the kettle is 40r / min, and the heating and heating program is: use a heating rate of 1.5°C / min to raise the temperature to 300°C, and keep the temperature constant for 30 minutes; The temperature was raised to 650°C at a heating rate of 2.0°C / min, and the temperature was maintained for 3 hours. Then, it was cooled to room temperature and sieved to obtain secondary particles with an average particle di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com