Multifunctional spectrum selective encapsulation material

A packaging material and selective technology, applied in photovoltaic power generation, electrical components, circuits, etc., can solve the problems that the solar PV/T system cannot work at night and the radiation cooling system cannot work during the day

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

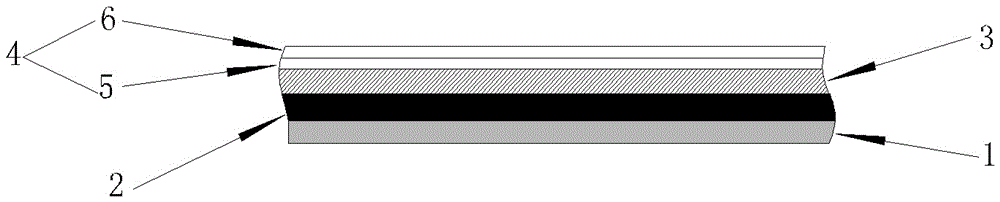

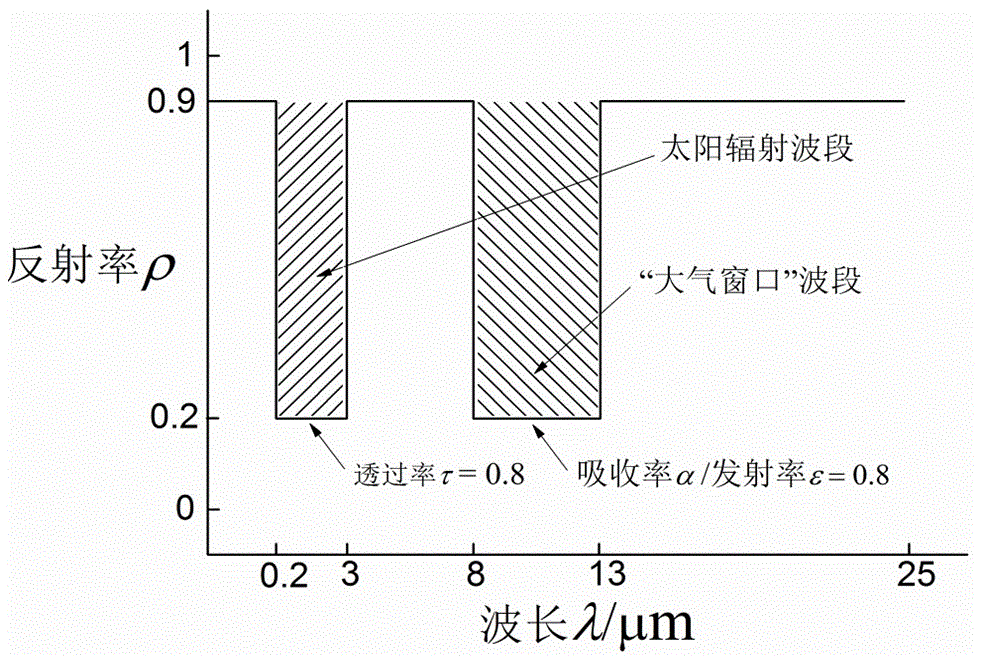

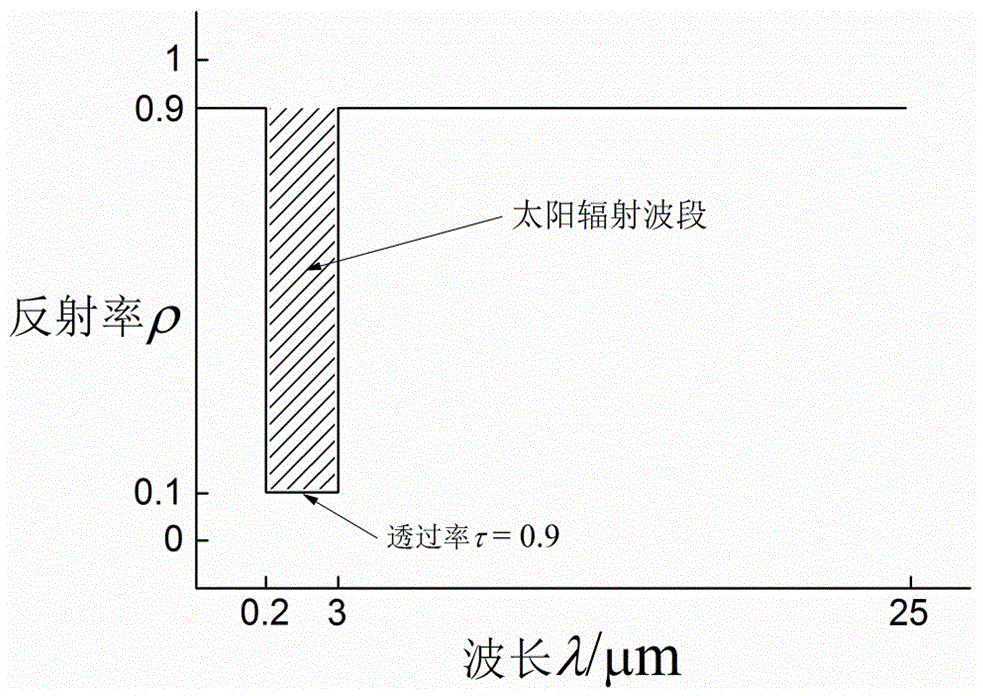

[0026] see figure 1 , a multifunctional spectrally selective packaging material includes a substrate 1, the material of the substrate 1 is an anodized aluminum plate with good thermal conductivity; one side of the substrate 1 is provided with a black polyvinyl fluoride-polyester-polyvinyl fluoride ( TPT) material layer 2; polyvinyl fluoride-polyester-polyvinyl fluoride (TPT) material layer 2 is installed with a photovoltaic cell 3, and the photovoltaic cell 3 is a monocrystalline silicon photovoltaic cell; the photovoltaic cell 3 is provided with a spectrally selective composite material Layer 4, the thickness of which is 25 μm, a simplified illustration of the spectral properties of the spectrally selective composite material layer 4 see figure 2 , the spectrally selective composite material layer 4 is made of a composite of a selective reflection film 5 and a selective emission film 6, and the simplified schematic diagrams of the spectral characteristics of the selective r...

Embodiment 2

[0031] The photovoltaic cell material is a polysilicon photovoltaic cell, and the selective reflection film 5 is indium oxide (In 2 o 3) thin film with a thickness of 12.5 μm, a transmittance greater than 0.9 in the solar radiation band of 0.2-3 μm, and a reflectance greater than 0.9 in other bands. The selective emission film 6 is a polyvinyl fluoride film with a thickness of 12.5 μm. The emissivity in the “atmospheric window” band of 8-13 μm is greater than 0.8, and the transmittance in other bands is greater than 0.9.

[0032] The spectrally selective composite material layer 4 has a thickness of 25 μm, its transmittance in the solar radiation band of 0.2-3 μm is greater than 0.8, its emissivity in the “atmospheric window” band of 8-13 μm is greater than 0.8, and its transmittance in the band above 13 μm is greater than 0.8. The reflectance is greater than 0.9.

[0033] Other structures are with embodiment 1.

Embodiment 3

[0035] The photovoltaic cell material is an amorphous silicon photovoltaic cell.

[0036] Other structures are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com