Top burning type hot blast stove with thermal insulation layer in precombustion chamber

A technology of pre-combustion chamber and thermal insulation layer is applied in the field of blast furnace hot blast stove, which can solve the problem of insufficient service life of hot blast stove, and achieve the effects of improving mixing effect and diversion effect, improving service life, and reducing thermal expansion and thermal stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

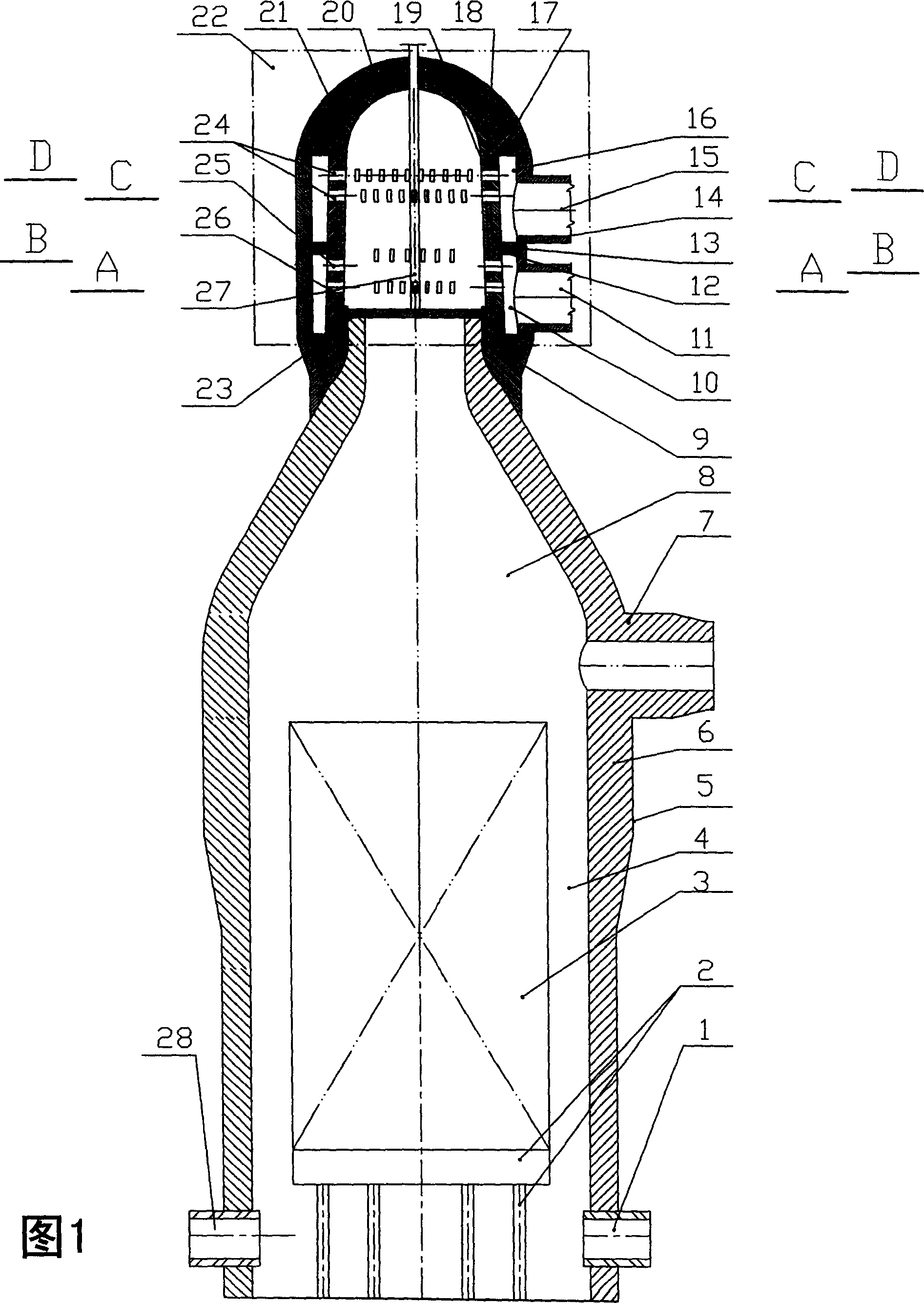

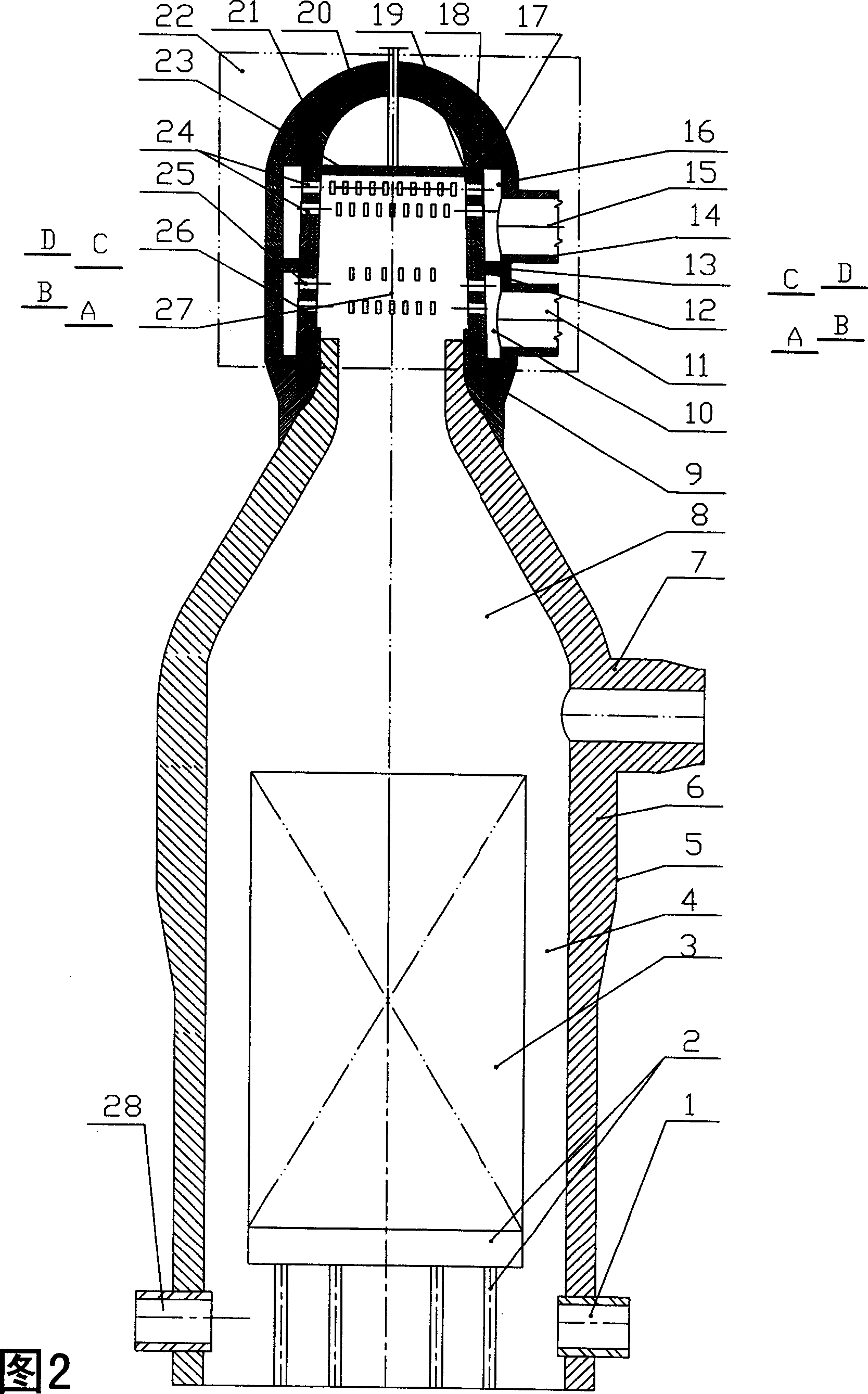

[0037] As shown in Figure 1 and Figure 2, they are the basic structural diagrams of the single-seat hot blast stove with the isolation cover located between the pre-chamber and the dome and in different positions above the pre-chamber in the embodiment of the present invention. Wherein, the top-combustion hot blast stove with a thermal insulation layer in the pre-combustion chamber consists of a cold air inlet 1, a furnace grate and a pillar 2, a flue gas outlet 28, a checker brick 3 as a heat storage body, a heat storage chamber 4, and a furnace shell. 5. Furnace lining 6, hot air outlet 7, dome (combustion chamber) 8, pre-combustion chamber support arm 9, pre-combustion chamber 22 (the part framed by dotted line in the figure).

