Modified desulfurization ash for cement and concrete and preparation method thereof

A desulfurization ash and concrete technology, applied in the field of concrete materials, can solve the problems of low sulfite, high sulfite content, unspecified conversion rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

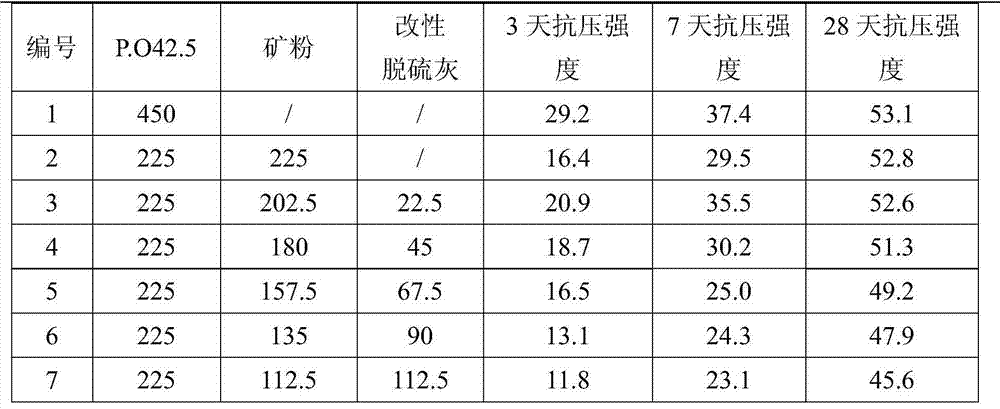

[0015] The following examples further explain the technical solutions of the present invention, but are not intended to limit the protection scope of the present invention.

[0016] The main mineral composition of desulfurization ash is CaSO 3 .0.5H 2 O and CaCO 3 , and a small amount of Ca(OH) 2 , and fly ash containing glass phase and mullite, etc. During flue gas desulfurization, because more lime is added and the ratio of calcium and sulfur is high, CaCO 3 more.

[0017] Preparation of oxidizing agent:

[0018] The components by mass ratio are: 70-80wt% of manganese dioxide, 5-10wt% of acetic acid and 10-25wt% of desulfurization residue.

[0019] Preparation of modified desulfurized ash used in cement and concrete:

[0020] Add the above oxidant to the desulfurization ash, so that CaSO 4 .2H 2 The conversion of O was 95-98%. CaSO 4 .2H 2 The conversion rate of O is the oxidation of CaSO in the original desulfurization ash 4 .2H 2 O CaSO 3 .0.5H 2 The propor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com