Solar Energy Collection Apparatus and Method

a solar energy and collection apparatus technology, applied in lighting and heating apparatus, instruments, machines/engines, etc., can solve the problems of poor process temperature control, less than optimal solar fireball focus, and catalyst sintering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

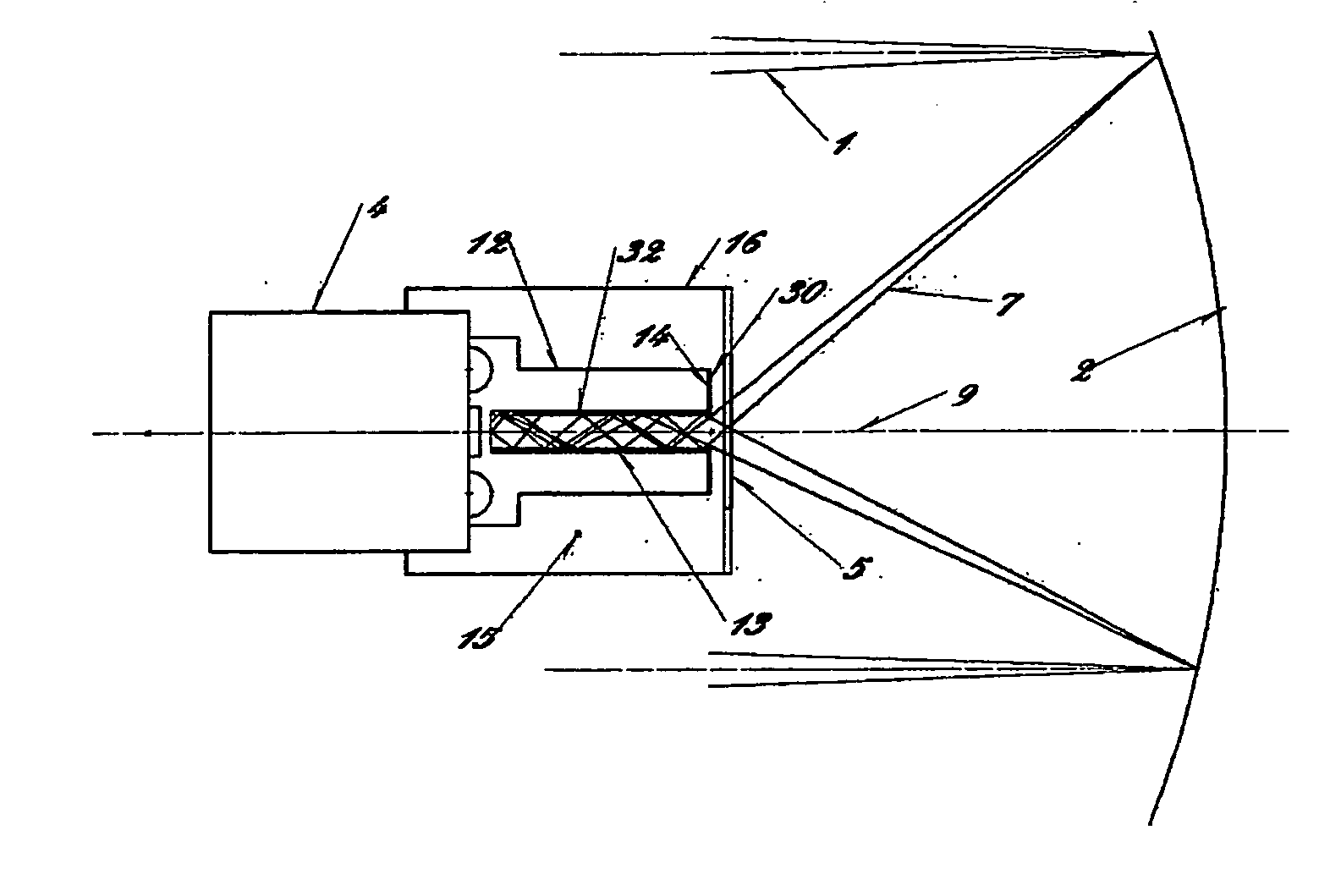

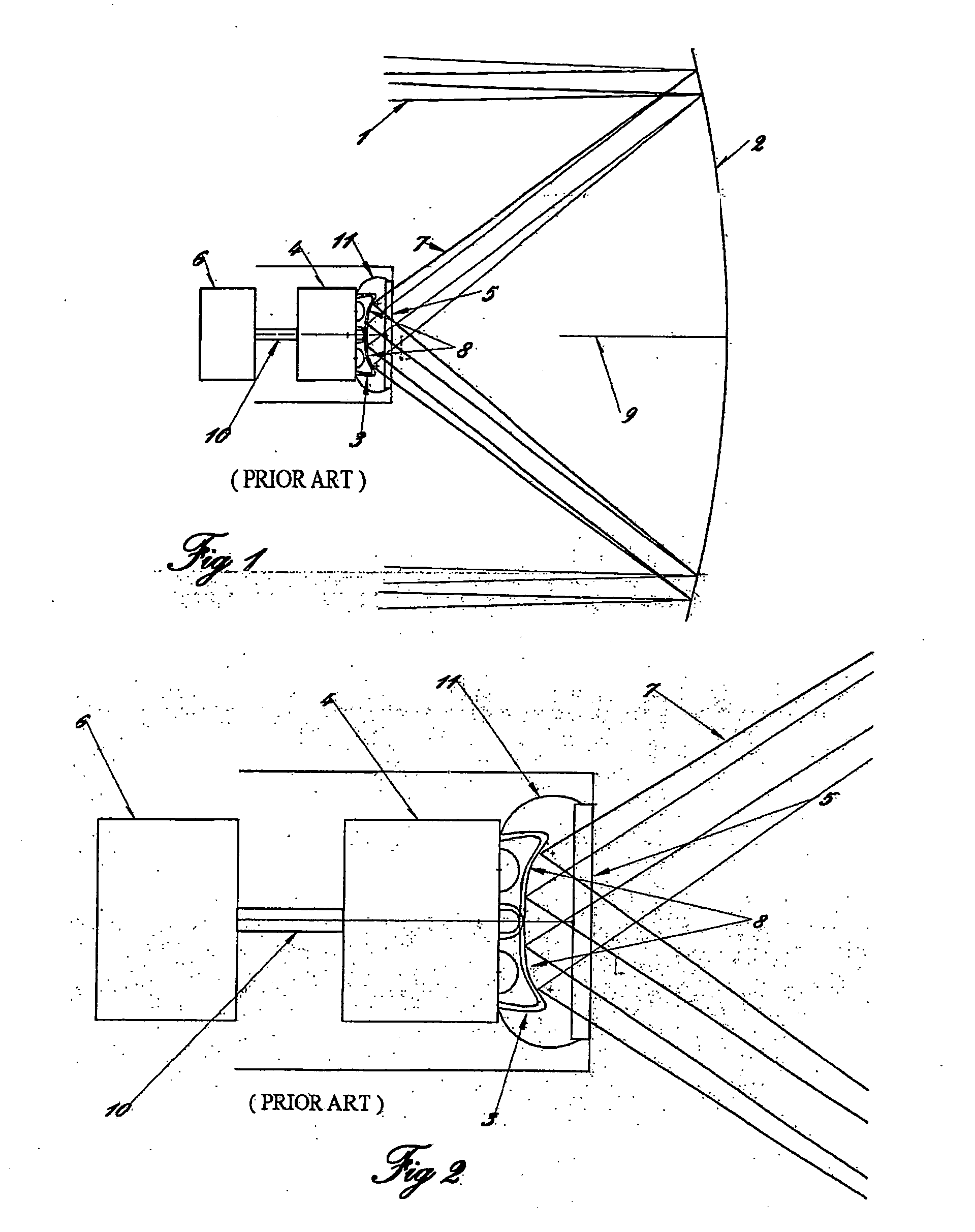

[0024]FIGS. 1 and 2 schematically illustrate a prior art system of solar heat collection driving a heat engine and electric generator combination. Solar heat collection systems are used to provide heat for a wide variety of purposes in which the collected heat is transferred to a heat sink, such as the illustrated heat engine, that essentially consumes the heat. The operating temperature will vary depending on the purpose, and the system will be designed such that all the collected heat will be drawn away by the heat sink once the operating temperature is at the desired temperature which can vary from about 100° C. to 1400° C. or more.

[0025]In this example solar radiation 1 is reflected by the solar concentrator 2 in solar rays 7 of a solar beam and focused on a target 8 positioned in a cavity 11 at the focus of a parabolic concentrator 2. The target 8 consists of a plurality of metal tubes 3 arranged symmetrically about the principal axis 9 of the parabolic solar concentrator 2 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com