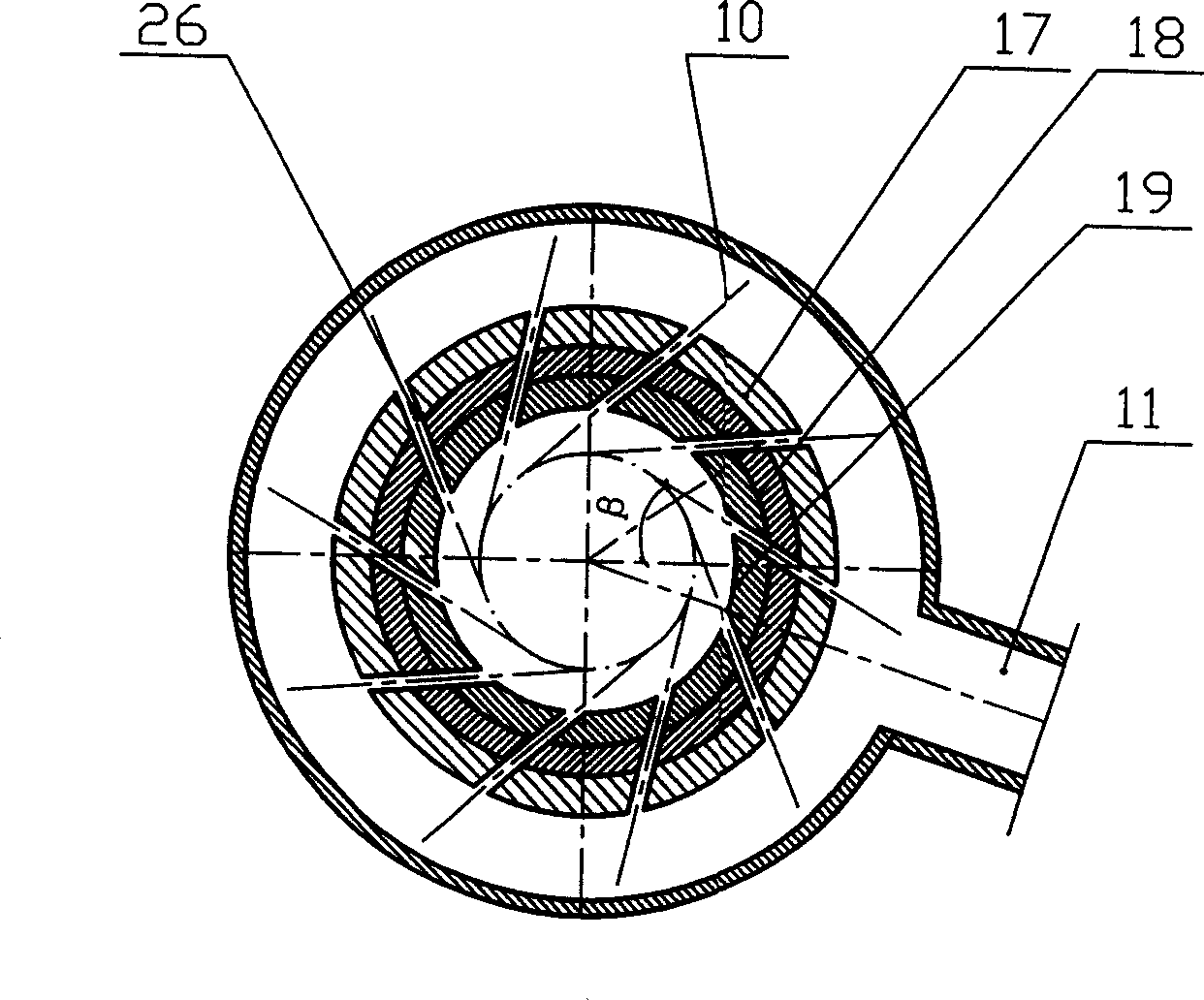

[0038] Described pre-chamber 22 is positioned on vault (combustion chamber) 8 and coaxial in vertical direction, and pre-chamber 22 is insulated by air ring cavity 10, air inlet 11, air ring cavity upper wall 12, ring cavity Layer 13, gas ring cavit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com